Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

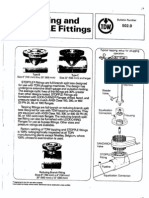

Model 8500A: Flame Trap Assembly

Caricato da

kasebTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Model 8500A: Flame Trap Assembly

Caricato da

kasebCopyright:

Formati disponibili

WASTEWATER

B IO GAS

CATA LO G

//

PAGE

37

Flame Trap Assembly

Model 8500A

This unit includes a Groth Model 7628

horizontal flame arrester and a Groth Model

8530 thermal operated shut-off valve. This

unit is generally installed in gas lines leading

from each digester and gas holder. They

are also installed in a line to gas utilization

equipment, as close as possible to the source

of combustion.

FEATURES

Sizes 2 (50 mm) through 12 (300 mm)

Aluminum (type 356-T6) and other

materials

Designed for quick and easy

maintenance

Factory Mutual approved flame arrester

SPECIAL FEATURES

The unit may be installed in horizontal or

vertical lines. The valve includes a fusible

element which melts at 260F and provides

shut-down within 15 seconds. A pyrex

sight glass is used to provide a view of the

indicator rod showing valve position. Easy

maintenance features are provided which

enable the quick removal and cleaning of

the Groth flame bank assembly. Additionally,

the fusible element is replaceable without

disassembly of valve.

END-OF-LINE

(Flanged Outlet with or without Discharge Piping)

Gas Group: NEC D, IEC IIA

Operating Temperature <= 140F (60C)

Pre-Ignition Pressure = Atmosphere

Discharge Piping Length <= 10 pipe diameters

S M A RT

RELIEF

BENEFITS

Simple replaceable fusible element for

ease of maintenance

Blocks gas flow in the presence of a flame

at the flame arrester, preventing damage

to upstream equipment

OPTIONS

Thermocouple/thermowell connection

Insulation jacket

Flame arrester drain connection

Instrument ports

IN-LINE

Gas Group: IEC IIA1, Methane

(includes most Biogas applications)

Operating Temperature <= 140F (60C)

Pre-Ignition Pressure <= 1 psig

Run-up Length <= 50 pipe diameters (2)

Run-up Length <= 20 pipe diameters (3)

Run-up Length <= 10 pipe diameters (4 12)

...

SA FE

SO LUTIO NS

Gas Safety & Control Equipment

FLAME TRAP ASSEMBLY

WASTEWATER

B I O G AS

CATALOG

//

PAG E

3 8

Flame Trap Assembly

Model 8500A

A

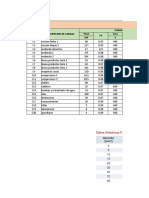

Specification Table Model 8500A

Specifications subject to change without notice.

Certified dimensions available upon request.

Size*

A

B

MAX

Approx. Ship

Wt. Lbs.

Length

Height

W.P.1

(Metric) (Metric) (Aluminum)

22.81

9.50

(50 mm)

(579 mm)

26.06

(241 mm)

(23 kg)

(80 mm)

(662 mm)

29.69

(279 mm)

12.50

(34 kg)

(100 mm)

(754 mm)

36.06

(318 mm)

16.50

(45 kg)

(150 mm)

(916 mm)

47.94

(419 mm)

20.50

(68 kg)

(200 mm)

(1218 mm)

55.75

(521 mm)

24.50

(91 kg)

(250 mm)

(1416 mm)

67.38

(622 mm)

28.50

(257 kg)

(300 mm)

(1711 mm)

(724 mm)

(325 kg)

10

12

0.689 barg

10 PSIG

11

50

75

100

150

200

565

715

* 150# ASME compatibility. F.F. on aluminum and R.F. on carbon steel and stainless steel alloys.

1. W.P. = Working Pressure

HOW TO ORDER

FOR EASY ORDERING, SELECT PROPER MODEL NUMBER

N OTES

MODEL #

SIZE

8500A

02

Thru

12

MATERIAL

OPTIONS

Flame Element

Flame Arrester

Z = Special Options

O = No Specials

Body Material

1 = Aluminum

Z = Special

For special options, consult factory.

EXAMPLE

Indicates a 2 Model 8500A with aluminum body, pallet and flame element and no special options.

S M ART

RELIEF

...

