Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pressure Driven Processes

Caricato da

dei_sandeep7994Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pressure Driven Processes

Caricato da

dei_sandeep7994Copyright:

Formati disponibili

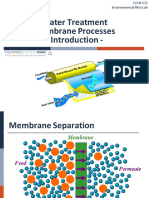

Membrane Separations

- Pressure-driven membrane processes:

P=

MF

0.11-0.3 MPa

UF

0.15-0.5 MPa

NF

0.5-1.5 MPa

Low molecular substances,

single charged ions

Mid-size organic substances,

multiple charged ions

High molecular substances, viruses

Bacteria, parasites, particles

RO

0.5-1.5 MPa

Membrane Separations

- Pressure-driven membrane processes:

Microfiltration (MF)

Ultrafiltration (UF)

Nanofiltration (NF)

Reverse Osmosis (RO)

Membrane Separations

Microfiltration (MF)

- First commercially developed (1930).

- Very popular and used (sharing with RO).

- Pore size between 0.05 and 10 m (0.45 m).

- Rejects particles between 0.2 and 10 m.

- Bacteria, fragmented cells or colloids.

- MW 300000.

- Driving force: pressure difference.

- Low operation pressure: 0.2 to 3.5 bar.

- Typical flux: > 200 L m-2 h-1.

Membrane Separations

Microfiltration (MF)

- Separation given by size exclusion mechanism.

- Flux: Hagen-Poiseuille or Kozeny-Carman.

- Hydrophobic membranes.

- Occurrence of adsorption

effects between the

membrane surface and the

rejected species.

- Important fouling and pore plugging.

- Dead-end filtration and cleaning.

Repels water

Absorbs oil

Fouls with free oils

Lower flux

Difficult to clean

Repels oils

Absorbs water

Not fouled by free oils

Higher flux

Easier to clean

Membrane Separations

Microfiltration (MF)

- Polymeric membranes made of a wide variety of

polymers or polymers blends:

PTFE, PVDF, PP, PS, CA, CN, CTA, PE, PC,

PEST, PI, Nylon ...

CA, CN o CTA are preferred due to their

hydrophilicity preventing fouling.

- Also ceramic, basically -Al2O3, because of

their easy cleaning, long lifetime and available

sterilisation

Membrane Separations

Microfiltration (MF)

- Applications:

Bioengineering, food industry, wastewater

treatment. Examples:

High organic loading water treatment.

Cutting oil emulsion treatment.

Juice, wine or beer clarification.

Fermentation product separation.

Recovering of precipitated metals.

Membrane Separations

Ultrafiltration (UF)

- Microporous membranes (?).

- Pore size between 1 and 50 nm.

- Rejects particles from 15 to 2000 .

- Polymers, proteins and colloids.

- Molecular weight from 5000 to 5106 Daltons*.

- Driving force: pressure difference.

- Moderate operating pressure: 1 to 10 bar.

- Typical flux: 5-200 L m-2 h-1.

* 1 Dalton 1.6610-24 g

Membrane Separations

Ultrafiltration (UF)

- Characteristic parameter: Molecular Weight Cut-Off

MWCO is the minimum MW the rejection being of

90%*.

Relation between MWCO and the pore size for UF

membranes.

Pore Diameter

MWCO (Daltons)

P

nm

1000000

0.1

100

1000

500000

0.02

20

200

100000

0.01

10

100

50000

0.04

40

10000

0.0025

2.5

25

5000

0.0015

1.5

15

* To design, the membrane MWCO must be taken about the half of lower MW species

to be retained.

Membrane Separations

Ultrafiltration (UF)

- Polymeric membranes made of a wide variety of

polymers or polymers blends:

CA, PS, PES, PAN, PVDF, PI

CA: low fouling, high flux.

PS: chemically stable.

PES: available sterilisation.

PI: solvent resistant, only tubular.

- Also ceramics, mainly made of and -Al2O3.

Easy cleaning, long lifetime and available

sterilisation.

