Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mettle Tiledo Ind 331 Terminal

Caricato da

dgfggfhghgdfhtCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mettle Tiledo Ind 331 Terminal

Caricato da

dgfggfhghgdfhtCopyright:

Formati disponibili

Weighing Terminals

Max Connectivity, Mini Footprint

Process Weighing in Hazardous Areas

Weigh

The IND131xx and IND331xx terminals deliver excellent accuracy,

reliability and efficiency for process

weighing applications in hazardous

areas.

Zone 2/22, Division 2

Comply

These superior weighing terminals

feature the performance and reliability expected of instruments designed

to comply with Weights & Measures,

hazardous area and product safety

regulations. They include features

and functionality never before offered

in such a compact and versatile form

factor.

Control

The inherent qualities of process

weighing terminals from METTLER

TOLEDO make it easier for OEMs

and system integrators to build bestin-class weighing systems costeffectively.

Connect

Easy integration into process-based

network architectures provides valuable plant-floor information to process owners to optimize production

and reduce down-time.

Multiple PLC interfaces

All IND131xx and IND331xx terminals

can be equipped with any of a wide

array of PLC options.

IECEx

IND131xx and IND331xx

Weighing Terminals

The IND131xx and IND331xx analog scale terminals

deliver precision measurement data in a single,

cost-effective package, safe for use in Zone 2/22 and

Division 2/Zone 2 hazardous areas. Terminal features

include:

Organic LED display readable in all light conditions

Ultra-fast A/D conversion rate and TraxDSP digital

filtering

Enclosures designed to match application

environment modular design enables multiple

mounting possibilities

24 VDC operation

Support for a wide variety of options, including DIO,

additional serial port, and PLC interfaces

Portable calibration/configuration settings and firmware update via an SD memory card

Scale calibration through PLC interface. CalFREE

allows scales to be calibrated without test weights

Weighing Terminals

IND131xx and IND331xx

Weighing Terminals

Technical Data

Enclosure types

IND131xx

DIN mounted

IND331xx

Panel mounted

IND131xx

JBox enclosure

DIN rail-mount, plastic, with

operator interface

Panel mount, stainless steel

with operator interface + plastic chassis

Stainless steel

enclosure including

internal board

to sum load cells

mm

in.

68 138 111

2.7 5.4 4.4

Front panel:

168 68 12

6.6 2.7 0.5

251 261 123

9.9 10.3 4.8

kg / lb

1 / 2.2

1.5 / 3.3

5.5 / 12.1

IP20, Type 1

IP65, Type 4x and 12

IP69k

Unit of

Measure

Dimensions

LHD

Shipping weight

Environmental protection

Ambient environment

Operation

C / F

-10 to 40 / 14 to 104, 10% to 90% relative humidity, non-condensing

Storage

C / F

-20 to 60 / -4 to 140, 10% to 90% relative humidity, non-condensing

Power requirements

VDC / mA

Type

Display

18-36; nominal 24 / 84-170; nominal 120 (IND131xx), nominal 130 (IND331xx)

Green OLED including weight display, weight units, gross/net indication and graphic symbols for

motion and center of zero. 10 updates/sec.

Character height

mm / in.

5.6 / 0.22

Weight display

12 / 0.47

Maximum displayed resolution of 100,000 divisions

Scale type

Analog load cells

Number of cells

Up to 4 350 load cells, 2 or 3 mV/V

Number of scales

Analog/Digital update rates

Hz

Internal analog: 366 / Target comparison: 50 / PLC Interface: 20

Digital Filtering

TraxDSP

Memory

Stores two-speed target control values and limit values for three comparators

Applications

Basic process weighing for gain-in-weight (filling), loss-in-weight (dosing) and level indication

Load cell excitation voltage

VDC

V Build Minimum/Approved

microvolts

5

0.1 / 0.6

4 keys (Clear, Zero, Tare, Print); 1.22mm thick polyester overlay (PET) with

polycarbonate display lens

Keypad

Communications

Serial

interfaces

Standard: One serial port (COM1), RS-232, 300 to 115,200 baud

Optional: Serial port (COM2), RS-232/485, 300 to 115,200 baud

Serial inputs: ASCII commands for CTPZ (Clear, Tare, Print, Zero),

SICS (most commands, levels 0 and 1)