SA FE

SO LUTIO NS

WASTEWATER

B IO GAS

CATA LO G

//

PAGE

39

Flame Trap Assembly

Pressure

InWC

0.25

0.50

0.75

1.00

1.50

2.00

3.00

4.00

5.00

6.00

8.0

10.0

12.0

14.0

16.0

18.0

20.0

25.0

30.0

Air Flow Capacity

oz/in2

0.25

0.50

0.75

1.00

1.50

2.00

3.00

4.00

5.00

6.00

8.0

10.0

12.0

14.0

16.0

18.0

20.0

25.0

30.0

3 (80 mm)

1000 Standard Cubic Feet per Hour at 60 F

4 (100 mm)

6 (150mm)

8 (200 mm) 10 (250 mm) 12 (300 mm)

0.10

0.62 1.40 2.48 5.58 9.92 15.5 22.3

0.30

0.99 2.24 3.97 8.94 15.9 24.8 35.8

0.40

1.29 2.90 5.15 11.6 20.6 32.2 46.4

0.58

1.54 3.46 6.15 13.8 24.6 38.5 55.4

0.90

1.96 4.42 7.85 17.7 31.4 49.1 70.7

1.16

2.32 5.23 9.29 20.9 37.2 58.1 83.6

1.73

2.93 6.59 11.7 26.4 46.9 73.2 105

2.31

3.44 7.75 13.8 31.0 55.1 86.1 124

3.00

3.90 8.76 15.6 35.1 62.3 97.4 140

3.47 4.30 9.69 17.2 38.7 68.9 108 155

4.62 5.03 11.3 20.1 45.3 80.5 126 181

5.78 5.67 12.8 22.7 51.1 90.8 142 204

6.93 6.26 14.1 25.0 56.3 100 156 225

8.00 6.79 15.3 27.2 61.1 109 170 244

9.00 7.29 16.4 29.1 65.6 117 182 262

10.00 7.75 17.4 31.0 69.8 124 194 279

11.60 8.20 18.4 32.8 73.8 131 205 295

14.40 9.21 20.7 36.9 82.9 147 230 332

17.30 10.1 22.8 40.5 91.2 162 253 365

Pressure

InWC

2 (50 mm)

Flow Capacity of 0.7 SG Digester Gas

oz/in

2

2 (50 mm)

0.10 0.74

0.30 1.19

0.40 1.54

0.58 1.84

0.90 2.35

1.16 2.78

1.73 3.50

2.31 4.11

3.00 4.66

3.47 5.15

4.62 6.02

5.78 6.78

6.93 7.48

8.00 8.12

9.00 8.71

10.00 9.27

11.60 9.80

14.40 11.0

17.30 12.1

3 (80 mm)

1000 Standard Cubic Feet per Hour at 60 F

4 (100 mm)

1.67

2.67

3.46

4.14

5.28

6.25

7.88

9.26

10.5

11.6

13.5

15.3

16.8

18.3

19.6

20.9

22.0

24.8

27.2

S M A RT

6 (150mm) 8 (200 mm) 10 (250 mm) 12 (300 mm)

2.97

4.75

6.16

7.36

9.39

11.1

14.0

16.5

18.6

20.6

24.1

27.1

29.9

32.5

34.8

37.1

39.2

44.0

48.4

RELIEF

...

SA FE

6.67

10.7

13.9

16.6

21.1

25.0

31.5

37.0

41.9

46.3

54.1

61.0

67.3

73.0

78.4

83.4

88.2

99.1

109

SO LUTIO NS

11.9

19.0

24.6

29.4

37.5

44.4

56.0

65.8

74.5

82.3

96.2

109

120

130

139

148

157

176

194

18.5

29.7

38.5

46.0

58.7

69.4

87.5

103

116

129

150

170

187

203

218

232

245

275

303

26.7

42.7

55.4

66.2

84.5

100

126

148

168

185

217

244

269

292

314

334

353

396

436

Gas Safety & Control Equipment

Model 8500A

WAST EWATER

B I O G AS

CATALOG

//

PAG E

4 0

Flame Trap Assembly

Model 8500A

Pressure

mmWC

6.35

12.7

19.1

25.4

38.1

50.8

76.2

102

127

152

203

254

305

356

406

457

508

635

762

mbar

0.60

1.00

2.00

3.00

4.00

5.00

7.50

10.00

12.50

15.00

20.00

25.00

30.00

35.00

40.00

45.00

50.00

62.00

75.00

Pressure

mmWC mbar

6.35

12.7

19.1

25.4

38.1

50.8

76.2

102

127

152

203

254

305

356

406

457

508

635

762

0.60

1.00

2.00

3.00

4.00

5.00

7.50

10.00

12.50

15.00

20.00

25.00

30.00

35.00

40.00

45.00

50.00

62.00

75.00

Air Flow Capacity

2 (50 mm)