Membrane Separations

Ultrafiltration (UF)

- Separation mostly given by size exclusion.

- In low pore size membrane, some solutiondiffusion phenomena are present (typical for

RO).

- Performance affected by pressure, temperature,

stirring, concentration and ionic environment.

- Significant fouling and pore plugging.

- Cross-flow filtration and cleaning.

- Any configuration.

Membrane Separations

Ultrafiltration (UF)

- Applications:

Food industry, wastewater treatment.

Also potentially useful paper pulping

or textile industry. Some Examples:

COD reduction in wastewater.

Treatment of cutting-oil emulsion.

Metal finishing water treatment.

Treatment of black-liquor from paper pulping.

Protein recovery from blood plasma.

Egg white concentration.

Serum recovery from milk.

Membrane Separations

Ultrafiltration (UF)

- Serum recovery from cheese production. The cheese production is a

biochemical process followed by precipitation (of the solid cheese). The

remaining solution contains, in addition to the water, the most part of the initial

lactose, proteins, vitamines and minerals.

Feed

Concentrate

UF

UF

UF

Permeate

Continuous UF process for recovering of lactoserum.

Membrane Separations

Nanofiltration (NF)

- Recent definition. Separation range between UF

and RO.

- Typical pore size 2 nm.

- Efficiently rejects, due to electrostatic interactions,

charged particles, mainly multivalent ions.

- Rejects non charged molecules (MW > 200 g/mol)

by molecular sieving.

- Driving force: pressure difference.

- Moderate Pressure: 15 bar.

- Typical flux: 20-80 L m-2 h-1.

Membrane Separations

Nanofiltration (NF)

- Polymeric membranes (CA, PA, PVA):

- Configuration of spiral-wound module.

- Applications: Water pretreatment, food industry,

recovery of metals.

Removal of coloured organic compounds and humic

acids (precursors of the trihalometanes).

Water softening (removal of multivalent ions).

- Still looking for applications. Potentially when

UF does not give sufficient rejection and RO is not

economical.

Membrane Separations

Nanofiltration (NF)

- In 1996 there were 150 plants all around the world

for drinking water by means of NF, with an overall

capacity of 600000 m3/day.

(compare with 3000000 m3/day capacity of plants

based on RO)

- For instance, it must be noted that NF is the

technology selected to obtain drinking water in

Florida (USA).

Membrane Separations

Reverse Osmosis (RO) [Hyperfiltration]

- Developed in the 50s.

- Very popular and used.

- Ions and low molecular weight species (MW < 200).

- Pore size < 1 nm.

- Water molecules freely pass (0.2 nm).

- Driving force: pressure difference.

- Operating pressure between 10-25 (brackish) and

40-80 bar (seawater).

- Average flux: 5-40 L m-2 h-1.

Membrane Separations

Reverse Osmosis (RO)

Membrane Separations

Reverse Osmosis (RO)

(1)

(2)

- Why does water cross the membrane ?

i = io (T )+ vi P + R T ln ( i ci )

(w1) = (w2)

v(w1) P (1) + R T ln a (w1) = v(w2) P ( 2) + R T ln a (w2)

membrane

v w P (1) P ( 2) = R T ln a (w2) R T ln a (w1)

=

Definition

R T

ln a w P =

vw

cR T

if csalts

Membrane Separations

Reverse Osmosis (RO)

Membrane Separations

Reverse Osmosis (RO)

- The water freely flows through the membrane

due to the pressure difference corrected by the .

J w = Q w = A (P )

Am

Jw: Solvent volume flux (m3/sm2)

Qw: Solvent volume flowrate (m3/s)

Am: Membrane area (m2)

A: Permeability (m3/sm2Pa)*

P: Hydraulic pressure difference (Pa)

: Osmotic pressure difference (Pa)

* A = AoKt Kc Ke

t: temperature; c: compaction; e: fouling

Membrane Separations

Reverse Osmosis (RO)

- Salt flux is due to both diffusion and convective

transport.

