Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gas Turbine Facts & Formulaes

Caricato da

ASHUTOSH RANJANCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gas Turbine Facts & Formulaes

Caricato da

ASHUTOSH RANJANCopyright:

Formati disponibili

mmmjnjjj1.

Efficiency of the gas turbine

The total energy balance in a gas turbine can be summarized as

Total energy input = Compressor load + Generator power output + Flue gas energy loss + rotational

losses

with the exception of the rotational losses all others can be calculated in a easy manner , what you need

is the following information.

1. Calorific value of the fuel (kcal/kg)

2. Mass flow rate of the fuel (kg/s or t/hr) (if only the volume flow is available then you need to know

the density of the fuel)

3. air flow into the turbine ( this is tricky most of the sites do not have a air flow meter , you have to get

it from the characteristic graphs which GE provides , you can also get the value form the site

acceptance test or the performance guarantee test done at commissioning)

if you have a HRSG , which you probably will have then you can calculate the efficiency of the HRSG

and also the combined efficient of the total co generation power plant, for this you need the additional

data

Note - i do not know the layout of your plant or its operating nature , i am assuming that the steam used

for deaeration is got from the plant itself and CPH if present is inside the HRSG itself. you need to

work out the details yourself , i am giving the calculations for a self sustaining plant. ie it takes only

water at room temp and fuel and gives out power and steam. The plant axillary consumption which will

be around 2-4% of the plant full load is neglected in the calculation. mainly because i do not have

sufficient data.

The basic equations for the calculation are

For GT

Efficiency = 860*MW output (MwHr) / (fuel flow(kg) * calorific value

of fuel(in kcal/kg))

this is the base formula where fuel flow is normally available in M3 which you

have to convert to mass with the known density.

for HRSG

efficiency (overall) = steam flow rate * enthalpy of steam / (HRSG

inlet temp * 0.25 * air flow rate)

efficiency (heat exchanger) = steam flow rate * enthalpy of steam / (

(HRSG inlet temp - HRSG outlet temp) * 0.25 * air flow rate)

the combined efficiency of the co generation is given by

efficiency = ( (860*MW output (MwHr)) + steam flow rate * enthalpy

of steam) / (fuel flow(kg) * calorific value of fuel(in kcal/kg))

sample calculation

I am now in a frame 5 site , so i am taking the daily production readings from

here. the values at your site will be different

Naptha consumption = 192m3

Power generation = 379 Mwhr

Average power generation / hr = 15.8 MW

Calorific value of naptha = 11250 kcal/kg

Naptha density = 0.7

the HRSG is a twin drum and produces two different steam varities one a VHP steam

at 48Kg/cm2 and 435 deg and other MP steam at 18kg/cm2 at 245 deg

Enthalpy of VHP steam = 785 kcal/kg

Enthalpy of IP steam = 692 kcal/kg

VHP steam production = 805 tonnes

average steam production / hr = 33.5 t/hr

MP steam production = 99 tonnes

average MP steam production /hr = 4.12 t/hr

HRSG inlet temperature = average GT exhaust temp

= 490 deg

HRSG outlet temperature = average stack temperature

= 140 deg

ambient temperature = 32 deg

air flow rate - the air flow for a frame 5 machine at site condition (32 deg

ambient) is 408 tonnes at 85 deg IGV opening , as the machine was put in cogen

cycle and the average IGV opening is 56 deg , from the chara graph the air flow is

estimated as 364 tonnes.

so

GT efficiency = (860 * 379 *100) / ( 192 * 0.7 * 11250)

=

21.57 %

HRSG efficiency (overall) = ( ( 33.5 * (785-30) ) + (4.12 * (692-30) ) ) / ( 490 *

0.25 * 364) ( here stack losses are taken into account)

=

62.83 %

HRSG efficiency (heat exchanger) = ( ( 33.5 * (785-30) ) + (4.12 * (692-30) ) ) /

( (490-140) * 0.25 * 364) ( here stack lossses not taken into account)

= 88 %

overall co-generation efficiency

= (860 * 379) + ( ( 805 * (785-30) ) + (99 * (69230) ) ) / ( 192 * 0.7 * 11250)

= 67 %

2.

MW = (J/s)*3600(s/hr)=3600(J/hr)=>MWhr=3600J

Lets say MWhr/kg value of naptha = 10,000; then your equation should read (there was a parentheses

misplaced in your equation, what you wrote was actually equal to 325940):

overall co-generation efficiency

>

= ((860 * 379)

>+ ( 805 * (785-30) ) + (99 * (692-30)

>) ) / ( 192 * 0.7 * 10,000)

>

= 74 %

3.