0.02

0.03

0.03

0.04

0.05

0.06

0.08

0.09

0.10

0.12

0.13

0.15

0.17

0.18

0.20

0.21

0.22

0.25

0.27

1000 Normal Cubic Meters per Hour at 0 C

3 (80 mm)

4 (100 mm)

0.04

0.06

0.08

0.09

0.12

0.14

0.18

0.21

0.23

0.26

0.30

0.34

0.38

0.41

0.44

0.47

0.49

0.55

0.61

0.07

0.11

0.14

0.16

0.21

0.25

0.31

0.37

0.42

0.46

0.54

0.61

0.67

0.73

0.78

0.83

0.88

0.99

1.08

6 (150mm)

0.15

0.24

0.31

0.37

0.47

0.56

0.71

0.83

0.94

1.04

1.21

1.37

1.51

1.64

1.76

1.87

1.98

2.22

2.44

8 (200 mm) 10 (250 mm) 12 (300 mm)

0.27

0.43

0.55

0.66

0.84

1.00

1.26

1.48

1.67

1.85

2.16

2.43

2.68

2.92

3.13

3.32

3.51

3.94

4.34

0.42

0.66

0.86

1.03

1.32

1.56

1.96

2.31

2.61

2.89

3.38

3.80

4.18

4.55

4.88

5.20

5.49

6.16

6.78

0.60

0.96

1.24

1.48

1.89

2.24

2.81

3.32

3.75

4.15

4.85

5.47

6.03

6.54

7.02

7.47

7.90

8.89

9.78

Flow Capacity of 0.7 SG Digester Gas

2 (50 mm)

0.02

0.03

0.04

0.05

0.06

0.07

0.09

0.11

0.12

0.14

0.16

0.18

0.20

0.22

0.23

0.25

0.26

0.29

0.32

3 (80 mm)

0.04

0.07

0.09

0.11

0.14

0.17

0.21

0.25

0.28

0.31

0.36

0.41

0.45

0.49

0.53

0.56

0.59

0.66

0.73

S M A RT

1000 Normal Cubic Meters per Hour at 0 C

4 (100 mm) 6 (150mm) 8 (200 mm) 10 (250 mm) 12 (300 mm)

0.08

0.13

0.17

0.20

0.25

0.30

0.38

0.44

0.50

0.55

0.65

0.73

0.80

0.87

0.93

0.99

1.05

1.18

1.30

RE LIEF

...

0.18

0.29

0.37

0.44

0.57

0.67

0.84

0.99

1.12

1.24

1.45

1.63

1.80

1.96

2.10

2.23

2.36

2.65

2.92

SA FE

SO LUTIO NS

0.32

0.51

0.66

0.79

1.00

1.19

1.50

1.76

2.00

2.20

2.58

2.92

3.21

3.48

3.72

3.96

4.21

4.72

5.20

0.50

0.80

1.03

1.23

1.57

1.86

2.34

2.76

3.11

3.46

4.02

4.55

5.01

5.44

5.84

6.22

6.56

7.37

8.12

0.72

1.14

1.48

1.77

2.26

2.68

3.38

3.96

4.50

4.96

5.81

6.54

7.21

7.82

8.41

8.95

9.46

10.61

11.68

Potrebbero piacerti anche

- Working of Breather Valve Working On TanksDocumento4 pagineWorking of Breather Valve Working On Tanks54045114Nessuna valutazione finora

- Calculo de Conductores E Interruptores Termomagneticos 380V, 60HzDocumento7 pagineCalculo de Conductores E Interruptores Termomagneticos 380V, 60HzGUTARRA QUISPE OSCAR ALEXANDERNessuna valutazione finora