Js = J w Cp = B (Cm Cp ) + M J w Cm

J s B (Cm Cp )

Cp =

=

+ M Cm

J w A (P )

Js: Solute mass flux (mol/sm2)

Bi: Permeability (m/s)

Cm: Solute concentration on the membrane surface (mol/m3)

Cp: Solute concentration in the permeate (mol/m3)

M: Distribution constant (~ 0.005)

Membrane Separations

Reverse Osmosis (RO)

- Thus a relation between the local rejection,

Rl, and the permeate flux (or applied pressure)

can be found.

Cm Cp

Cp

Rl =

= 1

Cm

Cm

1 = 1 + B 1

R l (1 M ) (1 M ) J w

1 = 1 + B

1

R l (1 M ) (1 M ) A (P )

Membrane Separations

Reverse Osmosis (RO)

- Membranes mostly made of CA or PA.

- Configuration in spiral-wound or hollow fiber.

- Typical conversion between 10 and 30%.

- Flow limited by concentration polarisation.

- Rejection up to 99% (sometimes higher).

- Fouling problems and cleaning. Pretreatment.

Membrane Separations

Reverse Osmosis (RO)

- Concentration polarisation

boundary

layer

ln

cm

bulk

Jc

J cp

cp

dc

dx

D: Diffusion coeficient (m2/s)

/: boundary layer thickness (m)

k=D//: mass transfer coeficient (m/s)

cb cp

J

D

cm cp

J

= exp

cb cp

D

cb

D

cm cp

cm

=

cb

J

exp

k

J

R l + (1 R l ) exp

k

Membrane Separations

Reverse Osmosis (RO)

- Applications: Drinking water, food industry,

wastewater treatment. Examples:

Desalting of process water.

Desalination of brackish or seawater.

Production of ultrapure water for laboratories or

electronic industry.

Concentration wastewater in paper pulping.

Concentration of juices, milk or sugar solutions.

Concentration of coffee, te or soups.

Concentration of aminoacids (and other

pharmaceutical substances).

Membrane Separations

ED

5%

Reverse Osmosis (RO)

RO

35%

EVM

60%

- Seawater desalination:

30-40% market

Desalination technologies (1996)

Very competitive process

Module cascade in series and parallel

Comparison between the energetic cost for

seawater desalination.

Process

Energy (kWh/m3)

Multiple distillation

15.5

Reverse Osmosis

RO with energy recovery

9

6.5

Electrodialysis

12

Membrane Separations

Reverse Osmosis (RO)

Feed

UF

pretreatment

Permeate

1st pressure stage

: RO module

2nd pressure stage

Concentrate

Water production plant based on RO.

Potrebbero piacerti anche

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFDocumento13 pagineRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesNessuna valutazione finora

- Complete Practical DistillingDocumento254 pagineComplete Practical DistillingMR X100% (5)

- Presentation - Water TreatmentDocumento48 paginePresentation - Water TreatmentSudhir Jadhav50% (2)

- Completions and WorkoverDocumento309 pagineCompletions and WorkoverFan Jack67% (3)

- Quiz BiochemistryDocumento100 pagineQuiz BiochemistryMedShare88% (25)

- Water Treatment Membrane Processes PDFDocumento80 pagineWater Treatment Membrane Processes PDFmehdi hennousNessuna valutazione finora

- Water Treatment Calculations UpdatedDocumento68 pagineWater Treatment Calculations UpdatedApsara Katugaha100% (3)

- Electronic Devices and Circuits: In Three VolumesDa EverandElectronic Devices and Circuits: In Three VolumesValutazione: 3.5 su 5 stelle3.5/5 (2)

- (T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterDocumento214 pagine(T. R. Chouhan) Bhopal, The Inside Story - Carbide Workers Speak Out On The World's Worst Industrial DisasterANTENOR JOSE ESCUDERO GÓMEZNessuna valutazione finora

- Cooling TowersDocumento38 pagineCooling Towerskelik.suparmanNessuna valutazione finora