Serial outputs: Continuous, Extended continuous, or Demand (limited formats)

Protocol

Weights and Measures

USA: NTEP Class III/IIIL - 10,000d; CoC 09-051

Canada: Class III/IIIHD - n max. 10,000/20,000; AM-5744

Hazardous locations

Approvals

USA - FM

Canada - FM

NI / I, II, III / 2 /

ABCDEFG / T5 Ta

= 40C

I / 2 / IIC / T5 Ta

= 40C

NI / I / 2 / ABCD / T5

Ta = 40C

DIP / II, III / 2 / EFG /

T5 Ta = 40C

ATEX

Install per Control Drawing 72238303R

Product safety, ordinary

locations

Options

COM2 / DIO, includes:

IECEx

NEPSI

Ex nA nL [nL] IIC T5

Ex tD A22 IP65

T100C

Pending

Install per Installation Drawing 72246295R

UL, cUL, CE

COM2 RS-232/485 serial

4 solid state discrete outputs

Modbus RTU capability

2 discrete inputs (selectable active or passive)

4-20mA Analog Output

Programmable Logic Control PROFIBUS DP

(PLC) interfaces

Allen-Bradley RIO

Accessories

II 3 G Ex nA nL [nL]

IIC T5

II 3 D Ex tD A22 IP

65 T 100C

Europe: OIML, Class III,

6000e; R76/2006-NL1-09.26

OIML R51 (Automatic Catchweighing) T10262

OIML R61 (Automatic Gravimetric Weighing) T10261

MID

Ethernet/IP

DeviceNet

Modbus TCP

ControlNet

Note: Explicit messaging not supported in IND131 and IND331 PLC intefaces;

upgrade to IND560 or IND780 for this capability.

Agency-approved (FM/CSA/ATEX) 24VDC DIN rail mount Power Supply

2GB Memory SD Card for configuration and calibration data backup and restore

ISB05 Intrinsically Safe Barrier when Load Cells are in Zone 1/21 or Div 1 areas

5.6 / 0.22 (internal)

PTPN Terminal adapter plate (for IND331 Panel unit)

IND331 with PTPN adapter plate

IND131xx and IND331xx Packaged Solutions

Enhanced Terminals in Robust Enclosures

Packaged IND131xx and IND331xx in Enclosures Approved for Division 2, Zone 2 and Zone 22

Each version can be configured with any of the terminals' multiple interface and connectivity options

Packages include an agency-approved 24 VDC power supply

Enclosure Specifications

The stainless steel enclosure housing the IND131xx DIN and IND331xx

panel packaged solutions is FMapproved for use in safe areas, and

in Division 2, Zone 2 hazardous

areas. The enclosure is ATEX/IECEx

certified for Zone 22 (dust) hazardous areas. Cable entry points can

be either conduit hubs for use in the

U.S., or ATEX-approved glands for

European applications.

Multiple Terminal Configurations Available

When a single terminal is not enough, multi-terminal

designs are available, with agency-approved power

supply, optional ISB (Intrinsically Safe Barrier) and additional features as required for the application.

FM-certified enclosure, gas and

dust

ATEX and IECEx certified for Zone

2/22 environments

Rated IP66, IP65 when used

with panel-mount terminal

T5 temperature class rating

Load Cells in Hazardous Areas

In applications with load cells installed in Division 1/

Zone 1 or Zone 1/21 areas, an intrinsically safe

analog load cell barrier (ISB) is required. IND131xx and

IND331xx terminals packaged with a METTLER TOLEDO

ISB05 intrinsically safe barrier provide an

integrated solution for such applications. Refer to the

control drawing for load cell compatibility.

Packaged Model Configurations

IND131xx and IND331xx packages are highly customizable. Table 1 shows the array of available primary

configurations.

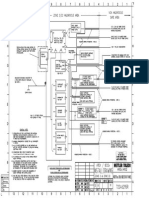

Two possible variants are illustrated below. Figure 1

shows a system comprising an IND131xx with optional

ISB05 barrier. Figure 2 shows an IND331xx panelmount terminal (its front panel interface not shown).

The packaged model configurations are available with

any of the PLC interfaces (EtherNet/IP, PROFIBUS DP,

Modbus TCP, Allen-Bradley RIO, ControlNet, DeviceNet), and Solid State DIO.

