Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Canusa Pipeline Repair Products Installation Guide

Caricato da

LewoskiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Canusa Pipeline Repair Products Installation Guide

Caricato da

LewoskiCopyright:

Formati disponibili

www.farwestcorrosion.

com

www.ccpco.com

Installation Guide

Pipeline Repair Products

Repair Patch, Melt Stick, Epoxy Primer and Mastic Filler

Pipeline Repair Products

Coating

Repair Patch

Base

Melt Stick

Canusa

Epoxy

Primer

Mastic Filler

Storage & Safety Guidelines

Equipment List

To ensure maximum performance, store

Canusa products in a dry, ventilated area. Keep

products sealed in original cartons and avoid

exposure to direct sunlight, rain, snow, dust or

other adverse environmental elements. Avoid

prolonged storage at temperatures above 35C

(95F) or below -20C (-4F). Product

installation should be done in accordance with

local health and safety regulations.

Cleaner

Cure

S

-CP

USA

CAN

The Coating Repair Patch (CRP) is typically shipped in

bulk rolls and can be cut-to-size in the field. Melt Sticks

and Mastic Fillers are used to repair holidays and/or fill

voids. Canusa Epoxy Primer is supplied in pre- measured

quantities.

These installation instructions are intended as a guide for

standard products. Consult your Canusa representative

for specific projects or unique applications.

Propane tank, hose, torch & regulator.

Appropriate tools for surface abrasion and cleaning,

including wire brush, abrasive paper, rags & approved cleaner.

Temperature measuring device. Misc. tools such as; knife,

putty knife, roller, paint brush or paint roller, tape measure,

and marker.

Standard safety equipment; gloves, goggles, hard hat, etc.

Removal of Damaged Coating

Solvent Cleaning

Surface Preparation

6

Cleaner

ir

Repae

Zon

Remove damaged coating with a knife or hand grinder to

prevent crack propagation in the coating.

Clean exposed steel and adjacent pipe coating with an

approved cleaner (as per SSPC-SP-1) to remove the

presence of oil, grease and other contaminants.

ged

Damra

A ea

Remove adhering rust, coating chalk, dirt, and roughen the

mill applied coating in the repair zone using an abrasive

paper/cloth or wire brush.

Epoxy Primer

8 Epoxy CB

Epoxy BP

7a

7b

Cure

Cure

Base

Base

Follow the Preparation, Mixing and Application

instructions provided with the supplied Canusa Epoxy

Pack. For bulk quantities: mix the primer cure with the

primer base (4 parts base to 1 part cure by volume). Stir

for a minimum of 30 seconds to assure uniform mixture.

Apply mixed epoxy to a minimum uniform thickness of

100microns (4 mils) on all exposed bare metal.

Preheat the area with a low to moderate intensity flame to

substantially cure the epoxy and warm the surface.

Skip to box 10

Melt Stick Application For Damage Up To 10mm x 10mm

8a Flame Intensity

8b

8c

Use a low intensity yellow flame for pre-heating the coating

and applying the repair products. With quick back and forth

strokes, pre-heat the repair zone sufficiently to remove

moisture and assist in adhesion.

Heat the melt stick with the torch until it becomes fluid.

Heat the melt stick and the repair zone simultaneously with

the torch and spread the melt stick over the damaged area.

Keep the flame moving to prevent damage to the coating.

Some ignition of the melt stick is acceptable.

For Sales & Information, Call Toll Free: (888) 532-7937

CANUSA-CPS is registered to ISO 9001:2000.

Part No. 99060-011

Pipeline Repair Products

Mastic Filler Installation

8d

8e

9a

Continue spreading the melt stick over the repair zone until

the entire area is covered. After sufficient melt stick material

is on the surface, apply additional heat in quick back-andforth strokes to create a smooth surface.

Ensure that the melt stick material completely covers the

repair zone. The melt stick material should be spread

liberally so that the material is raised above the coating

surface.

Fill deeper crevices with Canusa Mastic Filler (MF). Unroll

the filler material and cut off the required amount, leaving the

release paper in place.

9b Flame Intensity

9c

9d

Use a low intensity yellow flame for pre-heating the coating

and applying the repair products. With quick back and forth

strokes, pre-heat the repair zone sufficiently to remove

moisture and assist in adhesion.

