Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steel Tutorials

Caricato da

cuckoomodi1527Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Steel Tutorials

Caricato da

cuckoomodi1527Copyright:

Formati disponibili

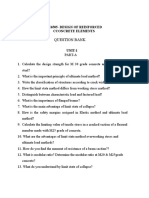

L. D. College of Engineering, Ahmedabad.

Applied Mechanics Department

170603 STRUCTURAL DESIGN 1

TUTORIAL 1

Introduction

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

List a few Indian standard codes that are followed while designing structures made of steel.

Explain various serviceability limit states considered by IS: 800-2007.

Write down the physical properties of structural steel.

Define the classes of steel cross section as per IS800-2007.

What is the maximum slenderness ratio for a member carrying compressive loads

resulting from dead loads and imposed loads?

For resistance, governed by ultimate stress, partial safety factor for materials, m is ___ .

What is the minimum thickness ts of rectangular slab bases, supporting columns under axial

compression?

What is the effective length in case of double angle discontinues struts connected by two or

more rivets?

What is the imperfection factor for buckling class b?

Effective length of prismatic compression members with one end fixed and other end

hinged is __________.

What is the effective slenderness ratio and minimum width of lacing bars?

What is the maximum slenderness ratio for maximum spacing of lacing bars?

What are the requirements for spacing of battens?

In the equation of design bending strength of laterally unsupported beam as governed by

lateral torsional buckling what is the value of b for plastic and compact sections.

What is the effective length for simply supported beam, when supports are full restrained

against torsion and both flanges fully restrained against warping?

What is the minimum and maximum spacing for fasteners?

What is the criteria for minimum and maximum edge distance for fasteners?

Typical average values for co-efficient of friction is _________ for surface not treated.

The equation for nominal tensile capacity of the bolt is ____________

What is the proof stress for friction type bolting?

What are the criteria for spacing of tacking fasteners for tension member and

compression member?

What is the minimum size of fillet weld for first run?

L. D. College of Engineering, Ahmedabad.

Applied Mechanics Department

170603 STRUCTURAL DESIGN 1

TUTORIAL 2

Connection

1.

What are the advantages of bolted connections over riveted or welded connections?

2.

Explain Lap and Butt joint with sketches.

3.

List the failure modes that may control the strength of a bolted joint.

4.

List some advantages of welding over bolting.

5.

Design a lap joint and butt joint between two plates having thickness 12 mm and 16 mm are

connected by a single bolted joint with 20 mm diameter bolts at 70 mm pitch.

6.

Calculate the efficiency of the joint. Take fu of plate as 410 MPa and assume 4.6 grade bolts.

Two plates 12 mm and 16 mm thick are to be joined by a double cover butt joint.

7.

Assuming cover plates of 8 mm thickness, design the joint to transmit a factored load of 650

kN. Assume Fe 410 and grade 4.6 bolts.

8.

Design a connection to joint two plates of size 250 12 mm of grade Fe410, to mobilize full

plate tensile strength using shop fillet welds, if (i) a lap joint is used (ii) a double cover butt

joint is used.

9.

An ISA 150 75 10 mm is subjected to axial tensile force of 180 kN connected by

its longer leg to 10 mm thick gusset plate. Design welded connection for shop welding.

10. A tie member of a truss consisting of an angle section ISA 65 65 6 of Fe 410 grade, is

welded to an 8 mm gusset plate. Design a weld to transmit a load equal to the full strength of

the member. Assume shop welding.

11. Calculate the size of the weld required to support a factored load of 150 kN.

12. Design a seat angle connection between a beam ISMB 300 and ISSC 250 for a reaction of

beam 150 kN, using M 20 bolts of property class 4.6. Take 410 grade steel and fy = 250 MPa.

13. Design a stiffened seat angle connection between a beam ISMB 400 and ISSC 250 for a

reaction of beam 300 kN, using M 20 bolts of property class 4.6. Take 410 grade steel and fy =

250 MPa.

L. D. College of Engineering, Ahmedabad.

Applied Mechanics Department

170603 STRUCTURAL DESIGN 1

TUTORIAL 3

Tension Member

1. List the different modes of failure of tension member.

2. Explain block shear failure in plates and angles.

3. Find tension carrying capacity of single angle ISA 100 x100 x 10 mm connected to an 10

mm thick gusset by means of three bolts of 22 mm diameter at pitch of 75 mm c/c in one

line, if the yield and the ultimate stress of the steel used are 250 MPa and 410

MPa, respectively.