Energy balance in Gasturbine

inlet ambient air = 25 deg

cdp = 6.8kg/cm2

ctd = 302 deg

exhaust = 507 deg

fuel input = 1.7 kg/s

calorific value of naptha = 11250 kcal/kg

density of naptha = 0.71

power = 16 MW

air flow into the turbine = 360 t/hr

specific heat capacity of air = 0.25 kcal/kg deg

input energy into the turbine = fuel input + air input

fuel input = 1.7 * 3.6 * 11250 *(1000) kcal

= 68850 Mcal

air input = 360 * 0.25 * 302

= 27180 Mcal

total energy input to the turbine = 96030 Mcal

power output from the generator = 16*860

= 13760 Mcal

flue gas losses = (360+1.6*3.6)*0.25*507

= 46390 Mcal

compressor load and rotational losses = 96030 - (46390 + 13760)

= 96030 - 60150

= 35880 Mcal

this equated in terms of power = 35880/860

= 41 MW

4.

Power energy equivalents

1 kilowatt (KW) = 1 kilo joule/ sec

1 kilowatt sec ( Kw s) = 1 kilo joule

converting sec to hours , as Kw Hr is the standard for electrical energy

measurement

1 kilowatt hour (Kw Hr) = 3600 Kilo joule

now we know

1 calorie = 4.187 joules , this is the joules constant so

1 Kilo calorie = 4.187 Kilo joules

1 kilo joules = 0.23883 Kilo calories

so

1 Kilowatt hour (Kw Hr) = 3600 * 0.23883 Kilo calories

= 859.80416 Kilo calories

= 860 kilo calories ( this is a reasonable approximation)

this is the electrical energy and heat energy equivalence . This is how the 860 in

the formula came from.

Efficiency of the gas turbine

efficiency of the turbine = energy equivalent of generator Generator power

output / energy input into the turbine

energy equivalent of generator Generator power output = 860 * Kw-Hr

energy input into the turbine = Calorific value of the fuel (Kcal /kg) * fuel flow

( Kg/hr)

= 860 * Kw-hr / Calorific value of the fuel (Kcal

/kg) * fuel flow ( Kg/hr)

now multiplying both the numerator and denominator by thousand

= 860 * Kw-hr * 1000 / Calorific value of the fuel

(Kcal /kg) * fuel flow ( Kg/hr) * 1000

this converts the Kw-Hr to Mw-Hr and kg/hr to t/hr

= 860 * Mw-hr / calorific value of the fuel (Kcal/kg) *

fuel flow ( t/hr)

so this is how the energy efficiency of the gas turbine is derived.

i am also deriving a formula for heat rate of the turbine to the efficiency

heat rate of the turbine is defined as the The ratio of fuel energy input as heat

per unit of net work output. It is expressed mostly in Btu/Kwhr or in kj

/Kwhr . I am not a fan of Btu , but i am a ardent fan of SI units :) so i will

derive the equation here in Si units.

Heat rate = Kj/ Kwhr

Efficiency = KwHr * 3600 / Kj

Efficiency = 3600 / (kj/kwhr)

efficiency = 3600 / Heat rate

5.

Potrebbero piacerti anche

- Iso 50001 2018 en PDFDocumento11 pagineIso 50001 2018 en PDFRavi Agrawal44% (9)

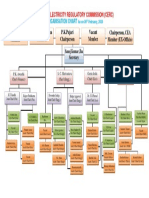

- ORGANIZATION CHART - Recent PDFDocumento1 paginaORGANIZATION CHART - Recent PDFASHUTOSH RANJANNessuna valutazione finora

- ORGANIZATION CHART - Recent PDFDocumento1 paginaORGANIZATION CHART - Recent PDFASHUTOSH RANJANNessuna valutazione finora

- Auction PhaseVIII Date Extend Corrigendum24012020Documento1 paginaAuction PhaseVIII Date Extend Corrigendum24012020ASHUTOSH RANJANNessuna valutazione finora

- NBPDCL Bill FormatDocumento1 paginaNBPDCL Bill FormatASHUTOSH RANJANNessuna valutazione finora

- Suzlonppt 130204115553 Phpapp01Documento10 pagineSuzlonppt 130204115553 Phpapp01ASHUTOSH RANJANNessuna valutazione finora

- Ifm Wind Power CMS enDocumento27 pagineIfm Wind Power CMS encesare.alcesteNessuna valutazione finora

- Tendernotice 1Documento15 pagineTendernotice 1ASHUTOSH RANJANNessuna valutazione finora