IND131xx-based package

ISB05 (optional)

FM/CSA/ATEX approved power supply,

24VDC at 1.3 A, 100-240 VAC, 50/60 Hz

ATEX glands (for European installations)

FM, ATEX and IECEx- certified enclosure

Table 1

FM-approved

conduit hubs

Terminal

Single

terminal

Dual

terminals

ATEX-approved glands

Single

terminal

Dual

terminals

IND131xx

DIN-mount

Standard*

Standard*

with ISB05(s)

with ISBO5(s)

IND331xx

Panel-mount

Standard*

Standard*

with ISB05(s)

with ISB05(s)

* Terminal with agency-approved 24VDC power

supply

IND331xx-based standard package

(front panel display not shown)

FM/CSA/ATEX approved power supply,

24VDC at 1.3 A, 100-240 VAC, 50/60 Hz

Conduit hubs (for installation in US/Canada)

FM, ATEX and IECEx-certified enclosure

Figure 1

Figure 2

Customized Interfaces

The packaged IND131xx and

IND331xx can be customized for

specific uses, to include agencyapproved operators for I/O, such

as annunciators and pushbuttons,

making operator interactions even

easier, more consistent and safer.

14001

Mettler-Toledo, Inc.

900 Polaris Parkway

Columbus, OH 43240

Tel. 800-METTLER / 614-438-4511

Fax 614-438-4900

Subject to technical changes

INDB0082.E0

04/2011 Mettler-Toledo, Inc.

METTLER TOLEDO

Service

Essential Services for Dependable Performance

METTLER TOLEDO is uniquely qualified to provide the installation,

calibration and maintenance services essential to ensuring accuracy, optimizing uptime and prolonging equipment life. Our service

representatives will be there at the right time, with the right parts,

the right tools and the right skills to meet your needs.

www.mt.com

for more information

Potrebbero piacerti anche

- Description: New Features!Documento6 pagineDescription: New Features!@@ngNessuna valutazione finora

- PanelView Component SpecificationsDocumento12 paginePanelView Component SpecificationsmateusT850Nessuna valutazione finora

- AT-1110 v3Documento4 pagineAT-1110 v3IvanNessuna valutazione finora

- K-84-11 Addressable Pull Station 3300Documento2 pagineK-84-11 Addressable Pull Station 3300Dani Setia RamdaniNessuna valutazione finora

- Scadapack 314 DatasheetDocumento4 pagineScadapack 314 DatasheetAqua Technology GroupNessuna valutazione finora

- Siemens Climatix IO ModuleDocumento10 pagineSiemens Climatix IO Moduleamitdesai1508Nessuna valutazione finora

- Ethernet Interface 1761 Net EniDocumento40 pagineEthernet Interface 1761 Net EniDaniel Castrellon MedellinNessuna valutazione finora

- V350 35 R6 - Tech SpecDocumento5 pagineV350 35 R6 - Tech Specchrobakpeter12345Nessuna valutazione finora

- Quad2 T1/E1 Echo CancellerDocumento2 pagineQuad2 T1/E1 Echo CancellerarzeszutNessuna valutazione finora

- Scadapack 100 DatasheetDocumento4 pagineScadapack 100 DatasheetAqua Technology GroupNessuna valutazione finora

- Remote I/O Is1+ Busrail End Piece End 9494/A1-E0 Art. No. 261934Documento2 pagineRemote I/O Is1+ Busrail End Piece End 9494/A1-E0 Art. No. 261934Alisson DominghettiNessuna valutazione finora

- Sitransl LR560 enDocumento5 pagineSitransl LR560 enknchnNessuna valutazione finora

- Siemens Sitrans ProbeLU PDFDocumento5 pagineSiemens Sitrans ProbeLU PDFdavidcevs89Nessuna valutazione finora

- Flexi/O and Flex Ex: Selection GuideDocumento144 pagineFlexi/O and Flex Ex: Selection GuideMaria MitaraNessuna valutazione finora

- F 30 1001 - PrintDocumento2 pagineF 30 1001 - PrintMido AbdoNessuna valutazione finora

- E3 Modulevel: Displacer Operated Level TransmitterDocumento12 pagineE3 Modulevel: Displacer Operated Level TransmitterAbhra ShauNessuna valutazione finora

