Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aiba 1968 Kinetics of Product Inhibition in Alcohol Fermentation

Caricato da

rishu2525Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aiba 1968 Kinetics of Product Inhibition in Alcohol Fermentation

Caricato da

rishu2525Copyright:

Formati disponibili

BIOTECHNOLOGY AND BIOENGINEERING

VOL. X, PAGES 845-864 (1968)

Kinetics of Product Inhibition

in Alcohol Fermentation

S. AIBA, 31. SHODA, and 11. SAGATAXI, Institute of Applied

Microbiology, Cniversify of Tokyo, Tokyo, J a p a n

Summary

The inhibitory effect of ethanol concentration p in a medium on the specific

rates of growth p and ethanol production v of a specific strain of bakers yeast was

studied in a chemostat, where except for ethanol as the product, only the concentration of glucose S was controlled t o limit the metabolic activity of the yeast.

This was designed t o supplement the previous findings from the batch experiment,

in which ethanol was added artificially and no substrate components were limiting

the metabolism of the same yeast, that p = p ~ e - ~ i pand v = v ~ e - ~ z pwhere

,

kl

and l i z are empirical constants and subscript the 0 denotes respective values a t

p = 0. The effects of p on the values of p and v were confirmed by the Lineweaver-Burk plot to belong t o noncompetitive inhibition. The formulas here for

p and v as affected by p , if extrapolated t o the case of no limiting substrates,

were in good agreement in respective forms with those derived previously from

the batch experiment, though the values of corresponding coefficients in these

formulas were different. The differential equations for p and v as functions of

both p and S and, in addition for the rate of glucose consumption as correlated

by the yield factors either with the cell growth rate or the rate of ethanol production, were solved properly with a digital computer. A kinetic pattern calculated

so far was discussed with reference to the data obtained in the batch experiment

and those relevant to actual sake brewing.

INTRODUCTION

It is well known that in an alcohol fermentation the accumulation

of ethanol continues incessantly even after a cessation of cell growth

at a level of about lo8 cells/ml. I t is not unusual in this stationary

phase to keep the temperature of a fermenting broth lower-e.g.,

around l5OC in the brewing of sake to prevent an inactivation of

the yeast cells due to the ethanol produced.

The fact that ethanol is inhibitory to the metabolic activity of the

845

846

S. AIBA, M. SHODA, M. NAGATANI

yeast cells is clear, if only a qualitative description is of interest.

The inhibitory effect of ethanol on the yeast cell growth is apparent

a t a relatively lower concentration, i.e., several per cent of ethanol,

while the fermentation activity of the cells seems to have tolerance

until ethanol approaches about 20% for example.

Despite a seemingly discrete effect of ethanol on yeast metabolism,

its inhibitory effect remains to be discussed in quantitative terms

from an aspect of kinetics. This implies that the effect should be in

continuous rather than in discrete patterns, provided the kinetics on

growth and ethanol production activities of yeast cells can be assessed

properly. It is difficult, indeed, to find any reference in which the

kinetic pattern of an alcohol fermentation is discussed extensively.

In this context, Hinshelwood derived from his experiments with

Bact. lactis aerogenes the following equation to describe the effect of

alcohol added into a growing culture.'

P = Pm(1 -

ap)

(1)

provided p,,, = maximum value of specific growth rate; p = concentration of alcohol; a = an empirical constant, depending presumably

on the species of alcohol added.

Recently, Holzberg et al. studied the effect of ethanol produced by

yeast cells on its rate of product (ethanol) formation in a fermentation

of grape juice.2 The region they studied was in a stationary phase of

the cell growth. The empirical equation presented by them is as

f 0llO~Vr-S

:

dp/dt

B(pm - p )

(2)

where B = an empirical coefficient; p m = the maximum value of

ethanol ever attainable.

The fact that neither the term of cell number nor that of cell

growth is found in the above equation originates from the fact that

alcohol in this instance is produced in a period lasting much longer

than that experienced from an inoculation until a cessation of the cell

growth. It is difficult from this approach to correlate the rate of

ethanol production with that of cell growth.

Now it is evident that one cannot establish a kinetic pattern of

product inhibition in alcohol fermentation unless the rates of cell

growth and ethanol production are studied regarding the case where

only one component of the original substrates becomes limited.

BIOTECHNOLOGY AND BIOENGINEERING, VOL. X, ISSVE 6

PRODUCT INHIBITION

847

A continuous fermentation in single vessels is used here to facilitate

the experiment in which glucose and only glucose in an original

culture medium limits the metabolic activity of the yeast cells. The

purpose of this work is to assess the inhibitory effect of ethanol on

the rates of cell growth and ethanol production such that one can gain

an access to the product inhibition kinetics both in continuous and in

batch runs of alcohol fermentation.

MATERIALS AND METHOD

Strain

The strain used was a respiration-deficient mutant of a bakers

yeast, H-1 (Japan Sugar Refinery Ltd., Yokohama), a protoplasmic

mutant of a tetraploid organism.

A principal reason for having adopted the specific strain was for

convenience of experimentation, because no strictly anaerobic conditions in the experiment were required oli-ing to the use of this strain.

Culture Media

The composition of the medium used is shown in Table I. The

concentration of glucose in the fresh medium was controlled a t all

times to l-2yo to realize the condition of glucose-limiting in a

chemostat in this work. This criterion of 1-2y0in the glucose concentration was predetermined from the preliminary batch experiments

that the values of specific growth rate p of the cells decreased appreciably when the concentration of the remaining glucose became lower

than this figure, provided other components, especially the yeast

extract in the original medium, were the same prescription as that in

Table I.3 Ethanol was added into the fresh medium to different

TABLE I

Composition of Culture Medium Used

Glucose

KHzPOa

(NH,)zSO4

M,SOI. 7H20

Yeast extract

Tap water

10 or 20 g

j g

2g

0.4 g

2g

1000 ml

pH 4.0

848

S. AIBA, M. SHODA, hf. NAGATANI

concentrations in each case to study the inhibitory effect of ethanol,

because ethanol due to be produced from the original medium

(1-2y0 in glucose concentration) was too dilute to produce the

adverse effect .

