Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Strength of Material

Caricato da

Marziana Mat DinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Strength of Material

Caricato da

Marziana Mat DinCopyright:

Formati disponibili

International Journal of Plasticity, Vol. 12, No. 2, pp.

191-213, 1996

Copyright 0 1996 Elsevier Science Ltd

Printed in Great Britain. All rights reserved

0749+X19/96 %lS.oO+ .OO

EVOLUTION

EQUATIONS FOR DISTORTIONAL

HARDENING

PLASTIC

T. Kurtyka and M. Zyczkowski

Politechnika

Krakowska

(Cracow

University

of Technology)

(Received in final revised form 15 May 1995)

Ash&act-In an earlier paper the authors proposed a geometrical description of distortional plastic

hardening. The parameters of this model describe, in turn, all the elements of transformation of the

initial yield surface, namely proportional expansion, translation, affine deformation, rotation, and

distortion. The present paper is devoted to evolution equations for individual parameters: after a

general discussion and analysis of existing experimental data, some effective equations are proposed. In particular, they are adjusted to describe Buis experiment on subsequent yield surfaces

under combined compression and torsion of a thin-walled tube.

I. INTRODUCTION

During a process of plastic deformation of a hardening (or softening) material, the

initial neutral surface (yield surface) is subject to subsequent transformations. Experimental results show that these transformations in a stress space consist of the following

five elements:

(i) Proportional expansion

(ii) Translation

(iii) Affine deformation

(iv) Rotation

(v) Distortion, exceeding affine deformation.

The simplest case of pure proportional expansion is called isotropic hardening,

though an, isotropic material may remain isotropic under much more general transformations (Zyczkowski [1981]). Pure translation is called kinematic hardening, and is

particularly extensively analyzed in the literature, starting with the early papers by

Melan [ 19381, Ishlinsky [1954], and Prager [ 19561. The combined case of expansion and

translation is called mixed isotropic-kinematic

hardening, or briefly mixed hardening and is often sufficiently accurate for engineering applications.

However, more precise description of plastic hardening requires taking the remaining

three of the above-mentioned elements into account. General affine transformations of

the Huber-Mises-Hencky

(HMH) yield condition, mentioned by Edelman and

Drucker [1951], were investigated in detail by Baltov and Sawczuk [1965], Backhaus

[1968], Danilov [1971], Tanaka and Miyagawa [1975], Rees [1982]. Extensive discussion

and comparison of the relevant equations was given by Rees [1989] and Skrzypek

[1993].

191

192

T. Kurtyka and M. iyczkowski

Numerous experimental investigations were gathered and discussed by Ikegami

[1976], Michno and Findley [1976], and Rees [1989]. Most of them show remarkable

distortion of subsequent yield surfaces, connected with increase of their curvature in

the vicinity of the control point (generic stress point), and flattening on the opposite

side. This effect was first (partly) described by the slip theory of Batdorf and Budiansky

[1949]: their theory predicts even a vertex (corner) at the control point, but no flattening on the opposite side. Further proposals used mostly stress invariants or mixed

invariants containing stress components in the third or fourth degree: Freudenthal and

Gou [1969], Williams and Svensson [1971], Shrivastava et al. [ 19731, Phillips and Weng

[1975], Shiratori et al. [1976, 19791, Axelsson [1978], Rees [1982], Ortiz and Popov

[1983], Eisenberg and Yen [1984].

A relatively simple geometric description of distortional plastic hardening, with clear

meaning of individual parameters, was given by Kurtyka and Zyczkowski [1985]. The

central idea of this description is to have the initial yield condition presented as a

hypersphere and to consider various transformations of such a hypersphere. For isotropic materials subject to the HMH yield condition this is obtained in the fivedimensional auxiliary stress space, proposed by Ilyushin [1954, 19631. For other materials this is also possible in modified Ilyushins spaces, provided the material is insensitive to the first stress invariant (a deviatoric material); otherwise a five-dimensional

space is not sufficient, and hence not adequate. Such modifications for relatively broad

classes of isotropic and anisotropic materials were proposed by Zyczkowski and Kurtyka [1984], [1990]. Parameter identification in the description of plastic hardening

proposed was discussed by Kurtyka [1988]. Equivalence of vectorial and tensorial

description of plastic hardening was investigated by Kurtyka [ 19901.

Recently, some other approaches to the description of distortional hardening were

suggested. Mazilu and Meyers [1985], Gupta and Meyers [1986,1992] used common

invariants of two stress tensors: actual stress deviator and the stress deviator corresponding to maximal prestrain. Helling and Miller [1987] developed the so-called

MATMOD4V model using a variable Hill-type anisotropy tensor. Watanabe [1987]

extended the Valanis endochronic theory of plasticity to cover distortion of subsequent

yield surfaces up to formation of a vertex; his approach uses, in principle, just two

parameters. Voyiadjis and Foroozesh [1990] based their proposal on variations of the

fourth-order anisotropy tensor and used three parameters to describe subsequent yield

surfaces.

Though the model proposed by the authors in [1985] uses, in total, many more

parameters, nevertheless the number of parameters responsible for distortions is comparable: it is equal to the number of dimensions of the auxiliary stress space, and hence

it reduces to two in the most important two-dimensional cases. Moreover, all parameters have clear geometrical meaning. Hence, we return to that model and in the

present paper we propose the relevant evolution equations: their general form and

some particular cases. Basic assumptions are as follows:

(i) The material is isotropic, subject to the HMH initial yield condition. However, in

view of possible above-mentioned modifications of Ilyushins space, a broader

class of isotropic and anisotropic materials may also be considered.

(ii) The material is elastic-plastic, rate independent. However, further generalizations

to viscoplastic_materials seem also possible; some preliminary ideas were given by

Kurtyka and Zyczkowski, [1991].

(iii) The material is conforming to Ilyushins postulate of isotropy.

Distortional plastic hardening

193

Considerations are restricted to small strains only.

The processes under consideration are isothermal, temperature changes are

neglected.

64 Plastic strains are incompressible.

(vii) Phenomenological approach to the description of plastic hardening is used.

II.

MODEL OF DISTORTIONAL

PLASTIC

HARDENING

II. 1. llyushin s auxiliary Jive-dimensional stress and strain spaces

Ilyushin [ 19541, [ 19631 introduced an auxiliary five-dimensional stress space, namely

the stress vector u = aiwi (i = 1,2,...5) is defined as follows

3

01 =-s11,

2

02 = +i+s22),

c73 =

d&2,

a4 =

x&23,

cj

d&3,,

(1)

where sij are deviatoric stress components, and wi are versors (unit vectors) of the axes.

The Huber-Mises-Hencky

yield condition takes here the form

InI = ffo

(2)

(where oO. stands for the yield stress in uniaxial tension), and hence it is represented by

a hypersphere in the five-dimensional space. In uniaxial tension in the physical direction 11

we have cl = cl i.

In view of the initial yield surface being a hypersphere in Ilyushins space, initial

yielding does not depend on the direction of the trajectory in that space. This fact

makes it possible to formulate and apply Ilyushins postulate of isotropy, which,

roughly speaking, states that in the five-dimensional space the transformation of the

initial. yield surface depends only on the geometrical invariants of the trajectory and

does :not depend on the direction.