4. Design a suitable angle section to carry tensile force of 300 kN. Use bolted

connection.

5. Select a suitable angle section to carry a factored tensile force of 190 kN assuming

welded end connection. Assume design strength as fy =250 MPa.

6. Design a tie member of roof truss subjected to working loads of 90 kN (DL) and 120 kN

(LL). Use double angle section connected back to back on either side of gusset 8 mm thick.

Use bolted connection. Fy = 250 MPa and fu = 410 MPa for both member and bolt material.

What will be the capacity if the angles are connected on the same side of the gusset plate?

7. A diagonal member of a roof carries an axial tension of 450 kN. Design the section and its

connection with a gusset plate and lug angle. Use fy =250 MPa and fu = 410 MPa.

L. D. College of Engineering, Ahmedabad.

Applied Mechanics Department

170603 STRUCTURAL DESIGN 1

TUTORIAL 4

Compression Member and Column bases

8. Explain different end conditions of columns with their effective length.

9. What is difference in behavior of short and long compression members?

10. Determine the compressive strength of a single angle strut ISA 90 x 60 x 8 mm with center

to center length of 3.0 m. The angle is loaded through one leg and ends are fixed. Consider

1 bolt at each end.

11. A double angle discontinuous strut is to carry a factored axial compression of 300 kN. The

length of the strut between the centres of intersection is 3.0 m. Design the member for the

following two cases:

(a) Angles placed back to back on opposite sides of gusset.

(b) Angles placed on the same side of gusset.

The angles are tack bolted and provided with minimum of two bolts. Use Fe 410.

12. A column consisting of ISHB 400 @ 774 N/m has an unsupported length 3.8 m. It is

effectively held in position at both ends, restrained against rotation at one end. Calculate the

axial load this column can carry. Assume fy = 250 MPa, fu =410 MPa.

13. Design a built up column with two channels toe-to-toe to carry a factored load of 1800 kN.

Take the effective length as 5.2 m. (a) Design it as a laced column and also design the

lacing. (b) Design it as a battened column and also design the battens.

14. An ISMB 500 is loaded by a factored compressive load of 450 kN at the midpoint of the

flange. Check the safety of the column if the effective length for both axial and bending is

3.0 m.

15. Design the Slab base for a built up column consisting of ISMB 600, 5m long and carrying

factored load of 700 kN. Concrete grade M25 and steel Fe 410, Bearing capacity of soil 250

kN/m2.

16. Design the Gusseted base for a column ISHB 400, 4.5 m long and carrying factored load

of 4500 kN. Take cover plates of size 400 20 mm on each flange. Concrete grade M20

and steel Fe 410, Bearing capacity of soil 300 kN/m2.

L. D. College of Engineering, Ahmedabad.

Applied Mechanics Department

170603 STRUCTURAL DESIGN 1

TUTORIAL 5

Beams

1. Discuss the various cross section of beam

2. What is difference between bending and buckling of beam?

3. Under what condition lateral buckling can occur?

4. Explain various failure modes of beam.

5. What is meant by effective length of beam?

6. Under what condition can a beam member be assumed as laterally restrained?

7. A simply supported beam 5 m span carries uniformly distributed load of 45 kN/m. In

addition, the beam carries point load of 35 kN. The beam is laterally supported. Design the

section and check the section for shear and deflection.

8. A beam of ISMB 500 has simple support span of 8.5 m and is laterally supported at center

only. Calculate the maximum all inclusive factored UDL it can support.

9. A three span continuous beam ABCD carries factored load inclusive of self-weight, 70

kN/m on AB with 3m length, 90 kN/m on BC with 5 m length and 100 kN/m on CD with

4.5 m length.

Determine the collapse moment using fy = 250 MPa. Assume that the beam is fully

restrained and supported laterally.

Also design the beam for following cases.

(i) Using uniform section throughout.

(ii) Using Non-uniform section.