- 3-Way Type Control Globe ValvesDocumento14 pagine3-Way Type Control Globe Valvesrohl55Nessuna valutazione finora

- ESAB Dual Shield 7100 UltraDocumento3 pagineESAB Dual Shield 7100 UltrahaldunNessuna valutazione finora

- Pipe Bending MachineDocumento4 paginePipe Bending MachineRockny2011Nessuna valutazione finora

- FlowCon SM DN50-250 Tech Note PDFDocumento7 pagineFlowCon SM DN50-250 Tech Note PDFViệt Đặng XuânNessuna valutazione finora

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Documento11 paginePDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18Nessuna valutazione finora

- MasterSeries 876V Specification SheetDocumento4 pagineMasterSeries 876V Specification SheetFEBCONessuna valutazione finora

- Fittings, Tubing & Nipples: Medium PressureDocumento12 pagineFittings, Tubing & Nipples: Medium PressureMehdi Mehdi100% (1)

- Silent Check Valve - Wafer and Globe Style - 2012Documento8 pagineSilent Check Valve - Wafer and Globe Style - 2012james_chan2178Nessuna valutazione finora

- KIMRAY ValveDocumento16 pagineKIMRAY ValveDenny Iskandar 'S-chuck'Nessuna valutazione finora

- Swagelok Ball ValveDocumento8 pagineSwagelok Ball ValveSyahirul AlimNessuna valutazione finora

- Felker LineCard-WebView 100319Documento4 pagineFelker LineCard-WebView 100319vineethNessuna valutazione finora

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Documento15 pagineInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)raobabar21Nessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- GgooDocumento4 pagineGgooPrem SharmaNessuna valutazione finora

- Service - Specifications Toyota ProboxDocumento85 pagineService - Specifications Toyota Proboxcpgmotors83% (6)

- Fresh Air AirconditioningDocumento1 paginaFresh Air AirconditioningMohammed Hassan Mohiuddin KhanNessuna valutazione finora

- Goulds AF: Axial Flow PumpsDocumento11 pagineGoulds AF: Axial Flow PumpsKarthick VenkateshNessuna valutazione finora

- Process Datasheet For Relief ValveDocumento3 pagineProcess Datasheet For Relief Valvemadhu8087Nessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- Basics of Piping EngineeringDocumento43 pagineBasics of Piping EngineeringAyushNessuna valutazione finora

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Documento5 pagineVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardNessuna valutazione finora

- MTX 2802S Guide en v1p 0105Documento6 pagineMTX 2802S Guide en v1p 0105sam77qNessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- Super Duty Coalescing FiltersDocumento2 pagineSuper Duty Coalescing FiltersEliasNessuna valutazione finora

- Wastewater Technical ManualDocumento32 pagineWastewater Technical ManualagonzalezcordovaNessuna valutazione finora

- Mapower Calculation & AllocationDocumento109 pagineMapower Calculation & AllocationSuresh GaneshNessuna valutazione finora

- Valia Group of CompaniesDocumento7 pagineValia Group of CompaniesEngr Arfan Ali DhamrahoNessuna valutazione finora

- Medidores AMERICAN METERSDocumento17 pagineMedidores AMERICAN METERSRaúl PalomoNessuna valutazione finora

- CS230 Consumables & Spare PartsDocumento2 pagineCS230 Consumables & Spare PartsMark FieldsNessuna valutazione finora

- Serie 740Documento4 pagineSerie 740Mabeli MartinezNessuna valutazione finora

- KirloskerDocumento36 pagineKirloskerArup NathNessuna valutazione finora

- ASME Boiler and Pressure Vessels Code - bpvc13Documento1 paginaASME Boiler and Pressure Vessels Code - bpvc13cristinelbNessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- Blackmer CompressorsDocumento4 pagineBlackmer CompressorsBesan LaduNessuna valutazione finora

- Showfou Electric BlowersDocumento27 pagineShowfou Electric BlowersSon Trinh PhuongNessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Documento4 pagineFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaNessuna valutazione finora

- Handbook of ElectromotorDocumento16 pagineHandbook of ElectromotorfrdnNessuna valutazione finora

- Catalog Profile Cu Pereti SubtiriDocumento52 pagineCatalog Profile Cu Pereti Subtirinelutu12345100% (1)