The postulate of isotropy has a mathematical part and a physical part. The

mathematical part is connected with rotation of the physical system of coordinates in

the body since then the auxiliary space is subject to a change. This part was proved by

Ilyushin: in fact, any rotation of physical coordinates does not affect geometrical

invariants in the auxiliary space. On the other hand, the physical part of the postulate

refers to plastic hardening under essentially different loading trajectories, e.g. hardening due to normal stresses and due to shearing stresses. This part cannot be proved

and remains simply as a hypothesis. It has been verified experimentally for isotropic

bodies by many investigators. In the present paper we assume the postulate of isotropy

to hold and make use of a purely geometric description of subsequent yield surfaces,

proposed by the authors in [1985]. Moreover, Ilyushin introduces an auxiliary, fivedimensional strain space. We define the strain vector 3=3i wi (i = 1,2...5) as follows

31= ell,

32=

-$(?j+ e22),

33=

-$2,

where ev denote deviatoric strain components.

condition takes the form

34=

-$23,

35=

-$e3*,

(3)

In this space the initial HMH yield

194

T. Kurtyka

and M. iyczkowski

and also is represented by hypersphere. Total strain vector may be decomposed into its

elastic and plastic part, 3 = se + +.

Ilyushins spaces were employed to describe plastic hardening by many investigators.

We mention here Shiratori et al. [ 1976, 19791, Ohashi and Tanaka [ 198 11,Andrusik and

Rusinko [ 19931.

11.2. Geometric description of distortional hardening

The hypersphere (2), representing the initial yield condition, during the process of

plastic hardening (or softening) is subject to subsequent transformations. Such transformations consist of five elements listed in Section I. They are described in a fairly

general way by the geometric proposal of Kurtyka and Zyczkowski [1985]: expansion,

translation, affine deformation and rotation are quite general, whereas distortion is

confined to a certain class, presented in two variants: broader and narrower. Now we

recall the main idea of this description.

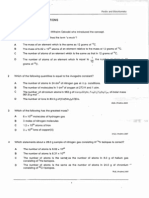

It is well known that an ellipse may be obtained from two concentric circles by a

projecting procedure where the pole of projecting radii coincides with the centres of

both circles, Fig. l(a). Now, a much more general curve may be obtained by similar

projecting if we distinguish the centres of circles O(i) and OC2)and the pole A, Fig. l(b).

Indeed, such a curve resembles a subsequent yield curve obtained from experiments for

a general curvilinear trajectory.

In the general five-dimensional case we introduce five hyperspheres with various radii

RC,)and various centres O,+ a pole A, and a system of mutually perpendicular projecting directions. The hyperspheres must have a common domain and the pole must be

located in this domain. Then the current radius intersects all the hyperspheres and the

Subsequent

yieldsurFace

Fig. 1. Proposed

description

of subsequent

yield surfaces

(b) as a generalization

of quadratic

surfaces

(a).

Distortional plastic hardening

195

projecting procedure means simply taking one coordinate (in the rotated system of

projecting directions) from each hypersphere.

The simplest analytical description is obtained in a moving system of coordinates, Si,

translated and rotated with respect to the original system rri. The directions of Si coincide with the projecting directions. The versors of 6i will be denoted by Ci, they are

related to the versors wi of the original system oi by the orthogonal transformation

(rotation) formulae

Gi = Qijwj,

i,j = 1,2..5,

(5)

where QUdenotes an orthogonal tensor (five-dimensional, in general). Now we define in

the moving system of coordinates the vector active stress, B = ci+i, related to the

stress vector CTby the formula

Si = Qij(gj - aj),

(6)

where the vector a = aiwi describes the translation of the centre of the moving coordinate system and may be interpreted as a vector of residual microstresses.

The position of the centres of hyperspheres 0~~~is defined in the moving coordinate

system by five vectors di = dcl>jtij. These vectors are responsible for nonelliptic (nonaffine) distortion of the yield surface, hence the notation d. Here a bracketed index

denotes a label (number of individual hypersphere) and is not subject to summation.

11.3. Equations for the general (broader) case

Kurtyka and iyczkowski [1985] derived the following parametric equations of the

distorted yield surface in Ilyushins space

aj = Q,{dci)ktk + [(dci)ktk)2 - d(i)dG)k + RtiJ]12}ti + aj,

(7)

where the summation goes over i (without brackets), and over k; ij,k = 1,2,...5. The

quantities ti denote current parameters, namely Cartesian coordinates of the unit vector

of the radius-vector in spherical rotated coordinate system. The conditions of the pole

to be located within all the hyperspheres have here the form

dci)kd(i)k< R?~J, i, k = 1,2,. . .5.

63)

Equation (7) contains in the general, five-dimensional case 45 fixed parameters

(counted as scalars): five of them are responsible for expansion and affine deformation

of the surface (radii Rc,)), 5 - for translation (aJ, 10 - for rotation (Qii>and 25 - for

distortion (dCzIk).The first 20 of them appeared in the proposals of Edelman-Drucker

and of Baltov-Sawczuk, whereas the remaining 25 are new. The last number seems too

big for applications, and in the above-mentioned paper a simplified, narrower version

was also proposed.

11.4. Equations for the simpl$ed (narrower) case

The description (7) is much simpler, but for most applications sufficiently general, if

we assume

dcib = 0

for

j # i

(9)

196

T. Kurtyka and M. iyczkowski

Then only five non-zero parameters responsible for distortion remain, namely d(+

denoted briefly by di. The total number of fixed parameters is reduced here to 25.

Equations (7) are simplified to

9 =

&[& + (dftf -

di

+ Rf)1/2]ti+ aj,

(10)

ij, = 1,2,..5, summation over i, no summation over 1. Using active stresses (6) we

may also write

c?i= [diti + (dftf - d!+ R;)I*]&

(11)

In this case the parameters ti may easily be eliminated and one obtains implicit equation

5

c

i=l

c$

Rf + 2di6i - 4 =

(12)

It is seen that in the case di = 0 eqn (11) corresponds to a hyperellipsoid, hence, in the

general case, (! 1) describes a distorted hyperellipsoid. Convexity of (11) was proved by

Kurtyka and Zyczkowki [1985] for the two-dimensional case. On the other hand, general surfaces (7) may also exhibit concavities.

The conditions (8) are here reduced to

]dil < Riy

III. EVOLUTION

i= 1,2...5.

EQUATIONS

(13)

FOR SIMPLE LOADING

Consider first the case of proportional change of all deviatoric stress components, as

the control process responsible for the formation of subsequent yield surfaces:

Sij =

(14)

(1)

(15)

Sijdi (t)

or, using (l),

gi =

~ifzfl

where t is a time-like parameter; the derivatives with respect to t will be marked by

dots. The function f,(t), may be increasing or decreasing, positive or negative (as it

happens in cyclic loading). Loading of this type is called simple loading, since then a

multidimensional case is reduced to a one-dimensional case (though the state of stress

is, in general, multiaxial).

The direction determined by (15) in the five-dimensional stress space will be denoted

by i, and will be considered as the axis after rotation (6), whereas the remaining four

directions cannot be distinguished for simple loading (subsequent yield surfaces remain

rotationally symmetric). Denote by ge the effective HMH stress for (14) or (15), then

The rotation tensor in (6) looks as follows

Distortional plastic hardening

-3u

iod

&

2

SJO+hQ

o4

IQ

arbitrary,

Qij =

197

x6%

x6%

but subject

to orthogonality

conditions

(17)

and does not change during the process.