The medium composition used for precultivating the cells a t 30C

for about 1.5 hr in shaken flasks (rotary type; each working volume =

2 liters) was the same as in Table I except that glucose was increased

from the original @yo)

to .5yo.

Analytical Method

Cell Mass. The optical density was measured a t a wavelength of

610 mF with a photometer (Node1 FPW-4, Hitachi Works, Tokyo);

the value was converted to that of dry cell mass per unit volume of

the medium (grams per liter) by using a linear calibration.

Glucose. The Somogyi method or the Somogyi-Kelson method

was used for the analysis of glucose. The latter method was adopted

when the glucose concentration was less than about 0.2 g/l. A

spectrophotometer used for the analysis a t a wavelength of 320 mfi

was model 101 from Hitachi Works, Tokyo.

Ethanol. The oxidation method by dichromate was used for the

determination of ethan01.~ Clearly, the ethanol to be analyzed from

time to time by samplings (see below) was a sum total of that which

was preadded into the medium and that which was produced in the

continuous fermentation.

Experimental Procedure

The chemostat used is shown schematically in Figure 1. The

body of a fermentor (nominal volume = 30 liters; working volume =

5 or 10 liters) is a cylindrical glass; the lid and the bottom, both of

which were made of stainless steel were bolted together in assembling.

The fermentor was equipped with four baffle plates and the broth in

the vessel was rotated by a standard flat-blade turbine a t 200 rpm

throughout each run. The vessel n-as fixed in a water bath, the temperature of which xvas adjusted to 30C by a controller as shown in

Figure 1, while the pH value of the broth was controlled a t 4.0.

The medium reservoir was made of stainless steel (nominal volume

= 32 liters; working volume = 30 liters of fresh and sterile medium

impregnated appropriately by ethanol, if required).

BIOTECHNOLOGY AND BIOENGINEERING, VOL. X, ISSUE 6

849

PRODUCT INHIBITION

14

P

I

2

3

I 10 I PIPE FOR ALKALI

1 FERMENTOR

I FLAT-BLADE TURBINE I I I I THERMOMETER

ADD.

~~

SAMPLING PIPE

BAFFLE PLATE

12 HEATER

13 TEMP. CONTROLLER

5

6

WATER BATH

DH ELECTRODE

14

15

7

8

I ALKALI

pH CONTROLLER

I ELECTRIC

I 16 I

VALVE

RESERVOIR

17

1

1

PLUNGER PUMP

MEDIUM RESERVOIR

PIPE FOR MEDIUM ADD.

SAMPLING FLASK

Fig. 1. Schematic diagram of experimental apparatus in continuous system.

A principal part of the plunger pump was made of glass (Type

T-63K, Sanyo Scientific Inst. Co., Ltd., Tokyo); the feed rate was

rather small (0.<5-1.2 l/hr).

Due attention was paid to guarantee a constant feed rate by a

direct measurement from time to time in each run. The maximum

fluctuation of the feed rate ever experienced was about f 1 0 7 G . If

the feed rate exceeded the allowable limit, its stroke was adjusted.

The vessel was sterilized by blowing live steam (100C for 1 hr)

850

S. AIBA, M. SHODA, M. NAGATANI

before initiating each run of the continuous fermentation. A vinyl

pipe for transporting the medium and the pH and reference electrodes

in Figure 1 were also sterilized with either live steam or with an

aqueous solution of ethanol (SOTo v/v).

In addition, the fresh medium (30 1) in the reservoir was placed

en bloc in an autoclave to effect sterilization a t 120C for 10 min; after

cooling the reservoir by exposing it to a running tap water, pure

ethanol was added into the medium, if needed.

A preculture (2 or 5 liters) was charged into the vessel, followed by

an addition of the sterile medium from the reservoir. The liquid

volume in the fermentor was adjusted to either 5 or 10 liters, depending on the dilution rate employed in each series of experiments.

Then a continuous run was started by rotating the impeller and by

actuating the plunger pump. The liquid was discharged constantly

through an overflow pipe as is clear from Figure 1.

After 20-24 hr a t a constant feed rate in each run, the sampling

was begun every 1-2 hr to confirm whether or not the steady state

could be attained. If the values of residual glucose and the yeast

cells determined by several samplings neither increased nor decreased

beyond each experimental error of measurement (less than 5Yo), the

steady state was assumed. Ethanol concentration in the medium

was then determined by the oxidation method.

The procedure of samplings used here must be mentioned briefly.

A long time was required to accumulate the flowing medium out of

the fermentor (see Fig. 1) in the case of smaller dilution rates (see

Table 11). For this particular case, a sampling flask in Figure 1 was

replaced uith a measuring cylinder, into which an aqueous solution

(20 ml) of 0.1% mercuric chloride had been charged. The medium

from the overflow pipe was discharged into the cylinder till the

liquid volume amounted to 45 ml. This was followed immediately

by neutralization with an aqueous solution of sodium hydroxide

(40%) first and, second, by supplemental distilled water to a final

volume of liquid exactly equal to 50 ml. The cells could be inactivated during this sampling; after separating the cells by centrifugation the supernatant liquid u-as subjected to a spectrophotometric

determination of the residual glucose. An existence of the fungicide

was confirmed from preliminary experiments to have no adverse

effect on the measurement.

BIOTECHNOLOGY AND BIOENGINEERING, VOL. X. ISSUE 6

PRODUCT INHIBITION

851

TABLE I1

Experimental Data of Steady State in Continuous Alcohol Fermentation

pa, g/l

X, g/!

