Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Development 2S Engine

Caricato da

Tapas ChaudhuriCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Development 2S Engine

Caricato da

Tapas ChaudhuriCopyright:

Formati disponibili

1

SLOW-SPEED TWO STROKE ENGINES

Nikolaos P. Kyrtatos

Professor of Marine Engineering

National Technical University of Athens, Greece

1 INTRODUCTION

The requirements for propulsion of merchant ships are generally satisfied with a simple

slow-speed diesel engine installation, meeting the speed and power demands, directly

connected to the propeller without gearboxes and clutches. The slow-speed engine is,

because of size, the most efficient thermal machine. These slow speed engines are able to

burn heavy fuel easier than a medium speed engine, because they have more time and

space available for combustion. Heavy fuel is a residual from the crude oil refining process

and therefore much cheaper than the refined products.

Unlike medium speed engines without crosshead, where the same lubricant oil has to be

used for the lubrication of the whole engine, which inevitably leads to some compromize as

to its properties, the slow-speed engine with a crosshead has a clear separation between the

crankcase and the cylinders. Therefore recirculating clean system oil can be used for

lubricating the bearings and a separate consumable cylinder luboil is used for piston rings

liner lubrication, but also importantly to deal with the acidic residues of combustion. Special

alkaline oils can be used in this case, injected by cylinder lubricant quills in precise

quantities, distributed in each cylinder and even in each part of the liner.

The slow speed engine has fewer cylinders and consequently fewer moving parts, which

means in principle higher overall reliability. Components, individually, are heavier but their

handling can be performed as easily with special tools and lifting devices. Also any

maintenance work is facilitated by more space available inside the engine and usually also in

the engine room. Maintenance costs often prove to be less than those of medium speed

engines. The noise level is much lower than that of medium speed engines.

The disadvantages of slow speed engines such as the larger footprint and higher space

requirements, the more weight and higher initial price, become less important when

considering the entire propulsion plant and not just the isolated engine.

2 GENERAL DESCRIPTION

All modern slow speed engines share some common characteristics: they are two-stroke,

have a cross head, are turbocharged and uniflow scavenged.

As the engine size increases, the relative advantage of the two-stroke cycle over the fourstroke cycle in specific power becomes more pronounced, surpassing any disadvantages.

With larger engine sizes, the sideways forces produced by the crank mechanism, to be

passed on to the engine body would require a sturdier piston skirt as well as heavy supports

for the relatively thin cylinder liners. The design that was adopted, had been used in the

double acting steam engine, where a gland sealed the piston rod connecting the

reciprocating piston to the top of the connecting rod, to allow steam also to the piston

underside. The sideways forces are taken by the cross head, having slippers sliding on

guides, which are in turn mounted on the engine body. This arrangement also allows for

easy piston removal during maintenance.

An important issue with these large engines is the rigidity of the engine frame. This was not

important for old steam engines, since their thin crankshafts were quite flexible and could

easily absorb the deformations of the ship. But modern large diesel engines have thick

crankshafts to withstand the large forces of combustion and the higher specific powers. The

crankshafts are so rigid that the deformations of the hull would produce excessive reactions

at the main bearings and high stresses in the shafts and couplings. So the machine frame

must be also made quite rigid to protect the crankshaft from unacceptable distortion. The

hull is also reinforced under the engine and supports the engine frame. This reinforcement

is continued for some distance beyond the length of the engine, so as not to cause a

discontinuity at the aft end of the engine, which would affect the propeller shaft.

In the development of large two-stroke engine several design problems had to be resolved.

The large size does not present a particular difficulty in itself, as the stresses due to

mechanical and inertial loads in geometrically similar engines of different sizes, remain in

accordance with the laws of similarity. The most important exceptions are the thermal

stresses. These increase with size and specific design solutions had to be used to develop

components strong enough to receive mechanical loads - which sometimes amount to

hundreds of tons - and at the same time to keep the thermal stresses low. Such designs

involved bore cooling of thick components and strong-back flame plate arrangements.

The operation of these large engines in two strokes, creates problems in the crosshead/

connecting rod top end bearing, which is always loaded in one direction downwards without

a period to refresh the film of lubricant, as in four-stroke engines. The lubrication of piston

rings is also more difficult due to absence the two extra strokes to refresh the oil film, before

it is necessary to seal the combustion gases. Additionally, the presence of ports in the liner

interrupts the smooth running of piston rings on the liner surface.

The engines are so large they have to be piecewise assembled in three major parts, namely

the bedplate, the A-frames (columns) and the cylinder block (entablature). The engine

bedplate is the foundation on which the other components of the engine are built. It

consists of a welded plate structure with cast transverse bearing girder members. The Aframes carry the crosshead guide rails. The entablature (the cylinder block) is from grey

cast iron made as a single part or split in individual cylinder blocks. It rests on the A-frames,

embodies the cooling water passages and forms the housing to receive the cylinder liners.

It may also incorporate the scavenge air receiver. To fasten the bedplate, the frames and

the entablature firmly together, long tie rods are hydraulically tightened through these

three components.

The crankshafts on the large two stroke crosshead engines are too large and heavy to

make as a single unit and so are built up by joining together forged parts (crank throws)

usually by shrink fit or deep welding, then machining on very large horizontal lathes.

The connecting rod connects the crankshaft to the piston assembly and is forged out of

round bar and machined. The crosshead has 4 cast guide shoes with white metal lining to

transmit the sideways forces to the engine structure through the guide rails.

