Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sipovi TU Eng

Caricato da

jasamnajCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sipovi TU Eng

Caricato da

jasamnajCopyright:

Formati disponibili

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.2

3. OPTI I TEHNIKI USLOVI

GENERAL AND TECHNICAL REQUIREMENTS

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.3

GENERAL CONDITIONS FOR CONSTRUCTION

Contractors are required to perform the works fully complying with these General and Technical

Requirements, which form an integral part of the project technical documents. Prior to

commencement of work, Contractors (Site Managers) are required to thoroughly review all the

designs and site investigation reports, and familiarize themselves with on site soil morphology and

hydrogeological conditions. During their review, the Contractors are required to notify the Supervisor

of all the irregularities identified in the design.

Contractors are required to prepare a critical-path-method-based detailed construction schedule and

coordinate the construction accordingly. The construction schedule should be supported by a written

document certifying that all the materials needed have been provided and that their delivery dates

correspond to the construction time schedule.

Contractors are required to organize construction management on the site, provide the necessary

premises and storages, as well as to appoint a Manager in Responsible Charge who will be

authorized to perform the required type of work.

Construction Manager needs to: be present on-site at all times while the construction lasts; register

with the AHJs in order to obtain the Notice of Commencement; and obtain all the permits and

approvals necessary for commencement of construction according to the regulatory requirements for

construction.

Prior to commencement of works the Contractor is required to survey and mark the building site,

routes of all existing and underground utilities, positions of existing facilities, as well as to form a

reference network using temporary bench marks, which will help control the elevations and directions

at all times during construction. The work needs to be performed in full compliance with these

conditions and other regulations for this type of work. If there happens to be an amendment of these

regulations or new ones are to be passed in the course of construction, the Contractor is required to

comply with their latest versions.

All items of the Priced Bill of Quantities suppose performing each item of works fully conforming to

the plans, technical description, static calculation, details and subsequent designer details, applicable

technical regulations, standards and instructions of the Supervisor and the Designer, with utmost

professionalism and precision.

All the works and materials specified in the itemized descriptions of the PBoQ need to be included in

the prices proposed by the Contractor. Prices contained in the PBoQ are the Contractor's selling

prices, and are inclusive of all the costs of work and material, onsite and offsite transport, scaffolding

(unless it is specified in a separate item of work), water, lighting, driving material and energy for the

machines, utility costs, social security, all state and municipal charges, Contractor's earnings and all

other costs that may be incurred due to the special conditions of work, envisaged by average norms

in construction.

A general description provided for one type of work and material binds the Contractor to perform all

such works appearing in other items as provided in that general description, irrespective of whether

or not the item concerned includes a reference to the general description, and, of course, unless

otherwise specified in that item.

All construction works and construction trades require use of 1st class quality material. The material

used for contracted works needs to correspond to the current SRP Standards or other recognized

norms and standards applicable to the use of this material and corresponding to the descriptions of

items of work that include it. Each material delivery must be supported with a certificate issued by the

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.4

Supplier. Those materials that are not approved by the Client's representative, for not being of 1st

class and planned properties, must not be used, unless the item of the PBoQ specifies its lower

quality. All the material found incompliant with the PBoQ and Conditions the Contractor is required to

remove off-site, and the Client's representative will suspend the works if the Contractor tries to use it.

In the event there is a problem with a material, such material needs to be sent to the institute for

material testing, whose results are authoritative both for the Client and for the Contractor. The

Contractor will be responsible for all the materials used and not used, as well as for all the works

performed before the final handover, i.e., before granting of the Occupancy Permit.

All construction works and construction trades require engagement of appropriate and qualified

workers, as provided in the current average norms in construction. Upon Client's request, the

Contractor is required to remove from the site all negligent and unprofessional workers.

The works need to be performed as specified in the design, contract and these conditions. Should

there be an inconsistency between them, the Contractor is required to timely ask the Supervisor or

the Design Professional in Responsible charge for a solution. Each change to the design needs to be

approved by the Design Professional in Responsible Charge, Supervisor and the Client.

It is necessary to perform building and soil surveys during construction as provided in the Bylaw on

Scope and Procedure of Building and Soil Surveys during Construction and Use.

In addition to these General Conditions for Construction, for building construction and overall

construction works current Law on Building Construction is also binding.

SPECIAL TECHNICAL CONDITIONS

Groundwork

Prior to commencement of ground work, the Contractor is required to perform clearing and grubbing

in the area of concern, and then in the presence of the Supervisor, based on the plans mark the

building footprint on the ground, make permanent reference points and elevations following

recognized surveying methods, and make a record of them in the construction log.