7.97

13.7

21.3

28.4

42.7

57.0

0

7.86

15.1

21.9

36.9

53.3

2.0

2.22

2.05

2.08

2.12

1.87

0.334

0.221

0.254

0.263

0.230

0.166

10.9

9.99

9.58

10.7

4.7

19.3

33.4

51.5

0

15.5

30.4

48.3

1.20

1.37

1.40

1.22

0.392

0.278

0.214

0.262

0.138

0.194

0.326

1.63

21.2

21.1

21.6

20.4

8.57

22.7

40.0

55.4

0

15.3

32.6

48.6

2.40

2.43

2.30

1.68

0.571

0.487

0.516

0.648

0.186

0.723

1.82

20.7

20.7

20.2

8.44

24.1

37.2

0

16.3

29.8

2.33

2.14

2.03

0.717

0.729

0.721

0.226

1.09

10.8

10.4

4.51

18.7

0

15.0

1.25

0.919

0.875

0.974

D=~,hr-'

S,gA

So, g/l

p, g/l

0.084

0.054

0.096

0.122

0.127

0.118

0.212

21.5

19.5

19.9

20.5

20.9

20.5

0.079

0.091

0.114

0.115

"

<'

I'

"

'

0. loo

"

'

0.160

"

'1

0.198

"

0.242

'

9,

hr-I

As for a larger value of the dilution rate, there was no necessity of

this particular procedure; each sampling \vas made directly into a

flask by 10 ml.

After the data required were taken in each run, another run of eontinuous fermentation was started without changing the feed rate.

A series of runs of the continuous experiments was repeated without

interruption a t a specific feed rate with different concentrations of

ethanol in the fresh medium flowing into the vessel.

The fermentor with its auxiliary equipment was disassembled for

cleaning and sterilizing before another series of experiments with

different values of the feed rate could be initiated.

852

S. AIBA, hZ. SHODA, 11. NAGATANI

RESULTS AND DISCUSSION

The experimental data are summarized in Table 11. The values

of specific rate of ethanol production u in Table I1 were calculated

from the data ( D , X , p , and po) in each run as follows:

u =

D(p

p,)ix

(31

The value of specific growth rate p of the cells is equal in this study

to each dilution rate. Most of the figures and discussion which will

appear later on originate from the data in Table 11.

The values of S are plotted against p in Figure 2 , the parameter

being the dilution rate, D (=p). Broken curves through the data

points deviate markedly from the curves, presumably due to experimental errors inherent especially in the smaller values of dilution

rate. It is difficult to discern directly from the figure to \\hat

extent ethanol did affect adversely the growth rate of the cells. A

symptom to this effect recognizable from Figure 2 is that the values of

S in a larger range of p more than 20 g/1 for example, depended

appreciably on the values of D; the appearance is similar to that

observable when n-ashout occurs. Otherwise, the curves should

have been closer together as can be seen near the origin of Figure 2 .

The Lineneaver-Burk plot n a s made in Figure 3 to rectify an

equivocal situation of the inhibition in Figure 2 . It must be remarked here t h a t the values of S pertaining to each value of p selected

for convenience a t round numbers were estimated from each broken

curve in Figure 2. It is evident from the plot in Figure 3 that the

inhibition is noncompetitive, because each data point at constant

value of p is on a straight line and, in addition, these straight lines

converge eventually a t a point 011 the abscissa of Figure 3.j It was

not difficult to draw these straight lines starting from the same point

on the abscissa, even if one pays particular attention t o specific points

which deviate markedly from respective broken curves constructed

in Figure 2 .

The value of a saturation constant, K , in this correlation can be

estimated from Figure 3 as K , = 0.22 gtl. The effect of ethanol

on the cell gron-th is then manifested in the maximum reaction

(growth) rate in each concentration of ethanol. Each maximum

value of the specific growth rate could be estimated by the intercepts

of the straight lines from the ordinate of Figure 3. The values of p

BIOTECHNOLOGI .IND BIOENGINEERING, VOL. X, ISSUE 6

853

PRODUCT INHIBITION

2.c

1

I

)=0.242

0=0.160

D=y.l9

I"

I

I

I

4I

1:.

I

I

I

I

I

I

I

I

5

-m

v)

1.c

I

I

+

I

0.5

I

I

I

I

/

/

/

I

/

D= 0.100//:

",/b

/'.

'0

<DL

0.084

I

3

Fig. 2 . S vs. p in the steady state (single vessels).

estimated from Figure 3 are plotted semilogarithmically against the

values of p as shown in Figure 4.

The experimental data (p versus p ) which 1%-ere

obtained separately

in the shaken-flask tests3 are cited in Figure 4. The values of p in

the shaken-flask tests were those pertaining to the logarithmic

growth phase of the cells which were not "limited" by any substrates.

It is seen from the figure that the data points in both cases are

correlated by straight lines on semilogarithmic paper.

854

S. AIBA, M. SHODA, M. NAGATANI

Fig. 3. Lineweaver-Burk plot;

l/p

vs. l/S in the steady state (single vessels).

Accordingly, the inhibitory effect of ethanol on the cell growth could

be formulated irrespective of the difference of operation (batch and

continuous) by t,he following equation:

provided: k, = an empirical coefficient; p o = specific growth rate

a t p = 0.

Equation (4)is assumed to represent the inhibitory effect of ethanol

in a batch fermentation when glucose becomes limiting, though no

experiment along this line was made. Also, the value of K , in eq. (4)

is assumed to be independent of operations, i.e., batch or continuous.

Discussion on these assumptions will be made later on in this work.

BIOTECHNOLOGY AND BIOENGINEERING, VOL. X , ISSUE 6

PRODUCT INHIBITION

855

Fig. 4. Specific growth rate p as affected by ethanol concentration p when

no substrates are limiting; for the continuous run the values of p were taken

from the intercepts of the Lineweaver-Burk plot in the ordinate of Fig. 3.