The cylinder liner forms the cylinder in which the piston works. The liner is manufactured

separately from the cylinder block. If they were cast together as one piece, then it would

be difficult to mitigate the thermal stresses. The liner is made of grey cast iron, containing

flake graphite, a lubricant and alloy metals to resist corrosion and wear at high

temperatures. Appropriate cooling of the liner is important to restrain wear. The cylinder

liner will inevitably wear with use and may have to be replaced.

The Piston comprizes two parts; the crown and the skirt. The crown is made of high alloy

steel providing strength and corrosion resistance at high temperatures. The crown is

subject to the high combustion temperatures and its surface may be eroded or burnt away.

The piston has a high topland with the ring grooves placed lower down in the crown to

reduce the combustion load on the rings. The cast iron skirt acts as a guide within the

cylinder liner. A forged steel piston rod bolted to the underside of the piston connects it to

the crosshead. A piston rod gland box separates the scraped down cylinder oil, which is

under scavenge space pressure from the system luboil in the crankcase.

The pistons are cooled using either water or oil. In some arrangements, to enhance

cooling, the oil is sprayed with high pressure jets to the underside of the crown. Water has

a better heat absorption capacity, but there are more risks if there is leakage into the

crankcase.

Modern two stroke crosshead engines have a single hydraulically operated exhaust valve

with an air spring. The water cooled valve cage is housed in the cylinder cover, which is

made of forged steel. The cylinder cover is fastened to the cylinder block by a number of

hydraulically tightened bolts. The fuel injection nozzles and starting valves are also housed

in the cylinder cover.

The turbocharger(s) may be arranged laterally or a single one at the driving end of the

engine. Downstream of the water cooled scavenge air cooler there is a water separator to

prevent condensed water carry over into the engine.

In the 1950s turbocharging helped the diesel engine to win the battle against the steam

turbine, which then dominated the region of high engine powers. Turbocharging not only

allowed increases in power but also improved fuel consumption considerably. Air

supercharging is obtained through an independent turbocharger comprising a centrifugal

compressor and turbine on the same shaft, which works on an open cycle gas turbine

principle, where the cylinders can be regarded as the combustion chamber. Such a cycle is

self-sustaining only if the temperature difference between the compressor and the turbine is

high enough not only to overcome the losses of the cycle but also to provide the required

boost pressure for scavenging of the cylinders. This easily occurs at high loads with modern

turbines and compressors of high efficiency. The turbine is connected downstream of an

exhaust receiver common for several cylinders, the so-called constant pressure

turbocharging system. In the past the more complex impulse system was used to offset the

then lower efficiency of the turbochargers. In that arrangement, the energy of the gas pulse

from the opening exhaust valve was retained, transmitted via narrow piping to the turbine,

but this more complex arrangement is no longer necessary. During low-load operation,

during startup and maneuvering, the exhaust gas temperature is very low, especially in two

stroke engines where scavenge air mixing with exhausting gases reduces further the exhaust

gas temperature upstream of the turbine. In four-stroke engines, the two additional strokes

render the engine capable of breathing on its own, but with large two-stroke engines, the

torque produced by the turbine at low loads usually cannot provide the necessary

compressor boost pressure for scavenging, which must then accomplished by some other

means, for example, by an electically driven scavenge blower in series with the

turbocharger, or with electric, hydraulic, or pneumatic power take-in driving the rotor of the

compressor when needed.

3 SHIP PROPULSION WITH DIRECT DRIVE ENGINES

Moving of a ships hull through water at a certain speed requires thrust usually provided by

a pushing propeller. The thrust required depends on the shape of the hull and the wetted

area, which affects the frictional resistance. The hull shape displaces water, which forms

waves moving out of the way and this wavemaking consumes part of the thrust input. Both

frictional resistance and wavemaking resistance increase with increased speed through

water. The ships superstructure also faces air resistance increasing with speed. If the hull is

loaded with more cargo then the draft increases and the wetted area increases and both

frictional and wavemaking resistance increase. Changes in the trim (attitude) of the hull also

influence the resistance. If the ship has to face waves in a seaway the thrust needed to

retain the set speed will increase. Over time the surface conditions of the submerged part of

the hull changes from accumulation and growth of microorganisms, animals and plants and

this hull biofouling increases frictional resistance.

For the propeller to produce thrust it must be rotated at a certain speed. Within the bounds

of draft necessary to keep the propeller submerged, the largest propeller rotating at the

lowest speed, will deliver the required thrust most efficiently. Occasionally the choice of

propeller diameter is limited by the need to keep the propeller submerged also in the ballast

condition. This is more important for tankers and bulk carriers, but less critical for

containerships, which seldom sail in ballast condition. The propulsion engine must provide

the required torque to the propeller shaft at this required rotational speed, therefore the

engine must be able to deliver the respective power (being the product of torque and

speed).

A new ship will be ordered on the basis of size, cargo type and ship speed through water (at

the design point, i.e. at certain conditions of loading and outside environment).

The two-stroke engine designer needs to get both power and speed right independently,

because the engine is directly coupled to shaft driving the propeller. Since every ship has a

potentially different design point, the engine makers in their portfolio offer engines, which

can be individually set up, tuned and optimized at any specific power/speed point anywhere

within the bounds of a so-called layout field of the engine family. This specific for the

individual engine point is called Contract Maximum Continuous Rating (Power) point. The

cost of the engine is directly related to the contract power.

Running the engine continuously at the CMCR point is possible, but it would probably mean

that the maintenance costs would be too high. Normally the engine would be run during

service at some lower power, where the torque delivered would be adequate for the

propeller to produce adequate thrust to move the hull at the specified speed through water.

This power margin between installed (CMCR) power paid for, but normally not used and

continuous service power, is some kind of insurance that if conditions get worse, the ship

can still fulfil its speed through water requirements.