Hence, the number of free parameters in the case of simple loading is equal to five in

dcl)l,

dop,j= 2, 3, 4, 5), and is equal to four in the simthe general case (RI, Rj,cil,

plified case, since then don = 0 (Fig. 2). The symbol cir denotes the coordinate of the

translation vector in the rotated system coordinates and is particularly convenient

when considering a simple loading process.

The radius RI is responsible for isotropic hardening and first we go back to classical

descriptions of this type of hardening. Odqvist [1933] proposed to consider it as a

Fig. 2.

Subsequent yield surfaces corresponding to simple loading: (a) general case, (b) simplified case.

T. Kurtyka and M. iyczkowski

198

function of the length of the trajectory in the nine-dimensional

(strain-hardening)

RI = a,[1 + $(Z,)]

space of plastic strains

(18)

where Zepdenotes this length and is called Odqvists parameter

(19)

and T denotes the variable of integration. In Ilyushins space Odqvists parameter is

proportional to the length of the trajectory with the multiplier m.

For simple

loading (14), assuming similarity of deviators at least for this process,

where the dependence between f2and fiis determined by the uniaxial stress-strain

diagram. Even earlier Taylor and Quinney [1931] proposed to consider isotropic hardening as dependent on the plastic work (work-hardening)

RI = ~4 + 1cI(?+91

(21)

where

(22)

For simple loading

Wp =

Uij&ijo

I

*.fl(&(+

010 310

J0

Lfl(+2(M.

(23)

So, for simple loading, we propose to retain (18) or (21) (in differential form) also for

distortional plastic hardening under consideration.

The radius Rj,

j = 2,3,4,5, denoted here briefly by Rz,is responsible for cross effects,

it means for transversal dimensions of subsequent yield surfaces. Experimental investigations show either an increase of these dimensions (e.g. Theocaris & Hazel1 [1965]),

or no cross effects (e.g. Phillips and Tang [1972]), or a decrease of transversal dimensions (e.g. Miastkowski & Szczepinski [1965]). So, denoting $(I,) by cp(Z,) we propose

a rule similar to (18),

Z& = cA1 + A,)cp(Z,)Z,,

R2(0)

00,

(24)

with the coefficient PC1responsible for cross effects. This coefficient is variable in general, but in the simplest approach may be regarded as constant.

If cp(Z,) > 0, then PC1 > 0 denotes increase of transversal dimensions, -1 < PC1 < 0

denotes also absolute increase, but relative decrease comparing to R,,finally ,BCi< -1

denotes absolute and relative decrease. If cp(Z,) < 0 (isotropic softening), then the

conclusions as regards ,B,i are opposite to those given above. In any case, for purely

isotropic hardening or softening ,L?=i= 0.

Distortional plastic hardening

199

The coordinate of rigid translation, 21, is responsible for kinematic hardening. In the

case of simple loading this type of hardening is usually connected directly with the

corresponding plastic strain rate,

where

denotes effective plastic strain (intensity of plastic strains). This strain may increase or

decre.ase, whereas Odqvists parameter Z,, (19), is a monotonically non-decreasing

quantity.

Finally, evolution equations for the parameters of distortion are quite new. Analysis

of experimental results shows that a decrease of < results in a decrease of di too. So, we

propose an equation of the type (25), namely

where the multiplier (R: - 4) ensures the condition (13) to be satisfied. A similar

relation may be proposed for d*(i) in the broader description (7); reasonable results are

obtained if ldc2)i1 < Id(i,il and this fact should be accounted for when constructing

particular functions of the type (27).

Change of the rotation tensor QU will be presented in the form

Q = hQ

Qij = h&Qkj,

i,j,k = 1,2 . . . . . 5,

(28)

where the tensor & has the interpretation of a tensor of angular velocities and is

antisymmetric (hik = -&), with 10 independent components in the general case. In

the case of simple loading there is no rate of rotation, and hence fiik = 0.

It ishould be noted that assuming cp(Z,) = const. = c, fa = const., we obtain linear

strain hardening with the hardening modulus

(2%

or

since for simple loading 81 = RI + 81. On the other hand, assuming $J = cWP in (21)

we do not obtain linear work hardening.

IV. GENERAL FORM OF EVOLUTION

EQUATIONS

Consider now just the simplified (narrower) case of distortional hardening, described

by the implicit equation (12). It may be written in the matrix form

200

T. Kurtyka and M. iyczkowski

F = (a - a)rQrDQ(n

- a) - 1 = 0

(31)

where the diagonal functional matrix D = D(a, Ri, a, diyQ), has the diagonal elements

DE = [Rt + 2diQg(ai - Uj) - d;?]-

(32)

with summation overi. So, F depends on the stress vector and on the parameters of the

yield surface, regarded as internal state variables

F = F(cii; Ri, ai, di, Qij),

i,j = 172, ..5.

Denote by p a generalized vector of appropriately

components)

(33)

ordered state variables (with 25

{P} = {Ri, ai, di, Qij}y

(34)

then (33) may be written briefly

F= F(c,p).

(35)

Subsequent yield surfaces F for a stable material should change continuously. This is

ensured by differential form of evolution equations for p: the right-hand side may be

discontinuous, but must not be of Diracs type, since such a type would result in a

discontinuity of p. These evolution equations should determine P in such a way as to

have it rate-independent. The simplest law conforming to this requirement has the form

P = By,

hi = B.+

l

J J

(36)

where B = B(p, CT,S-,...) is a matrix (25 x 5), depending on the arguments discussed in

detail in Section VI. Dependence on vectors or tensors denotes here, of course, just a

dependence of invariants of these quantities (except considering the vector a and the

tensor Q, when this is not necessary). The simple rule (36), proposed for other types of

plastic hardening, e.g. by Mroz [1974], Lubliner [1974], Nguyen and Bui [1974]. Dafalias and Popov [1976], is more general than one may expect. Assume the constitutive

equations in the form

ip = AnG,

3; =

/i&j,

(37)

where i is a scalar multiplier, and nc is the unit external normal to a certain function

G(ai) (plastic potential),

nG =

l~~$~~i,

IlGi =

dG/dui

J(aG/d~~)(dG/d~j)

not necessarily equal to F, (33). Considering the lengths of the vectors in (37) we find

(39)

hence

Distortional plastic hardening

201

Further, introduce the notation

2

?BnG = b,

(41)

where: b is a matrix 1 x 25, we can write briefly

p = bi EPP

(42)

The notation (42) is called the standard formulation of evolution equations, Bergander

[198Ojl,Bergander et al. [1992] (for finite strains). All the equations discussed in Section

III may be presented in the form (36) or (42). The generalized vector p consists in our

case of 25 coordinates: 10 scalars Riand Dip 5 coordinates of the translation vector a

and 10 independent coordinates of the rotation tensor Q.

During a plastically active process (loading) the stress point should remain at the

yield #surface (Pragers consistency condition), hence

dF

dF

dOj

dPj

-sj+-fij=o

(43)

Substituting (36) and (37) we obtain

(44)

and final general constitutive equations including evolution equations take the form

Plastically active process takes place, if (8F/l3t~)~&

> 0,otherwise $ = 0.

