Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

V 21302 - Rev.2 C

Caricato da

pandiangvTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

V 21302 - Rev.2 C

Caricato da

pandiangvCopyright:

Formati disponibili

3

ASME Sec VIII Div.1 2004 Edition,2006 Addenda

17100 Psi

Krishnagiri Hemanth

2008.06.16

18:32:15 +05'30'

2

Delete Girth Flange Calculations

Index

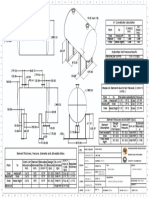

Cover Sheet.............................................................................................................................................................1

Index...........................................................................................................................................................................2

Applicable standard..........................................................................................................................................4

Design Standard...................................................................................................................................................5

Materials of construction...........................................................................................................................7

Warnings and Errors..........................................................................................................................................8

Input Echo...............................................................................................................................................................9

XY Coordinate Calculations.......................................................................................................................19

Flange Calculations FLANGE.......................................................................................................................20

Flange Calculations FLANGE.......................................................................................................................29

Internal Pressure Calculations.............................................................................................................34

External Pressure Calculations.............................................................................................................38

Element and Detail Weights.......................................................................................................................40

Nozzle Flange MAWP..........................................................................................................................................44

Natural Frequency Calculation................................................................................................................45

Forces/Moments Applied to Vessel (Combi........................................................................................46

Wind Load Calculation...................................................................................................................................47

Earthquake Load Calculation....................................................................................................................51

User Force/Moment Shear and Bending.................................................................................................54

Wind/Earthquake Shear, Bending.............................................................................................................55

Wind Deflection.................................................................................................................................................56

Longitudinal Stress Constants................................................................................................................57

Longitudinal Allowable Stresses...........................................................................................................58

Longitudinal Stresses Due to . . .....................................................................................................59

Stress due to Combined Loads..................................................................................................................62

Center of Gravity Calculation................................................................................................................69

Leg Check, (Operating Case)....................................................................................................................70

Nozzle Calcs. C4...............................................................................................................................................74

Nozzle Calcs. C5...............................................................................................................................................79

Nozzle Calcs. R1...............................................................................................................................................85

Nozzle Calcs. R2...............................................................................................................................................90

Nozzle Calcs. C1...............................................................................................................................................95

Nozzle Calcs. C2.............................................................................................................................................101

Nozzle Calcs. C3.............................................................................................................................................106

Nozzle Schedule...............................................................................................................................................112

Nozzle Summary.................................................................................................................................................114

Vessel Design Summary.................................................................................................................................117

Leg & Lug Analysis

WRC297 Analysis

Vessel Results

Lifting Lug.........................................................................................................120

: C1 & C3..................................................................................................................124

Summary..................................................................................................................132

Applicablestandard

SL.NO

ASME BOILER AND PRESSURE VESSEL CODE SECTION VIII

DIVISION 1 2004 ED. 2006ADD + PROJECT SPECIFICATION

ASME BOILER AND PRESSURE VESSEL CODE SECTION II PART

'D' 2004 EDITION , ADDENDA 2006

WIND LOADS CALCULATION ASCE 7-02 40 m/sec ,

EXPOSURE B , IMPORTANCE FACTOR 1.0 Use ASCE 7-05

EARTH QUAKE CALCULATIONS UBC 1997 , ZONE: 2B ;

IMPORTANCE FACTOR 1.25

WRC 107 : NOZZLE LOCAL LOAD ANALYSIS FOR NOZZLES ON

SPHERICAL HEADS

WRC 297 : NOZZLE LOCAL LOAD ANALYSIS FOR NOZZLES ON

CYLINDRICAL SHELL

SEAMLESS CARBON STEEL PIPE- ASME B 36.10 2000

10

DESCRIPTION

PIPE FLANGES - ASME B 16.5 2003 (1)

PIPE FITTINGS ASME B16.9 2003

METALLIC GASKETS ASME B16.20 - 1998 (R2004)

Designdata

S.No

DESCRIPTION

UNIT

Code Of Construction

ASME SEC VIII Div 1 EDITION 2004 , ADD 2006

Criticality Rating

SIZE

12 NB x 952 LG

Orientation & Support Type

Vertical , Leg Support

Design Internal Pressure

mmWc

(barg)

300 (0.03)

UG-21

Design External pressure

mmWc

(barg)

UG-21

Design Temperature (INT/EXT)

Deg C

65 / -

UG-20

Min.Design Metal Temperature

Deg C

UG-20

Test water Temperature

Deg C

Not less than 17

MAWP (Hot & Corroded)

MPag

19.65 @ 65 Deg

C

UG-98

MAP (New & Cold)

MPag

UG-98

390 (0.04)

UG-99 (b)

UG-99 (c)

10

11

Hydro pressure in corroded

condition at site (at top)

Hydro pressure in un-corroded

condition at shop (at top)

mmWc

(barg)

Operating Pressure (Max)

mmWc

(barg)

ATM

Operating Temperature (Max)

Deg C

38

Operating Medium

12

VALUES

WATER

Capacity

cu.m

0.065

Liquid Density

Kg/cu.m

1000

Vessel is in Lethal / Sour / Hydrogen Service NO / NO / NO

13

Corrosion allowance

14

Joint Efficiency

mm

3.0

REMARKS

Delete

6

1.0, Since seamless

Shell

0.85

UW-12

Dish ends

0.85

UW-12

Shell

SPOT

UW-11

Head

SPOT

H.T. of heads after forming

YES

UCS-56

PWHT

NO

UCS-56

17

Impact testing

NO

UG-20(f) & UCS66

18

Wind Design

ASCE-7 05 (144 Km/Hr.)

19

Seismic Design

20

Special service

21

Insulation

NO

22

Fireproofing

NO

Radiography (RT-3)

15

16

Confirm

UW-11

UBC 1997 , Category-2, Imp Factor 1.25)

NO

NOTE :1) MAWP MAP OF VESSEL IS GOVERNED BY SHELL.

Delete

UW-2

MaterialsofconstructionandstressvaluesasperASMESECIIPARTD

RFPADS/ExternalWelded

SA516Gr70

Stress at Hydrotest temp.

137.9

Stress at Design Temp.

Stress Ratio

SHELLPIPE/NOZZLESPIPES

137.9

1.0

MPa

SA106GrB

Stress at Hydrotest temp.

117.9

Stress at Design Temp.

117.9

Stress Ratio

MPa

MPa

MPa

1.0

ENDCAP/PIPEFITTINGSS

SA234GrWPB

Stress at Hydrotest temp.

117.9

Stress at Design Temp.

117.9

Stress Ratio

1.0

MPa

MPa

NOZZLES/BODYFLANGE

SA105

Stress at Hydrotest temp.

137.9

Stress at Design Temp.

137.9

Stress Ratio

1.0

MPa

MPa

STUDBOLTSANDNUTS

Stress at Hydrotest temp.

Stress at Design Temp.

Stress Ratio

SA193GRB7/

SA194GR2H

MPa

172.38

MPa

172.38

1.0

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Warnings and Errors

Step:

0

2:21p May 27,2008

Class From To : Basic Element Checks.

==========================================================================

Class From To: Check of Additional Element Data

==========================================================================

There were no geometry errors or warnings.

PV Elite 2008 1993-2008 by COADE Engineering Software

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

PV Elite Vessel Analysis Program: Input Data

Design Internal Pressure (for Hydrotest)

Design Internal Temperature

Type of Hydrotest

Hydrotest Position

0.03000

65

bars

C

UG99-b

Horizontal

Projection of Nozzle from Vessel Top

203.00

mm.

Projection of Nozzle from Vessel Bottom

0.0000

mm.

Minimum Design Metal Temperature

Type of Construction

Special Service

Degree of Radiography

Miscellaneous Weight Percent

8

Welded

Air/Water/Steam

RT 3

5.