10. Design a laterally unrestrained beam simply supported over a span of 3.5 m, with U.D.L. of

45 kN/m. use Fe 410 grade steel.

11. Calculate moment capacity of ISMB 400 beam having span 4.5 m with the compression

flange laterally unrestrained.

L. D. College of Engineering, Ahmedabad.

Applied Mechanics Department

170603 STRUCTURAL DESIGN 1

TUTORIAL 6

Torsion Design

1. Discuss uniform and non-uniform torsion.

2. Explain in detail types of torsion.

3. Design a : Simply Supported beam considering following data:

1. Span of beam = 6 m

2. Total load on beam = 10 kN/m as dead load + 12 kN/m as live load.

3. Eccentricity from centre of web = 80 mm.

4. Calculate Maximum shear stress and maximum angle of rotation of 2 m long shaft with

twisting moment of 15 kNm applied at the end. Take G = 75000N/mm2.

5. A cantilever beam of span 3.5 m is subjected to UDL of 30 kN at eccentricity. Design the

beam.

L. D. College of Engineering, Ahmedabad.

Applied Mechanics Department

170603 STRUCTURAL DESIGN 1

TUTORIAL 7

Plastic Design

1. Determine the required plastic moment of resistance for three span continuous beam

considering following data and for,

1. Uniform Section

2. Non- Uniform Section

Beam

AB

BC

CD

Length

4.0 m

5.0 m

6.5 m

Factored load

40 kN/m

120 kN/m

50 kN/m

2. Design an I-beam section for three span continuous beams ABCD. Using plastic method

for,

1. Uniform Section

2. Non- Uniform Section

Beam

AB

BC

CD

Length

5.5 m

3.5 m

4.5 m

3. Design following portal frames using I-section.

Factored load

25 kN/m

45 kN/m

35 kN/m

Potrebbero piacerti anche

- SD 1 AssignmentDocumento17 pagineSD 1 AssignmentAnuj Chandiwala100% (1)

- Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition): Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Da EverandComposite Steel and Concrete Structures: Fundamental Behaviour (Second Edition): Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Valutazione: 4 su 5 stelle4/5 (10)

- Tut 1 4 - SD I SteelDocumento4 pagineTut 1 4 - SD I SteelChirag N PatelNessuna valutazione finora

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDa EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNessuna valutazione finora

- Dss - Question BankDocumento10 pagineDss - Question Bankapi-306484475Nessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Se-2 Unit 2 Prevous Jntuh QuestionsDocumento3 pagineSe-2 Unit 2 Prevous Jntuh QuestionsNishanth NishiNessuna valutazione finora

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDa EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNessuna valutazione finora

- Exercises and REVIEW QUESTIONS 2018Documento12 pagineExercises and REVIEW QUESTIONS 2018Thiên LongNessuna valutazione finora

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDa EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNessuna valutazione finora

- ST7203 SteelStructuresquestionbankDocumento12 pagineST7203 SteelStructuresquestionbankAshok AmmaiyappanNessuna valutazione finora

- ST7203 Steel Structures Question BankDocumento12 pagineST7203 Steel Structures Question BankFinney WilsonNessuna valutazione finora

- ST CBC STDocumento5 pagineST CBC STRoshni TNessuna valutazione finora

- 08 601 DSS AssignmentDocumento4 pagine08 601 DSS Assignmentgskodikara2000Nessuna valutazione finora

- Dss - AssignmentDocumento4 pagineDss - Assignmentapi-306484475Nessuna valutazione finora

- CE6603-Design of Steel StructuresDocumento12 pagineCE6603-Design of Steel StructuresIsrael VenkatNessuna valutazione finora

- DRC Important QuestionsDocumento11 pagineDRC Important QuestionsAdithya31Nessuna valutazione finora

- Design of Reinforced Concrete Elements QuestionsDocumento16 pagineDesign of Reinforced Concrete Elements QuestionsbalabhaiNessuna valutazione finora

- 2769 ST7101 Concrete StructuresDocumento8 pagine2769 ST7101 Concrete StructureslavanyaNessuna valutazione finora

- Lec 2Documento22 pagineLec 2Prashant ShivhareNessuna valutazione finora

- Chapterwise Question bank-DSR-22502Documento5 pagineChapterwise Question bank-DSR-22502soumyasonawane100% (1)