- Microfiltration (MF), Ultrafiltration (UF)Documento52 pagineMicrofiltration (MF), Ultrafiltration (UF)WONG TS80% (5)

- 1 0UF PresentationsDocumento55 pagine1 0UF PresentationsMoustafa HelmyNessuna valutazione finora

- Reduction of Environmental ImpactDocumento16 pagineReduction of Environmental ImpactJohn Vincent MalvarNessuna valutazione finora

- Interconection Pipe RackDocumento16 pagineInterconection Pipe RackPhucChuVanNessuna valutazione finora

- Membrane Filtration TechniquesDocumento53 pagineMembrane Filtration TechniquesSreejesh P C100% (1)

- Membranes Processes in Water TreatmentDocumento124 pagineMembranes Processes in Water TreatmentMuhammad Ishfaq100% (1)

- Membrane TypesDocumento92 pagineMembrane TypesVanditaa Kothari100% (1)

- Membrane Separation ProcessesDocumento93 pagineMembrane Separation ProcessesMohammad ShafiNessuna valutazione finora

- Membrane Separation Process-Week 10Documento52 pagineMembrane Separation Process-Week 10baymaxxxxxNessuna valutazione finora

- MF Uf NFDocumento69 pagineMF Uf NFNguyen Huu HieuNessuna valutazione finora

- Scale-Up of Protein Purification Downstream Processing Issues PDFDocumento13 pagineScale-Up of Protein Purification Downstream Processing Issues PDFCapNessuna valutazione finora

- Water Treatment CalculationsDocumento68 pagineWater Treatment CalculationsMarco MezaNessuna valutazione finora

- CH 8 Membrane SeparationDocumento52 pagineCH 8 Membrane SeparationhaudeitbaNessuna valutazione finora

- Water Treatment Membrane Processes 1659565243Documento124 pagineWater Treatment Membrane Processes 1659565243Engold Gold100% (1)

- Membrane Separation: Configuration - Modules.Transport - FoulingDocumento27 pagineMembrane Separation: Configuration - Modules.Transport - FoulingDan JamesNessuna valutazione finora

- Cyanide Treatment TechnologiesDocumento3 pagineCyanide Treatment Technologiesdei_sandeep7994Nessuna valutazione finora

- Chapter 2. Membrane Technologies For Industrial Wastewaters TreatmentDocumento40 pagineChapter 2. Membrane Technologies For Industrial Wastewaters TreatmentSophie LvNessuna valutazione finora

- Membrane Separation Processes - Technology and Business OpportunitiesDocumento41 pagineMembrane Separation Processes - Technology and Business OpportunitiesMashiro Hikari0% (1)

- DowDocumento8 pagineDowrammu2001Nessuna valutazione finora

- Surgical Sutures & BandagesDocumento49 pagineSurgical Sutures & BandagesAnni Sholihah100% (1)

- 810.00 MR-N, NC, NSDocumento110 pagine810.00 MR-N, NC, NSnqh2009100% (1)

- 01 Chapter 1Documento17 pagine01 Chapter 1darshiniloganathan8Nessuna valutazione finora

- 5B FiltrationDocumento58 pagine5B FiltrationWazif ZakwanNessuna valutazione finora

- Hinkova Membrane Introduc Web 11Documento60 pagineHinkova Membrane Introduc Web 11Nagwa MansyNessuna valutazione finora

- Membrane Technology TestDocumento10 pagineMembrane Technology TestfasihaNessuna valutazione finora

- CH 9 - Principles of UF MFDocumento33 pagineCH 9 - Principles of UF MFMohammad AlrasasiNessuna valutazione finora

- 2 SlidesDocumento24 pagine2 SlidesPhaedon LomisNessuna valutazione finora

- Lecture 1Documento37 pagineLecture 1AbeeraShujatNessuna valutazione finora

- 13 MembranesDocumento49 pagine13 MembranesAna NurkaromahNessuna valutazione finora