Place the filler material onto the damaged area with the

release paper facing up. Firmly press the material into the

damaged area by hand and remove the release paper.

After filling the damaged area, remove the excess filler to

create a smooth surface. As an option, use a low intensity

yellow flame to warm the filler material and assist in

smoothing it out.

Patch Preparation

Pre-Heat

Patch Installation

10

11

12

Warm the damaged area (repair zone + 50mm (2)

overlap) to remove moisture and assist in adhesion.

After removing the release liner from the cut patch, place the

patch with the adhesive side up on a gloved hand, or on top

of the pipe, and heat gently. Heat until the adhesive softens

and the surface becomes glossy. Also, reheat the damaged

area to keep it warm.

Inspection

Backfilling Guidelines

14

15

Repair Zone

+ 100mm

10 - 25mm

+ 100 mm

or

+ 2 x 50mm

Repair Zone

+ 100mm

Cut a patch of CRP large enough to extend a minimum of

50mm (2") beyond the edge of the repair zone. Trim each

corner of the patch about 10-25mm (" - 1") at a 45 angle.

If the damage has a diameter greater than 10cm (4"), use an

appropriate heat-shrinkable sleeve.

13

After application, allow the repaired area to

cool before backfilling. To prevent damage to

the repaired material, use selected backfill

material (no sharp stones or large particles).

Apply the softened adhesive side of the patch to the

damaged area and press down firmly. Heat the patch with a

low intensity flame, and using a roller or a gloved hand, pat

down and remove wrinkles. Roll to ensure a good bond.

Visually inspect the installed patch for the following:

1. Patch is in full contact with the pipe coating.

2. There are no loose edges.

3. A successful patch has adhesive flow on the edges.

4. The patch has fully conformed to the coating.

5. No cracks or holes in patch backing.

For Sales & Information, Call Toll Free: (888) 532-7937

Printed on recycled paper.

Recyclable.

Potrebbero piacerti anche

- Geotechnical Investigation Report for MOTDocumento5 pagineGeotechnical Investigation Report for MOTSabu Abdul NoorNessuna valutazione finora

- Seat Material PDFDocumento2 pagineSeat Material PDFkrisNessuna valutazione finora

- 03 - Traffic and Equivalent Axle Loads (Updated)Documento88 pagine03 - Traffic and Equivalent Axle Loads (Updated)Besim QelajNessuna valutazione finora

- ERIKS - O-Ring Datasheet - FKM 75-Compound 514322 BlackDocumento1 paginaERIKS - O-Ring Datasheet - FKM 75-Compound 514322 Blackseeralan_1986Nessuna valutazione finora

- Squares and Square RootsDocumento8 pagineSquares and Square RootsJessica RamerNessuna valutazione finora

- Non-Intrusive Magnetic Pig SignallerDocumento2 pagineNon-Intrusive Magnetic Pig SignallerAndresNessuna valutazione finora

- Difference Between Izod and Charpy MethodsDocumento2 pagineDifference Between Izod and Charpy Methodsvasudeva yasasNessuna valutazione finora

- Thermoplastic Seals & Components For The Oil & Gas IndustryDocumento20 pagineThermoplastic Seals & Components For The Oil & Gas Industrya100acom100% (1)

- PMSS Ball ValveDocumento1 paginaPMSS Ball ValveGourav SharmaNessuna valutazione finora

- The Meaning of Angel Number 1111 Is A Question That Many People Ask Every DayDocumento2 pagineThe Meaning of Angel Number 1111 Is A Question That Many People Ask Every DayAsim Bashir100% (1)

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocumento4 pagineGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranNessuna valutazione finora

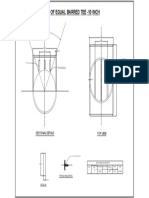

- Fabrication GAD of Equal Barred Tee - 10 Inch PDFDocumento1 paginaFabrication GAD of Equal Barred Tee - 10 Inch PDFThamaraikani Mani100% (1)

- Crack Opening DisplacementDocumento2 pagineCrack Opening Displacementsqaiba_gNessuna valutazione finora

- Pigging System for Dense Slurry PipelineDocumento4 paginePigging System for Dense Slurry Pipelineeka resmanaNessuna valutazione finora

- Surveying 2Documento81 pagineSurveying 2زبیر شاہNessuna valutazione finora

- Fracture Toughness TestingDocumento2 pagineFracture Toughness TestingArghadeep RoyNessuna valutazione finora