- CE2306-Design of RC Elements PDFDocumento16 pagineCE2306-Design of RC Elements PDFManikandanNessuna valutazione finora

- CE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksDocumento9 pagineCE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksrexdindigulNessuna valutazione finora

- CE 2306 Design of RC Elements Question Bank Download HereDocumento11 pagineCE 2306 Design of RC Elements Question Bank Download HereViswanathan NatesanNessuna valutazione finora

- 3 Winter-12Documento2 pagine3 Winter-12harnishtanna21285Nessuna valutazione finora

- Ce2306-Design of RC ElementsDocumento8 pagineCe2306-Design of RC ElementsAnu PartheeNessuna valutazione finora

- CE6505-Design of RC ElementsDocumento15 pagineCE6505-Design of RC ElementsManikandanNessuna valutazione finora

- Important RCC Questions-Short and LongDocumento15 pagineImportant RCC Questions-Short and LongmailjoelsamuelNessuna valutazione finora

- Unit - I: Subject Name: Design of RC ElementsDocumento10 pagineUnit - I: Subject Name: Design of RC ElementsManikandan SelvamNessuna valutazione finora

- Dss Question Bank 2022Documento7 pagineDss Question Bank 2022vcb57xbtd5Nessuna valutazione finora

- Ce6505 RCDocumento12 pagineCe6505 RCpwd2007Nessuna valutazione finora

- DRC Unit WiseDocumento12 pagineDRC Unit WiseSasikumar Viswanathan100% (1)

- 1.-BTCVC601 DCS-I UpdatedDocumento4 pagine1.-BTCVC601 DCS-I UpdatedAmaan ShaikhNessuna valutazione finora

- DRCE IAT 1 - 14.09.22 - StudentsDocumento2 pagineDRCE IAT 1 - 14.09.22 - Studentsandalsureshkumar123Nessuna valutazione finora

- Dss 5set New 2015 - PT MeDocumento11 pagineDss 5set New 2015 - PT MeVishnu SamyNessuna valutazione finora

- Dme Home Assignment 2019-20Documento4 pagineDme Home Assignment 2019-20VenkateshNessuna valutazione finora

- CE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksDocumento12 pagineCE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksBalaji KumarNessuna valutazione finora

- 9A01601 Design & Drawing of Steel StructuresDocumento5 pagine9A01601 Design & Drawing of Steel StructuressivabharathamurthyNessuna valutazione finora

- Steel Tutorial 2,3,4,5,6,7Documento7 pagineSteel Tutorial 2,3,4,5,6,7Sankalp LamaNessuna valutazione finora

- Tods-5 QBDocumento2 pagineTods-5 QBSayyam SanchetiNessuna valutazione finora

- Ce 2306 QB Unit-IDocumento2 pagineCe 2306 QB Unit-IManikandan SelvamNessuna valutazione finora

- STEEL AssignmentDocumento1 paginaSTEEL AssignmentthulscivilNessuna valutazione finora

- PSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterDocumento2 paginePSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterRamkumarNessuna valutazione finora

- Unit - Iii: Srividya College of Engineering and Technology Question BankDocumento8 pagineUnit - Iii: Srividya College of Engineering and Technology Question BankAravindNessuna valutazione finora

- Kings: Department of Mechanical EngineeringDocumento14 pagineKings: Department of Mechanical EngineeringAdam AhmadNessuna valutazione finora

- Design of Steel Structures Model Question Paper B.tech, III-II SemesterDocumento2 pagineDesign of Steel Structures Model Question Paper B.tech, III-II SemesterHarithaReddy1293Nessuna valutazione finora

- DoS ModelDocumento2 pagineDoS ModelKrishna KumarNessuna valutazione finora

- Mech-V-Design of Machine Elements I (10me52) - AssignmentDocumento10 pagineMech-V-Design of Machine Elements I (10me52) - AssignmentArunNessuna valutazione finora

- Prestressed ConcreteDocumento8 paginePrestressed ConcreteYeswanth RaghavendraNessuna valutazione finora

- Design of Reinforced Concrete StructuresDocumento6 pagineDesign of Reinforced Concrete StructuresRavindra MRNessuna valutazione finora