However, by using these assumptions, the point to differentiate the

continuous from the batch run in eq. (4)is in the value of kl. The

values of k, determined from Figure 4 are 0.016 and 0.028 g/l for the

continuous and shaken-flask tests, respectively.

The difference in the values of 10 in eq. (4)depending on the type of

operation (see Fig. 4) is attributed presumably to that of equipment

used: i.e., one, the shaken-flask, the other, the jar fermentor. The

above discussion regarding eq. (4) [cf. eq. (5) below] will be of use

from a kinetic approach to the scaleup.

The values of v cited from Table I1 are plotted against ethanol

concentration p in Figure 5 ; another parameter is the dilution rate D .

The values of v are expected from the figure to increase with an increase of dilution rate. However, it is difficult to assess the form of a

function to define the dependence of v values on the values of p in each

dilution rate. Therefore, the broken curves were prepared temporarily as shown in Figure 3 to estimate the value of v which could

correspond to any value of p other than that actually measured.

Unacceptable as this procedure may seem, it will become apparent

that this step is not accompanied by any grave error which totally

invalidates a conclusion here.

856

S. AIBA, M. SHODA, M. NAGATANI

Fig. 5 .

m. p in the steady state (single vessels).

The experimental data in Figure 5 were rearranged into the Lineweaver-Burk plot (l/v versus 1/S)in Figure 6. This plot was made

possible by reading the values of v from Figure 5 a t round numbers of

p arbitrarily selected with the use of respective broken curves in the

figure first and, second, by taking the corresponding values of S from

Figure 2 with further reference to the broken curves already established in the same figure.

BIOTECHNOLOGY A N D BIOENGINEERING, VOL. X, ISSUE 6

PRODUCT INHIBITION

857

Straight lines could be drawn easily through the data points as

shown in Figure 6 such that the lines converge to a point on the

abscissa. Then it is concluded that ethanol inhibition to the fermentation activity of the cells is also noncompetitive. The value

of Ks, the saturation constant, was estimated as 0.44 1/g from the

figure.

The intercepts of the straight lines from the ordinate in Figure 6

correspond to the values of v which are not limited by any substrates.

Consequently, the values of v estimated thus from Figure 6 \\-ere

plotted against ethanol concentration p in Figure 7. The values of

v could be correlated fairly well with those of p by an exponential

function, irrespective of the difference of experimental procedure.

The only difference is that of the initial value of v = v o a t p = 0 and

that of the slope of these lines in Figure 7.

The discussion mentioned earlier in Figures 3 and 4 for the specific

gron th rate p of the cells may also hold exactly for the values of v in

Figures 6 and 7. Then eq. (5) was derived to formulate the inhibitory effect of ethanol on the fermentation activity of the yeast

cells.

Fig. 6. Linen-eaver-Burk plot; 1,v vs. 1/S in the steady state (single vessels).

858

S. AIBA, M. SHODA, M. NAGATANI

p (94)

Fig. 7. Specific rate of ethanol production Y a8 d e c t e d by ethanol concentration p when no substrates are limiting; for the continuous run the values of Y

were taken from the intercepts of the Lineweaver-Burk plot in the ordinate of

Fig. 6.

provided: k , = an empirical coefficient; V O = specific rate of ethanol

production a t p = 0. The values of k z estimated from Figure 7 are

0.029 and 0.015 l/g for the continuous run and the Warburg respirometer, respectively.

One could calculate the values of yield factors Y P , sand Y x , ~from

the data shown in Table 11. The yield factors were plotted against

p in Figures 8 and 9. It is noted from these figures that both values

of yield factors remained nearly unchanged in the range of ethanol

concentration studied here. iilthough the data points scattered

considerably in Figures 8 and 9, the average values of YP,sand Y X , S

were taken as Y p I s= 0.35 and Y x l S = 0.10. The fact that the cell

growth was appreciable in this study could account for the lower

value of Yp,s compared with the theoretical value ( = 0.51).

The following equations which define either the yield factor, Yp,s

or another yield factor, YX/S must be used with eqs. (4)and (5) for

the calculation of a kinetic pattern of the yeast cells.

dS

--

dt

-1 d p YP,s dt

-1 d X

Y X I Sdt

A calculation of a batch alcohol fermentat.ion with a digital computer (HITAC 5020T, Computer center, University of Tokyo) by

BIOTECHNOLOGY AND BIOENGINEERING, VOL. X, ISSUE 6

PRODUCT INHIBITION

859

0.5

04

0.3

SYMBOL'

In

2

>

0.2

DILUTION RATE, D

0 1 9 8

0.I

10

20

I

30

40

I

50

C 3

p (g/Pl

Fig. 8. Y,,s vs. p in the steady state (single vessels).

10

20

30

40

50

60

p (Sd)

Fig. 9. Yx,s vs. p in the steady state (single vessels).

using eqs. (4), ( 5 ) , and (6) is shown in Figure 10; the ordinate represents either the values of S, p , or X , while the abscissa is fermentation time t. Data points described in the figure are bhe reproduction

of the batch fermentation with the jar ferrnent~r.~

S. AIBA, M. SHODA, 31. NAGATANI

860

20

10

(hr)

Fig. 10. Batch alcohol fermentation, observed and calculated. Xumerical

values substituted into respective coefficiennts of the kinetic equations (see the

text) are: k , = 0.028, k p = 0.015, p o = 0.408, y o = l.0,3K , = 0.22, K, = 0.44,

Y,,s = 0.35 ( I x , ~

= 0.10).

Solid curves in Figure 10 are the results of the computation. It

must be pointed out that the kinetic patterns could only be calculated starting from the initiation of the logarithmic phase to the period

when the substrate became nearly exhausted. The numerical values

substituted into the terms k 1 and k 2 in eqs. (4)and ( 3 ) for Figure 10

were obtained e~perirnentally;~

k l = 0.028, k2 = 0.015. The values

of po and v o used for the computation (see above the caption of Fig.