If the site is not prepared for construction, the Investor is required to provide the Contractor with

timely demolition permits, as well as with the permits for temporary or permanent relocation of

different facilities, utilities and trees.

All excavations need to be formed by proprely cutting their sides, to required slopes, with rough

and fine planing of their bottoms.

Foundation pit securing, i.e., strutting and shoring of trenches and its sides needs to be

performed in compliance with the Design of Foundation Pit and Foundation Pit Protection, as

well as the Bylaw on Technical Norms for Construction of Building Foundations.

During construction of foundations the Contractor is required to monitor groundwater levels. Prior to

or during excavation plan appropriate actions to drain away ground or storm water.

Prior to commencement of groundwork, perform clearing and grubbing of the site on which the

building will be constructed. After this, in the presence of a Suprvisor, measure the site on

which the structure will be errected. Bind the structure to the ground both horizontally and

vertically, and survey the cross sections in order to measure the excavated quantities for

payment.

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.5

Make sure to include all these works in the price of excavation, since they will not be paid for

separately.

Perform excavation exactly as planned, vertically and laterally cutting trench sides, and finely

planing its bottom on a level envisaged by the design.

If the soil undergoing excavation is of poor properties, the top layer about 20 cm thick needs to

be stripped immediately before the commencement of foundation construction.

Exacavation shall be performed in soils with natural moisture content, under normal working

conditions.

The Contractor is required to coordinate the excavation and fill. If for whatever reason they

cannot achieve this, the Contractor will be responsible to store excavated ground to a

designated area and backfill it when the opportune. As the fill obtained from the borrow pit the

final balance will admit only that part of the fill that could not have been obtained from the

excavations formed in order to construct the building of concern. This needs to be approved by

the Supervisor hired by the Employer.

Use the excavated ground primarily to fill over the foundations and around the walls, and

transport the surplus ground offsite to a location designated by local AHJs, municipality of

Supervisor hired by the Employer.

Drainage of constant groundwater, as well as the work under water will be paid as a separate

item of work if needed, while on the other hand, drainage of stormwater (precipitation) and of

the water periodically inflowing from time to time will not be paid for separately.

Once the excavation is completed, the Contractor is required to ask the Employer/Supervisors

for inspection and acceptance of completed excavation, i.e., approval that the building's

foundations will be constructed on levels envisaged in the design.

The Contractor will not be allowed any overexcavations; rather, the Contractor will be required

to backfill the overexcavated areas at their own expense using lean concrete, made with 100

kg of cement to 1 m3 of concrete.

Soil classification shall be performed by the Supervisor and the Contractor together, who will

document their findings in the construction diary. Pricing the groundwork quantities for

payment will be performed onsite, in compliance with the general norms in construction,

general conditions for construction, on the basis of longitudinal and cross sections surveyed

prior and posterior to excavation.

Payment shall be made for complete work on the basis of 1 m3 of excavated residual ground or

m1 of completed work, as described in the general conditions.

Bulk excavations shall be all those excavations the bottom of which exceeds 20 m2, and the

area of the smaller side exceeds 2,00 m1, including the excavations for foundations, pad

foundations and smaller cuts.

Prices of all kinds of excavations are inclusive of the transport of ground to its point of use or

the surplus ground landfill. This landfill will be chosed by the Supervisor.

Landfills and borrow pits will be treated in accordance with the temporary technical regulations.

Excavated ground is classified on the basis of the following criteria:

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.6

a) Classes 1 and 2 are all the excavations performed manually or with the aid of excavating machines

in fertile soils, subsoil and sandy soil, compact sand and fine-grained unbound gravel.

b) Classes 3 and 4 are all the excavations performed with pickaxes, all types of bulldozers with blades

and rippers, all types of excavators with a clamshell or a ripper, including conglomerate layers at

the most 50 cm thick. Classes referred to in item a) can be considered classes 3 and 4 when

excavated with pickaxes, buldozers or excavators.

The listed types of excavation under item a can not be classified in the 3 and 4 category and

when they are excavated by pickaxe, buldozer or bagger.

c) Classes 5 and 6 are all the excavations performed with pneumatic or electric drills, or mining, while

can be classified based on the criteria under a) and b).

Excavations of larger scale shall be classified by the specialized committee during excavation and

after drilling, but before concreting and bricking of building parts that would obstruct future inspection

of excavation structure.

This committee will be formed of permanent representative of the Contractor and the Employer, and

a neutral expert in exceptional cases, when the Contractor's and Employer's representatives cannot

agree of the soil class.

All representatives forming the excavation classification committee, as well as their replacements will

be appointed in a decision of the Contractor and the Employer.