- Meliadine Brine Project DescriptionDocumento22 pagineMeliadine Brine Project DescriptionNunatsiaqNewsNessuna valutazione finora

- tb2 Articulo 1 PDFDocumento9 paginetb2 Articulo 1 PDFKaty Milagros Pacheco CalderonNessuna valutazione finora

- Criteria For The Selection of Metallic Pipelines CoatingsDocumento10 pagineCriteria For The Selection of Metallic Pipelines CoatingsVinicius CarvalhoNessuna valutazione finora

- Testing and Analysis of Pipeline Ball Valves Part 1 PDFDocumento3 pagineTesting and Analysis of Pipeline Ball Valves Part 1 PDFNovianto Rachmad100% (1)

- Corrosion Coupon Installation Procedure PDFDocumento31 pagineCorrosion Coupon Installation Procedure PDFtrichysayeeNessuna valutazione finora

- PPI Handbook of PE Pipe - Chapter 10Documento37 paginePPI Handbook of PE Pipe - Chapter 10Nicko Adrianto100% (1)

- Pig Signaller PDFDocumento2 paginePig Signaller PDFMargaret DaughertyNessuna valutazione finora

- Book Abstract ICDEMOS 2014Documento70 pagineBook Abstract ICDEMOS 201423045566Nessuna valutazione finora

- Flocon Flange Tables GuideDocumento5 pagineFlocon Flange Tables GuideAngel AngeleyeNessuna valutazione finora

- Ball Valve GuideDocumento22 pagineBall Valve GuideBalakrishna BisoyiNessuna valutazione finora

- DBB ValveDocumento6 pagineDBB ValveshyamNessuna valutazione finora

- Corrosion Coupon Rack: Installation & Operation ManualDocumento7 pagineCorrosion Coupon Rack: Installation & Operation ManualVania Nicol Arapa YugarNessuna valutazione finora

- Lecture Note 4 (Metallic & Non-Metallic Pipes) PDFDocumento20 pagineLecture Note 4 (Metallic & Non-Metallic Pipes) PDFhkaqlqNessuna valutazione finora

- Technical Requirements For Pipes & FittingsDocumento7 pagineTechnical Requirements For Pipes & FittingsKyaw Kyaw AungNessuna valutazione finora

- Pig SignallerDocumento4 paginePig SignallerHạo Nam-Born To WinNessuna valutazione finora

- Pipeline Pigging Guide: Cleaning, Inspection & MaintenanceDocumento10 paginePipeline Pigging Guide: Cleaning, Inspection & MaintenanceTarunNessuna valutazione finora

- A Comparison of Double Block and Bleed Technologies: Angus BowieDocumento15 pagineA Comparison of Double Block and Bleed Technologies: Angus BowieMarcelo Varejão CasarinNessuna valutazione finora

- Product Data Booklet Fibertec Ultimate HDD Coating SystemDocumento8 pagineProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028Nessuna valutazione finora

- Law of AttractionDocumento61 pagineLaw of Attractionrajiv ranjanNessuna valutazione finora

- Ball ValvesDocumento4 pagineBall ValvesJorge Arana YiNessuna valutazione finora

- Pipeline Pigging Incident Injures WorkerDocumento7 paginePipeline Pigging Incident Injures WorkerSajid SattarNessuna valutazione finora

- API 5L 45-th Edition: Item No SawlDocumento6 pagineAPI 5L 45-th Edition: Item No SawlRob WillestoneNessuna valutazione finora

- Double Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEDocumento4 pagineDouble Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEBharuk MechNessuna valutazione finora

- A860 WPHY52-WPHY70: DescriptionDocumento2 pagineA860 WPHY52-WPHY70: DescriptionJuan SimbaNessuna valutazione finora

- MISC Materials ListDocumento10 pagineMISC Materials ListWaqas WaqasNessuna valutazione finora

- Pipeline ROUDocumento17 paginePipeline ROUchezy100% (2)

- Charpy Impact Test - WikipediaDocumento18 pagineCharpy Impact Test - WikipediaAshik Speed YuvanNessuna valutazione finora

- Coatings For HDDDocumento8 pagineCoatings For HDDrenato100% (1)

- Piping FBE Spool MethodologyDocumento28 paginePiping FBE Spool MethodologyHariharan MNessuna valutazione finora

