Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Compiled Latest

Caricato da

Lim LeongCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Compiled Latest

Caricato da

Lim LeongCopyright:

Formati disponibili

MONASH

University Malaysia

CHE 3162 Process Control Laboratory

CHE 3162 Process Control

Laboratory

Liquid Flow Control

Name

Mah

Wei-Jun

How

ZhongXing

Yang

Ge

Hoa

Ang

Lin

Yang

Student

ID

24640093

24554758

24686727

24133027

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Table

of

Contents

1.0 Summary

................................................................................................................................................................

4

2.0 Introduction

..........................................................................................................................................................

6

3.0 Objectives

..............................................................................................................................................................

7

4.0 Experimental Procedure

.................................................................................................................................

7

4.1 Diagram of Apparatus

................................................................................................................................

7

4.2 Description of Apparatus

...........................................................................................................................

8

4.3 Methodology

....................................................................................................................................................

8

4.3.1 Experimental Start-Up

...........................................................................................................................

8

4.3.2 Closed Loop Flow Control

..................................................................................................................

8

4.3.2.1 Proportional Controller

......................................................................................................................

8

4.3.2.2 Proportional-Integral (PI) Controller

............................................................................................

9

4.3.2.3 Proportional-Derivative (PD) Controller

.....................................................................................

9

4.3.2.4 Proportional-Integral-Derivative (PID) Controller

..................................................................

9

4.3.2.5 Step Test Closed Loop Tuning Method

.......................................................................................

9

4.3.2.6 Experimental Shut-Down

..............................................................................................................

10

5.0

Results

and

Analysis

...................................................................................................................................

11

5.1.0 Closed Loop Flow Control

..................................................................................................................

11

5.1.1 Proportional Controller

..................................................................................................................

11

5.1.2 Proportional-Integral (PI) Controller

......................................................................................

13

5.1.3 Proportional-Derivative (PD) Controller

................................................................................

15

5.1.4 Proportional-Integral-Derivative (PID) Controller

...........................................................

17

5.2 Step Test Closed Loop Tuning Method

............................................................................................

19

5.3 Calculation Step

..........................................................................................................................................

20

6.0 Discussion

...........................................................................................................................................................

23

6.1 Define proportional gain, integral gain and derivative gain

...................................................

23

6.2 The effects of proportional gain applied on the proportional-only control system and

the effects to response of the system.

.........................................................................................................

23

6.3 Discuss the effect of integral gain applied on the proportional-integral control system.

Relate the effect to the response of the system (e.g. rise time, overshoot percentage,

settling time and steady state error).

........................................................................................................

24

6.4 The effects of derivative gain applied on the proportional-derivate control system and

the effects to response of the system.

.........................................................................................................

25

MONASH University Malaysia

CHE 3162 Process Control Laboratory

6.5 Discuss the system response curve of PID controller tuned and compare it with the

system response curve obtained from proportional controller, proportional-integral

controller and proportional-derivative controller.

.............................................................................

26

6.6 Discuss whether the step test closed loop tuning method is suitable for all types of

process control.

...................................................................................................................................................

27

7.0 Conclusion

..........................................................................................................................................................

28

8.0 Nomenclature

....................................................................................................................................................

29

9.0 Reference

............................................................................................................................................................

29

MONASH University Malaysia

CHE 3162 Process Control Laboratory

1.0 Summary

Throughout the conduction of this experiment, a detailed application of how the

closed-loop proportional-only control (P control), closed-loop proportional-derivative

control (PD control), closed-loop proportional-integral control (PI control) and a closedloop proportional-integral-derivative control (PID control) are used in the regulations of

maintaining the liquid level at a fixed level inside a reactor or a tank is seen. Basically, a

proportional control will provides a fast response for adjustments made on the

manipulated variable, however it will always have an offset whereas for the proportionalintegral (PI) control it is able to remove the offset thus making the magnitude of error to

be zero. As for the proportional-integral-derivative (PID) control, it was proven to be the

best device among the other controllers as it can prevent large value overshoots by

removing offset values. Besides that, it also reduces the settling time if optimum values

of proportional, integral and derivative gains are entered to the controller.

Four different combinations of control system were performed in these

experiments, which are primarily made up from proportional (P), integral (I) and

derivative (D). These controllers are then used for different combinations of P, PI, PD

and PID. Among the combinations made, the combination that was able to provide the

least or shortest time to reach the steady state was chosen and used for our tuning on the

step test closed-loop system.

For the proportional (P) control system experiment, the Ki and Kd values were set

to zero while Kp is being varied. Results showed that when the Kp value was too small,

the offset of the system will be large and when the Kp was set to a large value, the system

will become unstable as it starts oscillating. However, a lower Kp value will require a

shorter time to achieve steady state compared to a higher Kp value. For the proportionalintegral (PI) control system, Kp was set to 5, Kd was set to zero while Ki was being

altered. In the tuning process, it was concluded that when Ki = 0.01, the response curve

was the best compared to the response for other values of Ki.

As for the proportional-derivative (PD) control system, values of Kp and Ki were

set to 5 and zero respectively with Kd being tuned to different values. Based on results

attained, it was concluded that the system was unable to achieve the set point value and

the system was starting to become less stable as oscillations were increasing when Kd was

changed from a smaller value to a bigger value. After series of observations and result

analysis that were made, values of Ki and Kd that gave the best response graph in the PI

and PD experiments was chosen for the proportional-integral-derivative (PID) control

system experiment. With these optimum values, the best response curve for the PID

control can be accomplished.