Such conditions are, for example, increased thrust hence power needs from increased

resistance over time due to hull fouling, from heavy weather encountered in a sea passage,

engine performance deterioration due to ageing, or the need for higher speed to catch up

with delays.

As mentioned, for constant ship speed and for a given propeller type, a larger slower

spinning propeller gives improved propulsive efficiency. This trend has led to engine designs

to accommodate the requirements for power at lower engine rotational speeds.

Considering the crank-piston mechanism and assuming the mean velocity of the piston in

the cylinder during the stroke remains unchanged, because of piston ring friction and

lubrication issues, then to obtain a lower crankshaft rotational speed leads to longer piston

stroke. The longer expansion stroke may also provide some efficiency benefits. If the bore

stays unchanged, then the long stroke results in oblong cylinders. In two-stroke engines such

long stroke geometries present difficulties for cylinder scavenging through inlet and exhaust

ports at the bottom of the liner, since the top part of the combustion space will be left

unscavenged. The arrangement followed by all modern slow-speed two-stroke engines, is

the uniflow scavenging pattern, with inlet ports at the bottom of the cylinder and a single

exhaust valve at the top, which inevitably complicates the design.

In the modern electronically controlled engines the timing of this hydraulically actuated

valve can be independently adjusted at various engine operating conditions. In electronic

engines also the fuel injection timing, rate and quantity can be controlled. Usually more than

one fuel injection valves are housed in each cylinder cover and each can be independently

controlled, allowing more flexibility in engine optimisation at all operating conditions. These

large engines start with timed injection of compressed air timed into the cylinders and the

starting air valve can also be electronically controlled.

All large direct coupled marine engines are reversible and can turn the propeller also in the

opposite direction to reverse the ship. The electronic control of the hydraulic actuation of

valves is much simpler than the mechanical shifting of camshafts, required to change the

timing of cylinder events as needed for reversing.

4 DESIGN OF LARGE TWO-STROKE MARINE ENGINES

The development of ship sizes and the expected ship design speed as foreseen by the engine

makers market intelligence, define the engine power and engine speed envelope in the

initial phase of a new engine design. An additional forcing term is the target engine footprint

geometry, which for large two stroke-engines is limited by the maximum bedplate width,

defined by the positioning of the engine in the aft part of the hull, where the hull lines will

inevitably be finer for improved hull performance.

The MEP (mean effective pressure) level is the next decision point based on past experience

and avoiding big jumps which may have reliability implications. The lowest speed for

constant MEP defines the size of components such as cross-head bearing, piston rod and

bottom end bearing, since the forces remain the same for lower rotational speed and this

affects the oil film thickness. The highest speed on the other hand affects the main bearing

size because of the rotating masses.

MEP and maximum cylinder pressure influence the long term condition of the cylinder, the

piston ring pack and the thermomechanical loading of the piston, the liner, the cylinder

cover and the exhaust valve.

The cylinder distance in long-stroke cross-head engines is defined by the drive train

components (unlike 4-stroke engines where this distance is defined by the piston width).

Cylinder distance is thus defined by the main bearing width plus two times half bottom end

bearing width. The cylinder number affects the dynamic torque on the shrink fit of the main

bearing journal to the web in the built crankshaft.

- 4 -5 cylinders require a big flywheel and may have limited space for adequate scavenge

receiver volume.

- 6-7 cylinders have good vibration qualities

- 8 cylinders have simple firing orders

- 9-10 cylinders have some complexity in firing order with respect to torsional vibration, 11

cylinders is worse

- 12 cylinders have good vibration qualities

- (13 cylinders nobody will buy due to superstition)

- 14 cylinders total length may be a problem

In general the number of cylinders chosen is 5-8, based on operator preferences in overhaul

and maintenance, with some countermeasures for dynamic effects due to hull engine

vibration considerations.

The piston speed affects the piston ring package performance and the cylinder lubrication

system design. Increases in mean piston speed are very moderate. The piston bore size

reflects the power per cylinder. The increases in piston stroke aiming for improved

expansion are tempered by limitations in engine width, to accommodate the larger crank

web radius of rotation. Longer stroke will lead to higher friction losses from the piston rings,

but lower friction in the bearings.

The accuracy of the cylinder lubrication system in achieving piston ring pack injection and

the proper spread and lub oil distribution on the liner is important. Liner protection is a

major issue and the derating potential of an engine, that is the optimising of a large

powerful engine for running continuity at lower power, is limited by cold corrosion which

may affect a colder running engine. Adaptive reduced cooling at lower loads for derated

engines is put forward to avoid cold spots. Piston cooling is often provided by combination

of oil jets and splash cocktail shaker arrangements.

The combustion space is best served by 3 peripheral injectors which, however, affect the

layout and packaging of the cylinder cover. The multi-hole injectors provide plenty of

opportunity for optimisation of timing sequence and spatial distribution of injection. Slide

valves with minimum sac volume are becoming standard. The fuel injection components

appear to follow the high volume production trend used in the 4-stroke engines.

The materials used in engine components rely strong on legacy and past experience. Since

large engines are almost exclusively manufactured under license, the designer provides

detailed weld seam quality instructions for the bedplate and the A-frames. The steel exhaust

valves usually have welded seats. For the future hot isostatic pressing (HIP) manufacturing

using powder metallurgy for valves has been considered.

The white metal bearings traditionally used in large engines with excellent embedability

characteristics for foreign matter, have some limitations in loading capacity. The adoption in

slow speed engines using aluminium based plain bearings with increased loading capability,

will lead to shorter cylinder to cylinder distances, and increased specific power with reduced

weight.