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- Common Specifications For Briggs & Stratton All Single Cylinder Ohv Engine Models Except Intek Models PDFDocumento2 pagineCommon Specifications For Briggs & Stratton All Single Cylinder Ohv Engine Models Except Intek Models PDFigrekqaNessuna valutazione finora

- Hot TappingDocumento6 pagineHot TappingbravoalfadeltaNessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Documento2 pagineEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNessuna valutazione finora

- Spir Star 2013Documento259 pagineSpir Star 2013Ahmadreza AminianNessuna valutazione finora

- L I G H TDocumento4 pagineL I G H TPrem SharmaNessuna valutazione finora

- Snap-Tite Check ValvesDocumento8 pagineSnap-Tite Check ValvesMauricio De'LeónNessuna valutazione finora

- MDDEDocumento4 pagineMDDEThanh DuyNessuna valutazione finora

- Lennox G26Documento53 pagineLennox G26Kyle ZielinskiNessuna valutazione finora

- 13 - Solenoid Operated Directional Valve WE-SNSDocumento16 pagine13 - Solenoid Operated Directional Valve WE-SNSNookang SeaSunNessuna valutazione finora

- Constant Hangers, Constant Supports: Product GroupDocumento27 pagineConstant Hangers, Constant Supports: Product GroupEttore MazzeiNessuna valutazione finora

- TUBACEX Power Generation 10Documento12 pagineTUBACEX Power Generation 10walitedisonNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Drilling Fluids Processing HandbookDa EverandDrilling Fluids Processing HandbookValutazione: 4.5 su 5 stelle4.5/5 (4)

- What Is The Difference Between Actual Standard and Normal FlowsDocumento13 pagineWhat Is The Difference Between Actual Standard and Normal FlowskasebNessuna valutazione finora

- Dezurik Uninterrupted Seat Resilient Seated Butterfly Valves Bos Us Bos Us Uninterrupted Seat Resilient Seated Butterfly Valves Sales 46-00-1aDocumento4 pagineDezurik Uninterrupted Seat Resilient Seated Butterfly Valves Bos Us Bos Us Uninterrupted Seat Resilient Seated Butterfly Valves Sales 46-00-1akasebNessuna valutazione finora

- Project Manual Water Plant No. 4 Ground Storage Tank Demolition CITY BID NO. 2122-05 City of Atlantic Beach, FloridaDocumento142 pagineProject Manual Water Plant No. 4 Ground Storage Tank Demolition CITY BID NO. 2122-05 City of Atlantic Beach, FloridakasebNessuna valutazione finora

- Process Costing and Hybrid Product-Costing Systems: Mcgraw-Hill/IrwinDocumento39 pagineProcess Costing and Hybrid Product-Costing Systems: Mcgraw-Hill/IrwinkasebNessuna valutazione finora

- Garlock 22 Red SBR Rubber Sheet Data SheetDocumento1 paginaGarlock 22 Red SBR Rubber Sheet Data SheetkasebNessuna valutazione finora

- Chapter 21 The Statement of Cash Flows RevisitedDocumento123 pagineChapter 21 The Statement of Cash Flows RevisitedkasebNessuna valutazione finora

- Chapter 1 - Coaching and Management - Mujtaba - 2008Documento22 pagineChapter 1 - Coaching and Management - Mujtaba - 2008kasebNessuna valutazione finora

- Chap 009 Managerial Accounting HiltonDocumento50 pagineChap 009 Managerial Accounting Hiltonkaseb100% (1)

- Chap 010Documento69 pagineChap 010Yuki TakenoNessuna valutazione finora

- Chapter 2. The Basics of Supply and DemandDocumento9 pagineChapter 2. The Basics of Supply and DemandkasebNessuna valutazione finora

- Chap 008 Managerial Accounting HiltonDocumento48 pagineChap 008 Managerial Accounting HiltonkasebNessuna valutazione finora

- Product Costing and Cost Accumulation in A Batch Production EnvironmentDocumento50 pagineProduct Costing and Cost Accumulation in A Batch Production EnvironmentHendro WijayaNessuna valutazione finora

- The Changing Role of Managerial Accounting in A Dynamic Business EnvironmentDocumento31 pagineThe Changing Role of Managerial Accounting in A Dynamic Business Environmentkaseb100% (2)