- 13 MembranesDocumento49 pagine13 Membraneswatersoul.nNessuna valutazione finora

- 13 MembranesDocumento49 pagine13 MembranesSusmit Nimje100% (1)

- 7 Membrane FiltrationDocumento52 pagine7 Membrane FiltrationFajar HusenNessuna valutazione finora

- Chapter 13: Membrane ProcessesDocumento26 pagineChapter 13: Membrane ProcessesJason ConnorNessuna valutazione finora

- Reverse Osmosis: Mohamed DarwishDocumento93 pagineReverse Osmosis: Mohamed DarwishHassanKMNessuna valutazione finora

- Membrane 1Documento41 pagineMembrane 1Abhishek GadhwalNessuna valutazione finora

- MF Uf NFDocumento69 pagineMF Uf NFShikha JaiswalNessuna valutazione finora

- Lecture 4Documento41 pagineLecture 4Yasemin KaradağNessuna valutazione finora

- Electronic Supplementary Information: Minimum Conductivity Needed Per Unit Membrane ThicknessDocumento16 pagineElectronic Supplementary Information: Minimum Conductivity Needed Per Unit Membrane ThicknessMadalinaNessuna valutazione finora

- Membrane TechnologyDocumento26 pagineMembrane TechnologyRajan sigdel100% (3)

- Membrane Separation Processes: G. H. Patel College of Engineering & Technology, V. V. NagarDocumento18 pagineMembrane Separation Processes: G. H. Patel College of Engineering & Technology, V. V. Nagarعمار ياسرNessuna valutazione finora

- BS 3 MembraneDocumento101 pagineBS 3 MembraneAyush Garg100% (1)

- Membrane Separations 3Documento29 pagineMembrane Separations 3NandhanNessuna valutazione finora

- Membrane Separation Processes: G. H. Patel College of Engineering & Technology, V. V. NagarDocumento18 pagineMembrane Separation Processes: G. H. Patel College of Engineering & Technology, V. V. NagarPaul Philip LabitoriaNessuna valutazione finora

- 18.0 RO Treatment ProcessDocumento42 pagine18.0 RO Treatment ProcessJawahir IlmNessuna valutazione finora

- CG5052 BPE 5.1-2 Membranes (Intro & Design) 20240118Documento45 pagineCG5052 BPE 5.1-2 Membranes (Intro & Design) 20240118RRNessuna valutazione finora

- Practical Theory Tertiary Treatment-P+TDocumento18 paginePractical Theory Tertiary Treatment-P+TsarfaNessuna valutazione finora

- Microfluidics-NEW (Compatibility Mode)Documento63 pagineMicrofluidics-NEW (Compatibility Mode)crocoreaderNessuna valutazione finora

- BS 3 MembraneDocumento33 pagineBS 3 MembranePratyush GoelNessuna valutazione finora

- Integrated Bioprocess Engineering - Downstream ProcessingDocumento18 pagineIntegrated Bioprocess Engineering - Downstream ProcessingPhuong NguyenNessuna valutazione finora

- Membrane Separation FinalDocumento49 pagineMembrane Separation FinalCester Avila DucusinNessuna valutazione finora

- Basic Principle of UltrafiltrationDocumento6 pagineBasic Principle of Ultrafiltrationmadhujayaraj100% (2)

- Remocion Micro, Ultra y Nano FiltracionDocumento3 pagineRemocion Micro, Ultra y Nano FiltracionJulio TovarNessuna valutazione finora

- Ict I Desalination and Water Reuse: "Sea To Sink To The Sea Again"Documento58 pagineIct I Desalination and Water Reuse: "Sea To Sink To The Sea Again"sagunthala92Nessuna valutazione finora

- Porozni MaterijaliDocumento67 paginePorozni MaterijaliAna RisticNessuna valutazione finora

- Reverse Osmosis RevisedDocumento17 pagineReverse Osmosis RevisedEtikNessuna valutazione finora