V. ASSOCIATED FLOW RULE

For the sake of generality we admitted any plastic potential G, but for most materials the plastic properties of which do not depend on the first stress invariant, the associated, flow rule holds, G = F.Then in eqns (37), (38) (40), (41) and (45) nG should be

replaced by nF, with F given by (12) or (31). Introduction of the associated flow rule

brings essential effects, since distortion of yield surfaces results in much larger differences in the values of derivatives than of the functions themselves.

The derivatives appearing now in the above-mentioned equations are equal

-c

aaidF

j=,

ZQj/cQji(gk

- ak)[Rj- 4 t diQjm(am - am)]

[RT -

4 + 24Qjn(an -

dF

dF

aai

aOi

an)]*

(46)

(47)

T. Kurtyka and M. iyczkowski

202

(48)

-24IQ&7ic

dF

wc)l*

dRi = [Rf- df + 2diQ&n

aF 2k4-_=

l3di

@k(flk

[Rf - df +

Uk)][&,&&

(49)

- an)]*

- u,)]2

2diQin(nn - d,J]*

(50)

These formulae need additional summation over k,m,n, but no summation over i. They

look complicated, but, for example, in a two-dimensional subspace, particularly

important in applications, they are fairly simple.

VI. MORE EFFECTIVE EVOLUTION EQUATIONS FOR ARBITRARY LOADING

VI. 1. General remarks

A deformation process may be prescribed in stresses, strains, or in a mixed way.

Choosing any six of the twelve quantities au, eii as independent, we obtain 12!/6!6! =

924 combinations (iyczkowski [1981]). Here, considering just deviatoric materials

(insensitive to the first stress invariant), we may have 10!/5!5! = 252 combinations. In

fact, the number of really independent combinations is much smaller. It would be difficult, for example, to assume that the stress o1 and the relevant strain s1 are both

independent. So, if we eliminate the combinations with stresses and strains corresponding to each other, we obtain just 2 5 = 32 combinations. Independent quantities,

which may serve as control variables of the process were discussed by iyczkowski

[1960, 1967, 19811, and called the exertion factors.

Here, in principle, we shall consider the processes prescribed either in stresses, or in

strains, but evolution equations depend always on plastic strains, hence both on total

strains and on stresses, and final equations are implicit anyway. In stresses the process

trajectory will be prescribed by

(51)

VI.2. Radii Ri

Usually it is assumed that eqn (18) is sufficient to describe evolution of Rip responsible for isotropic hardening component, even for general process trajectory. However,

according to the remarks of Ilyushin [ 19611, and Lensky [ 19611, a more precise

description needs certain parameters of the trajectory (51) to be included into relevant

evolution equations. Indeed, analyzing various experimental data we found that such

parameters are quite essential, even for RI and R2, and for RJ, Rq, and RS they are

necessary.

We propose the following generalizations of (18) and (24) for all five radii:

Distortional plastic hardening

203

(52)

with the initial condition R,{ZEp

= 0)= ao.Here the coefficients pCi,......@C4are responsible for primary, secondary ... cross effects (relative changes of transversal dimensions

in subsequent mutually perpendicular directions), whereas dimensionless parameters

(or functions along the trajectory) pz,...ps should describe deviations in the plastic

range from simple loading, from trajectory lying in a plane, from trajectory lying in a

three-dimensional and in a four-dimensional hyperplane, respectively. Without such

deviations the subsequent hyperspheres cannot be distinguished, and that is reflected in

(52). The parameter 1-1~is not necessary in (52), but will be used later, in evolution

equations for di.

Following Ilyushin [1954], [1961] we could choose as p2, p3, p4, the following quantities, proportional to three curvatures of the trajectory

pj =

4-1 I&,

j=2,3,4

(53)

where

c==

oi$idT

(54)

is the current length of the trajectory in the five-dimensional stress space. Indeed, they

describe deviations from a straight-line loading, from trajectory lying in a plane, from

trajectory lying in a three-dimensional hyperplane, but the problem is more complicated. Any curvature of the trajectory within the yield surface, and, in particular,

within the initial yield hypersphere is without any effect on plastic deformations. For

examiple, the trajectory shown in Fig. 3 may be regarded as simple loading, (since it is

radial. in the plastic range, though its shape in the elastic range is arbitrary), and just

two hyperspheres may be distinguished, as described in Section III.

On the other hand, if a trajectory crosses the initial yield surface at a certain boundary point ab with the angle (a, c+)different from zero, and all three curvatures (53) different from zero, we can distinguish all five directions tii = w& and all five hyperspheres

with the radii Riat the beginning of the plastic part of the process, it means at the point

Ub. To this aim we may use the Gram-Schmidt orthogonalization process.

Direction il = wib is always determined by the vector ffb and its coordinates are

given in the first row of (17), written now in the form

*lb =

3 Sllb &,lb

Nlb(Jj~, 2

0

+ h22b

fJ0

(55)

Direction tizb may be defined as perpendicular to i%tb,lying in the plane determined by

bb and & (Fig. 4). Writing i+2bin the form of a linear combination

T. Kurtyka and M. Zyczkowski

204

loading

trajectory

initial

yield

surface

Fig. 3. An example of simple loading in the plastic range.

load

traje

Fig. 4.

Rotated systems of coordinates.

(56)

and requiring

%2b . Ub = 0, Ifi

ii2b =

= 1, we find

-(ub

* b.6)

jab12cib

(57)

i~blj/l~bt2h+b/2

(cb

. 8)

Similarly, direction +Jb, may be defined as perpendicular

&b), lying in a three-dimensional

hyperplane determined

to +b, and 6~ (or to fib and

by 66, & and &b. Writing

+3b = (Y306b + a31&, + o&b

and requiring

ti3b . bb = 0, ti3b . C+.6= 0, l+X, = 1 we evaluate

(58)

a30, (Yap,a32, and finally

Distortional plastic hardening

205

where

labI2 t,b

ub

ub

&

* 6,,

.

C+b

j&l2

ub

ijb

&,

tib

l&l2

bb tib

In a similar manner we can define +db and +sb, using tib and orthogonality; the principles are clear, but the calculations are more and more cumbersone.

Now, there is an essential difference between stress trajectories starting from the

centre of coordinate system, as discussed by Ilyushin, and starting from the boundary

point mb.In the first case a certain curvature is necessary to describe deviation from

simple loading, whereas in the second case - an angle between ub and &. In the first

case a torsion of the trajectory is necessary to describe its deviation from a plane,

whereas in the second - a curvature out of the plane determined by ob and &. So, we

propose as p2 the absolute value of sin of the angle (a, &), not only at the point u = bb,

but at any point of the trajectory:

p2 = Isin(u,&)I = j/w

=

!

and after rearrangements

1- M

u

(61)

in the five-dimensional space

The above formula is useful for a trajectory prescribed in stresses, it means with

stress components as control variables (exertion factors). A similar formula may be

expressed in total (deviatoric) strain components, or even partly in stresses and partly

in strains for mixed control of the process. Indeed, for deviatoric materials we have

always p2 = 0 for a simple process, for any independent combination of stresses and

strains as control variables.

Some authors use similar parameters like p2, defined in other quantities: Benallal et

al. 119881use here the translation (backstress) vector a, whereas Schmitt et al. [1994] the plastic strain vector +. However, these quantities cannot serve as control variables,

they cannot be governed from outside, and so they seem to be less convenient in

applic,ations.