10) have no significant implication, n hereas the values of K,, Ks,

and Y, used \\-ere determined in this work.

-4pparently the calculation justifies that eqs. (4), ( 5 ) , and (6)

represent the kinetic pattern either in batch or in continuous operation, provided the values of k l and k2 in cqs. (4) arid ( 3 ) are duly

adopted, in particular.

BIOTECHNOLOGY AND B I O E S G I N E E R I N G , VOL. X, ISSUE 6

PRODUCT INHIBITION

861

This suggests that the kinetic pattern can be used to predict the

rate of ethanol production even after a practical cessation of the cell

growth, provided glucose is still available as in the brewing of sake,

for instance.

An example of the specific brewing of sake is cited in Figure 11.

The experimental data on which the figure was prepared came from

the Research Institute of Brewing, Tokyo. The ordinate of Figure 11

represents either the value of ethanol production rate d p l d t in a

logarithmic scale or the broth temperature, while the abscissa is

ethanol concentration, p (v/v 70)

of the fermenting broth. Various

symbols in the figure demonstrate the difference of runs, in which

various species of yeast including a specific yeast characterized by the

least amount of froth generation in the fermentation are employed.

The values of d p / d t were assessed graphically from the plot of p

versus time (days) ; incidentally, the period of fermentation for the

2,

l

0

L

w

c

Fig. 11. Example of sake brewing, accumulation of ethanol in the period after

a cessation of cell growth.

862

S. AIBA, M. SHODA, M. NAGATANI

data in Figure 11 was about 10 days. It must be mentioned here

that the values of p were taken from the original record of each

fermentation after the froth of the fermenting broth calmed down

onto the broth surface. Otherwise, an appropriate evaluation of

each ethanol production activity of the yeast cells becomes difficult,

because most of the yeast cells which tend to be adsorbed a t the

froth surface are due to loose contact with the broth during an

especially vigorous frothing period in each run, underestimating

thus far the value of ethanol production activity dp/dt of the cells in

question.

The cell growth in the fermenting period (Fig. 11) could be assumed

to be practically zero. An average pH value of the broth in the

figure ranged from 4.2 to 4.5, while the temperature was lowered with

the progress of each fermentation. Glucose, on the other hand, was

abundant in each run; in fact, the residual glucose a t the termination

of each run was about 1%. With reference to the value of K, = 0.44

g/l determined in this work, glucose was assumed not to have limited

the fermentation (Fig. 11).

It is interesting to find from the upper part of Figure 1 1 that the

solid curves prepared by hand through each set of the data points

were rather parallel. In particular, the curves could be assumed to

be straight lines in the semilogarithmic plot pertaining to a considerable range of p which started from p = 10% in the figure.

By using the assumption that glucose did not limit the fermentation, eq. ( 5 ) could be modified as follows:

dp/dt

voX e - k 2 p

(5)

Then,

log dp/dt = log VOX- 0.43kzp

(5j

Equation (5) suggests that a plot of dp/dt against p on semilogarithmic paper is shown by a straight line, the intersection of which

with the ordinate corresponds to the value of O X .

Apparently, each set of the data points in Figure 11 can be represented by eq. (5j for a wide range of p, starting from the origin of

the figure. Take, for example, the data points with an elliptic

symbol in the figure. Assuming that these data points are on a

straight line starting from p = 10 to p = 16y0in Figure 11, the

value of k2 could be estimated from its slope as 0.14s yo- = 0.019

BIOTECHNOLOGY AND BIOENGINEERING, VOL. X, ISSUE 6

PRODUCT INHIBITION

863

l/g [see eq. ( 5 ) ] . The point that the value of kz estimated

regarding the actual brewing of sake was near the value ever determined with the Warburg manometer3 (kq = 0.015 l/g; see

Fig. 7) seems interesting.

Taking the example further, the value of vOX could be calculated

from eq. (5) as 7.8yO/day = 61.5 g/l/day. If the value of Y O is

taken as 1.0 hr- (at 30C; see Fig. 7),3the value of X was estimated

as 2.56 g/l

7.7 x lo7 cells/ml. The value of v o for this example

of calculation may be much smaller than 1.O hr-I primarily due to the

lower temperature of operation (around 15C); however, another

point that the value of cell concentration X estimated above was in

the alleged order of magnitude in the alcohol fermentation seems

also interesting.

This illustration suggests that one can estimate from eq. (5) the

value of X in the actual sake brewing, if the value of d p / d t is

measured properly, and if the values of Y O and liq can be assumed most

appropriately. This approach may be of help from a standpoint of

control in the brewery.

Also, it is noted from Figure 11 that the data points deviate considerably from each straight line (not shown) assumed in the semilogarithmic plot. Although the factors responsible for this deviation

cannot be discussed definitely, the following factors might have been

contributing to this phenomenon.

One is the fact that the broth temperature was generally lowered

with the progress of each fermentation. Equation (5) was derived

by assuming implicitly that the operating temperature was constant.

The other is concerned with a possibility that the yeast cells might

have lost their viability with time in an environment of high ethanol

content. The latter possible factor responsible for the peculiar

degradation of fermentation activity of the cells around the end of

each run in Figure 11 is beyond the scope of eq. (5). With these

particular situations in mind, the kinetic equations discussed in this

study are considered promising from aspects of both basic comprehension and application of kinetics in an alcohol fermentation.

Nomenclature

a

B

empirical constant

empirical coefficient

dilution rate ( = F / V ) , hr-I

864

F

K,

K,'

k&

P

Po

P*

S

SO

t

I.