- BVD2273GB TersusDocumento4 pagineBVD2273GB TersusMohamed ElfawalNessuna valutazione finora

- Crompton Instruments Integra Ci3: Digital Metering SystemDocumento4 pagineCrompton Instruments Integra Ci3: Digital Metering SystemAmit BhatiaNessuna valutazione finora

- Foxboro IDP50Documento32 pagineFoxboro IDP50dennisheadley50% (2)

- SCADAPack 350 DatasheetDocumento6 pagineSCADAPack 350 DatasheetWiedNessuna valutazione finora

- Yokogawa DY050Documento43 pagineYokogawa DY050ares201216675Nessuna valutazione finora

- Remote I/O Is1+ Busrail For 2 Modules, End 9494/S1-E2 Art. No. 261799Documento2 pagineRemote I/O Is1+ Busrail For 2 Modules, End 9494/S1-E2 Art. No. 261799Alisson DominghettiNessuna valutazione finora

- Vortex: Gas Detection Control PanelDocumento4 pagineVortex: Gas Detection Control PanelDanny YapNessuna valutazione finora

- Please Download Drivers For This Product atDocumento1 paginaPlease Download Drivers For This Product attonnytoonsNessuna valutazione finora

- HD Coct S 010 Flex Vu Ud10Documento2 pagineHD Coct S 010 Flex Vu Ud10leunamsayanNessuna valutazione finora

- IAP10, IGP10, IAP20, IGP20 Pressure TransmitterDocumento40 pagineIAP10, IGP10, IAP20, IGP20 Pressure TransmitterTefa SernaNessuna valutazione finora

- SRD991Documento2 pagineSRD991Esteban ReyesNessuna valutazione finora

- Eclipse E300 Data Sheet ETSI PDFDocumento12 pagineEclipse E300 Data Sheet ETSI PDFJuanPiñeroNessuna valutazione finora

- Pulse Autonom 3052 PDFDocumento8 paginePulse Autonom 3052 PDFRobert RodriguezNessuna valutazione finora

- At200 K-TekDocumento2 pagineAt200 K-TekROGELIO QUIJANONessuna valutazione finora

- Serial Adapter: EN 50121-4 EN 61000-6-1 EN 61000-6-2 EN 61000-6-4Documento2 pagineSerial Adapter: EN 50121-4 EN 61000-6-1 EN 61000-6-2 EN 61000-6-4MBJSKNessuna valutazione finora

- p122c Ent b11 GLOBALDocumento284 paginep122c Ent b11 GLOBALAdip ChyNessuna valutazione finora

- TLV 320 Adc Stereo Evaluation Audio AmplifierDocumento85 pagineTLV 320 Adc Stereo Evaluation Audio AmplifierJay VoraNessuna valutazione finora

- Anybus Communicator - PROFIBUSDocumento4 pagineAnybus Communicator - PROFIBUSAymanNessuna valutazione finora

- Vacon PDFDocumento12 pagineVacon PDFstudskirbyNessuna valutazione finora

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocumento5 pagineSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicNessuna valutazione finora

- Los FastastiDocumento38 pagineLos Fastastialexander RodriguezNessuna valutazione finora

- SG-gateway With PROFINET-ASG4006Documento4 pagineSG-gateway With PROFINET-ASG4006sameer ahamedNessuna valutazione finora

- S&T TS & DRGSDocumento113 pagineS&T TS & DRGSShivendra KumarNessuna valutazione finora

- NX-CIF Datasheet en 201506 P55I-E-02 Rev3 1Documento14 pagineNX-CIF Datasheet en 201506 P55I-E-02 Rev3 1Lizbeth Soto CastilloNessuna valutazione finora

- Datek Receiver D2001KDocumento2 pagineDatek Receiver D2001KAkash KazamaNessuna valutazione finora

- XFC EspecificacionsDocumento19 pagineXFC Especificacionsadesa2013Nessuna valutazione finora

- UNI 50 Microwave Radio Transceiver SpecificationsDocumento4 pagineUNI 50 Microwave Radio Transceiver SpecificationssherwinpetrasNessuna valutazione finora

- AT10.1 Series: Float Battery ChargersDocumento12 pagineAT10.1 Series: Float Battery ChargersJ Salvador Calderón BarrancosNessuna valutazione finora