Lastly, series of calculations were carried out using optimum values of Kp, Ki and

Kd that was determined previously for the PID control system. The process gain, Kp was

calculated to be 0.06, time constant, Tp to be 0.0167 minutes while the dead time, P was

determined to be 0.0333 minutes by considering calculations based on 80% and 20%

valve openings as these 2 openings gave the smoothest flow in step change loop tuning.

MONASH University Malaysia

CHE 3162 Process Control Laboratory

To conclude this experiment, the PID control system gave the best response curve

as the overshoot was smaller, time required to achieve steady state was shorter and a

stable system without oscillations. However, values of Kp, Ki and Kd have to be altered

based on the process as different set points will have their own optimum Kp, Ki and Kd

values.

MONASH University Malaysia

CHE 3162 Process Control Laboratory

2.0 Introduction

Generally, every chemical processes will have some disturbances along its operation.

These processes usually deals with hazardous and dangerous chemicals and thus, process

control are necessary to ensure the safety of operation and also to maintain the quality of

the desired product. The simplest forms of both automatic and manual control rely on

adjusting a manipulated variable (MV) in order to compensate for observed undesired

variations of the process variable (PV) or output.

Basic elements that make up a process control system in industries consist of a controller,

process, measuring element and control element. A closed loop control exists when all

these components are interlinked and information can be passed around the loop.

Currently, the Proportional-Integral-Derivative (PID) algorithm is the most sort-after

algorithm used in industry. Some of the most common processes that require the usage of

PID are fluid flow monitoring, heating and cooling systems, flow control and temperature

control. Prior to using the PID control, we need to define a set point and a process

variable. The set point is the desired value of the controlled parameter while the process

variable refers to the system parameter that needs to be controlled such as the pressure,

temperature and flow rate. A PID controller determines a controller output value, such as

the heater power or valve position and applies the controller output value to the system,

which in turn drives the process variable towards the set point value.

In this experiment, the main function of the process control unit (LS-33 139 Basic Flow

Control Unit) is to control the water flow rate in the system. Firstly, a pump will deliver

water from a storage tank through a piping system. Next, the flow rate will be measured

by the flow sensor and the value will be fed back to the control valve to regulate the

incoming flow rate.

All the elements and units in this experiment represents a scaled down process model of a

common industrial process. Experiments were conducted on various closed loop control

systems as listed below.

(i)

Proportional Controller a type of linear feedback control system; controller

output signal is proportional to the error input signal.

(ii)

Proportional-Integral Controller two-term controller; integral action

eliminates offset and makes the control system less stable.

(iii)

Proportional-Derivative Controller two-term controller; derivative section

responds to the rate of change of the process error.

(iv)

Proportional Integral-Derivative Controller a generic control loop feedback

mechanism; a PID controller calculates an error value as the difference

between a measured process variable

MONASH University Malaysia

CHE 3162 Process Control Laboratory

3.0 Objectives

The objective of this experiment was to accomplish and develop understanding in the

basic flow control process through operation of the process control unit, which controls

the water flow rate in the system. In addition, responses from different PID settings in the

closed loop flow control are studied and interpreted. On top of that, the step test closed

loop tuning method in the flow control process is being demonstrated and analysed.

4.0 Experimental Procedure

4.1 Diagram of Apparatus

Water

Storage

Tank

Figure 1: LS-33 139 Basic Flow Control Unit

MONASH University Malaysia

CHE 3162 Process Control Laboratory

4.2 Description of Apparatus

The equipment shown above is the process control unit that is designed to control the

flow rate of water in the system. The pump located in water storage tank is used to

transfer water through a piping system. The water flow rate is then measured by a flow

sensor located along the pipe. This is followed by the transmission of the value which

will be fed back to the control valve to adjust the incoming flow rate in order to achieve

the required set point value.

4.3 Methodology

4.3.1 Experimental Start-Up

Before the experiment began, all the equipment was checked to ensure there are in good

and safe condition. Firstly, the process control unit was placed on a level surface. Also,

all the pipes and fittings were checked to ensure it is well-connected to prevent any

leakage of water. Next, the computer was turned on. Then lastly, it was followed by the

starting up of the LS-33 139 Basic Flow Control DAQ Software in the computer. Before

the main power supply and the apparatus power supply (on the control panel of the

equipment) was switched on, the water level in the storage tank was observed to be

approximately of the tank.

4.3.2 Closed Loop Flow Control

4.3.2.1 Proportional Controller

*The following procedures were carried out through the DAQ software on the

computer.*

First, the initial set point was set to 4LPM in the DAQ software. Then, the experiment

was continued by setting KP = 1, KI = 0 and KD = 0. To initiate the software, the

Run/Execute button was clicked. In order to record the data obtained, The Logging

Started button was clicked. To allow the traceability of results in future, the time the

experiment started was recorded. The submersible water pump was switched on. Then,

the system was allowed to run for few minutes and the response of the system from the

graph was observed. Next, the Data Analysis button was clicked to access all recorded

data and the response graph. Print Screen button was used to record the system response

graph. The experiment was again repeated with equal increment in the Proportional Gain

KP (4, 9, 13 and 17) and the system response to different Proportional Controller was

observed. Each time the KP value was altered, the time was recorded. The proportional

gain was increased until the response starts to oscillate or to a point where the offset

between the set value and process value was unable to be further decreased. Then, the

data and response graph were recorded. The water pump was turned off before pressing

the Stop button at the end of this experiment.