- 942 15Documento1 pagina942 15Gia Trish100% (2)

- Structural Analysis and Design of Commercial Building: Supervised byDocumento43 pagineStructural Analysis and Design of Commercial Building: Supervised bySudip ShresthaNessuna valutazione finora

- Pressure Rating For SSII Float EquipmentDocumento2 paginePressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikNessuna valutazione finora

- The Knelson Concentrator: Application and Operation at RoseberyDocumento9 pagineThe Knelson Concentrator: Application and Operation at RoseberyVivek RanganathanNessuna valutazione finora

- RKB Bearing Tolerances and Radial Internal ClearancesDocumento36 pagineRKB Bearing Tolerances and Radial Internal ClearancesCAT CYLINDERNessuna valutazione finora

- Diseño Cercha Metalica Tipo I VerificadoDocumento36 pagineDiseño Cercha Metalica Tipo I VerificadoJosé Mario Blacutt AléNessuna valutazione finora

- Ashby - Biomaterials PDFDocumento26 pagineAshby - Biomaterials PDFPao FrancavillaNessuna valutazione finora

- NFC 33-209Documento2 pagineNFC 33-209shivam dwivedi0% (1)

- Mitsubishi SF JFDocumento12 pagineMitsubishi SF JFLucky AndoyoNessuna valutazione finora

- Answers & Solutions: JEE (Advanced) - 2019Documento40 pagineAnswers & Solutions: JEE (Advanced) - 2019Amogh VaishnavNessuna valutazione finora

- Wolfson Eup3 Ch18 Test BankDocumento18 pagineWolfson Eup3 Ch18 Test BankifghelpdeskNessuna valutazione finora

- Math IMU CET Sample Questions 03Documento14 pagineMath IMU CET Sample Questions 03nh648rfhNessuna valutazione finora

- Lesson Plan Solar SystemDocumento4 pagineLesson Plan Solar SystemAnneValdezAcostaNessuna valutazione finora

- Gulfmaster Manual PDFDocumento15 pagineGulfmaster Manual PDFJoan RosanwoNessuna valutazione finora

- Koyo Oil SealDocumento119 pagineKoyo Oil Sealvicksgeorge100% (1)

- QTMS Brochure Rev2Documento8 pagineQTMS Brochure Rev2ManibalanNessuna valutazione finora

- 1 Introduction To Nodal AnalysisDocumento35 pagine1 Introduction To Nodal AnalysisuytNessuna valutazione finora

- Amc 05 QiDocumento7 pagineAmc 05 QiYosef KiakNessuna valutazione finora

- Contoh Dan Jawaban Soal Metode Elemen HinggaDocumento16 pagineContoh Dan Jawaban Soal Metode Elemen HinggadhiafahheraNessuna valutazione finora

- Aestiva MRIDocumento18 pagineAestiva MRImalamandeaceroNessuna valutazione finora

- Science 8 ExamDocumento5 pagineScience 8 Examangge21100% (1)

- Robotics Question Bank IIDocumento2 pagineRobotics Question Bank IIsai sudeepNessuna valutazione finora

- Y12 Chemistry Initial AssessmentDocumento58 pagineY12 Chemistry Initial AssessmentGeorge DrakeNessuna valutazione finora

- Product Specifications: CharacteristicsDocumento5 pagineProduct Specifications: CharacteristicsDaniel Herrera AstudilloNessuna valutazione finora

- MEG 203 Engineering ThermodynamicsDocumento77 pagineMEG 203 Engineering ThermodynamicsOyekale IniNessuna valutazione finora

- FEBio Theory Manual 1.0Documento43 pagineFEBio Theory Manual 1.0palmajoaquin99Nessuna valutazione finora

- 2.2 GHZ Laser HHODocumento32 pagine2.2 GHZ Laser HHOalkatrash100% (3)

- GNSS Based Synchronisation Solutions: Rakon AdvantagesDocumento2 pagineGNSS Based Synchronisation Solutions: Rakon AdvantagesullascsNessuna valutazione finora

- MALA MiniMIRA Technical SpecificationsDocumento1 paginaMALA MiniMIRA Technical SpecificationsALfian FebriantoNessuna valutazione finora