Use Higher Longitudinal Stresses (Flag)

Select t for Internal Pressure (Flag)

Select t for External Pressure (Flag)

Select t for Axial Stress (Flag)

Select Location for Stiff. Rings (Flag)

Use Hydrotest Allowable Unmodified

Consider Vortex Shedding

Perform a Corroded Hydrotest

Is this a Heat Exchanger

No

User Defined Hydro. Press. (Used if > 0)

0.0000

bars

User defined MAWP

0.0000

bars

User defined MAPnc

0.0000

bars

Load Case 1

NP+EW+WI+FW+BW

Load Case 2

NP+EW+EQ+FS+BS

Load Case 3

NP+OW+WI+FW+BW

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Load Case 4

NP+OW+EQ+FS+BS

Load Case 5

NP+HW+HI

Load Case 6

NP+HW+HE

Load Case 7

IP+OW+WI+FW+BW

Load Case 8

IP+OW+EQ+FS+BS

Load Case 9

EP+OW+WI+FW+BW

Load Case 10

EP+OW+EQ+FS+BS

Load Case 11

HP+HW+HI

Load Case 12

HP+HW+HE

Load Case 13

IP+WE+EW

Load Case 14

IP+WF+CW

Load Case 15

IP+VO+OW

Load Case 16

IP+VE+OW

Load Case 17

IP+VF+CW

Load Case 18

Load Case 19

Load Case 20

Wind Design Code

ASCE-7 98/02/05/IBC-03/STS-1

Design Wind Speed

40.000

Exposure Constant

Importance Factor

1.

Roughness Factor

Base Elevation

0.0000

Percent Wind for Hydrotest

mm.

33.

Use Wind Profile (Y/N)

Height of Hill or Escarpment

m/sec

N

H

0.0000

mm.

Lh

0.0000

mm.

Distance from Crest to the Vessel

0.0000

mm.

Height above Local Ground

0.0000

mm.Use 1000 mm for design calculation

Distance Upwind of Crest

Type of Terrain ( Hill, Escarpment )

Flat

10

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Damping Factor (Beta) for Wind (Ope)

0.0100

Damping Factor (Beta) for Wind (Empty)

0.0000

Damping Factor (Beta) for Wind (Filled)

0.0000

Seismic Design Code

UBC 1997

UBC Seismic Zone (1=1,2=2a,3=2b,4=3,5=4)

2B

UBC Importance Factor

1.250

UBC Seismic Coefficient Ca

0.360

UBC Seismic Coefficient Cv

0.840

UBC Seismic Coefficient Nv

1.000

UBC Horizontal Force Factor

2.000

Apply Allowables per paragraph 1612.3.2

No

Design Nozzle for Des. Press. + St. Head

Consider MAP New and Cold in Noz. Design

Consider External Loads for Nozzle Des.

Consider Code Case 2168 for Nozzle Des.

Material Database Year

Current w/Addenda or Code Year

Complete Listing of Vessel Elements and Details:

Element From Node

10

Element To Node

20

Element Type

Elliptical

Description

Distance "FROM" to "TO"

66.000

mm.

Inside Diameter

307.09

mm.

Element Thickness

8.3500

mm.

Internal Corrosion Allowance

3.0000

mm.

Nominal Thickness

10.000

mm.

Provide calcs

for Sch. 30 pipe

11

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

External Corrosion Allowance

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

0.0000

0.03000

65

0.0000

0

mm.

bars

C

bars

C

1.2

SA-234 WPB

Allowable Stress, Ambient

117.90

N./mm

Allowable Stress, Operating

117.90

N./mm

Allowable Stress, Hydrotest

153.27

N./mm

Material Density

7750.4

kg/m

P Number Thickness

31.750

mm.

Yield Stress, Operating

227.13

N./mm

UCS-66 Chart Curve Designation

External Pressure Chart Name

UNS Number

Product Form

B

CS-2

K03006

smls/wld ftgs

Efficiency, Longitudinal Seam

0.85

Efficiency, Circumferential Seam

0.85

Elliptical Head Factor

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

1.0 seamless

2.

10

Nozzle

C4

0.0000

mm.

Nozzle Diameter

1.

in.

Nozzle Schedule

160

Nozzle Class

150

Layout Angle

0.

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

Nozzle schedule is wrong.

Use XXS

N

25.803

N.

12

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Grade of Attached Flange

Nozzle Matl

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

GR 1.1

SA-106 B

10

Nozzle

C5

100.00

mm.

Nozzle Diameter

1.

in.

Nozzle Schedule

160

Nozzle Class

150

Layout Angle

180.

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

24.048

Grade of Attached Flange

GR 1.1

Nozzle Matl

Element From Node

Detail Type

Detail ID

Nozzle schedule is wrong.

Use XXH

N.

SA-106 B

10

Leg

LEGS

Dist. from "FROM" Node / Offset dist

170.00

mm.

Diameter at Leg Centerline

426.46

mm.

Leg Orientation

Number of Legs

Section Identifier

Length of Legs

ISA65X65X5

904.00

Element From Node

20

Element To Node

30

Element Type

mm.

Cylinder

Description

Distance "FROM" to "TO"

686.00

mm.

13

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Inside Diameter

307.09

mm.

Element Thickness

8.3500

mm.

Internal Corrosion Allowance

3.0000

mm.

Nominal Thickness

8.3500

mm.

External Corrosion Allowance

0.0000

mm.

Design Internal Pressure

Design Temperature Internal Pressure

Design External Pressure

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

0.03000

65

0.0000

0

bars

C

bars

C

1.2

SA-106 B

Allowable Stress, Ambient

117.90

N./mm

Allowable Stress, Operating

117.90

N./mm

Allowable Stress, Hydrotest

153.27

N./mm

Material Density

7833.4

kg/m

P Number Thickness

31.750

mm.

Yield Stress, Operating

227.13

N./mm

UCS-66 Chart Curve Designation

External Pressure Chart Name

UNS Number

Product Form

B

CS-2

K03006

Smls. pipe

Efficiency, Longitudinal Seam

0.85

Efficiency, Circumferential Seam

0.85

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

1.0

20

Nozzle

R1

575.00

mm.

Nozzle Diameter

1.

in.

Nozzle Schedule

160

Nozzle Class

150

LWN

14

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Layout Angle

0.

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

24.366

Grade of Attached Flange

GR 1.1

N.

SA-105

Nozzle Matl

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

SA-106 B

20

Nozzle

R2

100.00

mm.

Nozzle Diameter

1.

in.

Nozzle Schedule

160

Nozzle Class

150

Layout Angle

0.

LWN

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

24.366

Grade of Attached Flange

GR 1.1

Nozzle Matl

SA-105

SA-106 B

Element From Node

30

Element To Node

40

Element Type

N.

Flange

Description

Distance "FROM" to "TO"

114.00

mm.

Flange Inside Diameter

304.80

mm.

Element Thickness

32.000

mm.

Internal Corrosion Allowance

3.0000

mm.

Nominal Thickness

8.3500

mm.

External Corrosion Allowance

0.0000

mm.

Design Internal Pressure

Design Temperature Internal Pressure

0.03000

65

bars

C

15

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Design External Pressure

0.0000

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

bars

C

1.2

SA-105

Allowable Stress, Ambient

137.90

N./mm

Allowable Stress, Operating

137.90

N./mm

Allowable Stress, Hydrotest

179.26

N./mm

Material Density

7833.4

kg/m

P Number Thickness

31.750

mm.

Yield Stress, Operating

233.35

N./mm

UCS-66 Chart Curve Designation

External Pressure Chart Name

UNS Number

Product Form

B

CS-2

K03504

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

Y

0.0000

Class of ANSI B16.5/B16.47 Flange

None

Grade of ANSI B16.5/B16.47 Flange

None

Element From Node

40

Element To Node

50

Element Type

Forgings

N.

Indicate weight

Flange

Description

Distance "FROM" to "TO"

31.750

mm.

Flange Inside Diameter

482.60

mm.

Element Thickness

31.750

mm.

Internal Corrosion Allowance

3.0000

mm.

Nominal Thickness

32.000

mm.

External Corrosion Allowance

0.0000

mm.

Design Internal Pressure

Design Temperature Internal Pressure

0.03000

65

bars

C

16

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Design External Pressure

0.0000

Design Temperature External Pressure

Effective Diameter Multiplier

Material Name

1.2

SA-105

Perform Flange Stress Calculation (Y/N)

Weight of ANSI B16.5/B16.47 Flange

bars

Y

0.0000

N.

Class of ANSI B16.5/B16.47 Flange

Grade of ANSI B16.5/B16.47 Flange

Element From Node

Detail Type

40

Nozzle

Detail ID

Dist. from "FROM" Node / Offset dist

C1

90.000

mm.