X

Y,,s

YX,S

@

YO

V

yo

S. AIBA, hl. SHODA, M. NAGATANI

feed rate, l/hr

saturation constant, g i l

saturation constant, g/l

empirical exponents, l/g

product (ethanol) concentration, concentration of various sorts of

alcohol, g/l, v / v %

ethanol concentration in fresh medium, g/l

maximum value of ethanol ever attained, g/l

substrate (glucose) concentration, g/l

substrate (glucose) concentration in fresh medium, g/l

time, hr, day

liquid volume, 1

dry cell mass concentration, g 11

yield factor ( = - A p / A S )

yield factor ( = - A X / A S )

specific growth rate, hr-1

specific growth rate a t p = 0, hr-'

specific rate of ethanol production, hr-I

specific rate of ethanol production a t p = 0, hr-'

References

1. C. N. Hinshelwood, The Chemical Kinetics of the Bacterial Cell, Clarendon,

Oxford, 1952, p. 105.

2 . I. Holzberg, R. K. Finn, and K. H. Steinkraus, Biotechnol. Bioeng., 9, 413

(1967).

3. M. Nagatani, M. Shoda, and S. Aiba, J . Ferm. Technol., in press.

4. J. F. Guymon and E. A. Crowell, J . rissoc. O$c. Agri. Chem. Baltimore,

42, 393 (1959).

5 . E. 9.Dawes, Quantitative Problems in Bzochemastry E. S. Livingstone,

London, 1962, pp. 99-154.

Received March 22, 196s

BIOTECHNOLOGT AND BIOENGINEERING, VOL. X, ISSUE 6

Potrebbero piacerti anche

- Labster Simulator: Bioethanol Production: BE160L - 1Q SY 2021-2020Documento7 pagineLabster Simulator: Bioethanol Production: BE160L - 1Q SY 2021-2020Den Celestra0% (1)

- Williamson Synthesis Lab ReportDocumento5 pagineWilliamson Synthesis Lab ReportNicholas Johnson100% (2)

- Cot2 DLPDocumento5 pagineCot2 DLPLowie D GacetaNessuna valutazione finora

- CE6304 Surveying 1 Question Bank Download HereDocumento12 pagineCE6304 Surveying 1 Question Bank Download Hererishinathnehru100% (3)

- Activity 1.1.1 Simple Machine Investigation - Vex: NamesDocumento12 pagineActivity 1.1.1 Simple Machine Investigation - Vex: NamesBen Cheng100% (1)

- Box-Behnken Design An Alternative For The OptimizationDocumento8 pagineBox-Behnken Design An Alternative For The OptimizationlorencorumbaNessuna valutazione finora

- Butanol 2Documento0 pagineButanol 2Đứa Con Của BiểnNessuna valutazione finora

- Hojo 1999Documento11 pagineHojo 1999Berk YüzerNessuna valutazione finora

- II.1.5 Ethanol: by Kanako WatanabeDocumento8 pagineII.1.5 Ethanol: by Kanako WatanabeMadul15Nessuna valutazione finora

- Modelling Ethanol Production From Cellulose: Separate Hydrolysis and Fermentation Versus Simultaneous Saccharification and FermentationDocumento10 pagineModelling Ethanol Production From Cellulose: Separate Hydrolysis and Fermentation Versus Simultaneous Saccharification and FermentationlandolandazNessuna valutazione finora

- Factors Affecting Ethanol Fermentation Using SaccharomycesDocumento7 pagineFactors Affecting Ethanol Fermentation Using SaccharomycesLl FfNessuna valutazione finora

- Partitioning of Phenylalanine Ammonia-Lyase From Rhodotorula Glutinis in Aqueous Two-Phase Systems of PEG/saltsDocumento8 paginePartitioning of Phenylalanine Ammonia-Lyase From Rhodotorula Glutinis in Aqueous Two-Phase Systems of PEG/saltsDrVishwanatha HNNessuna valutazione finora

- Acido LacticoDocumento9 pagineAcido LacticoJuan Victor ChampeNessuna valutazione finora

- Optimumstarting UpprotocolDocumento8 pagineOptimumstarting Upprotocol60943807Nessuna valutazione finora

- Thesis On Ethanol FermentationDocumento6 pagineThesis On Ethanol Fermentationhollyhernandezdurham100% (2)

- Mechanism of Cytoplasmatic PH Regulation in Hypoxic Maize Root Tips and Its Role in Survival Under HypoxiaDocumento5 pagineMechanism of Cytoplasmatic PH Regulation in Hypoxic Maize Root Tips and Its Role in Survival Under HypoxiaGabriel ZahariaNessuna valutazione finora

- Modified Kinetic Model For Ethanol Fermentation From Oil Palm Trunk SapDocumento7 pagineModified Kinetic Model For Ethanol Fermentation From Oil Palm Trunk SapNORAZALIZA BINTI MOHD JAMILNessuna valutazione finora

- Ref (Ellman - 1961)Documento9 pagineRef (Ellman - 1961)Tasso SalesNessuna valutazione finora

- Urease Activity in Soybean MealDocumento4 pagineUrease Activity in Soybean MealAJ QuintoNessuna valutazione finora

- Estudos de Saccharomyces Cerevisiae Imobilizados. Análise de Fermentação Rápida Contínua de Etanol em Reator de Células ImobilizadasDocumento15 pagineEstudos de Saccharomyces Cerevisiae Imobilizados. Análise de Fermentação Rápida Contínua de Etanol em Reator de Células ImobilizadasMarina Cunha SiebenNessuna valutazione finora

- Beet Sugar Bioethanol FermentationDocumento12 pagineBeet Sugar Bioethanol FermentationDavidNessuna valutazione finora

- Antioxidant From PeelsDocumento5 pagineAntioxidant From PeelsEliana Otero PerezNessuna valutazione finora

- Pectin Extraction in The Presence of AlcoholsDocumento7 paginePectin Extraction in The Presence of AlcoholsIsabel Tacunan CastilloNessuna valutazione finora

- Qureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodDocumento12 pagineQureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodschall0Nessuna valutazione finora