MONASH University Malaysia

CHE 3162 Process Control Laboratory

4.3.2.2 Proportional-Integral (PI) Controller

*The following procedures were carried out through the DAQ software on the

computer.*

The second part of the experiment was continued by setting the desired set value flow

rate to 4 LPM. Next, the proportional gain was changed to the critical gain (KP = 5) and

KI was altered to 0.01. The software was then started by pressing the Run/Execute

button. Subsequently, the Logging Started button was clicked on to record the data.

The time the experiment started was recorded. Then the submersible water pump was

switched on. After allowing the system response to stabilize, the data was recorded and

the Print Screen button was again used to save the generated response graph. The

submersible water pump was turned off and the flow output was allowed to drop till 0

LPM. The experiment was repeated by varying the Integral gain, KI to values of 0.001,

0.01, 0.05, 1 and 10.

4.3.2.3 Proportional-Derivative (PD) Controller

*The following procedures were carried out through the DAQ software on the

computer.*

The third part of the experiment was started by setting the desired flow rate set value to 4

LPM. The proportional gain was set to the critical gain (KP = 5), while KI = 0 and KD =

0.01. The program was allowed to run and the response was observed. Before the data

could be recorded, the system response was allowed to stabilize. Subsequently, the data

was recorded and the Print Screen button was clicked to obtain the generated response

graph. Then the submersible water pump was turned off and the flow output was allowed

to drop till 0LPM. The experiment was repeated with increasing derivative gain, KD to

values of 0.02, 0.2, and 2.

4.3.2.4 Proportional-Integral-Derivative (PID) Controller

*The following procedures were carried out through the DAQ software on the

computer.*

By comparing the system response graphs generated previously, the KI and KD values

were altered to obtain the best system response by retuning the PID controller. Several

trials were carried out and the different system response graphs were compared

interpreted with each other to conclude the best combination of PID controller.

4.3.2.5 Step Test Closed Loop Tuning Method

*The following procedures were carried out through the DAQ software on the

computer.*

The initial set point was set to 4LPM in the DAQ software. The KP, KI and KD values

were determined to be 5, 0.01 and 0.01 respectively as these values provide the best

system response graph obtained previously. The software was again started by pressing

the Run/Execute button. After that, the submersible water pump was switched on and

the system was allowed to stabilize. The Open Loop button was clicked and the sliding

bar was adjusted to the maximum (100%). At the same time, the Logging Started

button was clicked on. The water was allowed to flow for 20 seconds for stabilization of

the system to be achieved. This was followed by adjusting the sliding bar to

MONASH University Malaysia

CHE 3162 Process Control Laboratory

approximately 90%. The steps stated were repeated with equal decreasing valve opening

(approximately decrement of 10%) until the valve was fully closed. Then, the Logging

Started button was clicked to stop recording the data. Next, from the system response

graph obtained, two different valve opening percentage which gave the smoothest flow

were selected. Subsequently, the Logging Started button was clicked followed by the

Open Loop button. The sliding bar was adjusted to the higher valve opening percentage

value of the two and the system was allowed to run for 20 seconds. Then, the sliding bar

was changed to the lower valve opening percentage value and again the water was

allowed to flow for 20 seconds. The data shown was recorded and analyzed carefully.

Lastly, calculations were performed according to the lab manual to determine the P, I and

D values for the closed loop control.

4.3.2.6 Experimental Shut-Down

The water pump was switched off, followed by the pressing of STOP button at the end of

the experiment. The DAQ software was closed and the control panel power was turned

off. All the .jpg files were transferred to USB drive. Lastly, the computer and the

process control unit was shut down.

10

MONASH University Malaysia

CHE 3162 Process Control Laboratory

5.0 Results and Analysis

5.1.0 Closed Loop Flow Control

5.1.1 Proportional Controller

Set point value = 4LPM

The response graphs for proportional flow control are shown below.

Figure 2: Proportional Controller response graph for Kp = 1, KI = 0, KD = 0

Figure 3: Proportional Controller response graph for Kp = 5, KI = 0, KD = 0

11

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Figure 4: Proportional Controller response graph for Kp = 9, KI = 0, KD = 0

Figure 5: Proportional Controller response graph for Kp = 13, KI = 0, KD = 0

Figure 6: Proportional Controller response graph for Kp = 17, KI = 0, KD = 0

12

MONASH University Malaysia

CHE 3162 Process Control Laboratory

5.1.2 Proportional-Integral (PI) Controller

Set point value = 4LPM

The response graphs for PI flow control are shown below.

Figure 7: Proportional-Integral Controller response graph for Kp = 5, KI = 0.001, KD = 0

Figure 8: Proportional-Integral Controller response graph for Kp = 5, KI = 0.01, KD = 0

13

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Figure 9: Proportional-Integral Controller response graph for Kp = 5, KI = 0.05, KD = 0

Figure 10: Proportional-Integral Controller response graph for Kp = 5, KI = 1, KD = 0

Figure 11: Proportional-Integral Controller response graph for Kp = 5, KI = 10, KD = 0

14

MONASH University Malaysia

CHE 3162 Process Control Laboratory

5.1.3 Proportional-Derivative (PD) Controller

Set point value = 4LPM

The response graphs for PD flow control are shown below.