- Plates and ShellsDocumento106 paginePlates and ShellsMadhu Kiran KolatiNessuna valutazione finora

- Pipes FittingsDocumento37 paginePipes Fittingsanand bandekarNessuna valutazione finora

- Application Instructions Petrolatum Tape SystemDocumento4 pagineApplication Instructions Petrolatum Tape Systemnikita6969Nessuna valutazione finora

- 2-Part Polyurethane Sealant for Airport Runways & Concrete JointsDocumento2 pagine2-Part Polyurethane Sealant for Airport Runways & Concrete JointsjoshepNessuna valutazione finora

- Coating Repair Products - PolypropyleneDocumento4 pagineCoating Repair Products - Polypropyleneadvis79Nessuna valutazione finora

- Interzone 101Documento0 pagineInterzone 101hennawijayaNessuna valutazione finora

- Waterproofing MethodDocumento2 pagineWaterproofing MethodJamie Jean MargateNessuna valutazione finora

- Fosroc GMS Nitoplate LaminateDocumento6 pagineFosroc GMS Nitoplate Laminatejohn paulNessuna valutazione finora

- Carbon Fibre Fishing Pole Repair Kit InstructionsDocumento4 pagineCarbon Fibre Fishing Pole Repair Kit InstructionsdaveagriffNessuna valutazione finora

- RTR - Assembly Instruction Butt-And-Wrap Lamination Joint (16 Bars) - BONDSTRANDDocumento8 pagineRTR - Assembly Instruction Butt-And-Wrap Lamination Joint (16 Bars) - BONDSTRANDPiping_Specialist100% (15)

- Alfa Laval Regasketing Plares HeatersDocumento9 pagineAlfa Laval Regasketing Plares Heatersvaleriy100% (1)

- Coaltar EpoxyDocumento3 pagineCoaltar EpoxyAkhtar aliNessuna valutazione finora

- Normac-Cement-Guide-ADS_Rev2Documento6 pagineNormac-Cement-Guide-ADS_Rev2kenedi74Nessuna valutazione finora

- Repair polyethylene pipelines with patches, epoxy and masticDocumento2 pagineRepair polyethylene pipelines with patches, epoxy and masticHendra AwanNessuna valutazione finora

- Preparation:: 26844 Adams Ave, Murrieta, CA 92562 Phone: 972-775-6130 Fax: 972-775-8125Documento1 paginaPreparation:: 26844 Adams Ave, Murrieta, CA 92562 Phone: 972-775-6130 Fax: 972-775-8125عبدول ناصير عبدول رحيمNessuna valutazione finora

- Middle East - Africa: Project HistoryDocumento1 paginaMiddle East - Africa: Project HistoryLewoskiNessuna valutazione finora

- VDocumento5 pagineVLewoskiNessuna valutazione finora

- Spcprog 3Documento2 pagineSpcprog 3LewoskiNessuna valutazione finora

- Procoat H.08.HT: Technical SpecificationDocumento2 pagineProcoat H.08.HT: Technical SpecificationLewoskiNessuna valutazione finora

- Epoxy Vs GalvanizedDocumento6 pagineEpoxy Vs GalvanizedLewoskiNessuna valutazione finora

- Astm A653Documento9 pagineAstm A653MEPNessuna valutazione finora

- SulzerMixpac Industry CoatingDocumento8 pagineSulzerMixpac Industry CoatingLewoskiNessuna valutazione finora

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocumento10 pagineEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNessuna valutazione finora

- Dow Epoxy ResinDocumento5 pagineDow Epoxy ResinSrinivasan ReddyNessuna valutazione finora

- Powercrete J: Product Data SheetDocumento2 paginePowercrete J: Product Data SheetFernando Ytozu TairaNessuna valutazione finora

- B1500 QD multi-purpose epoxy primerDocumento2 pagineB1500 QD multi-purpose epoxy primerali maulanaNessuna valutazione finora

- Valvotubi Dismantling Joints PN 63Documento2 pagineValvotubi Dismantling Joints PN 63M MNessuna valutazione finora

- Mold DesignDocumento9 pagineMold DesignA MahmoodNessuna valutazione finora

- Is Iec ListDocumento115 pagineIs Iec Listapptil0% (1)