3.

in.

Nozzle Diameter

Nozzle Schedule

160

XXS

Nozzle Class

150

Layout Angle

180.

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

101.00

Grade of Attached Flange

GR 1.1

Nozzle Matl

Element From Node

Detail Type

Detail ID

Dist. from "FROM" Node / Offset dist

N.

SA-106 B

40

Nozzle

C2

115.00

mm.

Nozzle Diameter

0.75

in.

Nozzle Schedule

XXS

Nozzle Class

150

Layout Angle

90.

Blind Flange (Y/N)

Indicate Weight

17

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Input Echo

Step:

1

2:21p May 27,2008

Weight of Nozzle ( Used if > 0 )

16.449

Grade of Attached Flange

GR 1.1

Nozzle Matl

SA-106 B

Element From Node

Detail Type

40

Nozzle

Detail ID

Dist. from "FROM" Node / Offset dist

N.

C3

90.000

mm.

3.

in.

Nozzle Diameter

Nozzle Schedule

XXS

160

Nozzle Class

150

Layout Angle

0.

Blind Flange (Y/N)

Weight of Nozzle ( Used if > 0 )

16.449

Grade of Attached Flange

GR 1.1

Nozzle Matl

Element From Node

Detail Type

Detail ID

N.

SA-106 B

40

For./Mom.

F/M:[1 of 1]

Dist. from "FROM" Node / Offset dist

0.0000

mm.

Force in X Direction

0.0000

N.

Force in Y Direction

0.0000

N.

Force in Z Direction

0.0000

N.

Moment about X Axis

0.0000

N.m.

Moment about Y Axis

0.0000

N.m.

Moment about Z Axis

0.0000

N.m.

Force/Moment Combination Method

PV Elite 2008 1993-2008 by COADE Engineering Software

SRSS

18

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------XY Coordinate Calculations

Step:

2

2:21p May 27,2008

XY Coordinate Calculations

From| To |

X (Horiz.)|

mm.

Y (Vert.) |DX (Horiz.)| DY (Vert.) |

mm.

mm.

10|

20|

0.00000 |

66.0000 |

0.00000 |

66.0000 |

20|

30|

0.00000 |

752.000 |

0.00000 |

686.000 |

30|

40|

0.00000 |

866.000 |

0.00000 |

114.000 |

40|

50|

0.00000 |

897.750 |

0.00000 |

31.7500 |

PV Elite 2008 1993-2008 by COADE Engineering Software

mm.

19

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

Flange Input Data Values

Description: FLANGE

Item: Node 30 to 40

Description of Flange Geometry (Type)

Description of Flange Analysis

Integral Weld Neck

Partial, Thickness

Design Pressure

Design Temperature

0.03

65

bars

C

Internal Corrosion Allowance

ci

3.0000

mm.

External Corrosion Allowance

ce

0.0000

mm.

Use Corrosion Allowance in Thickness Calcs.

Yes

Flange Inside Diameter

307.000

mm.

Flange Outside Diameter

483.000

mm.

Flange Thickness

32.0000

mm.

Thickness of Hub at Small End

go

8.5000

mm.

Thickness of Hub at Large End

g1

29.0000

mm.

82.0000

mm.

Length of Hub

Flange Material

SA-105

Flange Allowable Stress At Temperature

Sfo

137.90

N./mm

Flange Allowable Stress At Ambient

Sfa

137.90

N./mm

Bolt Material

SA-193 B7

Bolt Allowable Stress At Temperature

Sb

172.37

N./mm

Bolt Allowable Stress At Ambient

Sa

172.37

N./mm

432.000

mm.

Nominal Bolt Diameter

dB

24.0000

mm.

Type of Threads

TEMA Thread Series

Diameter of Bolt Circle

20

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

Number of Bolts

12

Flange Face Outside Diameter

Fod

381.000

mm.

Flange Face Inside Diameter

Fid

307.000

mm.

Flange Facing Sketch

1, Code Sketch 1a

Gasket Outside Diameter

Go

381.000

mm.

Gasket Inside Diameter

Gi

307.000

mm.

Gasket Factor

2.0000

Gasket Design Seating Stress

11.03

Column for Gasket Seating

2, Code Column II

Gasket Thickness

tg

4.5 mm

3.0000

N./mm

mm.

ASME Code, Section VIII, Division 1, 2007

Hub Small End Required Thickness due to Internal Pressure:

= (P*(D/2+Ca))/(S*E-0.6*P) per UG-27 (c)(1)

= (0.03*(307.0000/2+3.0000))/(137.90*0.85-0.6*0.03)+Ca

= 3.0040 mm.

Corroded Flange Thickness, tc = T-Fcor

Corroded Flange ID,

Bcor = B+2*Fcor

29.000

mm.

313.000

mm.

Corroded Large Hub,

g1Cor = g1-Fcor

26.000

mm.

Corroded Small Hub,

g0Cor = go-Fcor

5.500

mm.

Code R Dimension,

R = ((C-Bcor)/2)-g1cor

33.500

mm.

Gasket Contact Width,

N = (Go - Gi) / 2

37.000

mm.

18.500

mm.

10.839

mm.

359.323

mm.

Basic Gasket Width,

bo = N / 2

Effective Gasket Width,

b = sqrt(bo) / 2

Gasket Reaction Diameter,

G = Go - 2 * b

21

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 359.3228 * 0.030

= 304.200 N.

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P +

= 2 * 10.8386 * 3.1416 * 359.3228 * 2.0000 * 0.03

= 146.814 N.

Hydrostatic End Load at Flange ID [Hd]:

= Pi * Bcor * P

/ 4

= 3.1416 * 313.0000 *0.0300 / 4

= 230.822 N.

Pressure Force on Flange Face [Ht]:

= H - Hd

= 304 - 230

= 73.377 N.

Operating Bolt Load [Wm1]:

= max( H + Hp + H'p, 0 )

= max( 304 + 146 + 0 , 0 )

= 451.014 N.

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G

+ yPart * bPart * lp

= 11.03*10.8386*3.141*359.323+0.00*0.0000*0.00

= 134946.344 N.

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 451 / 172 , 134946 / 172

= 782.931 mm

22

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

Bolting Information for TEMA Imperial Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

----------------------------------------------------------------------------Bolt Area, mm

782.931

3243.864

Radial distance bet. hub and bolts

31.750

33.500

Radial distance bet. bolts and the edge

23.812

25.500

Circumferential spacing between bolts

52.400

111.810

114.050

-----------------------------------------------------------------------------

Min. Gasket Contact Width (Brownell Young) [Not an ASME Calc] [Nmin]:

= Ab * Sa/( y * Pi * (Go + Gi) )

= 3243.864 * 172.37 /(11.03 * 3.14 * (381.000 + 307.00 ) )

= 23.454 mm.

Flange Design Bolt Load, Gasket Seating [W]:

= Sa * ( Am + Ab ) / 2

= 172.37 * ( 782.9315 + 3243.8643 ) / 2

= 347029.97 N.

Gasket Seating Force [HG]:

= Wm1 - H

= 451 - 304

= 146.81 N.

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 432.0000 - 359.3228 ) / 2

= 36.3386 mm.

Distance to Face Pressure Reaction [ht]:

23

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

= ( R + g1 + hg ) / 2

= ( 33.5000 + 26.0000 + 36.3386 ) / 2

= 47.9193 mm.

Distance to End Pressure Reaction [hd]:

= R + ( g1 / 2 )

= 33.5000 + ( 26.0000 / 2.0 )

= 46.5000 mm.

Summary of Moments for Internal Pressure:

Loading

Force

Distance Bolt Corr

Moment

End Pressure,

Md

231.

46.5000

1.0000

11. N.m.

Face Pressure,

Mt

73.

47.9193

1.0000

4. N.m.

Gasket Load,

Mg

147.

36.3386

1.0000

5. N.m.

347030.

36.3386

1.0000

12616. N.m.

Gasket Seating, Matm

Total Moment for Operation,

Mop

20. N.m.

Total Moment for Gasket seating, Matm

12616. N.m.

Effective Hub Length, ho = sqrt(Bcor*goCor)

Hub Ratio,

Thickness Ratio,

41.491

h/h0 = HL / H0

mm.