Consequently, as the parameter ,u3 responsible for an out-of-plane trajectory we

propo;se the absolute value of sin of the angle between ii and the plane determined by u

and &-.It is equal to cosin of the angle between 6 and 63, calculated as (59) for a current point of the trajectory

206

T. Kurtyka and M. Zyczkowski

(63)

Substituting (59) we obtain, after rearrangements,

(64)

where A3 (a, c+,ii) is given by (60) for a current point U.

Formula (62), regarded as a hypothesis, may be used both for differentiable trajectories or trajectories with corners. In the latter case we obtain a jump-like change of p2,

but continuous change of R3. On the other hand, (64) cannot be used for trajectories

with corners, since then ti behaves like a Diracs function.

In some cases it is not difficult to replace (64) by a formula allowing for corners.

Consider, for example, a trajectory consisting of segments of straight lines, then for

each segment (n) and suitably chosen time-like parameter we have &,, = COIZSL

The

trajectory starts to be an out-of-plane if for three consecutive segments

\I

A3(k(n)r

P(n)

b(n)

I2

. +2+1)

+z+l),

b.(n+2))

k(n)

+ o

. +l,l)

P(n+l)

I2

where A3(bn, &cn+i),r+~~+~))is defined as (60). As it was mentioned above, the trajectory within the initial yield surface has no effect on plastic deformations, so instead of

&i we should substitute bb like the trajectory were straight, starting from the centre of

coordinates.

The parameter ~4 may be defined as the absolute value of the angle between ii: and

the hyperplane determined by 6, &, and ii; similarly pus. Final formulae will not be

quoted here.

VI.3. Translations ai

The coordinates of the vector a describe translation of the surface, (backstresses or

residual microstresses) characteristic for kinematic hardening. So, we propose here an

evolution equation generalizing well-known equations for kinematic hardening and

present the vector a as a combination of several other vectors employed to describe

plastic hardening

(66)

The coefficients Ci are, in general, some functions of the form

Ci = Ci(P, Q, k, &Li,

Lp, LJ?)

(67)

and should be chosen in such a way as to obtain i independent of the scale of time.

Hence Ci and C, must be homogenous functions of the time derivatives of the degree 0,

Distortional plastic hardening

207

whereas Cs, and Cd and Cs - of the degree 1. The classical evolution laws for kinematic Ihardening may be obtained from (66) as follows: assuming Cz = C3 = C4 = Cs

= 0 we arrive at the rule proposed by Melan [1938], Ishlinsky [1954], and Prager

[1956]; assuming C1 = Cs = C, = Cs = 0 we obtain the second proposal of Melan

[1938], whereas assuming C1 = Cz = C3 = 0, Cd = -Cs = C&, arrive at the rule

proposed by Ziegler [1959].

Many other evolution equations of kinematic hardening are also described by (66).

Assuming C, = C3 = Cd = 0, Cs = C&,, (Cs < 0) we obtain the well-known equation proposed by Armstrong and Frederick [1966]; assuming C, = Cd = Cs = 0,

Cs = (7&, (Cs < 0) we obtain a similar law proposed by Eisenberg and Phillips [1968],

Mroz (?t al. [1976]; assuming C3 = Cd = Cs = 0 we obtain the proposal of Phillips and

Lee [1979], Voyiadjis and Foroozesh [ 19901, generalized by Voyiadjis and Kattan [ 1990,

19911 to finite strains; assuming just C z = C3 = 0 we may derive a more complicated

proposal by Trampczynski and Mroz [1992]. A general approach to evolution laws for

kinem,atic hardening was also discussed by Zbib and Aifantis [1988]. A triple analogy

for tree variants of kinematic hardening in stress and in strain spaces was proposed by

Zyczkowski [ 19771.

It should be noted that the second Melans proposal C, # 0 is often criticized since it

does not conform to the postulate of continuous description of a neutral process.

However, it may be employed without violation of any postulate if C, contains a multiplier of the type cos(n, b), since then it vanishes for a neutral process. For initial

neutral surface (yield surface) in the form of a hypersphere we have cos(r+, b)

=

1 - & (61). For subsequent yield surfaces this relation in general does not hold

Jexactly, but may be used as an approximation. Hence we included the parameters of

the trajectory /.+ to the arguments of the multipliers Ci in (66).

VI.4. Rotations Qij

In Section VI.2 we constructed the initial rotated system of coordinates &j, determined by $bb, and also subsequent systems based on u, &,ii, 6. Denote directional

cosines of these systems with respect to (1) by P,. Experimental data show that the

projecting directions Qii, identical with P, for u = Ub, in general do not remain identical during the process, but follow Pij with a certain delay. So, one may be tempted to

propo;se the following type of evolution equations

However, such equations determine 25 quantities Qii with only 10 of them being independent, and, in general, they are contradictory. In some particular cases we may formulate the counterparts of (68) just for independent quantities. For example, in a twodimensional case the rotation is determined by one angle cp, and instead of (68) we may

propo,se

where pp is determined by U, and pQ gives the angles of projection. Similar equations

may be proposed for Eulers angles in a three-dimensional case.

T. Kurtyka and M. Zyczkowski

208

Another possible approach makes use of the substitution (28), since then the antisymmetric tensor fi has just 10 independent components. According to the general

form (42) we may propose the evolution equations

ti = A&,,

flij = Aijafq

(70)

The antisymmetric tensor A must vanish for simple loading and should describe

deviation from simple loading. So, we may construct it as follows

A =fX~,o,

Pkr &J[q)

~3 m(2)

m(2)

m(l)],

(71)

where the symbol @Idenotes dyadic product of two vectors mCl)and mC2).Such vectors

should be colinear for simple loading, since then A = 0. Hence, any two of the vectors

used in (66) may be employed in (71), since all of them are colinear for simple loading.

More effective formulation of (71) needs further research, both theoretical and

experimental. Existing data on rotation are very scarce. Though some evolution equations for rotation are hidden in general equations for affine hardening listed in Section I, and some experiments were devoted to the analysis of rotation (e.g. Skrocki

[1984]), the correlation between theory and experiments is still rather loose. We mention here just a proposal of Zilauts and Lagzdin [1992].

VI.5 Distortions di

Simple loading is characterized by just one distortional parameter, di. The remaining

four di depend essentially on the trajectory, and namely on the parameters p) Formation of the distortional parameters di takes place one step behind Ri. Indeed, the first

deviation from simple loading, characterized by p2, results in formation of R3 and of

d2. Hence, we propose the following evolution equations generalizing (27):

i=~~~~(P,a,~k,z~~,)(R~-d~)~p,

i= 1,2...5,

(72)

where the bracket ensures (13), and we introduced b1 = 1 for uniformity of notation.

There is no summation over i in (72); the functions fdi

may be different for each i.

The derivatives 5; in the rotating frame of coordinates should be understood as the

corotational derivatives

5; = !&

= Qij i$+ Qij 3; .

However, if the rotation is rather slow, we could approximately

tional derivatives,

3; = $&

(73)

use ordinary direc-

= Qjj 3;

Moreover, assuming associated flow rule, we may use direct differentiation

respect to &, arriving at a simple formula

(74)

of (12) with

(75)

where A is a factor of proportionality.