- Weighing TerminalDocumento171 pagineWeighing Terminalmemojimenez4024Nessuna valutazione finora

- 4as119068 - Uc 500e Ed.2 Data - SheeDocumento12 pagine4as119068 - Uc 500e Ed.2 Data - SheeayyakkottaiyurNessuna valutazione finora

- Ap 1600 GetstartDocumento38 pagineAp 1600 GetstartFrancisco DiazNessuna valutazione finora

- MAP DE Module (ICP MAP0007)Documento3 pagineMAP DE Module (ICP MAP0007)MounirNessuna valutazione finora

- Monitor Module PDFDocumento2 pagineMonitor Module PDFKalpa Helitha SilvaNessuna valutazione finora

- SERVOMEX - 2210 and 2213 Control UnitDocumento4 pagineSERVOMEX - 2210 and 2213 Control UnitManuel MarinNessuna valutazione finora

- CH20M Product InformationDocumento12 pagineCH20M Product InformationalltheloveintheworldNessuna valutazione finora

- Wika Il-10Documento4 pagineWika Il-10José MelâneoNessuna valutazione finora

- Aislador Digital Input 8DIDocumento1 paginaAislador Digital Input 8DIEduardo_77Nessuna valutazione finora

- Controlador Zelio RTC48 - Datasheet PDFDocumento4 pagineControlador Zelio RTC48 - Datasheet PDFM Daniel HuayancaNessuna valutazione finora

- Especificación Tecnica V350-35-R34Documento5 pagineEspecificación Tecnica V350-35-R34Germaín Hernández GómezNessuna valutazione finora

- Centurion PLUS Full-Featured Controller: Sect. 50Documento4 pagineCenturion PLUS Full-Featured Controller: Sect. 50Pranay GuptaNessuna valutazione finora

- Jet Con 1302Documento2 pagineJet Con 1302Paulius JuškevičiusNessuna valutazione finora

- Digital Timer: Easy To Use and Easy To ReadDocumento32 pagineDigital Timer: Easy To Use and Easy To ReadAlvin NguyenNessuna valutazione finora

- Is1+ Remote I/O Busrail End Piece Beginning 9494/A1-B0 Art. No. 261933Documento2 pagineIs1+ Remote I/O Busrail End Piece Beginning 9494/A1-B0 Art. No. 261933Alisson DominghettiNessuna valutazione finora

- Unipluse f701 CDocumento186 pagineUnipluse f701 CdgfggfhghgdfhtNessuna valutazione finora

- IND429Documento56 pagineIND429dgfggfhghgdfhtNessuna valutazione finora

- Mettler Toledo Terminal Solutions Pocketguide 10-09v06Documento2 pagineMettler Toledo Terminal Solutions Pocketguide 10-09v06dgfggfhghgdfhtNessuna valutazione finora

- IND131-331 Dim and Config enDocumento2 pagineIND131-331 Dim and Config endgfggfhghgdfhtNessuna valutazione finora

- IND331 Instal DrawingDocumento3 pagineIND331 Instal DrawingdgfggfhghgdfhtNessuna valutazione finora

- VPEG Sequence Control ST16Documento50 pagineVPEG Sequence Control ST16Nik Sayko100% (2)

- F701-C CC-Link I/F SpecificationsDocumento31 pagineF701-C CC-Link I/F SpecificationsdgfggfhghgdfhtNessuna valutazione finora

- VPEG Project Creation IOMDocumento37 pagineVPEG Project Creation IOMdgfggfhghgdfhtNessuna valutazione finora

- VPEG Software Input Output Functions PDFDocumento21 pagineVPEG Software Input Output Functions PDFdgfggfhghgdfhtNessuna valutazione finora

- VPEG Sequence Control ST16Documento50 pagineVPEG Sequence Control ST16Nik Sayko100% (2)

- VPEG Hardware Description FFCS LDocumento16 pagineVPEG Hardware Description FFCS Lwira ekaNessuna valutazione finora

- VPEG System OverviewDocumento26 pagineVPEG System OverviewdgfggfhghgdfhtNessuna valutazione finora