- Pre Stressed ConcreteDocumento8 paginePre Stressed Concretevamsi_rsNessuna valutazione finora

- Compression Members AssignmentsDocumento3 pagineCompression Members AssignmentsvivekNessuna valutazione finora

- DRCE IAT 1 - 15.09.23 - StudentsDocumento2 pagineDRCE IAT 1 - 15.09.23 - Studentsandalsureshkumar123Nessuna valutazione finora

- Design Drawing of Steel StructuresDocumento4 pagineDesign Drawing of Steel StructuresDEVINessuna valutazione finora

- (-) Design of Steel Concrete Composite Structures Question BankDocumento11 pagine(-) Design of Steel Concrete Composite Structures Question BankanhxuanqbNessuna valutazione finora

- UNIT-1: Department of Mechanical EngineeringDocumento14 pagineUNIT-1: Department of Mechanical EngineeringManivannan JeevaNessuna valutazione finora

- Advanced Steel StructureDocumento1 paginaAdvanced Steel StructureAmit ThoriyaNessuna valutazione finora

- Gujarat Technological University: Subject Code: 1055004 Subject Name: Structure V Time: 02:30 PM To 04:30 PMDocumento1 paginaGujarat Technological University: Subject Code: 1055004 Subject Name: Structure V Time: 02:30 PM To 04:30 PMwehoxak452Nessuna valutazione finora

- Unit - II Tension Members: Two Mark Question and AnswersDocumento7 pagineUnit - II Tension Members: Two Mark Question and AnswersSourabh SrivastavaNessuna valutazione finora

- The Little Liste: Lvashington, D.CDocumento5 pagineThe Little Liste: Lvashington, D.CNur AgustinusNessuna valutazione finora

- 1st Periodical Test in English 2019-2020Documento10 pagine1st Periodical Test in English 2019-2020ginadel timanNessuna valutazione finora

- MeasurementDocumento55 pagineMeasurementAna Mae AbiertasNessuna valutazione finora

- Interpolation and The Lagrange PolynomialDocumento9 pagineInterpolation and The Lagrange PolynomialEmmanuel Jerome TagaroNessuna valutazione finora

- Chlor-Alkali Membrane Cell ProcessDocumento213 pagineChlor-Alkali Membrane Cell Processdow2008Nessuna valutazione finora

- IGCSE Chemistry Chapter 1Documento7 pagineIGCSE Chemistry Chapter 1Spike ChingyenNessuna valutazione finora

- Predicting Drilling Mud Loss Occurrence While Using Directional Drilling To Install Pipelines Across RiversDocumento20 paginePredicting Drilling Mud Loss Occurrence While Using Directional Drilling To Install Pipelines Across RiversObumse Chukwuebuka MichaelNessuna valutazione finora

- Shigley Mechanical Engineering Design SODocumento182 pagineShigley Mechanical Engineering Design SOAtidech Tepputorn100% (1)

- Bisection MethodDocumento4 pagineBisection MethodSulaiman AhlakenNessuna valutazione finora

- KINEMATICS - Scientific PaperDocumento8 pagineKINEMATICS - Scientific PaperDai VenusNessuna valutazione finora

- Masters Thesis by Evan O'Brien Final Draft PDFDocumento184 pagineMasters Thesis by Evan O'Brien Final Draft PDFkatfy1Nessuna valutazione finora

- Effect of Corrugation Angle On Performance Evaluation of Plate Type Heat ExchangerDocumento6 pagineEffect of Corrugation Angle On Performance Evaluation of Plate Type Heat ExchangerZaw Htet WinNessuna valutazione finora

- Computer Vision Three-Dimensional Data From ImagesDocumento12 pagineComputer Vision Three-Dimensional Data From ImagesminhtrieudoddtNessuna valutazione finora

- Matrix InverseDocumento2 pagineMatrix InverseComFnoNessuna valutazione finora

- The Chemistry, Morphology, Topography of TitaniumDocumento11 pagineThe Chemistry, Morphology, Topography of TitaniumtihinjoNessuna valutazione finora

- Nitro Nic 60 BookDocumento36 pagineNitro Nic 60 BookGerman ToledoNessuna valutazione finora