Distortional plastic hardening

209

VI.6. Renumeration of axes

Numeration of axes in the five-dimensional auxiliary stress space, introduced by

Ilyushin [1954] by formulae (1) is quite arbitrary: any other numeration would be

equally good. On the other hand, numeration of axes of a rotating system &_, introduced for the point u = Ub by the formulae (55), (57), (59) and similar for w& and wsb,

is unique provided the derivatives &, ii, ii: are different from zero and the above-mentioned formulae are not degenerated.

The orientation of the rotating system must be equal to the orientation of the fixed

system. Hence, for a particular system of loadings it is convenient to renumerate axes

of the fixed system. For example, if we consider tension with torsion, we should leave

the notation o1 as in (l), but denote r& = si&

by ~2; if we consider double shear,

then <icy& = si2fi should be denoted b y (TV,and 7Xzfi = sis& by ~2. Then o1 is

transformed into c?i, 02 into 82, and so on.

VII. NUMERICAL

EXAMPLE: BUIS EXPERIMENT

Sublsequent yield surfaces depend in an essential manner on the definition of the yieldpoint stress. This definition is by no means unique: Haythornthwaite [1968] gives six

various definitions being in use by experimentators. Some of them are very sharp,

defining yield-point stress by very small deviations from the linearly elastic behaviour,

and some are of engineering type, with the yield-point stress connected with remarkable plastic effects. Many papers are devoted to experimental evaluation and comparison of subsequent yield surfaces corresponding to individual definitions: for example,

Khan and Wang [ 19931constructed families of subsequent yield surfaces corresponding

to various offset plastic strains and equimodulus surfaces in torsion-tension tests.

As a numerical example of evolution equations we use torsion-compression tests on

aluminium specimens, performed by Bui [1966], since the parameters for individual

surfaces were identified by Kurtyka [1988] for the distortional hardening model considered in the present paper. The definition of the yield-point stress, based on the

increment of plastic strain

A&-= 20 x 1O-6

(76)

may be regarded as intermediate: not as sharp as in Phillips experiments, but far from

engineering definitions.

Buis results overcalculated to Ilyushins space are shown in Fig. 5. It is seen that the

surface Fi does not conform to the sequence, probably due to larger experimental

errors.; hence, the evolution equations proposed will be based mostly on Fe, F2, and F3.

A two-dimensional case, as investigated by Bui, may be described by 8 evolution

equations, and namely for RI, R2, R3, al, a2, di, d2 and cp. However, Bui gave no data

as regards R3 (an additional internal pressure had to be added), and so we propose just

7 evolution equations. They should be completed by 2 constitutive equations, one

equation of subsequent yield surfaces, and two equations describing the trajectory.

These 12 equations interrelate 14 quantities: 7 internal state variables listed above, and

37, %$I,cl, u2, c?i, 32, ZEp.Total strains 31 and 32 may be calculated later, they are not

involved. So, two quantities may be regarded as independent (in our case pi and g2),

and the remaining 12 should be expressed in terms of those quantities.

The equations proposed, based on Kurtykas identification of individual parameters

and subsequent approximations, look as follows:

210

T. Kurtyka and M. Zyczkowski

Fig. 5. Approximation of experimental yield surfaces for the simplified distortional model. Experimental

points according to Bui [1966].

ril= 2000+~,

ir2= 2000 go*,

&=

-25oo/q/~~ R2-&. y

(c7=40000(1-p:)2 arctg~+mr-cp

01

(77)

211

Distortional plastic hardening

6,

-q

const. = dlcoscp - &sincp + al,

a2 = 61sincp + ~~cosy.~+ a2,

Rf - 4 8 + 2d,&, +R;-&+2dB

2 2

1.

Of course, the equation 01 = -00 is valid just for the loading trajectory considered by

Bui; otherwise it should be replaced by a more general equation f(~i, ~7~)= 0. The

multiplier n in the equation for ~3depends on the initial value pb; in our case n = 1 since

(Pb = tr for uniaxial compression.

The authors are fully aware that the proposal (77), based on three subsequent yield

surfaces only, may be not general enough, but at least it gives an idea as regards specific

forms of such equations.

The: time-like parameter t in (77) may be chosen arbitrarily, since it is subject to

cancellation. Some proposals of choice were given by Sobotka [1985]. In the problem

under consideration we may choose simply t = a2, since o2 is an independent, monotonica.lly increasing parameter.

VIII. CONCLUSIONS

The: model of distortional plastic hardening, proposed by the authors in 1985, has

been completed here by relevant evolution equations. They describe all five elements of

transformation of the initial yield surface, and are not too complicated as it is seen

from the example (77).

Acknowledgement - Grant KBN - 1960/91 is gratefully acknowledged.

REFERENCES

1931

1933

1938

1949

1951

1954

1954

1956

1959

Taylor, G.I. and Quinney, H., The Plastic Distortion of Metals, Phil. Trans. Roy. Sot., A23,323362.

Odqvist, F.K.G., Die Verfestigung von flusseisemihnlichen Kiirpem, Z. angew. Math. Mech., 13,

360-363.

Melan, E., Zur Plastixitat des raumlichen Kontinuums, Ing.-Archiv. 9, 116-126.

Batdorf, S. and Budiansky, B., A Mathematical Theory of Plasticity Based on the Concept of Slip,

NACA TN 1871.

Edelman, F. and Drucker, D. C., Some Extensions of Elementary Plasticity Theory, J. Franklin

Inst., 251, 581-605.

Ilyushin, A.A., On the Relation between Stresses and Small Strains in the Mechanics of Continua

(in Russian), Prikl. Mat. Mech., 18, 641-666.

Ishlinsky, A.Yu., A General Theory of Plasticity With Linear Hardening (in Russian), Ukrain.

Mat. Zhumal, 6, 314324.

Prager, W., A New Method of Analyzing Stresses and Strains in Work-Hardening Plastic Solids J.

Appl. Mech., 23,4933496.

Ziegler, H., A Modification of Pragers Hardening Rule, Quart. Appl. Math., 17, 1, 55-65.

212

1960

1961

1961

1963

1965

1965

1965

1966

1966

1967

1968

1968

1968

1972

1973

1974

1974

1974

1975

1975

1976

1976

1976

1976

1976

1977

1978

1979

1979

1980

1981

T. Kurtyka and M. Zyczkowski

Zyczkowski, M., Die Werkstoffanstrengung in unterkritischen Zusmnden, Bull. Acad. Pal., Ser.

SC. Techn., 8,333-341.

Ilyushin, A.A., On the Foundations of the General Mathematical Theory of Plasticity (in Russian), in Voprosy Teorii Plastichnosti, Izd. AN SSSR, Moskva, 3-29.

Lensky, V.S., Certain Peculiarities of the Behaviour of Metals Subject to Elastic-Plastic Deformation (in Russian), in Voprosy Teorii Plastichnosti, Izd. AN SSSR, Moskva, 58-82.

Ilyushin, A.A., Plasticity (in Russian), Izd. AN SSSR, Moskva.

Baltov, A. and Sawczuk, A., A Rule of Anisotropic Hardening, Acta Mech., 1, 81-92.

Miastkowski, J. and Szczepinski, W., An Experimental Study of Yield Surfaces of Prestrained

Brass, Int. J. Solids Struct., 1, 189-194.