5 THE LICENSEE CONCEPT IN LARGE ENGINE BUILDING

As the cost of production at the place where the engine is designed becomes higher, the

engine makers move to decentralized production. Three engine maker groups exist today

designing large two-stroke slow speed engines. MAN Diesel & Turbo in Copenhagen

continuing the legacy of Burmeister & Wein, Wrtsil in Switzerland continuing the legacy of

Sulzer and Mitsubishi in Japan. Much of the production of large 2-stroke engines takes place

in Asia, where the tradition for "own product" is strong and the shipyards often look for local

suppliers of engines. To protect this trading mode, part of the licensee agreement imposes

special permissions for licensees to sell outside their countries.

Often large engine builders seek to obtain licenses from more than one licensor, so as to

balance negotiations on fees. Large builders will also achieve volume discounts through

reduction in royalties. From the side of the licensor balance must be achieved between the

number of licensees and market share in terms of optimizing effort and quality. In general

the price for large engines ranges from 100$/kW to 200$/kW depending on size and the

royalty fees are a small fraction of this price. Regarding capacity, the largest builders can

build about 400 engines per year.

The quality of the licensee is of prime importance. The larger ones may have in-house

foundry, welding shop and forging shop, whilst the smaller ones will outsource all these to

subsuppliers. The very small ones will only have assembly and testing work done in-house.

The common practice is to make engines near shipyards and the market is dominated by

licensees affiliated to a large shipyard. The quality assurance imposed by the licensor in the

approval procedure during initial production involves making, measuring, non-destructive

testing, destructive testing, inspection and QA actions. This procedure is applied also to each

sub-supplier e.g. for crankshaft, block, fuel injection parts, but not for non sensitive parts

such as engine tools.

The licensees take drawings in English then probably convert in own language and

engineering standards prior to starting production. The cost estimators within the licensee

are a key department, to make sure not to sell below cost level at a loss. The licensor would

probably have a site office at the licensee, with permanent personnel in consultative role in

production and testing.

An obvious clause in the licensee agreement is that if the licensee attempts to design an own

engine competing with the licensed engine then the license stops. However, it is unlikely

that the licensee would risk loosing a market share with an established product by

embarking in a new and expensive engine own design.

Recently there is a distinct trend of the engine makers to move into the realm of the total

integrated solution provider in ship machinery, including main and auxiliary engines, shafts,

propellers and bridge equipment.

6 DEVELOPMENTS IN MARINE DIESEL ENGINES

The market of marine engines is affected by the technological advances, but most

importantly by the activity in newbuildings and the developments in ship sizes. These in turn

depend on the worlds economy and the need to replace older vessels.

The design developments of marine engines are influenced by:

-The cost of crude oil, heavy fuel and distillates as well as the cost and availability of

alternative fuels.

- The introduction of new regulations

-The state of the newbuildings market

-The hull design in relation to the draft and propeller diameter, as well as the positioning of

the engine and the hull lines in the aft of the ship.

-The operational profile of vessels and the combination of fuels costs and freight rates.

The development aims at three general targets, increase of efficiency, reduction of

emissions and improvement of reliability.

6.1 Increase of efficiency

Large engines are more efficient than smaller engines purely because of large size and low

speed of operation. Large size means that lower surface to volume ratios in the combustion

chamber result in lower heat transfer losses. Lower gas velocities result in lower pumping

losses. Reduced rotational speed means lower friction losses. At the same time, the size and

cost of large engines makes economically viable to install energy recovery systems, which

can increase the total energy efficiency.

The practical limitations to engine efficiency are due to irreversible losses such as

combustion irreversibilities and friction and the work extraction efficiency. There are also

material properties to consider, which limit the engine operating parameters. One possibility

of increasing efficiency would be to increase the extraction of work by the piston or

alternatively to increase the energy available in the exhaust and use energy recovery

arrangements.

The work output can increase with change of volume, change of pressure and change of

the adiabatic index (specific heat ratio). Changes in cylinder volume and cylinder pressure

can be effected through changes in the compression ratio, cycle changes through variable

stroke or variable valve and port timing, changes in charge density via higher boost pressure

and rapid pressure rise through rapid heat release rate combustion.

The quest for increasing of maximum and mean cylinder pressure for achieving higher

specific power is moderated by the problems with materials, tribology, wear and effectively

reliability.

The technological advances have resulted in improved materials and design methods that

allowed the production of engines with increased thermal and mechanical loadings. The

improvements in the efficiency of turbochargers and the production of high pressure fuel

injection components have contributed in the increase of mean effective cylinder pressure.

10

The developments allowed improvements in the design of the combustion chamber to allow

higher maximum pressures with reduced thermal loading and improved air-fuel mixing. In 2stroke direct drive engines the increase in the piston stroke / bore ratio, whilst retaining the

mean piston speed at levels imposed by tribology, allows for lower propeller shaft rotational

speeds.

Work extraction by further increasing stroke will produce diminishing returns due to friction

and scavenging limitations. The ability to electronically control the fuel injection allows

optimisation of combustion for various engine loads. The use of multiple injections and the

change in timing and injection rate shaping leads to controllable combustion.

The improvements of efficiency of large marine engines in the last 30 years have been

impressive, but now the limits of practical thermodynamic cycles are approached. Some

further reductions in the fuel consumption and CO2 emissions can be achieved by optimizing

the energy use at steady state operation and with improvements in power production

during transients, through electronic control and optimal adjustments. Systems for

monitoring engine operations further allows for control and automatic adjustment

(autotuning) of the various cylinders to ensure good operation.