1.976

g1/g0 = (g1Cor/goCor)

4.727

Flange Factors for Integral Flange:

Factor F per 2-7.2

0.515

Factor V per 2-7.3

0.021

Factor f per 2-7.6

1.000

Factors from Figure 2-7.1

1.543

T =

1.692

U =

5.109

Y =

4.650

Z =

2.448

d = .30353E+06 mm.

Stress Factors

K =

e =

ALPHA =

0.0124 mm.^-1

1.360

24

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

BETA =

1.480

GAMMA =

0.804

DELTA =

0.080

Lamda =

0.884

Longitudinal Hub Stress, Operating [SHo]:

= ( f * Mop / Bcor ) / ( L * g1 )

= ( 1.0000 *19 / 313.0000 ) / ( 0.8842 *26.0000 )

= 0.10 N./mm

Longitudinal Hub Stress, Seating [SHa]:

= ( f * Matm / Bcor ) / ( L * g1 )

= ( 1.0000 * 12615 / 313.0000 ) / ( 0.8842 * 26.0000 )

= 67.41 N./mm

Radial Flange Stress, Operating [SRo]:

= ( Beta * Mop / Bcor ) / ( L * t )

= ( 1.4801 *19 / 313.0000 ) / ( 0.8842 *29.0000 )

= 0.12 N./mm

Radial Flange Stress, Seating [SRa]:

= ( Beta * Matm/Bcor ) / ( L * t )

= ( 1.4801 *12615 /313.0000 ) / ( 0.8842 *29.0000 )

= 80.20 N./mm

Tangential Flange Stress, Operating [STo]:

= ( Y * Mo / (t * Bcor) ) - Z * SRo

= ( 4.6495 *19 / (29.0000 *313.0000 ) ) - 2.4480 *0

= 0.04 N./mm

Tangential Flange Stress, Seating [STa]:

= ( y * Matm / (t * Bcor) ) - Z * SRa

= ( 4.6495 *12615 / (29.0000 *313.0000 ) ) - 2.4480 *80

= 26.43 N./mm

Average Flange Stress, Operating [SAo]:

25

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

= ( SHo + max( SRo, STo ) ) / 2

= ( 0 + max( 0 , 0 ))/ 2

= 0.11 N./mm

Average Flange Stress, Seating [SAa]:

= ( SHa + max( SRa, STa ) ) / 2

= ( 67 + max( 80 , 26 ))/ 2

= 73.80 N./mm

Bolt Stress, Operating [BSo]:

= ( Wm1 / Ab )

= ( 451 / 3243.8643 )

= 0.14 N./mm

Bolt Stress, Seating [BSa]:

= ( Wm2 / Ab )

= ( 134946 / 3243.8643 )

= 41.60 N./mm

Stress Computation Results:

Operating

Actual

Allowed

Gasket Seating

Actual

Allowed

Longitudinal Hub

0.

207.

67.

207. N./mm

Radial Flange

0.

138.

80.

138. N./mm

Tangential Flange

0.

138.

26.

138. N./mm

Maximum Average

0.

138.

74.

138. N./mm

Bolting

0.

172.

42.

172. N./mm

Minimum Required Flange Thickness

26.111

mm.

Estimated M.A.W.P. ( Operating )

30.0

bars

Estimated M.A.W.P. ( Gasket Seating )

42.2

bars

Estimated Finished Weight of Flange at given Thk.

39.7

kg.

Estimated Unfinished Weight of Forging at given Thk

97.5

kg.

26

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

Flange Rigidity Based on Required Thickness [ASME]:

Flange Rigidity Index, Seating (rotation check) per APP. 2 [Js]:

= 52.14 * Ma * Cnv_fac * V / ( Lambda * Eamb * go2 * ho * Ki )

= 52.14 * 12615 * 999.645 * 0.021 / ( 0.801 * 199948 * 5.500

* 41.491 * 0.300 )

= 0.230

(should be <= 1)

Flange Rigidity Index Operating (rotation check) per APP. 2 [J]:

= 52.14 * Mo * Cnv_fac * V / ( Lambda * Eop * goc2 * ho * Ki )

= 52.14 * 19 * 999.645 * 0.021 / ( 0.801 * 197853 * 5.500

* 41.491 * 0.300 )

= 0.000

(should be <= 1)

Flange Rigidity Based on Given Thickness [ASME]:

Flange Rigidity Index, Seating (rotation check) per APP. 2 [Js]:

= 52.14 * Ma * Cnv_fac * V / ( Lambda * Eamb * go2 * ho * Ki )

= 52.14 * 12615 * 999.645 * 0.021 / ( 0.884 * 199948 * 5.500

* 41.491 * 0.300 )

= 0.209

(should be <= 1)

Flange Rigidity Index Operating (rotation check) per APP. 2 [J]:

= 52.14 * Mo * Cnv_fac * V / ( Lambda * Eop * goc2 * ho * Ki )

= 52.14 * 19 * 999.645 * 0.021 / ( 0.884 * 197853 * 5.500

* 41.491 * 0.300 )

= 0.000

(should be <= 1)

Minimum Design Metal Temperature Results:

27

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

3

2:21p May 27,2008

Min Metal Temp. w/o impact per UCS-66

Min Metal Temp. at Rqd thickness (UCS 66.1)[rat 0.00]

PV Elite 2008 1993-2008 by COADE Engineering Software

-29

-104

28

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

4

2:21p May 27,2008

Flange Input Data Values

Description: FLANGE

Item: Node 40 to 50

Description of Flange Geometry (Type)

Blind

Description of Flange Analysis

Partial, Thickness

Design Pressure

Design Temperature

0.03

65

bars

C

Internal Corrosion Allowance

ci

3.0000

mm.

External Corrosion Allowance

ce

0.0000

mm.

Use Corrosion Allowance in Thickness Calcs.

Yes

Flange Outside Diameter

482.600

mm.

Flange Thickness

31.7500

mm.

Flange Material

SA-105

Flange Allowable Stress At Temperature

Sfo

137.90

N./mm

Flange Allowable Stress At Ambient

Sfa

137.90

N./mm

Bolt Material

SA-193 B7

Bolt Allowable Stress At Temperature

Sb

172.37

N./mm

Bolt Allowable Stress At Ambient

Sa

172.37

N./mm

Span

0.000

mm.

Diameter of the Load Reaction, Short Span

0.000

mm.

Perimeter along the Center of the Bolts

1356.540

mm.

Diameter of Bolt Circle

431.800

mm.

Nominal Bolt Diameter

dB

24.0000

mm.

Type of Threads

TEMA Thread Series

Diameter of the Load Reaction, Long

29

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

4

2:21p May 27,2008

Number of Bolts

12

Flange Face Outside Diameter

Fod

381.000

mm.

Flange Face Inside Diameter

Fid

304.800

mm.

Flange Facing Sketch

1, Code Sketch 1a

Gasket Outside Diameter

Go

381.000

mm.

Gasket Inside Diameter

Gi

304.800

mm.

Gasket Factor

2.0000

Gasket Design Seating Stress

11.03

Column for Gasket Seating

2, Code Column II

Gasket Thickness

tg

3.0000

N./mm

mm.

ASME Code, Section VIII, Division 1, 2007

Gasket Contact Width,

Basic Gasket Width,

N = (Go - Gi) / 2

bo = N / 2

Effective Gasket Width,

b = sqrt(bo) / 2

Gasket Reaction Diameter,

G = Go - 2 * b

Basic Flange and Bolt Loads:

Hydrostatic End Load due to Pressure [H]:

= 0.785 * G * Peq

= 0.785 * 359.0030 * 0.030

= 303.658 N.

Contact Load on Gasket Surfaces [Hp]:

= 2 * b * Pi * G * m * P +

= 2 * 10.9985 * 3.1416 * 359.0030 * 2.0000 * 0.03

38.100

mm.

19.050

mm.

10.999

mm.

359.003

mm.

30

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

4

2:21p May 27,2008

= 148.848 N.

Operating Bolt Load [Wm1]:

= max( H + Hp + H'p, 0 )

= max( 303 + 148 + 0 , 0 )

= 452.506 N.

Gasket Seating Bolt Load [Wm2]:

= y * b * Pi * G

+ yPart * bPart * lp

= 11.03*10.9985*3.141*359.003+0.00*0.0000*0.00

= 136815.703 N.