Figure 12: Proportional-Derivative Controller response graph for Kp = 5, KI = 0, KD = 0.01

Figure 13: Proportional-Derivative Controller response graph for Kp = 5, KI = 0, KD = 0.02

15

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Figure 14: Proportional-Derivative Controller response graph for Kp = 5, KI = 0, KD = 0.2

Figure 15: Proportional-Derivative Controller response graph for Kp = 5, KI = 0, KD = 2

16

MONASH University Malaysia

CHE 3162 Process Control Laboratory

5.1.4 Proportional-Integral-Derivative (PID) Controller

Set point value = 4LPM

After concluding findings from previous controller set up experiments, the controller is

then retune by adjusting values of Kp, KI, and KD to determine the best PID value for the

best system response.

The response graphs for PID controller are shown below.

Figure 16: PID Controller response graph for Kp = 5, KI = 0.01, KD = 0.005

Figure 17: PID Controller response graph for Kp = 5, KI = 0.01, KD = 0.01

17

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Figure 18: PID Controller response graph for Kp = 5, KI = 0.01, KD = 0.05

Figure 19: PID Controller response graph for Kp = 5, KI = 0.05, KD = 0.01

Figure 20: PID Controller response graph for Kp = 5, KI = 0.10, KD = 0.01

18

MONASH University Malaysia

CHE 3162 Process Control Laboratory

5.2 Step Test Closed Loop Tuning Method

Set point value = 4LPM

Figure

21:

Step

change

response

graph

for

10%

valve

opening

decrement

from

100%

Figure

22:

Response

graph

of

2

valve

openings

for

smoothest

flow

(80%

and

20%)

19

MONASH University Malaysia

CHE 3162 Process Control Laboratory

5.3 Calculation Step

1) Process Gain, Kp

,

! =

,

! =

!"#$% !"!#!$%

!"#$% !"!#!$%

Values for flow rate at the respective valve opening percentage are obtained from Figure 22.

! =

2.8 6.4

20.1754 80.2632

= .

where PV is the flow rate in LPM and CO is the valve opening percentage

2) Time Constant, TP

a)

= !"#$% !!"#"$%

= 2.8 6.4

= .

b) Initial steady state = 6.4 LPM

+ 0.63 = 6.4 + 0.633.6

= .

c) From Figure 22, the time when PV passes through the initial steady state + 0.63(PV)

is 03:42:36 PM.

d) From Figure 22, the time when PV starts a first clear response to the step change in the CO

is 03:42:35 PM.

e)

! =

!"#$ !"#$ !"#$ ! !!"#$ !"#$ !"#$ !

!"

= .

20

MONASH University Malaysia

CHE 3162 Process Control Laboratory

3) Dead Time, P

a) From Figure 22, the time when PV starts a first clear response to the step change in the CO

is 03:42:35 PM.

b) From Figure 22, the time when CO was stepped from its original value to its new value

is 03:42:37 PM

c)

! =

!"#$ !" !"#$ ! !!"#$ !" !"#$ !

!"

= .

4) P, I and D value for Closed Loop Control

TC is the larger of (0.1TP) or (0.8P)

Since TP = 0.0167 and P = 0.0333

a) 0.1TP = 1.6710-3

b) 0.8P = 0.0267

Therefore, TC = 0.0267

PI Controller

For PI controller, the KC value is calculated using the equation below,

! =

!

! ! + !

0.0167

0.06 0.0333 + 0.0267

= .

Ti value for PI controller is the same as TP, thus

= = .

21

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Ideal PID

For the ideal PID, KC value is calculated from the equation below where,

! =

! + 0.5!

! ! + 0.5!

0.0167 + 0.50.0333

0.06 0.0267 + 0.50.0333

= .

Ti is calculated using,

! = ! + 0.5!

= 0.0167 + 0.50.0333

= .

Td is then calculated using the equation shown below,

! =

! !

2! + !

0.01670.0333

20.0167 + 0.0333

= . !

The values calculated for both PI and Ideal PID are then tabulated in Table 1 as shown below.

Table

1:

P,

I

and

D

values

for

Closed

Loop

Control

KC

Ti

Td

PI

4.639

0.0167

Ideal

PID

12.82

0.03335

8.33710-3

22

MONASH University Malaysia

CHE 3162 Process Control Laboratory

6.0 Discussion

6.1 Define proportional gain, integral gain and derivative gain

Proportional controller is a type of closed-loop feedback control system in which the

adjustment to the manipulated variable is proportional to the error signal; increasing the

manipulated variable will cause an increase in the error. The corrections for a

proportional control are based on present errors. The proportional gain, Kp is a type of

control in which adjusting the output will require the constant value to be multiplied with

the error. The effect of using a proportional gain is that the rise time can be reduced

significantly. Adding to that, the steady state error can be reduced but it cannot be

eliminated completely. In order to eliminate the effect of disturbances completely, an

integral controller is introduced in which the manipulated variables can be altered until

the magnitude of error is eliminated completely for a step-like input. Corrections for an

integral control are based on the sum or integral of past errors. The integral gain, Ki has

the ability to eliminate the steady-state error; however, the downside of it is that the

transient response will behave much slower as compared to the proportional controller.