Costs of hiring a neutral expert will be paid by the Contractor and the Employer together, in all the

cases.

The committee will document the information on excavation classification in the construction diary of

the building concerned.

WIDE EXCAVATION OF SOIL

Works include wide excavations of all types of soil materials which are planned by the

design together with transport i.e. pushing of excavated materials to the waste dump on the

side in the zone owned by the Client due to later placement.

The design covers for the excavated mkaterials to be storaged to the local waste dump

located within the plot.

All excavations should be executed accordign to profiles, described levels, presribed

design slopes, taking into consideration the required characteristics for dedicated use of

excavated materials and in conformity with these technical conditions and SRPS.U.E1.010.

Prior to commencement of works the Contractor is obligated to perform control of the

designed profiles and to notify the Supervisor regarding possible discrepancies which will

together with the contractor perform a new control. The necessary corrections will be inscribed

into profiles and into the Site Book which must be signed, as the profiles, by authorized

representatives by the Client and Contractor. The precision of excavation should be 5cm. This

procedure verifies the correctness of profiles for calculation.

Excavation should be performed by adequately selected mechanization so that the

manual work is limited to the necessary minimum.

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.7

Excavation categorization in the mixed materials is mandatory regardless if the

Contractor requested it. It is executed towards the transversal profiles during construction in

the percentage from the overall surfaces of transversal profiles for certain types of soil

materials which is the basis for determining of total quantities for a certain category. Excavation

categorization is performed by the Committe in the following constitution: Client certified

geomechanical labboratory, supervisor and contractor; they make a minute and on the basis of

recognized percentages, through the minute, the Clients representatives calculates the

categories.

During execution of excavation all necessary protective measures should be enforced

for the complete safety during work and all necessary securing of the existing buildings and

circulation areas. In each work phase efficient dewatering of the road trunk must be enabled.

Sequence for execution of excavation should be adjusted in such manner so that pockets

would not form where water would collect in case of rain. Difficult work due to occurence of

water during excavation will not be paid separately. Attention should be paid so that

undermining does not occur, ballance disturbance or damage of slopes which are planned by

the design. The contractor is obligated to repair any such case according to the instructions by

the Supervisor and at his own expense.

Metering of quantities for excavation calculation is performed on the basis of actual

volume of excavation metered in autochtonous state, on the basis of metering of transversal

profiles after taking of humus and per the final excavation within the deisgn, namely changes

approved by the supervisor.

Larger excavated quantities from those in the designed are not paid if they occured by the fault

of the contractor.

Payment per m3 of autochton excavation separately for certain types of soil materials.

The price includes all excavation works with loading, transportation and unloading of materials

on the side of the construction waste dump in the zone owned by the client.

MAKE AND MECHANICAL COMPACTING OF MATERIALS FROM FILL

These works include filling, srepading, rough i.e. fine spreading, wetting and compacting

of materials by adequate selected means in conformity with the dimensions and levels from the

design.

Making of fill is in layers.

All works must be executed in conformity with the design and these technical conditions.

Value of compressibility module for certain materials is determined by the

geomechanical laboratory on the basis of material characteristics.

The required compactness by the deisgn is minimum minMe=25MPa.

Slab testing should be executed on materials whose humidity is close to optimum.

Ready fill must have the designed slope descents, dimensions and levels with tolerance

of maximum 5cm. Dimensions and slopes are metered after taking off from the slopes of non

compacted layer, which is not paid separately because those works are included in the price

for executed and compacted fill, wide and higher executed slopes occured by the contractors

fault will not be calculated and the contractor is obligated to execute proper repairs to the

designed dimensions with the tollerance of maximum 5cm.

Calculation and payment is per m3 of executed (compacted) fill metered per profiles.

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.8

May, 2015.

Design Engineer in Responsible Charge:

Zoran NOGULOVI, MSCCE

Licence 310 0290 03

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.9

TECHNICAL REQUIREMENTS FOR PILE DRIVING PROCESS

EARTHWORKS

Prior to commencement of earthworks on site, earth onto which the building will be

erected will be clear of weeds and shrubs. Furthermore, site survey will be carried out

in the presence of a Supervisor so as to decide the exact position of the future

building. The survey will be performed both horizontally and vertically. Cross profiles

will be surveyed as well in order to calculate future soil excavation. All of these works

will be included in the price of excavation as they will not be charged for separately.

Soil will be dug exactly according to plan, all of which will be accompanied by either

vertical or sloped removal of lateral excavation sides, whilst excavaton bottom will be

leveled adequately so as to meet the design level. If the soil of poor quality is

discovered on site, the last layer of cca 20 cm in thickness will be dug right before

foundation has been formed. The term work used in the course of excavation means

an excavation of moist soil in its natural state under the normal working conditions at

the site.