- Investigation of Acetone-Butanol-Ethanol (ABE) Fermentation by FluorescenceDocumento4 pagineInvestigation of Acetone-Butanol-Ethanol (ABE) Fermentation by FluorescencechelogkNessuna valutazione finora

- 1 SM PDFDocumento5 pagine1 SM PDFMohammad Zohaib AkhterNessuna valutazione finora

- DBH AssayDocumento6 pagineDBH AssayArunibha GhoshNessuna valutazione finora

- Efectos de Las Concentraciones de Oxígeno Disuelto y Ácido Acético en La Producción de Ácido Acético en El Cultivo Continuo de Acetobacter AcetiDocumento6 pagineEfectos de Las Concentraciones de Oxígeno Disuelto y Ácido Acético en La Producción de Ácido Acético en El Cultivo Continuo de Acetobacter AcetiWendy Rivera100% (1)

- N7 Acetic Acid Production by An Electrodialysis Fermentation MethodDocumento6 pagineN7 Acetic Acid Production by An Electrodialysis Fermentation MethodGerardo OrihuelaNessuna valutazione finora

- An Experiment in Enzyme Characterization: Banana Polyphenoloxidase Michael C. Archer and James K. PalmerDocumento3 pagineAn Experiment in Enzyme Characterization: Banana Polyphenoloxidase Michael C. Archer and James K. PalmerThu HàNessuna valutazione finora

- Study 2010Documento7 pagineStudy 2010hoplittaNessuna valutazione finora

- 15bgal PDFDocumento8 pagine15bgal PDFRaul Enrique Carrasco ConchaNessuna valutazione finora

- Bioethanol Production From Sugarcane Bagasse Using Fermentation ProcessDocumento9 pagineBioethanol Production From Sugarcane Bagasse Using Fermentation ProcessHarsh DoshiNessuna valutazione finora

- AbstractDocumento14 pagineAbstractlinda83514100% (3)

- Effect of PH On Enzyme ActivityDocumento12 pagineEffect of PH On Enzyme ActivityAb AbNessuna valutazione finora

- Analysis of Wheat Germ Acid Phosphatase Lab Week 6Documento5 pagineAnalysis of Wheat Germ Acid Phosphatase Lab Week 6Jay PatelNessuna valutazione finora

- Bioc Module 2 Lab ReportDocumento11 pagineBioc Module 2 Lab ReportMimi BoisterNessuna valutazione finora

- Patulin Analysis With LC-MSDocumento5 paginePatulin Analysis With LC-MSbohemian84Nessuna valutazione finora

- J. Bacteriol.-1980-Ingram-481-8Documento9 pagineJ. Bacteriol.-1980-Ingram-481-8Phytomenadione La Vitamine KNessuna valutazione finora

- Alcoholic Fermentation With Different Initial Glucose Concentration Using Immobilized Yeast in Calcium Alginate GelDocumento7 pagineAlcoholic Fermentation With Different Initial Glucose Concentration Using Immobilized Yeast in Calcium Alginate GelViệt Euro ĐinhNessuna valutazione finora

- Enzyme Biochem Lab KGDocumento13 pagineEnzyme Biochem Lab KGKimberly George-Balgobin50% (2)

- Jarzebski 1989 PDFDocumento6 pagineJarzebski 1989 PDFblooom_00Nessuna valutazione finora

- Bioethanol Production From Sugarcane Bagasse Using Fermentation ProcessDocumento7 pagineBioethanol Production From Sugarcane Bagasse Using Fermentation ProcessM Syafiq SamadNessuna valutazione finora

- Laboratory Analytical Procedure: Chemical Analysis and Testing TaskDocumento8 pagineLaboratory Analytical Procedure: Chemical Analysis and Testing TaskJuan Alzate JaramilloNessuna valutazione finora

- Improvements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase ProductionDocumento16 pagineImprovements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase Productionguime27Nessuna valutazione finora

- Egg White Proteins II An Ethanol Fractionation SCHDocumento8 pagineEgg White Proteins II An Ethanol Fractionation SCHThammana NishithareddyNessuna valutazione finora

- Or-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisDocumento6 pagineOr-Amylase Production in Aqueous Two-Phase Systems With: Bacillus SubtilisHong HanhNessuna valutazione finora

- Lovastatin Production by Pleurotus Ostreatus: Effects of The C:N RatioDocumento4 pagineLovastatin Production by Pleurotus Ostreatus: Effects of The C:N RatioAhmed BadrNessuna valutazione finora

- Thermostable Amylase Activity Produced by Thermophilic Bacteria Isolated From Pulu Hotspring, Central SulawesiDocumento6 pagineThermostable Amylase Activity Produced by Thermophilic Bacteria Isolated From Pulu Hotspring, Central SulawesiAbdul ThalibNessuna valutazione finora

- Biotech Bioengineering - 20 April 1987 - Bar - An Unusual Pattern of Product Inhibition Batch Acetic Acid FermentationDocumento3 pagineBiotech Bioengineering - 20 April 1987 - Bar - An Unusual Pattern of Product Inhibition Batch Acetic Acid FermentationEvelin RamirezNessuna valutazione finora

- 15jan12 - 163611 - Kunchada SingasintuDocumento4 pagine15jan12 - 163611 - Kunchada SingasintuRizka Rinda PramastiNessuna valutazione finora

- Determination of CholineDocumento4 pagineDetermination of Cholinerahul1809Nessuna valutazione finora

- Jobses 1Documento10 pagineJobses 1Mindy MunozNessuna valutazione finora

- IBG 202 LAB 6 Production of EthanolDocumento5 pagineIBG 202 LAB 6 Production of EthanolLow Pik KuanNessuna valutazione finora

- Enzyme Catalytic Promiscuity The Papain-Catalyzed Knoevenagel Reaction (Paper 2)Documento6 pagineEnzyme Catalytic Promiscuity The Papain-Catalyzed Knoevenagel Reaction (Paper 2)thamtusieuquayNessuna valutazione finora