The fuel used has some effect on efficiency. Higher energy fuels give higher output and

simpler fuels produce lower combustion irreversibilities. Any increased thermal and

mechanical stresses and increased friction due to increases in cylinder pressure must be

considered. Increase in the ratio products / reactants leads to higher work extraction, so

the fuel type may contribute a little if products increase. Combustion in engines is away

from chemical equilibrium and some energy is used to severe chemical bonds and to heat

reactants. There may be some potential here for future research.

6.2 Change in the "Classical" Diesel cycle

Improvements in engine performance may be achieved with variable compression ratio,

possibly with a variable geometry piston, but more likely through changes in the valve and

port opening /closing timing and rate. The Variable Valve Actuation (VVA) systems usually

have electromagnetic or hydraulic motion electronic control. The uncoupling of valve

actuation from the crank-piston mechanism allows interesting interventions in the engine

operation.

One application is the so called Miller cycle, where the compression phase is dissimilar to

the expansion phase. In one arrangement, the intake valve closes before Bottom Dead

Centre, so that the air intake is stopped and the trapped mass is slightly expanded in 4stroke engines, hence with VVA one can achieve variable compression. In 2-stroke uniflow

engines the equivalent can be achieved with the exhaust valve. This flexibility allows for very

high boost pressures, without the danger of high cylinder maximum pressures.

11

6.3 Reduction of internal losses

The reduction in combustion energy losses to cooling is an interesting target for improving

the engine efficiency. However, it has been amply demonstrated that the construction of

combustion chamber walls from materials able to withstand higher temperatures and their

insulation, hence reduction in the heat loss, does not improve the thermodynamic efficiency

of the engine. At the same time the hotter walls lead to volumetric efficiency reductions.

Due to the lower heat rejection, the exhaust gas temperature will be increased, hence the

turbocharger can use some of the extra energy for providing extra boost to mitigate the

volumetric efficiency reduction. A small gain from the reduced coolant pumping is also

possible. Reducing the in-cylinder heat losses (hot engines, insulated-adiabatic engines)

provides more work potential, but conversely very small if any gains in piston work. The end

result is hotter exhaust gases which may be used in an exhaust gas boiler, in

turbocompounding or with other waste heat recovery methods. The recovery potential of

the waste heat in the exhaust stream is also related to the extra cost of the additional

installation, with steam turbine or power turbine and the requisite generator gear.

The friction increases with engine speed and load and its reduction through advanced

materials, redesign of rubbing components and lubrication advances will directly benefit

efficiency. Advanced materials and lubricants with high thermal durability can be used to

obtain reduced friction. Gas pumping losses could be somewhat reduced via optimized

scavenge volume and port design as well as reduced valve blow-down losses, but the

benefits are quite small. Computer controlled intelligent cooling and optimisation of

common rail pumps and other parasitic loads could also contribute.

6.4 Change in working fluid

Some past applications of heavy fuel-water emulsions in engines were aiming to improve

combustion of variable quality fuels. This approach exhibited numerous problems with

emulsion instabilities, corrosion of injectors, poor atomization at low loads. For injecting

other fuels into the combustion chamber various injector arrangements have been

examined, including multiple injectors with pilot and main injections.

Direct injection of water into the cylinder has been used to cool the charge and has

occasionally shown improved air-fuel mixing, purportedly due to the extra turbulence

created from the gasification of waterdroplets. The main interest was in lowering the mean

combustion temperature hence the NOx production. Fumigation of water or direct steam

injection into the cylinder has been used to add to the expansion work, with steam

generated from waste heat recovery. Most of the above systems remain mechanically

complicated with dubious reliability.

One simpler version of such arrangements is the saturation of the intake air with water

sprinkled in the scavenge receiver, which reduces the air temperature due to the latent heat

absorption. However any short-circuit of saturated scavenge air onto the exhaust receiver

12

leads to undesirable cooling of the exhaust gases before the turbine, especially in 2-stroke

engines. A less severe problem is the possible liner corrosion due to the saturated air, which

may be counteracted with redesign of the lubrication system and the liner-piston ring coagency.

6.5 Increase of boost pressure

The increase of boost pressure with requisite adjustments in fuel injection may lead to

substantial increase in specific power and some increase in efficiency. However, the

maximum cylinder pressure increase poses additional issues with the mechanical loading of

crankshaft and bearings as well as lubrication issues. Single stage turbocharging has a

practical pressure ratio limit of 5:1 if a reasonable width of operating range is needed. Above

this limit the centrifugal compressor wheels from aluminium alloys suffer from creep

problems due to the wheel tip high speeds and the high temperature of the compressed air,

requiring tip cooling or titanium wheels. Turbocharger efficiency is quite high and

improvements are difficult, but there may be some more margin for improving part load

performance. The increase of turbocharger efficiency over the years allows for excess

turbine power at high engine loads, which could be used to drive a generator on the same

shaft. A motor/generator in a PTI/PTO (power take-in, take-out) arrangement can be used to

improve the total overall efficiency of the installation. New designs appear to tackle past

problems of generator inertia and cooling, high speed bearings, generator to compressor

shaft coupling.

Two-stage turbocharging allows a relatively simple solution for increasing the specific power,

but at a higher cost, complicated plumbing arrangement and reduced efficiency at low loads

where the wheels operate at low efficiencies. It will probably be used in conjunction with

Miller-Atkinson valve timing.

Variable geometry is proposed for improving the turbocharger operating range. This involves

pre-rotation vanes and variable diffuser vanes on the compressor, as well as variable nozzle

valves on the turbine side, even for operation with heavy fuel.

7 POLLUTANTS EMISSIONS

The legislation of limits to gas emissions from engines is a complex technical, social and

political issue. Emissions limits for Nitrogen oxides and Sulfur Oxides are currently in place

for large engines. Black carbon and particulates emissions may be limited in the future.