- Lab Report 7 Center of MassDocumento8 pagineLab Report 7 Center of Massartemm27Nessuna valutazione finora

- Structural Analysis NotesDocumento166 pagineStructural Analysis NotesdunyNessuna valutazione finora

- Catalogue Axces Silenciadores de EscapeDocumento47 pagineCatalogue Axces Silenciadores de EscapeBenjamín AlainNessuna valutazione finora

- 14.4D ExerciseDocumento18 pagine14.4D ExerciseKnyazev DanilNessuna valutazione finora

- Chapter 3 Haemoglobin Pattern Analysis: 3.1. Chromatographic Methods (For Hba Determination)Documento27 pagineChapter 3 Haemoglobin Pattern Analysis: 3.1. Chromatographic Methods (For Hba Determination)সোমনাথ মহাপাত্রNessuna valutazione finora

- High Power CycloconverterDocumento7 pagineHigh Power Cycloconverternapster26Nessuna valutazione finora

- Vfd-E: Parameter ManualDocumento26 pagineVfd-E: Parameter ManualMohamed ElsayedNessuna valutazione finora

- Problem Set 6: 2m 00 E E Ikx IkxDocumento3 pagineProblem Set 6: 2m 00 E E Ikx IkxDaljot Singh KangNessuna valutazione finora

- Cathedrals of Science - The Personalities and Rivalries That Made Modern ChemistryDocumento400 pagineCathedrals of Science - The Personalities and Rivalries That Made Modern ChemistryPushkar Pandit100% (1)

- BC Series 7 - 04-05-10Documento39 pagineBC Series 7 - 04-05-10Krista TranNessuna valutazione finora

- By Dr. Gamal Helmy, PH.D., P.EDocumento43 pagineBy Dr. Gamal Helmy, PH.D., P.EAhmed ArafaNessuna valutazione finora

- Seminar MehkaDocumento23 pagineSeminar MehkaRudi HermanaNessuna valutazione finora

- E 140Documento23 pagineE 140Luna Hernandez Ricardo100% (1)

- Jyotish How K P Pinpoint Events Prasna K HARIHARANDocumento116 pagineJyotish How K P Pinpoint Events Prasna K HARIHARANSunil Rupani100% (5)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDa EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureValutazione: 4.5 su 5 stelle4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDa EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresValutazione: 1 su 5 stelle1/5 (2)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsDa EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNessuna valutazione finora

- Advanced Modelling Techniques in Structural DesignDa EverandAdvanced Modelling Techniques in Structural DesignValutazione: 5 su 5 stelle5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (138)

- Piping Engineering Leadership for Process Plant ProjectsDa EverandPiping Engineering Leadership for Process Plant ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Da EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Valutazione: 4 su 5 stelle4/5 (3)

- Non-destructive Testing and Evaluation of Civil Engineering StructuresDa EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacNessuna valutazione finora

- Predicting Lifetime for Concrete StructureDa EverandPredicting Lifetime for Concrete StructureNessuna valutazione finora

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesDa EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesValutazione: 4.5 su 5 stelle4.5/5 (13)

- Structural Cross Sections: Analysis and DesignDa EverandStructural Cross Sections: Analysis and DesignValutazione: 4.5 su 5 stelle4.5/5 (19)

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildDa EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildValutazione: 5 su 5 stelle5/5 (5)

- Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsDa EverandMechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsNessuna valutazione finora

- A Welder’s Handbook to Robotic ProgrammingDa EverandA Welder’s Handbook to Robotic ProgrammingValutazione: 5 su 5 stelle5/5 (3)

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSDa EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSNessuna valutazione finora

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsDa EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsValutazione: 5 su 5 stelle5/5 (3)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDa EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsValutazione: 4 su 5 stelle4/5 (16)

- Earthquake-Resistant Structures: Design, Build, and RetrofitDa EverandEarthquake-Resistant Structures: Design, Build, and RetrofitValutazione: 4.5 su 5 stelle4.5/5 (8)

- The AI Generation: Shaping Our Global Future with Thinking MachinesDa EverandThe AI Generation: Shaping Our Global Future with Thinking MachinesValutazione: 4 su 5 stelle4/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Da EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Valutazione: 4 su 5 stelle4/5 (5)