Required Bolt Area [Am]:

= Maximum of Wm1/Sb, Wm2/Sa

= Maximum of 452 / 172 , 136815 / 172

= 793.777 mm

Bolting Information for TEMA Imperial Thread Series (Non Mandatory):

----------------------------------------------------------------------------Minimum

Actual

Maximum

----------------------------------------------------------------------------Bolt Area, mm

793.777

3243.864

Radial distance bet. bolts and the edge

23.812

25.400

Circumferential spacing between bolts

52.400

111.758

113.450

-----------------------------------------------------------------------------

Min. Gasket Contact Width (Brownell Young) [Not an ASME Calc] [Nmin]:

= Ab * Sa/( y * Pi * (Go + Gi) )

= 3243.864 * 172.37 /(11.03 * 3.14 * (381.000 + 304.80 ) )

= 23.529 mm.

Flange Design Bolt Load, Gasket Seating [W]:

= Sa * ( Am + Ab ) / 2

= 172.37 * ( 793.7771 + 3243.8643 ) / 2

31

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

4

2:21p May 27,2008

= 347964.62 N.

Gasket Seating Force [HG]:

= Wm1

= 452.51 N.

Moment Arm Calculations:

Distance to Gasket Load Reaction [hg]:

= (C - G ) / 2

= ( 431.8000 - 359.0030 ) / 2

= 36.3985 mm.

Tangential Flange Stress, Flat Head, Operating [STo]:

= 1.9 * Wm1 * hG * Bcor/(t * G) + C * Z * Peq * G/t

= 1.9 * 452 * 36.3985 * 1.0000 /(28.7500 * 359.0030 ) +

0.30 * 1.0000 * 0.03 * 359.0030 )/28.7500

= 0.25 N./mm

Tangential Flange Stress, Flat Head, Seating [STa]:

= 1.9 * W * hG * Bcor /(t * G)

= 1.9 * 347964 * 36.3985 * 1.000 /(28.7500 * 359.0030 )

= 81.10 N./mm

Bolt Stress, Operating [BSo]:

= ( Wm1 / Ab )

= ( 452 / 3243.8643 )

= 0.14 N./mm

Bolt Stress, Seating [BSa]:

= ( Wm2 / Ab )

= ( 136815 / 3243.8643 )

= 42.18 N./mm

32

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Flange Calculations FLANGE

Flng:

4

2:21p May 27,2008

Stress Computation Results:

Operating

Actual

Allowed

Gasket Seating

Actual

Allowed

Tangential Flange

0.

138.

81.

138. N./mm

Bolting

0.

172.

42.

172. N./mm

Reqd. Blind Flange Thickness at Center

25.048

mm.

Reqd. Blind Flange Thickness at Gasket

25.048

mm.

Estimated M.A.W.P. ( Operating )

16.8

bars

Estimated Finished Weight of Flange at given Thk.

45.5

kg.

Estimated Unfinished Weight of Forging at given Thk

45.5

kg.

Minimum Design Metal Temperature Results:

Min Metal Temp. w/o impact per UCS-66

Min Metal Temp. at Rqd thickness (UCS 66.1)[rat 0.00]

PV Elite 2008 1993-2008 by COADE Engineering Software

-29

-104

33

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Internal Pressure Calculations

Step:

5

2:21p May 27,2008

Element Thickness, Pressure, Diameter and Allowable Stress :

| Int. Press |

From| To | + Liq. Hd

bars

|

|

Nominal | Total Corr|

Element |

Allowable |

Thickness | Allowance |

Diameter |

Stress(SE)|

mm.

mm.

mm.

N./mm

10|

20|

0.030000 |

10.0000 |

3.00000 |

307.090 |

100.215 |

20|

30|

0.030000 |

8.35000 |

3.00000 |

307.090 |

100.215 |

30|

40|

0.030000 |

8.35000 |

3.00000 |

304.800 |

117.211 |

40|

50|

0.030000 |

32.0000 |

3.00000 |

482.600 |

117.211 |

Element Required Thickness and MAWP :

Design |

From| To |

Pressure |

|

Corroded

bars

M.A.P. |

Actual |

Required |

| New & Cold |

Thickness |

Thickness |

10|

20|

0.030000 |

34.1324 |

54.2038 |

8.35000 |

5.38125 |

20|

30|

0.030000 |

33.5609 |

52.7765 |

8.35000 |

5.38125 |

30|

40|

0.030000 |

29.9695 |

58.1736 |

32.0000 |

26.1112 |

40|

50|

0.030000 |

16.8301 |

20.5257 |

31.7500 |

25.0482 |

Minimum

bars

M.A.W.P. |

16.830

bars

mm.

19.650

MAWP: 0.033 bars, limited by: Nozzle Reinforcment.

Internal Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2007

Elliptical Head From 10 To 20 SA-234 WPB , UCS-66 Crv. B at 65 C

mm.

34

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Internal Pressure Calculations

Step:

5

2:21p May 27,2008

Thickness Due to Internal Pressure [Tr]:

= (P*D*K)/(2*S*E-0.2*P) Appendix 1-4(c)

= (0.030*313.0900*3.00)/(2*117.90*0.85-0.2*0.030)

= 0.0047 + 3.0000 = 3.0047 mm.

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 2.3812 mm. will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

= (2*S*E*t)/(K*D+0.2*t) per Appendix 1-4 (c)

= (2*117.90*0.85*5.3500)/(1.00*313.0900+0.2*5.3500)

= 34.132 bars

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (2*S*E*t)/(K*D+0.2*t) per Appendix 1-4 (c)

= (2*117.90*0.85*8.3500)/(1.00*307.0900+0.2*8.3500)

= 54.204 bars

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(K*D+0.2*t))/(2*E*t)

= (0.030*(1.00*313.0900+0.2*5.3500))/(2*0.85*5.3500)

= 0.104 N./mm

Required Thickness of Straight Flange = 3.005 mm.

Percent Elongation per UCS-79

(75*tnom/Rf)*(1-Rf/Ro)

13.913 %

Min Metal Temp. w/o impact per UCS-66

-29

Min Metal Temp. at Rqd thickness (UCS 66.1)[rat 0.38]

-48

Cylindrical Shell From 20 To 30 SA-106 B , UCS-66 Crv. B at 65 C

35

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Internal Pressure Calculations

Step:

5

2:21p May 27,2008

Thickness Due to Internal Pressure [Tr]:

= (P*R)/(S*E-0.6*P) per UG-27 (c)(1)

= (0.030*156.5450)/(117.90*0.85-0.6*0.030)

= 0.0047 + 3.0000 = 3.0047 mm.

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 2.3812 mm. will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

= (S*E*t)/(R+0.6*t) per UG-27 (c)(1)

= (117.90*0.85*5.3500)/(156.5450+0.6*5.3500)

= 33.561 bars

Maximum Allowable Pressure, New and Cold [MAPNC]:

= (S*E*t)/(R+0.6*t) per UG-27 (c)(1)

= (117.90*0.85*8.3500)/(153.5450+0.6*8.3500)

= 52.777 bars

Actual stress at given pressure and thickness, corroded [Sact]:

= (P*(R+0.6*t))/(E*t)

= (0.030*(156.5450+0.6*5.3500))/(0.85*5.3500)

= 0.105 N./mm

Percent Elongation per UCS-79

(50*tnom/Rf)*(1-Rf/Ro)

2.647 %

Min Metal Temp. w/o impact per UCS-66

-29

Min Metal Temp. at Rqd thickness (UCS 66.1)[rat 0.38]

-48

MINIMUM METAL DESIGN TEMPERATURE RESULTS :

36

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Internal Pressure Calculations

Step:

5

2:21p May 27,2008

Minimum Metal Temp. w/o impact per UCS-66

-29.

Minimum Metal Temp. at Required thickness

-48.

8.