- PROTOCOL Extraction and Determination of ProlineDocumento4 paginePROTOCOL Extraction and Determination of ProlineclventuriniNessuna valutazione finora

- Optimal Fermentation Conditions For Maximizing The Ethanol Production by Kluyveromyces Fragilis From Cheese Whey PowderDocumento6 pagineOptimal Fermentation Conditions For Maximizing The Ethanol Production by Kluyveromyces Fragilis From Cheese Whey Powder1039danielNessuna valutazione finora

- Protein Synthesis in Avocado Fruit Tissue PDFDocumento4 pagineProtein Synthesis in Avocado Fruit Tissue PDFdr.sameer sainiNessuna valutazione finora

- Acetylcysteine BP2Documento12 pagineAcetylcysteine BP2RPh Krishna Chandra Jagrit100% (1)

- Batch ReactorDocumento10 pagineBatch Reactorgrobois_enikoNessuna valutazione finora

- Effect of Yeast Extract On Alpha-Amylase Synthesis by Bacillus AmyloliquefaciensDocumento6 pagineEffect of Yeast Extract On Alpha-Amylase Synthesis by Bacillus AmyloliquefaciensAndalib TabassumNessuna valutazione finora

- 10 1007@bf00522476Documento12 pagine10 1007@bf00522476thiagoNessuna valutazione finora

- Effect Enzyme Concentration On The Catalytic Rate Lab 3Documento8 pagineEffect Enzyme Concentration On The Catalytic Rate Lab 3ammar elbedwehyNessuna valutazione finora

- Brain Tumor MriDocumento23 pagineBrain Tumor MrisekharraoNessuna valutazione finora

- ODEs With Scilab - Gilberto UrrozDocumento107 pagineODEs With Scilab - Gilberto UrrozGermán BrescianoNessuna valutazione finora

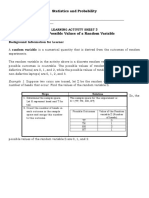

- Statistic and Probability Assign. #2Documento16 pagineStatistic and Probability Assign. #2Kyla Mae OrquijoNessuna valutazione finora

- Milano LecturesDocumento60 pagineMilano LecturesSkiptippNessuna valutazione finora

- WNL Users GuideDocumento852 pagineWNL Users Guidemichael.jorge5307Nessuna valutazione finora

- Statistics and Probability 12 LAS 3Documento3 pagineStatistics and Probability 12 LAS 3Cfourr SteelWorksNessuna valutazione finora

- Stat Prob - Q3 - Week 5 6 - Module 4 - Sampling Distribution Its Mean and Variance - For ReproductionDocumento26 pagineStat Prob - Q3 - Week 5 6 - Module 4 - Sampling Distribution Its Mean and Variance - For ReproductionCharles Alexander J. SandhuNessuna valutazione finora

- Sample Problem ThermoDocumento25 pagineSample Problem ThermoJonnah Faye Mojares0% (1)

- MEC 236 - Computer Applications 3Documento224 pagineMEC 236 - Computer Applications 3Wafaa AimanNessuna valutazione finora

- ACI 224r - 90 PDFDocumento43 pagineACI 224r - 90 PDFvelmurug_balaNessuna valutazione finora

- Programming QuestionsDocumento2 pagineProgramming QuestionsAhmad AhmadNessuna valutazione finora

- Deep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanDocumento11 pagineDeep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanmahadimasnadNessuna valutazione finora

- TAU - DLR Deutsh Software Flow Aero SolverDocumento7 pagineTAU - DLR Deutsh Software Flow Aero SolverilyesingenieurNessuna valutazione finora

- Motilal Nehru National Institute of Technology Allahabad Department of Mathematics Admission To M.Sc. Programme 2008Documento6 pagineMotilal Nehru National Institute of Technology Allahabad Department of Mathematics Admission To M.Sc. Programme 2008jaydee45Nessuna valutazione finora

- PhysyllDocumento48 paginePhysyllThanviomNessuna valutazione finora

- Harmon Axon PDFDocumento13 pagineHarmon Axon PDFAnonymous 0LyWrL4Nessuna valutazione finora

- Jackson Electrodynamics, Notes 1Documento5 pagineJackson Electrodynamics, Notes 1Tianyi ZhangNessuna valutazione finora

- RR210402 Signals - SystemsDocumento8 pagineRR210402 Signals - SystemsThanikonda Reddy SreedharNessuna valutazione finora

- Effect of Stacking Sequence On Notch Strength in LaminatesDocumento10 pagineEffect of Stacking Sequence On Notch Strength in Laminatesசெல்வ குமார்Nessuna valutazione finora

- Dumas 1998Documento48 pagineDumas 1998Yuming MaNessuna valutazione finora

- Complete The Truth Table For This Logic Circuit:: 9608/31/M/J/15 © UCLES 2015Documento19 pagineComplete The Truth Table For This Logic Circuit:: 9608/31/M/J/15 © UCLES 2015Nayu OumiNessuna valutazione finora

- Huawei 2G GBSS9.0 Parameters Suggestion V1.0Documento48 pagineHuawei 2G GBSS9.0 Parameters Suggestion V1.0Diego Blanco100% (4)

- Tractor Systems Controls PDFDocumento88 pagineTractor Systems Controls PDFSARGEN SARENNessuna valutazione finora

- Preamble Heat TransferDocumento8 paginePreamble Heat TransferkdsahooNessuna valutazione finora

- 1819 SM015 - 1 Solution Latihan Sem1Documento15 pagine1819 SM015 - 1 Solution Latihan Sem1Suha WzneNessuna valutazione finora

- Basic Calculus: Quarter 3 - Module 6 Extreme Value Theorem and Optimization ProblemsDocumento18 pagineBasic Calculus: Quarter 3 - Module 6 Extreme Value Theorem and Optimization ProblemsJessa Cuanan CaloNessuna valutazione finora