The derivative gain, Kd is a variable that allows the controller to reduce the output

whenever the process value (PV) overshoot the set point (SP). Some advantages of using

a derivative gain would be that the stability of the system can be improved, overshoot can

be reduced and also the transient response can be improved.

6.2 The effects of proportional gain applied on the proportional-only control

system and the effects to response of the system.

In a practical industrial system, disturbances are often present in the system as there are

unavoidable. These disturbances are undesirable as they present errors within the system

and thus, needs to be eliminated with a processing control system. For the first part of the

experiment, the simplest controlling system which is the proportional control (P) system

is used to maintain the water level in the tank by regulating the amount of water flow rate

being pumped into the system, in which it is set to a desired value of 4 litres per minute

(LPM). Based on theoretical explanations, the steady state error of a typical proportional

control system is inversely proportional to the proportional gain of the control system, KP. This means that when the value of the proportional gain is increased to a larger value,

the steady state error of the system will be reduced.

Based on analysis and observations on the response graph of different KP values from KP

= 1 to KP = 17, it can be seen that when KP value is increased with Ki and Kd values being

fixed, settling time taken for the proportional control system to reach steady state is

longer but with a smaller steady state error. Besides that, when the KP is increased from a

smaller value to a larger value, it is very obvious that the overshoot (difference between

the first peak value to the steady state value) increased dramatically. The rise time of the

system varies with increasing proportional gain as there are no obvious trends for the rise

time. For example, in Figure 2 where KP = 1 and Figure 6 where KP = 17, the rise time

for the both system based on the graphs are having slight changes only.

23

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Aside from that, it is also observed that when the ! value is increased, the response of

the system starts to oscillate instead of approaching the steady state value. This

oscillation of the response indicates that the system is unstable. From all the proportional

control response graphs above, the best proportional control system response graph was

Figure 5 with a KP value of 13. This is because the output flow rate was 2.5 LPM, which

is closest to the set point of 4 LPM compared to the other lower proportional gain values

used, which contain a greater offset value. However, even though using a proportional

gain of 13 reduces the offset value, the settling time will be increased. So, there are exact

proportional gain value that can give the best graph for this system that could reach the

steady state with the shortest time possible as the value of the gain increases, the control

system graph will eventually oscillating and become unstable. Hence, from the analysis

made, the proportional control system is expected to always have an offset value and will

not reach the set point even though different values of KP are being used.

6.3 Discuss the effect of integral gain applied on the proportional-integral

control system. Relate the effect to the response of the system (e.g. rise time,

overshoot percentage, settling time and steady state error).

For the proportional integral (PI) controller experiment, the proportional gain was fixed

at Kp = 5, while the integral gain was varied accordingly with values of Ki = 0.01, 0.001,

0.05, 1, 10 respectively. Based on figure 7 to figure 11, it was observed that the value of

the integral gain would result in a different control system. As what we can observe from

the graph, when the value of Ki increases, the response graph will take a longer time to

reach the steady state that means it is having a greater settling time.

Clearly, it can be seen from the graph that when the integral gain is the lowest, the

overshoot value will be the highest. When Ki = 0.001, the overshoot value is the highest

and oscillations were observed in the graph. As for the settling time to converge to steady

state, it was found that the value increases as the integral gain is increased. However, if

the integral gain value were too small, the system would not achieve steady state and will

continue to oscillate as can be seen when Ki = 0.001. Besides that, unlike proportionalonly controller, the steady state errors are completely eliminated in this type of control

system as the integral gain is increased. As we can see from figure 8, the system has

started to achieve steady state at the step point, even when the Ki is only increased to

0.01. However, it was found that at Ki value of greater than 1, the steady state is reached

at PV value greater than the set point.

In this proportional integral system, the output of the controller is always proportional to

the amount of time the error is present. Next, the respond of the integral controller is

quite slow at first, but in a long period of time, the offsets can be eliminated completely.

However, integral action tends to produce some undesired oscillations to the system. This

explained well on why the time required for settling to the set-point value is longer as

compared to the proportional-only controller mode.

24

MONASH University Malaysia

CHE 3162 Process Control Laboratory

Based on the 5 data obtained from the experiment, it can be concluded that the best

proportional integral controller would be the one with Kp value of 5 and Ki value of 0.01.

This is because there is no oscillation produced and the system achieved steady state at

the set point value at the shortest period of time.

6.4 The effects of derivative gain applied on the proportional-derivate control

system and the effects to response of the system.

From the experiment conducted previously, the proportional gain was set to 5 (! = 5)

and integral gain was kept at zero (! = 0) with varying value of derivative gain, ! for

the proportional-derivative control system experiment.

In the experiment, Kd value was being varied from 0.01 to 2. Based the output of the

graphs from the Figure 12 to Figure 15, the control system will vary according to the

value of the derivative gain of the system. For the derivative control system, when the

value of the derivative gain is increased, the instability of the system increases as it starts

to oscillate.