- AU7842Documento17 pagineAU7842dgfggfhghgdfhtNessuna valutazione finora

- MBB50 50Documento45 pagineMBB50 50dgfggfhghgdfhtNessuna valutazione finora

- Owner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13Documento18 pagineOwner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13mediacampaigncc24Nessuna valutazione finora

- 13 Alvarez II vs. Sun Life of CanadaDocumento1 pagina13 Alvarez II vs. Sun Life of CanadaPaolo AlarillaNessuna valutazione finora

- Exercise 8 BeveragewareDocumento9 pagineExercise 8 BeveragewareMae Cleofe G. SelisanaNessuna valutazione finora

- Grounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiDocumento42 pagineGrounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiSatyam PathakNessuna valutazione finora

- Kenwood Report FinalDocumento43 pagineKenwood Report Finaltooba siddiquiNessuna valutazione finora

- Universal Robina Sugar Milling Vs AciboDocumento7 pagineUniversal Robina Sugar Milling Vs AciboCeresjudicataNessuna valutazione finora

- S:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Documento19 pagineS:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Lui TCC BariaNessuna valutazione finora

- Ammonia Synthesis ConverterDocumento26 pagineAmmonia Synthesis ConverterKvspavan Kumar100% (1)

- Mobil Delvac 1 ESP 5W-40Documento3 pagineMobil Delvac 1 ESP 5W-40RachitNessuna valutazione finora

- Pentacam Four Maps RefractiveDocumento4 paginePentacam Four Maps RefractiveSoma AlshokriNessuna valutazione finora

- Traditional vs. Enterprise Risk Management - How Do They DifferDocumento4 pagineTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanNessuna valutazione finora

- Qualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific ApproachDocumento23 pagineQualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific Approachmicrobioasturias100% (4)

- SRV SLB222 en - 05062020Documento2 pagineSRV SLB222 en - 05062020Nguyen ThuongNessuna valutazione finora

- ME-317 Internal Combustion Engines - TurbochargingDocumento21 pagineME-317 Internal Combustion Engines - TurbochargingHamzaJavedNessuna valutazione finora

- INTELLECTUAL DISABILITY NotesDocumento6 pagineINTELLECTUAL DISABILITY Notesshai gestNessuna valutazione finora

- Ransport and Installation Instructions CTX 510 EcoDocumento32 pagineRansport and Installation Instructions CTX 510 EcoMiliano FilhoNessuna valutazione finora

- Liquid Enema ProcedureDocumento3 pagineLiquid Enema Procedureapi-209728657Nessuna valutazione finora

- EDAH EnglishDocumento2 pagineEDAH EnglishMaría SanchoNessuna valutazione finora

- Wa0016Documento3 pagineWa0016Vinay DahiyaNessuna valutazione finora

- API 650 10th Edition ErrataDocumento6 pagineAPI 650 10th Edition ErrataJosé Ramón GutierrezNessuna valutazione finora

- CL Analyzer: Coagulometric, Chromogenic and Immunological AssaysDocumento2 pagineCL Analyzer: Coagulometric, Chromogenic and Immunological AssaysEdwinNessuna valutazione finora

- 2008 NOHC - JPHDSupplementDocumento62 pagine2008 NOHC - JPHDSupplementEliza DNNessuna valutazione finora

- OA Standard 050505Documento75 pagineOA Standard 050505fido_dagemNessuna valutazione finora

- CH 13 RNA and Protein SynthesisDocumento12 pagineCH 13 RNA and Protein SynthesisHannah50% (2)

- Reference Document GOIDocumento2 pagineReference Document GOIPranav BadrakiaNessuna valutazione finora

- Crime Free Lease AddendumDocumento1 paginaCrime Free Lease AddendumjmtmanagementNessuna valutazione finora

- Bulk-Fill Composite RestorationsDocumento9 pagineBulk-Fill Composite RestorationssusethNessuna valutazione finora

- Laughter, It Is Good For YouDocumento2 pagineLaughter, It Is Good For YouClaire B.L.Nessuna valutazione finora

- Select Event Venue and SiteDocumento11 pagineSelect Event Venue and SiteLloyd Arnold Catabona100% (1)

- 1 BSC Iriigation Engineering 2018 19 Std1Documento70 pagine1 BSC Iriigation Engineering 2018 19 Std1Kwasi BempongNessuna valutazione finora