The technologies to reduce NOx emissions from engines can be classified into Primary (within

the engine- cylinder) methods and Secondary methods (exhaust gas aftertreatment).

13

7.1 Primary methods

The formation of Nitrogen Oxides is primarily dependent on the mean gas temperature in

the cylinder. Lowering this temperature reduces NOx.. The most common way to reduce this

mean temperature in value and time duration is through delay in timing of the start of

injection. However, this will lead to increases in fuel consumption due to the shift of the

heat release later in the cycle, producing lower pressures and temperatures. To partly

compensate this, the injection rate must be increased and the duration of combustion

decreased, so that the end of injection remains unchanged. To retain the ignition quality the

compression ratio may also be increased, to the extent that the mechanical stresses due to

the firing higher processes do not affect the robustness of the engine. The effect of possible

higher exhaust gas temperatures to the thermal stresses of valves must be taken into

account.

The use of water injection techniques has already been mentioned. The cooling of the

charge air reduces the temperature near the burning gas but also in the cooler extremes of

the cylinder. Thus the production of NOx in these regions is reduced, but also the expansion

work capacity of the gas is reduced. The charge cooling with Miller timing has already been

mentioned.

The EGR (Exhaust Gas Recirculation) has multiple effects. Since the exhaust gases have

greater heat capacity than the air charge, they capture heat reducing the mean temperature

of the cylinder contents. At the same time, the exhaust gases contain less oxygen thus the

rate of combustion is reduced.

EGR has been used for many years in Otto cycle engines, but in Diesel engines and in

particular those which use heavy fuel, there are many problems. To retain the volumetric

efficiency of the engine, the recirculated exhaust gas must be cooled. Also to reduce the

contamination of the turbocharger compressor (if the EGR loop is a low pressure onedownstream of the turbine, upstream of the compressor) and generally to reduce engine

wear from particulates, the recirculated exhaust gas must be cleaned, either passing through

a filter or by wet scrubbing.

If a filter is used then the blocking tendency due to the use of heavy fuel is much higher and

thus the need for frequent regeneration. In addition the substantial problem of sulfuric acid

corrosion in the cooled exhaust gas of the EGR loop from sulfur in the fuel must be

addressed, as well as the issue of management of acidic waste water from scrubbing.

The high efficiency of marine engine turbochargers probably entails that there is insufficient

pressure difference to overcome the backpressure of the EGR loop and maintain positive

EGR gas supply throughout the engine operating range, so it is usually necessary to use a

special electric driven boosting blower, even for low pressure recirculation.

An interesting variant is the combustion gas recirculation, which effectively is bleeding

cylinder combustion gas at some pressure before exhaust valve opens, from a special valve,

then through a cleaning scrubber to downstream of the turbocharger compressor, without

14

need for a boosting blower. However the large size of the extra valve required for

substantial EGR apart from the engineering complexity, places severe demands to the

cylinder head design. Another possibility is to intentionally impair scavenging, but this has

associated problems of increased engine thermal load and reduced volumetric efficiency.

The NOx generated inside the cylinder could conceivably be reduced by direct injection of

ammonia. The dosing control, dispersion and ammonia slip problems make this method

practically unworkable.

It is obvious that the reduction of NOx with any of the above methods would result also in

changes to engine performance, therefore a re-optimisation would be necessary.

7.2 Secondary Methods

Aftertreatment of exhaust gases through selective Catalytic Reduction SCR units for the

reduction of NOx has been used in thermal power stations for many years. The process uses

ammonia injected in the exhaust flow to react with NOx in a catalyst. The reduction of NOx to

Nitrogen can be up to 98%. One issue is ensuring that the proper amount of ammonia is

injected and used completely to avoid slip of un-reacted raw ammonia - which is highly toxic

out of the exhaust. Hydrolized urea can be used in the reaction, which is much safer than

anhydrous or aqueous ammonia in handling. Urea requires thermal decomposition for

conversion to ammonia.

Such SCR units have already been installed in more than 400 ships. The installation cost of

marine SCR is about 20% -30% of the engine cost. The cost of reductant must also be

considered in the operating costs.

An important issue in marine SCR is the poisoning of the catalyst. The catalyst is usually

some ceramic carrier with active components being oxides or metals or zeolites.

Contamination and plugging of the catalyst is more pronounced with the compounds

present in the combustion gas of heavy fuel. Poisoning refers to the destruction of catalysts

ability to promote the reaction. Sulfur and other components in the heavy fuel and in the

cylinder lubricants lead to catalyst poisoning.

Cleaning of the exhaust gas with filters and/or scrubbing prior to the SCR may be needed to

avoid excessive contamination builtup. Scrubbing involves water washing, using the natural

alcalinity of the sea water to reduce the acidic sulfur compounds present in the exhaust gas

stream. These are produced from the reaction of sulfur in the heavy fuel with oxygen during

combustion in the cylinder. Proper handling of wash water must be ensured. When seawater

does not process the required alcalinity e.g. in river estuaries, it cannot be used in an open

loop scrubber. In such case chemicals must be added to provide alcalinity, usually caustic

soda. Since some sea areas have been designated SOx emission control areas and sulfur

limits have been imposed then scrubbing must be used if heavy fuel is used. Alternatively

use of other fuels with low sulfur may be a more straightforward option subject to cost and

availability of such fuels.