For this derivative mode, it is clear that when the derivative gain is low, the overshoot

value is not as high as compared to the response for a higher value of ! which has a

higher overshoot value and oscillations in the response. Besides that, by varying the value

of the derivative gain, the offset of the system does not change which means the

derivative gain will not influence the steady state error but instead will cause the output

to oscillate in a high frequency mode when the KD value is increased to a bigger value. In

addition, the rise time for the lower value of derivative gain is shorter compared to the

rise time of the higher value of derivative gain which can be seen from Figure 12 and

Figure 15. From Figure 15, due to its large derivative gain value of 2, the system is

oscillating and a longer rise time is required compared to Figure 12 which has a

derivative gain of 0.01.

By comparing Figure 12 and Figure 15, the stability of the system is very obvious that

when KD is low, the system can still be considered a stable system whereas for a larger

value of KD, the system will become unstable and oscillates. Thus it can be said that the

settling time of the response for a lower KD is shorter compared to the response for a

higher KD value due to the instability of the system as KD is increased.

25

MONASH University Malaysia

CHE 3162 Process Control Laboratory

6.5 Discuss the system response curve of PID controller tuned and compare it

with the system response curve obtained from proportional controller,

proportional-integral controller and proportional-derivative controller.

Based on the PID controller experiment conducted, the Kp value chosen was kept

constant at 5 throughout the experiment. The experiment was conducted with the Ki and

Kd values that gave the best system response curve under PI and PD controllers. Ki value

selected was 0.01 and Kd value chosen was 0.005. From the system response curve,

overshoot is observed and it takes 15 seconds settling time to reach steady state. By

keeping Ki constant and increasing Kd value to 0.01, initially overshoot is again observed,

but at a relatively lower offset value compared to the previous graph. It also takes a

shorter settling time of 8 seconds to achieve steady state condition. Next, by increasing

the Kd value to 0.05 with Kp and Ki being kept constant, oscillation is observed and steady

state cannot be achieved. Therefore with Kd value being set at optimum value of 0.01, the

best system response curve among the three can be obtained.

Then, the experiment is proceeded by keeping Kd value constant at 0.01 while increasing

the Ki value to 0.05 and 0.10 respectively. Hence the results obtained from this section

can be compared with the second result obtained from the previous paragraph. By setting

Ki value to be 0.05, overshoot can be seen at a similar peak; however it takes 52 seconds

for the system to remove the offset value to achieve steady state system. Subsequently,

the Ki value was altered to 0.1, in which again an overshoot can be obtained but it takes

100 seconds to reach steady state, which is relatively longer compared to the previous

experiments. From this section, with the Ki value being set at 0.01, the system response

curve observed is the most desired among the three different sets of values.

For the comparisons of system response curve of PID controller with other controllers,

the best system response curve from each section is chosen for further analysis and

comparison. By comparing PID controller to P controller, the system response curve of

PID controller is much desired as the system response curve of P controller does not

achieve the desired set point value of 4LPM. As for PI controller, its best system

response curve obtained has an overshoot of 7.2, which is higher than that of PID

controller. It also has a higher settling time of 15 seconds compared to 8 seconds as

required by a PID controller. Last but not least, for a PD controller, it is impossible to

obtain a system that can provide the desired flow rate of 4LPM and reaching the steady

state on the same set-up of gain values. Therefore, it can be deduced that a PID controller

proves to be the best device among the others controllers as it can prevent large value

overshoot by removing offset values. Besides that, it also reduces the settling time if

optimum values of proportional, integral and derivative gains are entered to the

controller.

26

MONASH University Malaysia

CHE 3162 Process Control Laboratory

6.6 Discuss whether the step test closed loop tuning method is suitable for all

types of process control.

For the step test closed loop tuning method we have used in our experiment, it is actually

a type of method known as Zeigler-Nichols tuning method. It is a type of trial and error

looping repeating technique used in the control system. After conducting the step test

closed loop tuning method experiment by following the procedures as mentioned above,

the gain and period could be computed. This method is an effective way that can be used

in the control system to obtain the gain and period, however it is not a general tuning

method that can be used for all types of process control. Furthermore, a guaranteed

success rate with this method in all processing control system should not be expected.

The reasons that the step test closed loop tuning method is not suitable for all types of

process control is because this method requires the entire process in the system to be

brought to the extreme ends of the instability state in order to determine the gain. In

practical applications, industries are always trying to reduce the operational time since

the operating costs are not cheap. When large adjustments or changes on the gain are

made, the instability of the process increases dramatically as well. Thus, it is not suitable

for applications in real industrial plants due to the oscillations that will occur when the

gain is changed. These permanent oscillations in the system to determine the gain and

period will put the operations of the plant at risk. Furthermore, unit operations such as

distillation columns, furnaces, separators, reactors and such will be dangerous if the

system approaches unstable state. As the system approaches unsteady state, it would be a

very alarming proposition for the plant personnel.

This Ziegler-Nichols tuning method is not suitable for all types of processes as the

recommended settings are not suitable for systems that are lag-dominated, which

basically means the control output has a slower respond due do delay present in the

system. This method can only be used on processes where the lag-phase of the output

exceeds 180 degrees at high frequencies. A clear example would be that this method does

not work on a simple second order process. Lastly, this method is time consuming and is

a monetarily expensive technique. The trial and error method could take few hours for the

loop testing procedure. In real life industry scenarios, this method consumes a lot of time

and would be a very inefficient and wasteful method. This is so because in the industrial

world, minutes or seconds could mean thousands or millions of dollars. However,

Zeigler-Nichols method is useful for fine and specialty chemical industries, where

products require high quality and purity instead of mass volume produced.