Excavated soil will be chiefly used for backfilling around the foundation and walls,

whilst surplus soil will be removed from the site and taken to the landfill. Bracing of

lateral excavations as well as protection of adjacent facilities will depend on the natural

state of the soil as well as on the position of adjacent facilities. The protection will be

included in the price of excavation as it will not be charged for separately. In the same

way the price will also include marking out of both building foundation and equipment,

all of which has not been included in the project. Drainage of present groundwaters, as

well as underwater activities will be charged for separately under specific work item if

necessary, whereas the mentioned drainage of storm waters, i.e., precipitations which

may represent occasional water flow into foundations will not be charged for

separately.

After excavation has been formed a Contractor has to request both inspection and

acceptance of formed excavation from the Client, i.e., control which will confirm that

the building sits on design foundations.

Foundation redigging by a Contractor will not be allowed, therefore a Contractor will be

obligated to fill all holes during redigging at his/her own expense up to design levels by

use of lean concrete, i.e., 100kg cement per m3 of concrete.

Soil category will be decided by both a Supervisor and a Contractor; all of which will be

entered up in the Site Book. Earthworks will be calculated at the site according to

Required Standards in Civil Engineering, General Work Performance Requirements

and in line with both longitudinal and cross profiles surveyed both before and after

excavation.

Payment will either be made per m3 of excavated soil or per m3 of formed excavation,

all in conformity with the General Technical Requirements. Wide excavation means all

excavations stretching over 20,00m2 whose smaller side is over 2,00m, it also means

excavations on foundations and pad foundations as well as excevations at cuts.

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.10

Excavation price includes soil transport to the trench or to a landfill where surplus soil

is deposited.

Excavated soil is categorized according to the following criteria below:

- I and II category refers to all excavations performed either manually or mechanically

onto fertile land, sub-soil and sandy soil, compacted sand and fine unbound gravel

- III and IV category refers to all excavations performed by pickaxe, all types of

bulldozers with the blade and a ripper, all types of excavators with a stick and bucket,

including all conglomerate layers maximum 50 cm thick. Soil types specified under I

and II category cannot fall under III and IV category not even when they are dug by

pickaxe, bulldozer or a bagger

- V and VI category refers to those excavations formed by electric pneumatic drills,

which do not belong to any of soil categories mentioned above

Categorisation concerning excavations of bigger size is decided by the Inspection

Committee in the course of excavation and after they have been formed i.e., prior to

both casting in place and brick laying which could hinder later insight into excavation

structure.

The Committee is composed of Contractors representatives, Client and possibly of a

neutral expert when Contractors and Clients representatives cannot agree on

excavation categorisation. Above mentioned representatives are appointed by both the

Client and the Contractor through official certificate delivered to the Excavation

Categorisation Committee. Data on excavation categorization are entered up in the

Site Book by the Committee.

Expenses concerning engagement of neutral persons will be incurred equally by both

the Contractor and Client at all times.

REINFORCEMENT

Reinforcement B500B will be used in full compliance with SRPS EN 10080.

Reinforcing bar has to be clear of dirt, rust, grease and other. In the course of further

concrete casting in place, reinforcement ends which protrude from the concrete will

have to be cleaned adequately as described above. The main reinforcement will be

attached to every U-bolt, whilst protruding reinforcement will be taut by a burnt wire

1mm, all of which will be done adequately so as to meet the details. Only those

quantities actually installed in concrete will be considered during payments, supply and

laying of reinforcing bars, all of which will be done either fully in line with reinforcement

plans or Supervisors decision if the quantity is exceeded, i.e., after a Supervisor has

allowed it. If the Contractor fails to provide adequate reinforcement diameters the

same Contractor will change details, calculate them again and produce new ones at

his/her own expense. Structural design and details are submitted to both a Designer

and a Client for an approval, i.e., work is commenced after a go-ahead signal. In such

case, reinforcement weight installed in the said way will not be paid by the Client, i.e.,

the Client will not pay for more than agreed in design details. Payment regarding

installed reinforcing bar will be made per unit price for one kg of iron, which includes:

purchase and delivery of reinforcing bars, binding wires, washers and other additional

fittings, cleaning, cutting, bending, installation, welding and all other expenses in

connection with purchase and laying of a reinforcing bar.

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.11

CONCRETE AND REINFORCED CONCRETE WORKS

Both casting in place and concrete laying will be performed mechanically. Designated

concrete class will be achieved through proper mixure of Portland cement, water and

aggregate, as well as by use of mixtures of adequate quality and testing of selected

cubes sampled by the Contractor and sent to the Institute for Materials Testing.