Note: Heads and Shells Exempted to -20F (-29C) by paragraph UG-20F

Minimum Design Metal Temperature ( Entered by User )

Hydrostatic Test Pressure Results:

Pressure per UG99b

= 1.3 * M.A.W.P. * Sa/S

Pressure per UG99b[34] = 1.3 * Design Pres * Sa/S

Pressure per UG99c

= 1.3 * M.A.P. - Head(Hyd)

Pressure per UG100

= 1.1 * M.A.W.P. * Sa/S

0.043

bars

0.039

bars

25.525

bars

0.036

bars

Horizontal Hydrotest performed in accordance with: UG-99b

Stresses on Elements due to Hydrostatic Test Pressure:

From To

Stress

Allowable

Ratio

Pressure

10

20

0.2

153.3

0.001

0.07

20

30

0.2

153.3

0.001

0.07

Elements Suitable for Internal Pressure.

PV Elite 2008 1993-2008 by COADE Engineering Software

37

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------External Pressure Calculations

Step:

6

2:21p May 27,2008

External Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2007

Elliptical Head From 10 to 20 Ext. Chart: CS-2 at 0 C

Elastic Modulus from Chart: CS-2 at 149 C :

0.19995E+06 N./sq.mm.

Results for Maximum Allowable External Pressure (MAEP):

Tca

OD

D/t

Factor A

5.350

323.79

60.52

0.0022949

106.74

EMAP = B/(K0*D/t) = 106.7357 /(0.9000 *60.5215 ) = 19.5955 bars

Cylindrical Shell From 20 to 30 Ext. Chart: CS-2 at 0 C

Elastic Modulus from Chart: CS-2 at 149 C :

0.19995E+06 N./sq.mm.

Results for Maximum Allowable External Pressure (MAEP):

Tca

OD

SLEN

D/t

L/D

Factor A

5.350

323.79

777.59

60.52

2.4015

0.0011781

90.18

EMAP = (4*B)/(3*(D/t)) = (4*90.1762 )/(3*60.5215 ) = 19.8665 bars

Results for Maximum Stiffened Length (Slen):

Tca

OD

SLEN

5.350

323.79

0.20E+34

D/t

L/D

Factor A

60.52 .5000E+02

0.0003003

30.02

EMAP = (4*B)/(3*(D/t)) = (4*30.0234 )/(3*60.5215 ) = 6.6144 bars

External Pressure Calculations

Section |

Outside |

Corroded |

Factor

Factor |

38

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------External Pressure Calculations

Step:

6

2:21p May 27,2008

From| To |

Length |

mm.

Diameter | Thickness |

mm.

mm.

N./mm

10|

20|

No Calc |

323.790 |

5.35000 |

0.0022949 |

106.736 |

20|

30|

777.591 |

323.790 |

5.35000 |

0.0011781 |

90.1762 |

30|

40|

No Calc |

0.00000 |

29.0000 |

No Calc |

No Calc |

40|

50|

No Calc |

0.00000 |

28.7500 |

No Calc |

No Calc |

External Pressure Calculations

From| To |

External |

External

Actual T. | Required T.|Des. Press. |

M.A.W.P.

mm.

External |

mm.

External

bars

bars

10|

20|

8.35000 |

No Calc |

0.00000 |

19.5955 |

20|

30|

8.35000 |

No Calc |

0.00000 |

19.8665 |

30|

40|

32.0000 |

26.1112 |

0.00000 |

No Calc |

40|

50|

31.7500 |

25.0482 |

0.00000 |

No Calc |

Minimum

19.596

External Pressure Calculations

| Actual Len.| Allow. Len.| Ring Inertia | Ring Inertia |

From| To | Bet. Stiff.| Bet. Stiff.|

mm.

mm.

Required |

in**4

10|

20|

No Calc |

No Calc |

No Calc |

No Calc |

20|

30|

777.591 |

1.971E+33 |

No Calc |

No Calc |

30|

40|

No Calc |

No Calc |

No Calc |

No Calc |

40|

50|

No Calc |

No Calc |

No Calc |

No Calc |

Elements Suitable for External Pressure.

PV Elite 2008 1993-2008 by COADE Engineering Software

Available |

in**4

39

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Element and Detail Weights

Step:

7

2:21p May 27,2008

Element and Detail Weights

Element |

Element |

From| To | Metal Wgt. | ID

kg.

Corroded |

Volume |Metal Wgt. |

m

kg.

Corroded | Extra due

ID Volume | Misc %

kg.

|

|

10|

20|

14.4226 |

0.0086808 |

10.0958 |

0.0091003 |

0.72113 |

20|

30|

44.4668 |

0.050819 |

28.7617 |

0.052824 |

2.22334 |

30|

40|

39.6996 |

0.0085336 |

37.0904 |

0.0087733 |

1.98498 |

40|

50|

45.8535 |

0.00000 |

45.8535 |

0.00000 |

2.29268 |

--------------------------------------------------------------------------Total

144

121

Weight of Details

From|Type|

|

Weight of |

X Offset, | Y Offset, |

Detail | Dtl. Cent. |Dtl. Cent. | Description

kg.

mm.

mm.

10|Nozl|

2.76291 |

0.00000 |

6.39771 |

C4

10|Nozl|

2.57501 |

0.00000 |

6.39771 |

C5

10|Legs|

20.9802 |

0.00000 |

-282.000 |

20|Nozl|

2.60900 |

166.245 |

575.000 |

R1

20|Nozl|

2.60900 |

166.245 |

100.000 |

R2

40|Nozl|

10.8151 |

0.00000 |

1080.00 |

C1

40|Nozl|

1.76135 |

0.00000 |

1380.00 |

C2

40|Nozl|

1.76135 |

0.00000 |

1080.00 |

C3

40|Forc|

0.00000 |

0.00000 |

0.00000 |

F/M:[1 of 1]

LEGS

Total Weight of Each Detail Type

Total Weight of Nozzles

24.9

14

40

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Element and Detail Weights

Step:

7

2:21p May 27,2008

Total Weight of Legs

21.0

--------------------------------------------------------------Sum of the Detail Weights

45.9 kg.

Weight Summary

Fabricated Wt.

- Bare Weight W/O Removable Internals

197.5 kg.

Shop Test Wt.

- Fabricated Weight + Water ( Full )

265.5 kg.

Shipping Wt.

- Fab. Wt + Rem. Intls.+ Shipping App.

197.5 kg.

Erected

- Fab. Wt + Rem. Intls.+ Insul. (etc)

197.5 kg.

Ope. Wt. no Liq - Fab. Wt + Intls. + Details + Wghts.

197.5 kg.

Operating Wt.

- Empty Wt. + Operating Liquid (No CA)

197.5 kg.

Field Test Wt.

- Empty Weight + Water (Full)

265.5 kg.

Wt.

Mass of the Upper 1/3 of the Vertical Vessel

113.4 kg.

Outside Surface Areas of Elements

Surface

From| To |

Area

mm

10|

20|

183794. |

20|

30|

697810. |

30|

40|

251786. |

40|

50|

231438. |

----------------------------Total

1364828.000 mm

Element and Detail Weights

| To |

From| To |

Total Ele.| Total. Ele.|Total. Ele.|

Empty Wgt.|

Total Dtl.| Oper. Wgt. |

Oper. Wgt.|Hydro. Wgt.| Offset Mom.| No Liquid

41

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Element and Detail Weights

Step:

7

2:21p May 27,2008

10|Legs|

kg.

kg.

kg.

N.m.

kg.

52.7557 |

52.7557 |

75.1017 |

0.00000 |

52.7557 |

Legs|

20|

-32.2741 |

-32.2741 |

-45.9446 |

0.00000 |

-32.2741 |

20|

30|

51.9081 |

51.9081 |

102.696 |

8.50981 |

51.9081 |

30|

40|

41.6846 |

41.6846 |

50.2130 |

0.00000 |

41.6846 |

40|

50|

62.4840 |

62.4840 |

62.4840 |

0.00000 |

62.4840 |

Cumulative Vessel Weight

| Cumulative Ope | Cumulative | Cumulative

From| To | Wgt. No Liquid | Oper. Wgt. | Hydro. Wgt. |

|

10|Legs|

kg.

kg.

kg.

-52.7557 |

-52.7557 |

-75.1017 |

Legs|

20|

123.803 |

123.803 |

169.448 |

20|

30|

156.077 |

156.077 |

215.393 |

30|

40|

104.169 |

104.169 |

112.697 |

40|

50|

62.4840 |

62.4840 |

62.4840 |

Note: The cumulative operating weights no liquid in the column above

are the cumulative operating weights minus the operating liquid

weight minus any weights absent in the empty condition.