27

MONASH University Malaysia

CHE 3162 Process Control Laboratory

7.0 Conclusion

Based on the experiments that were conducted, the overall characteristics of each

different control systems were analysed and investigated. This is done by changing

different values of gains for different control systems and analysing the response and

study effect after changing certain gains.

For the proportional control system, Ki and Kd values were fixed to zero while Kp

was being varied. The smallest Kp value gave the most stable response system and when

the Kp value was increased, the system starts becoming unstable as oscillations are

present. Also, offsets are always present in the response for all values of Kp. For

proportional-derivative (PD) controller system, the Kp and Ki was set to 5 and zero

respectively while Kd was set initially to 0.01 and then being varied. For the PD control,

the system was unable to achieve the set point thus causing offsets. Moreover, a larger

derivative gain will cause the system to oscillate and end up being unstable. Thus, since

the response when Kd = 0.01 was the best, this value chosen as the optimum value to be

used in the PID control system tuning process. Not to forget, a value of 0.01 was chosen

as the optimum value for Ki since it was found out that the response when Ki = 0.01 gave

the shortest settling time without any oscillations in the proportional-integral (PI) control

although the initial Ki value was set at 0.001.

Subsequently, after the P, PI and PD experiments were conducted, the

optimum gain values that is to be used for the PID control system was concluded to be

Kp, = 5, Ki = 0.01 and Kd = 0.01. These values were chosen as the optimum values as they

are able to provide the shortest settling time and with an zero offset value. In addition, a

series of calculations was performed in the step test closed loop tuning method and the 2

valve openings that gave the smoothest flow were determined to be 80% and 20%. With

consideration of values for the 2 valve openings chosen, the process gain, Kp, time

constant, Tp, and dead time, P were calculated to be 0.06, 0.0167 minutes and 0.0333

minutes respectively.

As a whole to conclude this experiment, PID was concluded to be the best system

that can be used for a closed-loop flow controlling system, followed by the PI controlling

system and PD controlling system. The proportional-only controlling system is not

suitable as a stand-alone control system because the offset cannot be eliminated with this

control system. Furthermore, another downside would be that the system will start

becoming unstable if the proportional gain was set at a certain large value. Similarly, the

PD controlling system will become unstable as well if a high value of derivative gain is

used. On the other hand, PI controlling system can achieve stability and reach the set

point value as it is able to eliminate the offset. However, if the Ki value is too small, it

will tend to oscillate and become unstable. When the Ki value is too big, the settling time

of the system will also increase as shown in Figure 10 and the output response will reach

to a value that is above the set point value and the settling time required would be very

long as shown in Figure 11.

28

MONASH University Malaysia

CHE 3162 Process Control Laboratory

8.0 Nomenclature

Symbol

Meaning

Kp

Ki

Kd

Proportional Gain

Integral Gain

Derivative Gain

Proportional Integral Derivative

Control

Proportional Integral Control

Proportional Control

Proportional Derivative Control

Dead Time

Time Constant

Manipulated Variable

Process Value

Critical Time

Set Point

PID control

PI control

P Control

PD control

P

Tp

MV

PV

TC

SP

9.0 Reference

Moodle. 2014. Monash University CHEMICAL ENGINEERING LABORATORY

MANUAL CHE3162 Process Control. [ONLINE] Available

at:http://moodle.vle.monash.edu/pluginfile.php/2528762/mod_resource/content/3/

Sunway%20Lab%20Manual%202014.pdf. [Accessed 24 August 14].

Seborg, Edgar and Mellichamp, Process Dynamics and Control 2nd edition,

Wiley, 2004. [Accessed 24 August 14].

29

Potrebbero piacerti anche

- Literature Review ReportDocumento1 paginaLiterature Review ReportLim LeongNessuna valutazione finora

- CHE3167 - Transport Phenomena and Numerical MethodsDocumento2 pagineCHE3167 - Transport Phenomena and Numerical MethodsLim LeongNessuna valutazione finora

- Lecture 7 Mass Transfer Coefficients IIDocumento21 pagineLecture 7 Mass Transfer Coefficients IILim LeongNessuna valutazione finora

- Internship Project Final Report Des/Sbtap Automotive Repair and Refinishing Environmental Compliance On-Site Evaluations Ali EtebariDocumento15 pagineInternship Project Final Report Des/Sbtap Automotive Repair and Refinishing Environmental Compliance On-Site Evaluations Ali EtebarijaitunlNessuna valutazione finora

- CHE3175 - Sustainable Process Engineering Case Studies (2015 2nd Sem)Documento1 paginaCHE3175 - Sustainable Process Engineering Case Studies (2015 2nd Sem)Lim LeongNessuna valutazione finora

- CHE3175 - Sustainable Process Engineering Case Studies (2015 2nd Sem)Documento1 paginaCHE3175 - Sustainable Process Engineering Case Studies (2015 2nd Sem)Lim LeongNessuna valutazione finora

- 20 Examination StrategiesDocumento3 pagine20 Examination StrategiesLim LeongNessuna valutazione finora

- 4023867Documento106 pagine4023867kidane hailuNessuna valutazione finora

- Chapter 3 P&idDocumento101 pagineChapter 3 P&idLim Leong100% (1)