- Commercial Aerospace Coatings: Revised February 2020Documento9 pagineCommercial Aerospace Coatings: Revised February 2020Jose Miguel Atehortua ArenasNessuna valutazione finora

- Underwater Concreting With Rescon TDocumento12 pagineUnderwater Concreting With Rescon TPrateek JainNessuna valutazione finora

- Epoxy - WikipediaDocumento11 pagineEpoxy - Wikipediaramthecharm_46098467Nessuna valutazione finora

- ASTM D2369 Volatile Content of CoatingsDocumento5 pagineASTM D2369 Volatile Content of CoatingsMario Rodrigo Ramirez MesaNessuna valutazione finora

- SigmaCover 280Documento5 pagineSigmaCover 280ajuhaseenNessuna valutazione finora

- Technical Product Bulletin SummaryDocumento2 pagineTechnical Product Bulletin SummaryLuis Velasquez SilvaNessuna valutazione finora

- Health Consideration at Work Place and PPE's: Airborne DiseasesDocumento12 pagineHealth Consideration at Work Place and PPE's: Airborne DiseasesRafa AnanNessuna valutazione finora

- Easily Dispersible PigmentsDocumento44 pagineEasily Dispersible PigmentsGwen WalkerNessuna valutazione finora

- Mastertop 1210 Pds Asean 020811Documento2 pagineMastertop 1210 Pds Asean 020811hemajsuryaNessuna valutazione finora

- D 6412 - D 6412m - 99 Rdy0mtivrdy0mtjnDocumento4 pagineD 6412 - D 6412m - 99 Rdy0mtivrdy0mtjnMarceloNessuna valutazione finora

- Repair, Rehabilitation &retrofitting of RCC For Sustainable Development With Case StudiesDocumento15 pagineRepair, Rehabilitation &retrofitting of RCC For Sustainable Development With Case StudiesMatthew JohnsonNessuna valutazione finora

- Study of Mechanical and Acoustic Properties of Flax - Kenaf-Tamarind Seed Fiber Reinforced Hybrid Composites: Effect of Flax Fiber HybridizationDocumento36 pagineStudy of Mechanical and Acoustic Properties of Flax - Kenaf-Tamarind Seed Fiber Reinforced Hybrid Composites: Effect of Flax Fiber HybridizationREMIGIUS MARIOENessuna valutazione finora

- TREMCO CPG - Vulkem Traffic Coatings BrochureDocumento12 pagineTREMCO CPG - Vulkem Traffic Coatings BrochurePT Gigantara Sukses Mandiri RaharjaNessuna valutazione finora

- Review of Related Literature and StudiesDocumento12 pagineReview of Related Literature and StudiesJersey PerlasNessuna valutazione finora

- Carboguard 504 PDSDocumento4 pagineCarboguard 504 PDSNicholas ColesNessuna valutazione finora

- DFBDFBDocumento8 pagineDFBDFBEnas AbdrabelnabyNessuna valutazione finora

- Datasheet Chockfast RedDocumento2 pagineDatasheet Chockfast RedAlexander0% (1)

- Concrete Protection - Sika Concrete Repair and Protection - 102011 OrdnerDocumento56 pagineConcrete Protection - Sika Concrete Repair and Protection - 102011 OrdnerTan Peng LeakNessuna valutazione finora

- Preparation of Porous Carbons From Non-Metallic Fractions of Waste Printed Circuit Boards by Chemical and Physical ActivationDocumento6 paginePreparation of Porous Carbons From Non-Metallic Fractions of Waste Printed Circuit Boards by Chemical and Physical ActivationTudor ArgheziNessuna valutazione finora

- Probably The Toughest Epoxy Coatings in The WorldDocumento4 pagineProbably The Toughest Epoxy Coatings in The WorldMachonga LimitadaNessuna valutazione finora

- Dura-Plate 235 PW NSF: Protective & Marine CoatingsDocumento4 pagineDura-Plate 235 PW NSF: Protective & Marine CoatingsAnn HewsonNessuna valutazione finora

- Thermal Shock Effects on Adhesive Joint StrengthDocumento6 pagineThermal Shock Effects on Adhesive Joint StrengthCandace FrankNessuna valutazione finora

- P6100HEDocumento1 paginaP6100HERamirez Indeleble0% (1)

- LoxealDocumento16 pagineLoxealLeandro LibrandaNessuna valutazione finora