- Revised CORRIGENDUM TO NIT RFX 3000006938 Dated 10-Dec-2019Documento14 pagineRevised CORRIGENDUM TO NIT RFX 3000006938 Dated 10-Dec-2019ASHUTOSH RANJANNessuna valutazione finora

- FGD NewnormsDocumento4 pagineFGD NewnormsKumarrathinamNessuna valutazione finora

- Corrigendum1dtd03022020 PDFDocumento1 paginaCorrigendum1dtd03022020 PDFASHUTOSH RANJANNessuna valutazione finora

- Technological Parameters in Selecting Systems To Control Emissions in Thermal Power Plants BHELDocumento58 pagineTechnological Parameters in Selecting Systems To Control Emissions in Thermal Power Plants BHELASHUTOSH RANJANNessuna valutazione finora

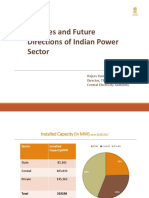

- Updates and Future Directions of Indian Power Sector: Rajeev Kumar Director, TPRM Division Central Electricity AuthorityDocumento28 pagineUpdates and Future Directions of Indian Power Sector: Rajeev Kumar Director, TPRM Division Central Electricity AuthorityASHUTOSH RANJANNessuna valutazione finora

- ABT Meter Details FormatDocumento4 pagineABT Meter Details FormatASHUTOSH RANJANNessuna valutazione finora

- Updates and Future Directions of Indian Power Sector: Rajeev Kumar Director, TPRM Division Central Electricity AuthorityDocumento28 pagineUpdates and Future Directions of Indian Power Sector: Rajeev Kumar Director, TPRM Division Central Electricity AuthorityASHUTOSH RANJANNessuna valutazione finora

- Annual Newsletter How Power Plant Try To Improve Their Merit Order RatingDocumento2 pagineAnnual Newsletter How Power Plant Try To Improve Their Merit Order RatingASHUTOSH RANJANNessuna valutazione finora

- Village Bill Complaint NoDocumento1 paginaVillage Bill Complaint NoASHUTOSH RANJANNessuna valutazione finora

- PGBDA 2019 Answer Key: Dear PGDBA 2019 Candidates, IMS Experts Have Released Answer Key For PGDBA 2019 TestDocumento3 paginePGBDA 2019 Answer Key: Dear PGDBA 2019 Candidates, IMS Experts Have Released Answer Key For PGDBA 2019 TestASHUTOSH RANJANNessuna valutazione finora

- Crisil Audit For Class of 2016Documento15 pagineCrisil Audit For Class of 2016ASHUTOSH RANJANNessuna valutazione finora

- Sample Bus TicketDocumento2 pagineSample Bus TicketASHUTOSH RANJANNessuna valutazione finora

- Url NRLDCDocumento1 paginaUrl NRLDCASHUTOSH RANJANNessuna valutazione finora

- Bus Ticket ConfirmationDocumento27 pagineBus Ticket ConfirmationASHUTOSH RANJANNessuna valutazione finora

- Extractine PR Drop and HPH TTD-DCA ImpactDocumento32 pagineExtractine PR Drop and HPH TTD-DCA ImpactASHUTOSH RANJANNessuna valutazione finora

- Sample Bus TicketDocumento2 pagineSample Bus TicketASHUTOSH RANJANNessuna valutazione finora

- Etuslggr Etghnrts DND Emoc Nyol Uoghhtr Frtoef Nda Hortwg OcuinuntsoDocumento6 pagineEtuslggr Etghnrts DND Emoc Nyol Uoghhtr Frtoef Nda Hortwg OcuinuntsoASHUTOSH RANJANNessuna valutazione finora

- Sample Questions Pgpex-VlmDocumento5 pagineSample Questions Pgpex-VlmASHUTOSH RANJANNessuna valutazione finora

- Energy Savings Calculator - VFD Retrofit AnalysisDocumento37 pagineEnergy Savings Calculator - VFD Retrofit AnalysisASHUTOSH RANJANNessuna valutazione finora

- Inteecpa Otmiaoibncn Nad Nitspparerio Na Lbuaaeetbn Orf Uessscc Esiencspetr EakmDocumento6 pagineInteecpa Otmiaoibncn Nad Nitspparerio Na Lbuaaeetbn Orf Uessscc Esiencspetr EakmASHUTOSH RANJANNessuna valutazione finora

- Energy Saving Measures and Payback CalculationsDocumento5 pagineEnergy Saving Measures and Payback CalculationsASHUTOSH RANJANNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Module 2Documento14 pagineModule 2Reginald VelanoNessuna valutazione finora