Theocaris, P.S. and Hazell, C.R., Experimental Investigation of Subsequent Yield Surfaces Using

the Moire Method, J. Mech. Phys. Sol., 13, 281-294.

Armstrong, P.J. and Frederick, C.O., A Mathematical Representation of the Multiaxial Bauschinger Effect, Centr. Electr. Gener. Board. Report No RD/B/N731.

Bui, H.D., Ecrouissage des Metaux, Comp. Rend. Acad. Sci., AB262, A401-A404.

Zyczkowski, M., Combined Loadings in the Theory of Plasticity, Int. J. Non-Linear Mechanics,

2, 173-205.

Backhaus, G., Zur Fliessgrenze bei allgemeiner Verfestigung, Z. angew. Math. Mechanik, 48,99-108.

Eisenberg, M.A. and Phillips, A., On Nonlinear Kinematic Hardening, Acta Mechanica, 5, 1-13.

Haythornthwaite, R.M., A More Rational Approach to Strain-Hardening Data, in Engineering

Plasticity, J. Heyman and F.A. Leckie (eds). Cambridge University Press, pp. 201-218.

Freudenthal, A.M. and Gou, P. F., Second Order Effects in the Theory of Plasticity, Acta

Mechanica, 8, 34-52.

Danilov, V.L., On the Formation of Deformational Hardening Rule (in Russian), Izv. AN SSSR,

Mekh. TV. Tela, 6, 146-150.

Williams, J.F. and Svensson, N.L., A Rationally Based Yield Criterion for Work Hardening

Materials, Meccanica, 6, 104-l 14.

Phillips, A. and Tang, J.L., The Effect of Loading Path on the Yield Surface at Elevated Temperatures, Int. J. Solids Struct., 8, 463-474.

Shrivastava, H.P., Mroz, Z. and Dubey, R.N., Yield Criterion and the Hardening Rule for a Plastic

Solid, Z. angew. Math. Mechanik, 53,625-633.

Lubliner, J., A Simple Theory of Plasticity, Int. J. Solids Struct., 10, 313-319.

Mroz, Z., A Description of Workhardening of Metals With Application to Variable Loading in

Foundations of Plasticity, A. Sawczuk (ed.). Noordhoff, pp. 551-570.

Nguyen, Q.S. and Bui, H.D., Sur les materiaux elastoplastiques a Bcrouissage positif ou nigatif, J.

de Mecanique, 13,321-342.

Phillips, A. and Weng, G.J., An Analytical Study of an Experimentally Verified Hardening Law,

J. Appl. Mech., 42, 375-378.

Tanaka, M. and Miyagawa, Y., On Generalized Kinematic Hardening Theory of Plasticity, Ing.Archiv., 44, 255-268.

Dafalias, Y.F. and Popov, E.P., Plastic Internal Variables Formalism of Cyclic Plasticity, J. Appl.

Mech., 43, 645-65 1.

Ikegami, K., An Historical Perspective of Experimental Study on Subsequent Yield Surfaces for

Metals. British Ind. Sci. Int. Translation Service 14420.

Michno; M.J. and Findley, W.N., An Historical Perspective of Yield Surface Investigations for

Metals, Int. J. Non-Linear Mechanics, 11, 59-82.

Mroz, Z., Shrivastava, H.P. and Dubey, R.N., A Non-Linear Hardening Model and Its Application to Cyclic Loading, Acta Mechanica, 25, 51.

Shiratori, E., Ikegami, K., Yoshida, F., Kaneko, K. and Koike S., The Subsequent Yield Surfaces

After Preloading Under Combined Axial Load and Torsion, Bull. Japan Sot. Mech. Engng., 19,

877-883.

Zyczkowski, M., Eine dreifache Analogie fiir kinematische Verfestigung von plastischen Korpern,

Festschrift Alf Pfliiger, TU. Hannover, 289-294.

Axelsson, K., Finite Element Application of Mixed and Distortional Plastic Hardening, in Proc.

Int. Conf. Fin. El. Nonlin. Solids. Struct. Mech.. Geilo 1977, nubl. Trondheim, 191-209.

Phillips, A. and Lee, C.-W., Yield Surfaces and Loading Surfaces, Experiments and Recommendations, Int. J. Solids and Structures, 15, 715-729.

Shiratori, E., Ikegami, K. and Yoshida, F., Analysis of Stress-Strain Relations by Use of an Anisotropic Hardening Plastic Potential, J. Mech. Phys. Solids, 27, 213-229.

Bergander, H., Plastische Deformationsgesetze in differentieller Standardformulierung, Z. angew.

Math. M, 509-519.

Ohashi, Y. and Tanaka, E., Plastic Deformation Behavior of Mild Steel Along Orthogonal Trilinear Strain Trajectories in Three-Dimensional Vector Space Strain Deviator, J. Eng. Mat. Techn.,

103,287-292.

Distortional plastic hardening

1981

1982

1983

1984

1984

1984

1985

1985

1985

1986

1987

1987

1988

1988

1988

1989

1990

1990

1990

1990

1991

1991

1992

1992

1992

1992

1993

1993

1993

1994

213

Zycxkowski, M., Combined Loadings in the Theory of Plasticity, PWN-Nijhoff, WarszawaAalphen aan den Rijn.

Rees, D.W.A., Yield Functions That Account for the Effects of Initial and Subsequent Plastic

Anisotropy Acta Mechanica, 43,223-241.

Ortix, M. and Popov, E.P., Distortional Hardening Rules for Metal Plasticity, Trans. ASCE, J.

Eng. Mech., 109, 1042-1057.

Eisenberg, M.A. and Yen, C.F., The Anisotropic Deformation of Yield Surface, J. Eng. Techn.

Mat., 106, 355-360.

Skrocki, H., Analysis of the Effect of Memory and of the Flow Surface Rotation in Complex Stress

State. Bull.Ac.Pol.. Technical Sciences. 32. 657-666.

Zyczkowski, M. and Kurtyka, T., Genera&d Ilyushins Spaces for a More Adequate Description

of Plastic Hardening, Acta Mechanica, 52, 1-13.

Kurtyka, T. and Zyczkowski, M., A Geometric Description of Distortional Plastic Hardening of

Deviatoric Materials, Arch. Mech., 37, 383-395.

Mazilu, P. and Meyers, A., Yield Surface Description of Isotropic Materials After Cold Prestrain,

Ing.-Archiv, 55, 213-220.

Sobotka, Z., Time Measures and Parameters of Evolution in the Theory of Plasticity, Acta

Technica CSAV, No. 5,479-498.

Gupta, N.K. and Meyers, A., Description of Initial and Subsequent Yield Surfaces, Z. angew.

Math. Mechanik, 66435-439.

Helling, D.E. and Miller, A.K., The Incorporation of Yield Surface Distortion into a Unified

Constitutive Model, Part I, Acta Mechanica, 69, 9-23.

Watanabe, O., Anisotropic Hardening Law of Plasticity Using an Internal Time Concept, Jap.

Sot. Mech. Eng. Int.d., 30, 912-920.

Benallal, A., Le Gallo, P. and Marquis, D., Cyclic Hardening of Metals Under Complex Loadings, Proc. MECAMAT, ed. by G. Cailletaud et al., Besancon, pp. V/361-V/371.

Kurtyka, T., Parameter Identification in a Distortional Model of Subsequent Yield Surfaces,

Arch. Mech., 40, 433-454.