- Apuntes Filtración Con MembranasDocumento21 pagineApuntes Filtración Con MembranasCarlos MedinaNessuna valutazione finora

- MFUF Pre-Treatment ToDocumento1 paginaMFUF Pre-Treatment TorezaNessuna valutazione finora

- Handbook of Petrochemicals Production Processes Mcgraw Hill HandbooksDocumento25 pagineHandbook of Petrochemicals Production Processes Mcgraw Hill HandbooksMD SHAHJADNessuna valutazione finora

- Membrane Lecture 1Documento16 pagineMembrane Lecture 1writtingtuNessuna valutazione finora

- Lecture 6 Thin Film Deposition, Physical Vapour DepositionDocumento44 pagineLecture 6 Thin Film Deposition, Physical Vapour DepositionHari HarryNessuna valutazione finora

- Characterization of Thin FilmsDocumento56 pagineCharacterization of Thin FilmsBerenice LoredoNessuna valutazione finora

- Temperature: Page 1 of 16Documento16 pagineTemperature: Page 1 of 16dei_sandeep7994Nessuna valutazione finora

- How To Do Progressive Muscle Relaxation: Helpful HintsDocumento4 pagineHow To Do Progressive Muscle Relaxation: Helpful HintsSyeda MahnoorNessuna valutazione finora

- MixingDocumento36 pagineMixingdei_sandeep7994Nessuna valutazione finora

- Light Interference Frequency MasersDocumento5 pagineLight Interference Frequency Masersdei_sandeep7994Nessuna valutazione finora

- Master Alloys - HPNbMasteralloysDocumento8 pagineMaster Alloys - HPNbMasteralloysdei_sandeep7994Nessuna valutazione finora

- ForkliftDocumento2 pagineForkliftdei_sandeep7994Nessuna valutazione finora

- Calibation - RotameterDocumento4 pagineCalibation - Rotameterdei_sandeep7994Nessuna valutazione finora

- Hydrogen Leak DetectorDocumento1 paginaHydrogen Leak Detectordei_sandeep7994Nessuna valutazione finora

- Plastics Compatibility With HFDocumento1 paginaPlastics Compatibility With HFdei_sandeep7994Nessuna valutazione finora

- Chlorine Emergency Kit B: Product DescriptionDocumento2 pagineChlorine Emergency Kit B: Product Descriptiondei_sandeep7994Nessuna valutazione finora

- MixingDocumento36 pagineMixingdei_sandeep7994Nessuna valutazione finora

- Electron Emission From Solids (I) : History & TheoryDocumento6 pagineElectron Emission From Solids (I) : History & Theorydei_sandeep7994Nessuna valutazione finora

- ISO F Flange SizesDocumento5 pagineISO F Flange Sizesdei_sandeep7994Nessuna valutazione finora

- Beautiful Butterfly RhymesDocumento10 pagineBeautiful Butterfly Rhymesdei_sandeep7994Nessuna valutazione finora

- National BirdsDocumento1 paginaNational Birdsdei_sandeep7994Nessuna valutazione finora

- ISO F Flange SizesDocumento5 pagineISO F Flange Sizesdei_sandeep7994Nessuna valutazione finora

- Roof ExtractorDocumento1 paginaRoof Extractordei_sandeep7994Nessuna valutazione finora

- Roots PumpDocumento1 paginaRoots Pumpdei_sandeep7994Nessuna valutazione finora

- Guidelines For OralPresentationsDocumento1 paginaGuidelines For OralPresentationsdei_sandeep7994Nessuna valutazione finora

- SSA CalculationDocumento1 paginaSSA Calculationdei_sandeep7994Nessuna valutazione finora

- Cooling TowersDocumento38 pagineCooling Towersdei_sandeep7994Nessuna valutazione finora

- Visual Fluoride Detection Kit: Fig. 1. Colour Chart For Three Different Fluoride ConcentrationsDocumento1 paginaVisual Fluoride Detection Kit: Fig. 1. Colour Chart For Three Different Fluoride Concentrationsdei_sandeep7994Nessuna valutazione finora