Expenses regarding the tests will be included in the unit price of concrete. Portland

cement will be delivered to end users on site in either original bags or cisterns. Cement

must be kept in dry areas and moved to another location every 3 days, whereas

cement from cisterns has to be stored in closed airtight tanks. If a poor concrete quality

is achieved when compared to a tolerance required in technical regulations, such laid

concrete will be replaced only if the reduced quality places the structure in jeoperdy,

i.e, only if the previous approval is obtained by both a Designer and a Supervisor.

Both interruption and continuation of concrete casting will be performed in full

compliance with technical regulations and instructions given by both a Supervisor and

a Designer. Possible honeycombing in concrete will be both filled and plastered by the

Contractor after it has been given a go-ahead signal by the Supervisor, with no right to

compensation. Concrete segregation will be avoided either by use of funnel or by

stirring. The structure will be protected against the sun, wind and frost during the day,

which will be included in the price of concrete.

All works must be performed in a way to correspond to layouts, details and structural

analysis, i.e., in a higly professional manner by engaging adequate professional work

force and professional supervision on site. All concrete surfaces will be made smooth

so that noticeable concrete surfaces will be flat and its edges undamaged.

Unplastered concrete surface will be placed in a formwork plastered on the inside.

Calculation regarding completed works will be made according to actual quantities

used at the site. The price also includes formation of utility tunnels for water supply

pipes, sewer pipes, central heating, formwork and other. Reinforcement will be

calculated separately.

Fluvial aggregate of exactly the same grading as Moravac gravel will be used for

casting of concrete.

For that reason, constant control both over dosing and granulometric composition will

be introduced on site. Water, which is needed for concrete production, will come from

the water main.

Formwork will be sprinkled over the course of casting, which will be included in the

price of concrete.

The price of formed concrete includes all expenses in connection with delivery of

concrete both inside and outside the site (both horizontal and vertical), overheads, all

taxes, tools, work and material, electricity and other, all of which will not be charged for

separately. Both Bylaw on Technical Measures and Requirements for Concrete and

Reinforced Concrete and Bylaw on Technical Merasures and Requirements for

Prestressed Concrete will be fully adhered to in the course of concrete casting.

Contractor is obligated to test the aggregate prior to concreting of structure elements in

conformity with SRPS B.B.0B001, U.M.8.020, U.M.8.021, B.B.8.030, B.B.8.032,

B.B.8.034, B.B.8.035, B.B.8.036, B.B.8.037, B.B.8.038, B.B.8.039, B.B.8.040,

B.B.8.044, B.B.8.047 and B.B.8.048 prior to casting of structural members.

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.12

As for concrete class MB-30 and 40, Contractor has to test the cement in conformity

with SRPS B.C.1.012, and B.C 8.020.

Contractor is obligated to test cube samples to SRPS U.M.1.010, U.M.1.011, i

U.M.1.012.

PILE DRIVING

After ground has been adequately leveled, piles will be marked by temporarily driven

stakes. Pile driver will be positioned adequately at its intended position for pile driving,

whilst its associated equipment parts will be positioned vertically. Boring is carried out

on the rough site surface which is cca 20cm higher when compared to the level of

design low foundation surface. Boring can also be carried out in the presence of

groundwaters, whereas a borehole has to be lined with a steel casing in the course of

drilling, rebar installation and pile concreting at all times.

If pad foundations, parts of old foundations, MEP systems or alike are discovered at

the site in the course of boring in such case both a Supervisor and a Designer will be

informed about it.

After boring has been completed, the position of steel casing will be surveyed with an

adequate instrument and its exact position entered up into the Site Book. Under no

circumstances will a bore hole axis depart from a design one for more than 5 cm along

its entire height.

If bigger bore holes are observed on site when compared to design ones, such bore

holes will be backfilled with sand and new ones drilled at Contractors expense.

Once the pipes are lowered down to borehole bottom, on no account will such pipes be

pulled out until a pile has been cast in place.

Excavated material from the bore hole will be placed at boreholes lateral sides and as

such it will be shown to a Supervisor for inspection, who will in turn in the event of any

kind of irregularity or doubt require Designers opinion.

After excavated material has been inspected by a Supervisor and if a Supervisor will

allow it, the said material will be removed from the construction site.

REINFORCEMENT CAGE

Reinforcement cages or rebars made from reinforcing bars will not be assemblied at

the site, i.e, they will be delivered as ready-made. Used steel has to be fully compliant

with regulations. Cross reinforcement will be 50% welded to a longitudinal one. Rebars

will be delivered in a careful manner at the site so they would neither suffer

deformations nor distortions.