Cumulative Vessel Moment

| Cumulative | Cumulative |Cumulative |

From| To | Empty Mom. | Oper. Mom. |Hydro. Mom.|

|

10|Legs|

N.m.

N.m.

N.m.

0.00000 |

0.00000 |

0.00000 |

Legs|

20|

8.50981 |

8.50981 |

8.50981 |

20|

30|

8.50981 |

8.50981 |

8.50981 |

30|

40|

0.00000 |

0.00000 |

0.00000 |

42

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Element and Detail Weights

Step:

7

2:21p May 27,2008

40|

50|

0.00000 |

0.00000 |

0.00000 |

PV Elite 2008 1993-2008 by COADE Engineering Software

43

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Nozzle Flange MAWP

Step:

8

2:21p May 27,2008

Nozzle Flange MAWP Results :

Flange Rating

Operating

bars

Ambient

Temperature

bars

Class

Grade|Group

---------------------------------------------------------------------------18.806

19.650

65

150

GR 1.1

---------------------------------------------------------------------------Minimum Rating

18.806

19.650

bars

Note: ANSI Ratings are per ANSI/ASME B16.5 2003 Edition

PV Elite 2008 1993-2008 by COADE Engineering Software

44

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Natural Frequency Calculation

Step:

9

2:21p May 27,2008

The Natural Frequencies for the vessel have been computed iteratively

by solving a system of matrices. These matrices describe the mass

and the stiffness of the vessel. This is the generalized eigenvalue/

eigenvector problem and is referenced in some mathematical texts.

The Natural Frequency for the Vessel (Empty.) is 33.9529 Hz.

The Natural Frequency for the Vessel (Ope...) is 33.9529 Hz.

PV Elite 2008 1993-2008 by COADE Engineering Software

45

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Forces/Moments Applied to Vessel

Step:

10

2:21p May 27,2008

Forces/Moments Applied to Vessel (Combined w/Wind Loads)

| X and Z Dir| X,Z Moment |

From| To | Force Res. | and For Res|

|

N.

N.m.

10|

20|

0.00000 |

0.00000 |

20|

30|

0.00000 |

0.00000 |

30|

40|

0.00000 |

0.00000 |

40|

50|

0.00000 |

0.00000 |

Forces/Moments Applied to Vessel (Combined w/Seismic Loads)

| X and Z Dir| X,Z Moment |

From| To | Force Res. | and For Res|

|

N.

N.m.

10|

20|

0.00000 |

0.00000 |

20|

30|

0.00000 |

0.00000 |

30|

40|

0.00000 |

0.00000 |

40|

50|

0.00000 |

0.00000 |

User Input Forces and Moments:

From

Node

Distance

From

----Fx

Forces --------Fy

------- Moments ------------

Fz

40

PV Elite 2008 1993-2008 by COADE Engineering Software

Mx

My

Mz

46

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Wind Load Calculation

Step:

11

2:21p May 27,2008

Wind Analysis Results

Wind Load Results per ASCE-7 98/02/05:

Note: Per Section 1609 of IBC 2003/06 these results are also applicable

for the determination of Wind Loads on structures (1609.1.1).

User Entered Importance Factor is

1.000

Gust Effect Factor (Ope)(G or Gf)

0.800

User entered Beta Value ( Operating Case )

Shape Factor (Cf)

0.528

User Entered Basic Wind Speed

Sample Calculation for the First Element

The ASCE code performs all calculations in Imperial Units

only. The wind pressure is therefore computed in these units.

Value of [Alpha] and [Zg]

Exposure Category = 2 (B) thus from Table C6-2:

Alpha = 7.000 : Zg = 365760.000 mm.

Effective Height [z]

= Centroid Hgt. + Vessel Base Elevation

= 83.336 + 0.000 = 83.336 mm.

= 0.273 ft. Imperial Units

Compute [Kz]

Because z (0.273 ft.) < 15 ft.

= 2.01 * ( 15 / Zg )

0.0100

2 / Alpha

40.0

m/sec

47

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Wind Load Calculation

Step:

11

2:21p May 27,2008

= 2.01 * ( 15 / 1200.000 )2

/ 7.000

= 0.575

Type of Hill: No Hill

Directionality Factor for round structures [Kd]:

= 0.95 per [6-6 ASCE-7 98][6-4 ASCE-7 02/05]

As there is No Hill Present: [Kzt]

K1 = 0, K2 = 0, K3 = 0

Topographical Factor [Kzt]

= ( 1 + K1 * K2 * K3 )

= ( 1 + 0.000 * 0.000 * 0.000 )

= 1.0000

Basic Wind Pressure, Imperial Units [qz]:

= 0.00256 * Kz * Kzt * Kd * I * Vr(mph)

= 0.00256 * 0.575 * 1.000 * 0.950 * 1.000 * 89.479

= 11.191 psf [535.811 ] N./m

Force on the first element [F]:

= qz * Gh * Cf * WindArea

= 535.811 * 0.800 * 0.528 * 51620.574

= 11.676 N.

Element

Hgt (z)

K1

K2

K3

Kz

Kzt

mm.

qz

N./m

--------------------------------------------------------------------------Node 10 to 20

83.3

0.000

0.000

0.000

0.575

1.000

535.811

Node 20 to 30

485.8

0.000

0.000

0.000

0.575

1.000

535.811

48

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Wind Load Calculation

Step:

11

2:21p May 27,2008

Node 30 to 40

885.8

0.000

0.000

0.000

0.575

1.000

535.811

Node 40 to 50

958.6

0.000

0.000

0.000

0.575

1.000

535.811

Wind Vibration Calculations

This evaluation is based on work by Kanti Mahajan and Ed Zorilla

Nomenclature

Cf

- Correction factor for natural frequency

- Average internal diameter of vessel mm.

Df

- Damping Factor < 0.75 Unstable,

Dr

- Average internal diameter of top half of vessel mm.

f

f1

L

> 0.95 Stable

- Natural frequency of vibration (Hertz)

- Natural frequency of bare vessel based on a unit value of (D/L)(104)

- Total height of structure mm.

Lc

- Total length of conical section(s) of vessel mm.

tb

- Uncorroded plate thickness at bottom of vessel mm.

V30 - Design Wind Speed provided by user m/sec

Vc

- Critical wind velocity m/sec

Vw

- Maximum wind speed at top of structure m/sec

- Total corroded weight of structure N.

Ws

- Cor. vessel weight excl. weight of parts which do not effect stiff. N.

- Maximum amplitude of vibration at top of vessel mm.

Dl

- Logarithmic decrement ( taken as 0.03 for Welded Structures )

Vp

- Vib. Chance, <= 0.314E-05 (High); 0.314E-05 < 0.393E-05 (Probable)

P30 - wind pressure 30 feet above the base

Check other Conditions and Basic Assumptions:

#1 - Total Cone Length / Total Length < 0.5

49

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Wind Load Calculation

Step:

11

2:21p May 27,2008

0.000 / 897.750 = 0.000

#2 - ( D / L ) * 104 < 8.0 (English Units)

- ( 1.11 / 2.95 ) * 104 = 1275.874 [Geometry Violation]

Compute the vibration possibility. If Vp > 0.393E-05 no chance. [Vp]:

= W / ( L * Dr)

= 1703 / ( 897.75 * 324.923 )

= 0.000

Since Vp is > 0.393E-05 no further vibration analysis is required !

The Natural Frequency for the Vessel (Ope...) is 33.9529 Hz.

Wind Load Calculation

Wind

Wind |

Wind |

Height

Element |

From| To |

Height

Diameter |

Area |

Factor

Wind Load |

mm.

mm.

mm

10|

20|

83.3365 |

388.548 |

51620.6 |

535.811 |

11.6758 |

20|

30|

485.772 |

388.548 |

266544. |

535.811 |

60.2884 |

30|

40|

885.773 |

442.560 |

50451.8 |

535.811 |

11.4115 |

40|

50|

958.648 |

655.320 |

20806.4 |

535.811 |

4.70611 |

PV Elite 2008 1993-2008 by COADE Engineering Software

N./m

N.

50

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Earthquake Load Calculation

Step:

12

2:21p May 27,2008

Note: Loads multiplied by the Scalar multiplier value of 0.7143

Earthquake Analysis Results per UBC 1997

The UBC Zone Factor for the Vessel is .............