15

Some closed loop control involving measuring NO in the exhaust is needed to ensure proper

ammonia flow for all engine operating conditions. Reasonably high exhaust gas

temperatures are needed for ammonia to react and this is a problem downstream of the

turbocharger especially in 2-stroke engines and in all engines during startup. Placing the

ceramic catalyst before the turbocharger practically on the engine structure - requires

proper design to account for the increased mechanical vibration loading. Combining a

particle filter with a catalyst SCR surface may be a way to compact units for both NOx and

PM reduction.

8 ENGINE MONITORING AND PERFORMANCE ASSESSMENT

Most shipping companies operate vessels of various types and sizes, equipped with engines

built by different manufacturers. The size and complexity of modern marine engines has

increased and the operators must comply with more strict safety and environmental

regulations. With newbuildings and sales/purchases of second-hand vessels, the owners

inevitably end up with ships of various sizes and engines of different make, with different

histories of maintenance.

About half of all reported engine failures are due to the thermally loaded components and

from these the largest percentage is due to poor cylinder condition. Turbocharger failures

also account for a sizeble percentage of breakdowns.

The complexity of monitoring systems may also differ among a fleet of ships. The general

practice in ship engine performance monitoring is to record important engine parameters

(i.e. pressures, temperatures, speeds etc.). Some shipping companies include cylinder

pressures and shaft torque recordings. One fundamental issue of any monitoring system, is

that each sensor is the interface with the actual process and in order to check if the sensor is

working properly can only be performed with other parallel sensors or through some

mathematical inference of expected values. Periodically, data is collected in a service report

and forwarded to headquarters for further processing and evaluation. With modern data

acquisition and communication technology, such "reports" can be forwarded almost real

time resulting in a flood of data in need of processing and evaluation, both onboard and at

the main office.

In principle, engine performance evaluation and fault diagnosis can be accomplished by

comparison of actual monitored data to some "reference" of expected performance. The

monitored data must be reliable (considering sensor or monitoring system malfunctions, as

well as human errors in recording and reporting) and the reference data must relate to the

actual operating and environmental conditions.

Shipping companies with large fleets, must formulate appropriate operation and

maintenance policies The above requirements call for increased sophistication in engine

performance assessment.

16

9 EPILOGUE

The propulsion engine may cost 10% of the total cost of a ship and is the most expensive

item onboard. The large slow-speed two-stroke marine diesel engine has the highest

efficiency of all thermal powerplants. Still, the engines initial cost will be matched in less

than 6 months by the cost of fuel consumed by this engine. The reliability and the fuel

consumption are the two major attributes aimed for by large engine makers. The expected

lifetime of a large marine engine is 30 years (180.000hrs) with time between major

overhauls 5 years, which poses heavy demands on reliability. The design and operation of

ships is also influenced by the legislation on engine emissions. Fuel costs account for the

largest part of total operating costs and thus affect the economics and profitability margins

of ship operation.

FURTHER GENERAL READING

Dragsted, Jorn "The first 50 years of turbocharged 2-stroke, crosshead marine diesel

engines", CIMAC, 2013 [www.cimac.info/about-cimac/historyindex.html]

Pounders Marine Diesel Engines and Gas Turbines, 9th edition, Elsevier, 2009.

Kuiken, Kees, "Diesel Engines for ship propulsion and powerplants" Target Global,

Netherlands, 2012

[www.mariendiesels.co.uk]

[www.cimac.com]

[www.mandieselturbo.com/lowspeed]

[www.wartsila.com/en/media/articles]

[www.hercules-c.com]

Potrebbero piacerti anche

- 0 50 S Fuel OperationDocumento56 pagine0 50 S Fuel Operationargentum19619692Nessuna valutazione finora

- KS-0179-1 Procedures For Determination of Lightship Displace ENGDocumento13 pagineKS-0179-1 Procedures For Determination of Lightship Displace ENGBharath Kumar VasamsettyNessuna valutazione finora

- Disadavantage of Radioactive Level Indicators For Co2 BottlrDocumento2 pagineDisadavantage of Radioactive Level Indicators For Co2 BottlrTapas ChaudhuriNessuna valutazione finora

- Double Bottom Engine RoomDocumento6 pagineDouble Bottom Engine RoomTapas ChaudhuriNessuna valutazione finora

- Abs-Trends Nox December2015Documento3 pagineAbs-Trends Nox December2015Tapas ChaudhuriNessuna valutazione finora

- Marpol Practical Guide PDFDocumento57 pagineMarpol Practical Guide PDFCharlie MakNessuna valutazione finora

- ISM-PR-09 Procedure For Major Non-ConformitiesDocumento2 pagineISM-PR-09 Procedure For Major Non-ConformitiesTapas ChaudhuriNessuna valutazione finora

- Good Practice Guide CH 3 Container SpecificationsDocumento107 pagineGood Practice Guide CH 3 Container Specificationsnichaev100% (1)

- 213-35746 Future IMO LegislationDocumento65 pagine213-35746 Future IMO Legislationerudite_0206Nessuna valutazione finora

- Governor Control Systems, Inc.: Prime Movers and Governors BasicsDocumento37 pagineGovernor Control Systems, Inc.: Prime Movers and Governors BasicsTapas Chaudhuri100% (1)

- Dragsted History Booklet 2013 PDFDocumento98 pagineDragsted History Booklet 2013 PDFTapas ChaudhuriNessuna valutazione finora

- Training Manual For Fire Safety PracticeDocumento50 pagineTraining Manual For Fire Safety PracticeMatthew BennettNessuna valutazione finora

- Weld JointDocumento44 pagineWeld JointPratiek RaulNessuna valutazione finora

- Training Manual On Life Saving AppliancesDocumento98 pagineTraining Manual On Life Saving AppliancesTapas Chaudhuri100% (5)