Delivered rebar at site will be lifted carefully by either a hoist or a pile driver, positioned

vertically and lowered down the borehole immediately after the bore hole has been

cleared and Supervisors approval in writing on pile driving continuation process

obtained.

If problems of any kind would be encountered during rebar installation, the same rebar

will be pulled out, inspected, dimensions checked and possible mistakes rectified.

Rebar will not touch the borehole bottom; instead it will be placed at about 10cm above

its bottom so as to provide a protective layer for adequate pile positioning. Time

between rebar installation and casting of concrete will not last for more than 2 hours,

i.e., only under special circumstances and after Supervisors approval in writing has

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.13

been obtained will time between rebar installation and casting of concrete last up to 4

hours so as to stop fouling of reinforcement and formation of clay film on it.

Boring schedule and pile driving depend on conditions at the construction site.

Pile concreting schedule is decided by a Supervisor in full accordance with work

performance schedule and general conditions observed on site.

CAST-IN-PLACE CONCRETE PILES

Pile casting is carried out in full compliance with regulations and TUI by MB 40

(C30/37) ready made concrete delivered at the site.

Concrete is poured into steel casing D=200mm, i.e., casing is pushed into both rebars

axis and concrete to a depth of 2,00m, whereas at the start of casting the casing is

lowered to a depth of about 10 to 15 cm above the borehole bottom, meaning that

concrete is pumped inside until steel casing is lowered to a depth of 2,00m and later

forced out following concreting.

Lowering of steel casing down the borehole is mandatory so as to avoid contact

between fresh concrete and the first layer of cast concrete which emerges at the

surface, meaning the steel casing is slowly and gradually forced out at the top of the

borehole and cropped.

Depth at which the steel casing is lowered has to be controlled at all times so as to

ensure depth of around 2,00m at which the casing will be positioned.

When dismantling, removing and cropping the steel casing, the same casing will be

pulled out above the concrete surface, low part of the casing will be secured to the

surface around the borehole, one segment /part/ will be forced down into concrete,

concrete will be poured into the funnel, the funnel will further lower the casing down

through which concrete will be poured. The whole operation concerning pipe cropping

will not last for more than 10 min.

If the requirement set out in item V.03 is met and concrete mix still continues to be

poured quickly, in such case water cement factor of concrete should be reduced.

Casting may also be performed with pumps if better concrete quality is required.

Funnel for concrete pouring has to be in a shape of a cone, whose sides sit at an angle

of not less than 45 when compared to their horizontal plane. Funnel dimensions

should assure funnel volume of approximately of total steel casing volume, which

allows continuity of concrete pouring through the casing. As far as the casing of

D=200mm and concrete pouring depth of 20,00m is concerned, funnel volume of about

V=0,65 m is required.

Proper casting of concrete at its very beginning is essential for the quality of a driven

pile; therefore special attention will be paid to it. As far as the first concrete pouring

goes, the quantity of prepared concrete has to be such to meet the volume of borehole

at the depth of 2,00m. After the first concrete layer is poured casting will continue in

parallel with forcing out of casing at the height of 5 to 10 cm making sure that the low

part of the casing does not empty. If the casing does empty during concrete pouring

the same casing will be forced back into the concrete mix until concrete level in the

funnel is brought to an equal level with the level of both funnel and casing. Pile will be

concreted at the level of minimum 30 cm which is higher when compred to the level of

low edge of girders positioned at the same place, fully in accordance with design data.

Pile will be concreted in continuation with no interruptions whatsoever, all of which

depends on adequate concrete delivery organization which assures concrete pouring

prior to its binding. Concrete binding process will not last less than 2h from the moment

of its mixing. Used concrete has to be of such properties to ensure both safe and

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

2014U060G11

IZMENA /

REVISION

STRANA /

PAGE

1.14

proper grouting of a borehole through the casing, whereby all impurities on the

reinforcement will be cleared away, i.e., ejected onto the surface.

Either portland cement PC 350 or the one of better characteristics will be used in order

to form concrete, whereas quantity per m of concrete will not be less than 380 kg/m.

Aggregate grain diameter will not exceed 38mm.

Admixtures inside the concrete mix will not affect its quality at any time, while

permission for their use is given by a Supervisor.

Piles will be cropped at the height of 20 to 30 cm all the way down to a low edge

of a foundation beam at least 72 hours upon pile casting.

Designer

Nikola Muravljov, MSCCE

Licence 310 0169 03

Belgrade, February 2015.