- Air Turbine Generator Lab EfficiencyDocumento4 pagineAir Turbine Generator Lab EfficiencyLim LeongNessuna valutazione finora

- CHE3166 - Process Design UnitDocumento2 pagineCHE3166 - Process Design UnitLim LeongNessuna valutazione finora

- CIE Grade A+Documento4 pagineCIE Grade A+Lim LeongNessuna valutazione finora

- Graph of 1/v vs 1/S with linear regressionDocumento2 pagineGraph of 1/v vs 1/S with linear regressionLim LeongNessuna valutazione finora

- CIE AssemblyDocumento1 paginaCIE AssemblyLim LeongNessuna valutazione finora

- CIE MayJune 2012Documento1 paginaCIE MayJune 2012Lim LeongNessuna valutazione finora

- Teaching in Formations 13 Pre CalculusDocumento8 pagineTeaching in Formations 13 Pre CalculusLim LeongNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Basics of Hacking and Pen TestingDocumento30 pagineThe Basics of Hacking and Pen TestingAnonNessuna valutazione finora

- 【小马过河】35 TOEFL iBT Speaking Frequent WordsDocumento10 pagine【小马过河】35 TOEFL iBT Speaking Frequent WordskakiwnNessuna valutazione finora

- Fluorescent sensors for detection of heavy metalsDocumento36 pagineFluorescent sensors for detection of heavy metalskawtherahmedNessuna valutazione finora

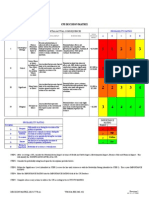

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocumento15 pagineRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Blank Character StatsDocumento19 pagineBlank Character Stats0114paolNessuna valutazione finora

- PSPO I Question AnswerDocumento11 paginePSPO I Question AnswerAurélie ROUENessuna valutazione finora

- Mind MapDocumento1 paginaMind Mapjebzkiah productionNessuna valutazione finora

- RAGHAV Sound DesignDocumento16 pagineRAGHAV Sound DesignRaghav ChaudhariNessuna valutazione finora

- SMK ST GabrielDocumento39 pagineSMK ST Gabrielzanariah1911Nessuna valutazione finora

- PLC 2 Ladder DiagramDocumento53 paginePLC 2 Ladder DiagramAnkur GuptaNessuna valutazione finora

- Modal Analysis of Honeycomb Structure With Variation of Cell SizeDocumento3 pagineModal Analysis of Honeycomb Structure With Variation of Cell Sizeprateekg92Nessuna valutazione finora

- Materi Green SCMDocumento38 pagineMateri Green SCManandaailanthusNessuna valutazione finora

- 0418 w08 QP 1Documento17 pagine0418 w08 QP 1pmvarshaNessuna valutazione finora

- JEE Test Series ScheduleDocumento4 pagineJEE Test Series ScheduleB.K.Sivaraj rajNessuna valutazione finora

- RealPOS 70Documento182 pagineRealPOS 70TextbookNessuna valutazione finora

- Lenovo IdeaPad U350 UserGuide V1.0Documento138 pagineLenovo IdeaPad U350 UserGuide V1.0Marc BengtssonNessuna valutazione finora

- Mitchell 1986Documento34 pagineMitchell 1986Sara Veronica Florentin CuencaNessuna valutazione finora

- Time Series Data Analysis For Forecasting - A Literature ReviewDocumento5 pagineTime Series Data Analysis For Forecasting - A Literature ReviewIJMERNessuna valutazione finora

- Capitalism Communism Socialism DebateDocumento28 pagineCapitalism Communism Socialism DebateMr. Graham Long100% (1)

- Jakobson Linguistics and PoeticsDocumento8 pagineJakobson Linguistics and PoeticsPhil KostovNessuna valutazione finora

- Google Fusion Tables: A Case StudyDocumento4 pagineGoogle Fusion Tables: A Case StudySeanNessuna valutazione finora

- Sprite Graphics For The Commodore 64Documento200 pagineSprite Graphics For The Commodore 64scottmac67Nessuna valutazione finora

- McKinsey & Co - Nonprofit Board Self-Assessment Tool Short FormDocumento6 pagineMcKinsey & Co - Nonprofit Board Self-Assessment Tool Short Formmoctapka088100% (1)

- SYS600 - Visual SCIL Application DesignDocumento144 pagineSYS600 - Visual SCIL Application DesignDang JinlongNessuna valutazione finora

- Signal Processing Problems Chapter 12Documento20 pagineSignal Processing Problems Chapter 12CNessuna valutazione finora

- Windows Server 2016 Editions ComparisonDocumento4 pagineWindows Server 2016 Editions ComparisonmasterredhardNessuna valutazione finora

- Decision MatrixDocumento12 pagineDecision Matrixrdos14Nessuna valutazione finora

- The Effect of Reward Practices on Employee Performance in Ethio TelecomDocumento29 pagineThe Effect of Reward Practices on Employee Performance in Ethio TelecomZakki Hersi AbdiNessuna valutazione finora

- NMIMS MBA Midterm Decision Analysis and Modeling ExamDocumento2 pagineNMIMS MBA Midterm Decision Analysis and Modeling ExamSachi SurbhiNessuna valutazione finora

- Cellulose StructureDocumento9 pagineCellulose Structuremanoj_rkl_07Nessuna valutazione finora