- What's A Screw Pump? Understanding The Unique Characteristics and Operating Principles of 1, 2 and 3 Screw PumpsDocumento4 pagineWhat's A Screw Pump? Understanding The Unique Characteristics and Operating Principles of 1, 2 and 3 Screw PumpsTapas ChaudhuriNessuna valutazione finora

- Amsa PSC ChecklistDocumento11 pagineAmsa PSC Checklistdassi99100% (1)

- Operation On Low-Sulphur FuelsDocumento14 pagineOperation On Low-Sulphur Fuelsgiannis2Nessuna valutazione finora

- 11 - Reversing of Two Stroke EngineDocumento13 pagine11 - Reversing of Two Stroke EngineAisha Zaheer90% (29)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Recycled Concrete Roadbase Swis 4003Documento45 pagineRecycled Concrete Roadbase Swis 4003Mircea BobarNessuna valutazione finora

- Mobile Master Card PayPass TSM Functional Requirements v1-0Documento40 pagineMobile Master Card PayPass TSM Functional Requirements v1-0Wiraj GunasingheNessuna valutazione finora

- Analysis of Challenges Facing Rice Processing in NDocumento8 pagineAnalysis of Challenges Facing Rice Processing in Nanon_860431436Nessuna valutazione finora

- The Economic Essentials of Digital StrategyDocumento13 pagineThe Economic Essentials of Digital StrategydhietakloseNessuna valutazione finora

- Emission Test Station - Workshop: Multi-FuelDocumento2 pagineEmission Test Station - Workshop: Multi-FuelARMANDO HERNANDEZNessuna valutazione finora

- OPA237Documento21 pagineOPA237philprefNessuna valutazione finora

- Plant and Maintenance Managers Desk BookDocumento477 paginePlant and Maintenance Managers Desk BookHugoCabanillasNessuna valutazione finora

- Computer Viruses: What Is A Virus?Documento4 pagineComputer Viruses: What Is A Virus?Ako GwapoNessuna valutazione finora

- Compresores TecumsehDocumento139 pagineCompresores TecumsehRicardo EstrellaNessuna valutazione finora

- Mechanical Engineering Manufacturing.149Documento1 paginaMechanical Engineering Manufacturing.149Anonymous QvIxEazXGdNessuna valutazione finora

- Gea 01 RyDocumento2 pagineGea 01 RyHasan CelebesNessuna valutazione finora

- Pumps and Filters: 345D, 349D, and 349D Excavator Hydraulic SystemDocumento2 paginePumps and Filters: 345D, 349D, and 349D Excavator Hydraulic SystemTeknik MakinaNessuna valutazione finora

- G700 03 603333 1Documento382 pagineG700 03 603333 1Jorge CruzNessuna valutazione finora

- 24 - Counting of Bottles - Solution - ENGDocumento3 pagine24 - Counting of Bottles - Solution - ENGhaftu gideyNessuna valutazione finora

- A Database of Aerothermal Measurements in Hypersonic Flow in "BuildingDocumento60 pagineA Database of Aerothermal Measurements in Hypersonic Flow in "BuildingNeoNessuna valutazione finora

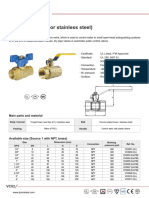

- VC02 Brass Ball Valve Full Port Full BoreDocumento2 pagineVC02 Brass Ball Valve Full Port Full Boremahadeva1Nessuna valutazione finora

- Administration Guide Open Bee Doc Office Manager (En)Documento31 pagineAdministration Guide Open Bee Doc Office Manager (En)peka76100% (1)

- 3 - Pitot-Static Inst, System & ADC - OcrDocumento110 pagine3 - Pitot-Static Inst, System & ADC - OcrtmhoangvnaNessuna valutazione finora

- E MAX - E Max Brushless Motor Specs EE July 08Documento11 pagineE MAX - E Max Brushless Motor Specs EE July 08ewaigel0% (1)

- My Restaurant API DocumentDocumento60 pagineMy Restaurant API DocumentJosé FranciscoNessuna valutazione finora

- SAP LandscapeDocumento4 pagineSAP LandscapeSiddharth PriyabrataNessuna valutazione finora

- Centrica, Scottish Gas Training AcademyDocumento1 paginaCentrica, Scottish Gas Training AcademyGary McAlpineNessuna valutazione finora

- Shot PeeningDocumento5 pagineShot Peeningcaddcentre velacheryNessuna valutazione finora

- Shutdown SIS: Motor Grader 120G Motor Grader 4Hd 120G Motor Grader 4HD00001-UP (MACHINE) POWERED BY 3304 EngineDocumento2 pagineShutdown SIS: Motor Grader 120G Motor Grader 4Hd 120G Motor Grader 4HD00001-UP (MACHINE) POWERED BY 3304 EngineStevenNessuna valutazione finora

- Error Rateio NorunDocumento725 pagineError Rateio Norunmatheus felipeNessuna valutazione finora

- Atlas Copco ZT55 Instruction ManualDocumento90 pagineAtlas Copco ZT55 Instruction ManualRafael Martin Anaya Figueroa100% (4)

- Tutorial 5 UpdatedDocumento2 pagineTutorial 5 UpdatedChiraag ChiruNessuna valutazione finora

- DIY Homemade Septic System PDFDocumento9 pagineDIY Homemade Septic System PDFCebu CribsNessuna valutazione finora

- Global Trends 2030 Preview: Interactive Le MenuDocumento5 pagineGlobal Trends 2030 Preview: Interactive Le MenuOffice of the Director of National Intelligence100% (1)

- Aalco StocklistDocumento36 pagineAalco StocklistjsfscibdNessuna valutazione finora