- Field Desorption, Field IonisationDocumento13 pagineField Desorption, Field Ionisationhey80milionNessuna valutazione finora

- Planetary Ball Mill Process in Aspect of Milling EnergyDocumento11 paginePlanetary Ball Mill Process in Aspect of Milling EnergyJesús IbarraNessuna valutazione finora

- SubhradipDocumento10 pagineSubhradipGreatNessuna valutazione finora

- Atomic Structure - JEE Mains PYQ 2020-2022Documento147 pagineAtomic Structure - JEE Mains PYQ 2020-2022pankaj baidNessuna valutazione finora

- Effects of Sugarcane Bagasse Ash and Nano Eggshell Powder On High Strength Concrete PropertiesDocumento18 pagineEffects of Sugarcane Bagasse Ash and Nano Eggshell Powder On High Strength Concrete PropertiesAce De GuzmanNessuna valutazione finora

- Year 8 - Atoms and Elements and Compounds and MixturesDocumento8 pagineYear 8 - Atoms and Elements and Compounds and MixturesAbhiraj SamantaNessuna valutazione finora

- Technical Data Sheet: Typical PropertiesDocumento2 pagineTechnical Data Sheet: Typical PropertiesahmedNessuna valutazione finora

- Types of pumps explainedDocumento1 paginaTypes of pumps explainedI AM NOT CHINESENessuna valutazione finora

- HMT Question Paper - Internal Test 1Documento2 pagineHMT Question Paper - Internal Test 1cbeprabhugmailNessuna valutazione finora

- Lee 2019Documento9 pagineLee 2019OkymailNessuna valutazione finora

- Introduction To Molecular Spectros PDFDocumento333 pagineIntroduction To Molecular Spectros PDFmekoki86% (7)

- Is 14331 1995Documento11 pagineIs 14331 1995shamrajjNessuna valutazione finora

- Yield Strength MatcalcDocumento91 pagineYield Strength MatcalcSibnath Kayal0% (1)

- Bmat Physics Formula SheetDocumento2 pagineBmat Physics Formula SheetsrinivasNessuna valutazione finora

- CFD FDM1 PDFDocumento2 pagineCFD FDM1 PDFSujoy DeNessuna valutazione finora

- Quantum Dot Laser Seminar Report 2004Documento27 pagineQuantum Dot Laser Seminar Report 2004yuben josephNessuna valutazione finora

- Chemistry Final Exam For Grade 9Documento5 pagineChemistry Final Exam For Grade 9debbie teferaNessuna valutazione finora

- Problems-6 40-6 41Documento7 pagineProblems-6 40-6 41Hasil SharmaNessuna valutazione finora

- Additive and Colour Preparations: For Extruded Polystyrene FoamsDocumento22 pagineAdditive and Colour Preparations: For Extruded Polystyrene FoamsKarim HakimNessuna valutazione finora

- Natural DisastersDocumento2 pagineNatural DisastersChue Sandi Woon SettNessuna valutazione finora

- Solution Manual For Principles of General Chemistry 3rd Edition by SilberbergDocumento19 pagineSolution Manual For Principles of General Chemistry 3rd Edition by Silberberga625797803100% (1)

- IB Chemistry Practical # Determines Standard Enthalpy Changes of Combustion for AlcoholsDocumento5 pagineIB Chemistry Practical # Determines Standard Enthalpy Changes of Combustion for Alcoholsysuzuki16Nessuna valutazione finora

- Engineering ThermoplasticsDocumento20 pagineEngineering ThermoplasticsclaurlNessuna valutazione finora

- p111 Lecture13Documento22 paginep111 Lecture13venkateshyadav2116Nessuna valutazione finora

- Ansi Isa-75.01.01-2012 (60534-2-1 Mod)Documento70 pagineAnsi Isa-75.01.01-2012 (60534-2-1 Mod)Abdelaadim FadlallahNessuna valutazione finora

- PM1610 - Leaflet (2023.04)Documento2 paginePM1610 - Leaflet (2023.04)Роман РакусовNessuna valutazione finora

- Tsunami Simulations Using Dashboard and Delft3DDocumento17 pagineTsunami Simulations Using Dashboard and Delft3DbukanastutikNessuna valutazione finora

- Combustion Physics by C K LawDocumento11 pagineCombustion Physics by C K LawSuvendu Kumar SethyNessuna valutazione finora

- Welding Process Related DefectsDocumento1 paginaWelding Process Related DefectskapsarcNessuna valutazione finora