Design Engineer in Responsible Charge

Zoran Nogulovi, MSCCE

Licence 310 0290 03

MAINOPROJEKT KOPRING JVC. Dobrinjska street, number 8a, Belgrade

Potrebbero piacerti anche

- 10 1 1 531 3723Documento11 pagine10 1 1 531 3723jasamnajNessuna valutazione finora

- Lecture 5 FoundationsDocumento44 pagineLecture 5 Foundationsbeddows_sNessuna valutazione finora

- Lecture 4 Slabs - Oct 12 - EndDocumento131 pagineLecture 4 Slabs - Oct 12 - EndajayNessuna valutazione finora

- 45 (4) 0137Documento24 pagine45 (4) 0137jasamnajNessuna valutazione finora

- Torque Wrench Pump: Hydraulic/ElectricDocumento1 paginaTorque Wrench Pump: Hydraulic/ElectricjasamnajNessuna valutazione finora

- Geo5 Fem Theoretical GuideDocumento113 pagineGeo5 Fem Theoretical GuideAnonymous 87xpkIJ6CFNessuna valutazione finora

- Eta 09-0013 TTM Multistrand enDocumento56 pagineEta 09-0013 TTM Multistrand enjasamnaj100% (1)

- Layout TypicalDocumento1 paginaLayout TypicaljasamnajNessuna valutazione finora

- Lesson4 CustomComponents Precast PDFDocumento28 pagineLesson4 CustomComponents Precast PDFKadutrisampaNessuna valutazione finora

- GEO5 programs - Part 2Documento66 pagineGEO5 programs - Part 2jasamnaj100% (1)

- Behavior of Bonded and Unbonded Prestressed Normal and High Strength Concrete BeamsDocumento13 pagineBehavior of Bonded and Unbonded Prestressed Normal and High Strength Concrete BeamsjasamnajNessuna valutazione finora

- 18 Analysis and Settlement of A Pile GroupDocumento10 pagine18 Analysis and Settlement of A Pile GroupjasamnajNessuna valutazione finora

- Analysis of vertical load-bearing capacity of a single pile using GEO 5 - PILESDocumento12 pagineAnalysis of vertical load-bearing capacity of a single pile using GEO 5 - PILESjasamnajNessuna valutazione finora

- 15 Analysis of A Single Pile SettlementDocumento10 pagine15 Analysis of A Single Pile SettlementmavessNessuna valutazione finora

- Engineering Properties of MaterialsDocumento6 pagineEngineering Properties of Materialspapilolo2008Nessuna valutazione finora

- GEO5 programs - Part 2Documento66 pagineGEO5 programs - Part 2jasamnaj100% (1)

- 19 Analysis of Deformation and Pile Group Dimensioning 1Documento9 pagine19 Analysis of Deformation and Pile Group Dimensioning 1jasamnajNessuna valutazione finora

- 18 Analysis and Settlement of A Pile GroupDocumento10 pagine18 Analysis and Settlement of A Pile GroupjasamnajNessuna valutazione finora

- I140Documento1 paginaI140jasamnajNessuna valutazione finora

- 17 Analysis of Horizontal Bearing Capacity of A Single Pile 1Documento8 pagine17 Analysis of Horizontal Bearing Capacity of A Single Pile 1jasamnajNessuna valutazione finora

- 15 Analysis of A Single Pile SettlementDocumento10 pagine15 Analysis of A Single Pile SettlementmavessNessuna valutazione finora

- 16 Analysis of Vertical Load Bearing Capacity and Settlement CPTDocumento9 pagine16 Analysis of Vertical Load Bearing Capacity and Settlement CPTjasamnajNessuna valutazione finora

- Megaplate: Karbonske Ploče Za Strukturalna OjačanjaDocumento2 pagineMegaplate: Karbonske Ploče Za Strukturalna OjačanjajasamnajNessuna valutazione finora

- Concrete Batch PlantsDocumento4 pagineConcrete Batch Plantsirenemv4Nessuna valutazione finora

- 19 Analysis of Deformation and Pile Group Dimensioning 1Documento9 pagine19 Analysis of Deformation and Pile Group Dimensioning 1jasamnajNessuna valutazione finora

- SAFE Tutorial For Slab DesignDocumento38 pagineSAFE Tutorial For Slab Designbahaa_alamiri7476100% (9)

- Off 3270Documento6 pagineOff 3270jasamnajNessuna valutazione finora

- Freyssinet Post Tension Ing - C RangeDocumento36 pagineFreyssinet Post Tension Ing - C RangeMotlatjo RakgothoNessuna valutazione finora