- Gas Absorption - Cat-IDocumento32 pagineGas Absorption - Cat-Idei_sandeep7994Nessuna valutazione finora

- List of Probable SuppliersDocumento2 pagineList of Probable Suppliersdei_sandeep7994Nessuna valutazione finora

- Screw PumpsDocumento11 pagineScrew Pumpsdei_sandeep7994Nessuna valutazione finora

- Evaporation RateDocumento9 pagineEvaporation Ratedei_sandeep7994Nessuna valutazione finora

- Holding PumpDocumento2 pagineHolding Pumpdei_sandeep7994Nessuna valutazione finora

- Indice Combinado Eph 9TH Hasta S 9.8 - 2019Documento56 pagineIndice Combinado Eph 9TH Hasta S 9.8 - 2019Diana PortilloNessuna valutazione finora

- Salting-Out Crystallisation Using NH Ina Laboratory-Scale Gas Lift ReactorDocumento10 pagineSalting-Out Crystallisation Using NH Ina Laboratory-Scale Gas Lift ReactorChester LowreyNessuna valutazione finora

- Al Techbull Al195Documento2 pagineAl Techbull Al195Ian OttoNessuna valutazione finora

- Carbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFDocumento2 pagineCarbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFJorgeSantosAquinoNessuna valutazione finora

- 0620 w07 QP 5 PDFDocumento8 pagine0620 w07 QP 5 PDFIndianagrofarmsNessuna valutazione finora

- Drain Cleaner: Safety Data SheetDocumento5 pagineDrain Cleaner: Safety Data SheetSuresh SubbuNessuna valutazione finora

- 0423a ASKIN XFLAM Performance Panel Roofing-1Documento11 pagine0423a ASKIN XFLAM Performance Panel Roofing-1MacNessuna valutazione finora

- Pulse GerminationDocumento21 paginePulse GerminationChetan KambojNessuna valutazione finora

- Presenters Post16 Tcm18-118246Documento18 paginePresenters Post16 Tcm18-118246Kamariah IsmailNessuna valutazione finora

- Sales Contract Bangladesh Complete and Signed by Jolly 22 July 2021Documento18 pagineSales Contract Bangladesh Complete and Signed by Jolly 22 July 2021Fantania BerryNessuna valutazione finora

- Gen Bio W3-5Documento9 pagineGen Bio W3-5Alyson EscuderoNessuna valutazione finora

- Determination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Documento11 pagineDetermination of Heavy Metals in Soil by Atomic Absorption Spectrometry (AAS)Irvine MupambaNessuna valutazione finora

- E - 2 - Effect of Casting Shape and Size On Solidification TimeDocumento6 pagineE - 2 - Effect of Casting Shape and Size On Solidification Timeoğuz kağanNessuna valutazione finora

- Boas Práticas para Produção de ADBlueDocumento27 pagineBoas Práticas para Produção de ADBluewelyson_henriqueNessuna valutazione finora

- Carboxylic Acids and Derivatives (Formal Report)Documento5 pagineCarboxylic Acids and Derivatives (Formal Report)Sar Caermare0% (4)

- Cell Wall: Presented by M. Vijaya LakshmiDocumento9 pagineCell Wall: Presented by M. Vijaya LakshmiATCHUNALA SAINessuna valutazione finora

- Artificial Blood: Dr. Pragasam Viswanathan, Professor, SBSTDocumento21 pagineArtificial Blood: Dr. Pragasam Viswanathan, Professor, SBSTMaru Mengesha Worku 18BBT0285Nessuna valutazione finora

- 4 Different Ways To Use Hair Oils Curly Hair Care The Wild CurlDocumento1 pagina4 Different Ways To Use Hair Oils Curly Hair Care The Wild CurlMaria jose MondragonNessuna valutazione finora

- Waste Management AustriaDocumento34 pagineWaste Management AustriaregiapursofNessuna valutazione finora