Zbib, H. M. and Aifantis, E.C., On the Concept of Relative and Plastic Spins and its Applications

to Large Deformation Theories, Part II, Acta Mechanica, 75, 35-56.

Rees, D.W.A., Theoretical and Experimental Aspects of Infinitesimal Plasticity, Res Mechanica,

28, l-68.

Kurtyka, T., Invariant Formulation of a Distortional Model of Plastic Hardening, Mech. Teor.

stos., 28, 115-131.

Voyiadjis, G.Z. and Foroozesh, M., Anisotropic Distortional Yield Model, J. Appl. Mech., 57,

537-547.

Voyiadjis, G.Z. and Kattan, P.I., A Generalized Eulerian Two-Surface Cyclic Plasticity Model for

finite Strains, Acta Mechanica, 81, 143-162.

Zyczkowski, M. and Kurtyka, T., A Description of Distortional Plastic Hardening of Anisotropic

Materials, in Yielding, Damage and Failure of Anisotropic Solids, J. P. Boehler (ed.), MEP

London, 97-l 11.

Kurtyka, T. and Zyczkowski, M., Some Attempts to Describe Distortional Hardening in Viscoplasticity, in Creep in Structures IV, M. Zyczkowski (ed.). Springer, 131-138.

Voyiadjis, G.Z. and Kattan, P.I., Phenomenological Evolution Equations for the Backstress and

Spin Tensors, Acta Mechanica, 8899-l 11.

Bergander, H., Kreissig, R., Gerlach, J. and Knauer, V., Standard Formulation of Elastic-Plastic

Deformation Laws, Acta Mechanica, 91, 157-178.

Gupta, N.K. and Meyers, A., Considerations of Translated Stress Deviators in Describing Yield

Surfaces, Int. J. Plasticity, 8, 729-740.

Trarnpczynski, W. and Mroz, Z., Anisotropic Hardening Model and its Application to Cyclic

Loading Int. J. Plasticity, 8, 925-946.

Zilauts, A.F. and Lagzdin, A.Zh., A Variant of the Theory of Plasticity with Cross Effects, Mekh.

Kompozits. Mat., 6, 735-740.

Andrusik, Ya.F. and Rusinko, K.N., Plastic Deformation of Hardening Materials under Loading

in Three-Dimensional Subspace of a Five-Dimensional Deviatoric Space (in Russian), Izv. RAN,

Mekh. TV. Tela, 2, 92-101.

Khan, AS. and Wang, X., An Experimental Study on Subsequent Yield Surface After Finite Shear

Prestraining, Int. J. Plasticity, 9, 889-905.

Skrzypek, J., Plasticity and Creep, Theory, Examples, and Problems, CRC Press, Boca Raton.

Schmitt, J.H., Shen, E.L. and Raphanel, J.L., A Parameter for Measuring the Magnitude of a

Change of Strain Path, Int. J. Plasticity, 10, 535-551.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 3 Carbide Precipitation: 3.1 Upper BainiteDocumento28 pagine3 Carbide Precipitation: 3.1 Upper BainiteMarziana Mat DinNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Magnetic PMCDocumento47 pagineMagnetic PMCMarziana Mat DinNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Microcentrifugen PRO FinalDocumento20 pagineMicrocentrifugen PRO FinalMarziana Mat DinNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Haake MixerDocumento7 pagineHaake MixerMarziana Mat DinNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Ijso 2012 MCQDocumento15 pagineIjso 2012 MCQmpecth100% (1)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Subatomic ParticleDocumento10 pagineSubatomic ParticlemcmusbixNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Economix Agitator Data SheetDocumento2 pagineEconomix Agitator Data Sheetdumb2471817Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Chemical Bonding ModuleDocumento35 pagineChemical Bonding ModuleMark Paul Lipata Benitez100% (2)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Finite Element Simulation of Springback in Sheet Metal FormingDocumento7 pagineFinite Element Simulation of Springback in Sheet Metal FormingأبومحمدالزياتNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Lesson1 WindenergycalcDocumento3 pagineLesson1 WindenergycalcLuis Augusto CarvalhoNessuna valutazione finora

- Puddephatt Chemistry of GoldDocumento46 paginePuddephatt Chemistry of GoldnapoleonNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Basics and Statics of Particles - Unit I - GE6253Documento57 pagineBasics and Statics of Particles - Unit I - GE6253stkrNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Differential Geometry of Curves and Surfaces by Manfredo Perdigão Do Carmo Homework4Documento4 pagineDifferential Geometry of Curves and Surfaces by Manfredo Perdigão Do Carmo Homework4publicacc71Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Creep TestingDocumento26 pagineCreep TestingAmjad MehmoodNessuna valutazione finora

- Serway 6 e Problems 27Documento12 pagineSerway 6 e Problems 27David SaucedoNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- First Order de Problem Set 2010 Math 208Documento3 pagineFirst Order de Problem Set 2010 Math 208Jen ChavezNessuna valutazione finora

- Vector and Tensor AnalysisDocumento221 pagineVector and Tensor Analysispasquale_dottorato100% (1)

- StatisticsDocumento34 pagineStatisticsPoth BaliyanNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Organic Chemistry With A Biological EmphasisDocumento120 pagineOrganic Chemistry With A Biological EmphasisjoshuxNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Module Exercise 2Documento30 pagineModule Exercise 2Andrea MagtutoNessuna valutazione finora

- Electrostatics 11: Electric ChargeDocumento69 pagineElectrostatics 11: Electric ChargeManas kumarNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Level 2 Ques (1) RTDocumento34 pagineLevel 2 Ques (1) RTVishal Sharma100% (1)

- 3.electricity and Magnetism EOT 2021 TestDocumento9 pagine3.electricity and Magnetism EOT 2021 TestvaraprasadNessuna valutazione finora

- Symmetrical Components 2Documento15 pagineSymmetrical Components 2CaribNessuna valutazione finora

- Lab 10 Spherical Mirrors and LensesDocumento16 pagineLab 10 Spherical Mirrors and LensesOtto ManNessuna valutazione finora

- Transistor LaserDocumento19 pagineTransistor LaserUnn krishnan BNessuna valutazione finora

- BDW 94 CFPDocumento4 pagineBDW 94 CFPNegru P. PlantatieNessuna valutazione finora

- INTRODUCTION TO PHYSICS-Physics 9Documento25 pagineINTRODUCTION TO PHYSICS-Physics 9Onur YavuzcetinNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A-Level H2 Chemistry 01 Redox StoichiometryDocumento35 pagineA-Level H2 Chemistry 01 Redox StoichiometryWilliam Yu Kai Wong50% (2)

- Lecture Notes PDFDocumento46 pagineLecture Notes PDFManex ManNessuna valutazione finora

- Me6301 EtDocumento137 pagineMe6301 EteanestNessuna valutazione finora

- Phy1 11 - 12 Q1 0603 PF FDDocumento68 paginePhy1 11 - 12 Q1 0603 PF FDhiroNessuna valutazione finora

- Ieee 304-1977.PDF Procedimientos y Evaluacion de Aislamiento para Maquinas DCDocumento19 pagineIeee 304-1977.PDF Procedimientos y Evaluacion de Aislamiento para Maquinas DCNer Amiel Montes LazaroNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)