0.2000

The Importance Factor as Specified by the User is .

1.250

The UBC Force Factor as Specified by the User is ..

2.000

The UBC Total Weight (W) for the Vessel is ........

1731.3

N.

The UBC Total Shear (V) for the Vessel is .........

389.6

N.

The UBC Top Shear (Ft) for the Vessel is ..........

0.0

N.

The UBC Seismic Coefficient Value Ca is ...........

0.360

The UBC Seismic Coefficient Value Cv is ...........

0.840

Note: The base shear and top load printed above have been modified

by the user defined Earthquake scalar.

Calculation Steps for Computing the design Base Shear (V) per UBC 1997

Computation of V per equation (34-1):

V = 0.7 * Ca * I * W

V = 0.7 * 0.360 * 1.250 * 1731

V = 545.4 N.

Computation of V per equation (30-5):

V = 2.5 * Ca * I * W / R

V = 2.5 * 0.360 * 1.25 * 1731 / 2.000

V = 973.9 N.

The computed base shear is the minimum of V from 34-1 and 30-5.

51

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Earthquake Load Calculation

Step:

12

2:21p May 27,2008

Computation of V per equation (34-2), minimum V. V cannot be less than

this value !

V = 0.56 * Ca * I * W

V = 0.56 * 0.360 * 1.250 * 1731

V = 436.3 N.

Total Adjusted Base Shear V:

= V * Scalar Multiplier = 545.4 * 0.7143 = 389.6 N.

Next compute the top load per equation 30-14. The top load is

zero if the period of vibration (T) is less than 0.7 seconds.

Note: This value does not need to exceed 0.25V.

Ft = Min( 0.07 * T * V, 0.25 * V )

Ft = Min( 0.07 * 0.029 * 545 , 0.25 * 545 )

Ft = 0.0 N.

Next Sum the earthquake weights times their heights (wi*hi):

Current Sum = Prev. Sum + Wght 517. * Hght -104.000 = -54.

Current Sum = Prev. Sum + Wght -316. * Hght -19.000 = -48.

Current Sum = Prev. Sum + Wght 509. * Hght 409.000 = 160.

Current Sum = Prev. Sum + Wght 409. * Hght 809.000 = 491.

Current Sum = Prev. Sum + Wght 613. * Hght 881.875 = 1032.

Compute the load at each level based on equation 30-15 and multiply

by the load case scalar. The sum will be the total adjusted shear.

Fx = (( V - Ft ) * wx * hx / ( sum of ( wi * hi ))) * EqFact

Fx = [(545.) * 517. * -104.000 / 1032.]*0.7143 = -20.

Fx = [(545.) * -316. * -19.000 / 1032.]*0.7143 = 2.

52

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Earthquake Load Calculation

Step:

12

2:21p May 27,2008

Fx = [(545.) * 509. * 409.000 / 1032.]*0.7143 = 79.

Fx = [(545.) * 409. * 809.000 / 1032.]*0.7143 = 125.

Fx = [(545.) * 613. * 881.875 / 1032.]*0.7143 = 204.

The Natural Frequency for the Vessel (Ope...) is 33.9529 Hz.

Earthquake Load Calculation

| Earthquake | Earthquake |

From| To |

|

10|Legs|

Height |

mm.

Element |

Weight | Ope

N.

Load |

N.

Element |

Emp Load |

N.

-104.000 |

517.323 |

-20.3202 |

-20.3202 |

Legs|

20|

-19.0000 |

-316.480 |

2.27109 |

2.27109 |

20|

30|

409.000 |

509.011 |

78.6293 |

78.6293 |

30|

40|

809.000 |

408.759 |

124.896 |

124.896 |

40|

50|

881.875 |

612.718 |

204.081 |

204.081 |

Top Load

1631.75

PV Elite 2008 1993-2008 by COADE Engineering Software

53

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------User Force/Moment Shear and Bending

Step:

13

2:21p May 27,2008

Bending Moments due to user defined forces and moments.

User Force/Moment Shear and Bending

| Distance to| Cummulative|Cumulative |

From| To |

|

10|Legs|

Support|Shr Wind Cas|Shr Eqk Cas|

mm.

N.

N.

Wind | Earthquake |

Bending |

Bending |

N.m.

N.m.

85.0000 |

0.00000 |

0.00000 |

0.00000 |

0.00000 |

Legs|

20|

52.0000 |

0.00000 |

0.00000 |

0.00000 |

0.00000 |

20|

30|

239.000 |

0.00000 |

0.00000 |

0.00000 |

0.00000 |

30|

40|

639.000 |

0.00000 |

0.00000 |

0.00000 |

0.00000 |

40|

50|

711.875 |

0.00000 |

0.00000 |

0.00000 |

0.00000 |

PV Elite 2008 1993-2008 by COADE Engineering Software

54

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Wind/Earthquake Shear, Bending

Step:

14

2:21p May 27,2008

The following table is for the Operating Case.

Wind/Earthquake Shear, Bending

| Distance to| Cummulative|Earthquake |

From| To |

|

10|Legs|

Support|

mm.

Wind Shear|

N.

Shear |

N.

Wind | Earthquake |

Bending |

Bending |

N.m.

N.m.

85.0000 |

-58.0077 |

-409.877 |

2.55734 |

1.72792 |

Legs|

20|

52.0000 |

58.0077 |

409.877 |

23.4609 |

242.370 |

20|

30|

239.000 |

76.4060 |

407.606 |

33.0106 |

286.388 |

30|

40|

639.000 |

16.1176 |

328.977 |

1.26217 |

33.6377 |

40|

50|

711.875 |

4.70611 |

204.081 |

0.074740 |

3.24110 |

PV Elite 2008 1993-2008 by COADE Engineering Software

55

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Wind Deflection

Step:

15

2:21p May 27,2008

Wind Deflection Calculations:

The following table is for the Operating Case.

Wind Deflection

| Cumulative |

Centroid | Elem. End | Elem. Ang. |

From| To | Wind Shear | Deflection |Deflection |

|

10|Legs|

N.

mm.

mm.

Rotation

|

|

-58.0077 |

0.12485 |

0.12485 | 0.00020716 |

Legs|

20|

58.0077 |

0.12485 |

0.12486 | 0.00020694 |

20|

30|

76.4060 |

0.12489 |

0.12504 | 0.00020763 |

30|

40|

16.1176 |

0.12506 |

0.12509 | 0.00020763 |

40|

50|

4.70611 |

0.12510 |

0.12511 | 0.00020763 |

Critical Wind Velocity for Tower Vibration

1st Crit. |

2nd Crit. |

From| To | Wind Speed | Wind Speed |

|

m/sec

m/sec

10|

20|

65.7844 |

411.152 |

20|

30|

65.7844 |

411.152 |

30|

40|

74.9290 |

468.306 |

40|

50|

110.951 |

693.444 |

Allowable deflection at the Tower Top (Ope)(

Allowable deflection : 4.489

6.000"/100ft. Criteria)

Actual Deflection : 0.125 mm.

PV Elite 2008 1993-2008 by COADE Engineering Software

56

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Longitudinal Stress Constants

Step:

16

2:21p May 27,2008

Longitudinal Stress Constants

| Metal Area | Metal Area |New & Cold |

From| To | New & Cold |

mm

Corroded

Corroded |Sect. Mod. | Sect. Mod. |

mm

mm.

10|

20|

8274.72 |

5352.19 |

636161. |

419166. |

20|

30|

8274.72 |

5352.19 |

636161. |

419166. |

30|

40|

8274.72 |

5352.19 |

636161. |

419166. |

40|

50|

8274.72 |

5352.19 |

636161. |

419166. |

PV Elite 2008 1993-2008 by COADE Engineering Software

mm.

57

PV Elite 2008 Licensee: MEFCO ENGINEERING PVT. LTD.,.

FileName : v-21302

--------------------------------------Longitudinal Allowable Stresses

Step:

17

2:21p May 27,2008

Longitudinal Allowable Stresses

All. Str. |

All. Str. | All. Str. |

All. Str. |

From| To | Long. Ten. | Hydr. Ten. |Long. Com. | Hyr. Comp. |

|

10|Legs|

N./mm

N./mm

N./mm

N./mm

120.258 |

156.336 |