- Tensacciaia Rock AnchorsDocumento28 pagineTensacciaia Rock AnchorsjoebriffaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 18.pipe SupportsDocumento16 pagine18.pipe SupportsEnrique BlancoNessuna valutazione finora

- The Mineral Insulation Solution For Sustainable BuildingsDocumento8 pagineThe Mineral Insulation Solution For Sustainable BuildingsMarcela MontesNessuna valutazione finora

- GATE-2022 Test Series: OnlineDocumento7 pagineGATE-2022 Test Series: OnlineSHAHBAZ AKHTARNessuna valutazione finora

- SBC of Well FoundationDocumento9 pagineSBC of Well FoundationPrakash KumarNessuna valutazione finora

- Pump CavitationDocumento5 paginePump Cavitationjrri16Nessuna valutazione finora

- Chapter 3 Plastic Analysis For BeamsDocumento26 pagineChapter 3 Plastic Analysis For BeamsDem Austria EspinoNessuna valutazione finora

- Civil Engineering MCQ'S: Ans. (D) Ans. (D)Documento4 pagineCivil Engineering MCQ'S: Ans. (D) Ans. (D)NISHIKANTA MONDALNessuna valutazione finora

- CE 4780 - Introduction To Slope StabilityDocumento15 pagineCE 4780 - Introduction To Slope StabilityEdwin CornejoNessuna valutazione finora

- Mobilization & Demobilization: Quantity Unit Description Material CostDocumento21 pagineMobilization & Demobilization: Quantity Unit Description Material CostDERICK CANUELNessuna valutazione finora

- Method Statement For Pipe Culvert Anil SahabDocumento2 pagineMethod Statement For Pipe Culvert Anil SahabAsad AshfaqNessuna valutazione finora

- Honey HeaterDocumento1 paginaHoney HeaterCalujnaiNessuna valutazione finora

- Plumbing Quotation RatesDocumento3 paginePlumbing Quotation RatesbabukcdNessuna valutazione finora

- 13.2 Fluid Mechanics 02 SolutionsDocumento11 pagine13.2 Fluid Mechanics 02 Solutionsjeruel sabacan100% (1)

- ST-350 Strain TransducerDocumento2 pagineST-350 Strain TransducerasimovvNessuna valutazione finora

- FDOT Item Average Unit Cost Report for 2015-2016Documento37 pagineFDOT Item Average Unit Cost Report for 2015-2016Roberteau HarrisNessuna valutazione finora

- 1 PressureReducingValve PDFDocumento84 pagine1 PressureReducingValve PDFKerwin CastañedaNessuna valutazione finora

- Chapter 1 - Design of Special BeamsDocumento15 pagineChapter 1 - Design of Special BeamsSine EntertaimentNessuna valutazione finora

- Ashrae 标准2022.6Documento3 pagineAshrae 标准2022.6Vinsen ShiNessuna valutazione finora

- Centrifugal Pump FundamentalsDocumento30 pagineCentrifugal Pump FundamentalsdndudcNessuna valutazione finora

- Ashrae Commercial c19 GuidanceDocumento29 pagineAshrae Commercial c19 GuidanceLord's VineyardNessuna valutazione finora

- DOKA Inspection SheetDocumento2 pagineDOKA Inspection SheetDeepu RavikumarNessuna valutazione finora

- Design Calculation For Sprinkler For Shell Cooling: Friction Loss Per Meter of Riser LineDocumento4 pagineDesign Calculation For Sprinkler For Shell Cooling: Friction Loss Per Meter of Riser Linekmas1612Nessuna valutazione finora

- Chapter 13Documento4 pagineChapter 13Tessa RebetaNessuna valutazione finora

- Uh CatalogDocumento4 pagineUh CatalogArif BinorikaNessuna valutazione finora

- Overpasses/Underpasses: DescriptionDocumento3 pagineOverpasses/Underpasses: DescriptionshafiullahNessuna valutazione finora

- AB-3P BrochureDocumento12 pagineAB-3P Brochurealisya.blwsNessuna valutazione finora

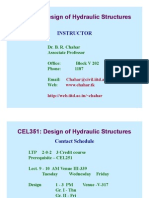

- CEL351 - Hydrualic Structure DesignDocumento32 pagineCEL351 - Hydrualic Structure DesignnourNessuna valutazione finora

- Mechanical 2nd Semester Notes PDFDocumento6 pagineMechanical 2nd Semester Notes PDFchannu rolliNessuna valutazione finora

- Introduction to Reinforced ConcreteDocumento5 pagineIntroduction to Reinforced Concretemike smithNessuna valutazione finora

- Revised Task 1 RIICWD601Documento5 pagineRevised Task 1 RIICWD601jekolaf936Nessuna valutazione finora