Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TLIV507C - Clean and Inspect Pallets - Learner Guide

Caricato da

romerofredCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TLIV507C - Clean and Inspect Pallets - Learner Guide

Caricato da

romerofredCopyright:

Formati disponibili

Certificate II

in

Transport and Logistics

Learning and Assessment Material

TLIV507C

CLEAN AND INSPECT PALLETS

TLIV507C Clean and inspect pallets February 2008 Version 1 Page i of 25

Contents

What are housekeeping tasks?........................................................................................ 3

What equipment is used in housekeeping?...................................................................... 4

What is the link between housekeeping and OH&S?....................................................... 4

How is OH&S applied to housekeeping?......................................................................... 5

What protective clothing and equipment is used?............................................................ 6

How do you use, maintain and store safety equipment in a safe and secure way?......... 6

Cleaning the work site…………………………………………………………………………. 7

Tagging and isolating………………………………………………………………………….. 7

Shutting down…………………………………………………………………………………… 8

Preventing an accidental start up…………………………………………………………….. 8

What terms are used to categorise chemicals and dangerous goods?............................ 8

What are the sources of hazard information?.................................................................. 9

What are Material Safety Data Sheets (MSDS’s)?......................................................... 10

Who is responsible for providing MSDS’s?.................................................................... 10

When does a MSDS need to be supplied?..................................................................... 10

When does a MSDS need to be revised?...................................................................... 10

Who needs access to MSDS’s?..................................................................................... 10

What does "sanitize" mean?........................................................................................... 11

The Sanitation Cycle………………………………………………………………………….. 11

What Should I Sanitize?................................................................................................. 12

What are some approved sanitation methods?.............................................................. 12

Conclusion……………………………………………………………………………………... 15

How do you carry out waste removal?............................................................................ 16

Work area maintenance……………………………………………………………………… 17

TRAINING AND ASSESSMENT ACTIVITIES AND QUESTIONS………………………. 18

Assessment task………………………………………………………………………………. 19

ASSESSMENT MODE A - Oral questioning………………………………………………. 20

ASSESSMENT MODE B - Skills observation checklist…………………………………… 21

Participant survey of materials………………………………………………………………. 24

Suggested Answers…………………………………………………………………………... 25

Hinson Institute of Training

TLIV507C Clean and inspect pallets February 2008 Version 1 Page ii of 25

TLIV507C CLEAN AND INSPECT PALLETS

Element of competency:

1. Identify workplace procedures, resources and requirements for cleaning

pallets

2. Inspect and clean pallets

3. Monitor and maintain cleanliness and tidiness of pallet cleaning and storage

areas

4. Complete assigned pallet cleaning and inspection duties

What are housekeeping tasks?

Housekeeping tasks can be grouped into a number of areas, including, but not

limited to:

OH&S

- Safety

- Cleanliness (sanitation) controls

Damage avoidance

Fire prevention and protection

Safe, secure storage systems

Regular inspections

Stock control

Personal hygiene and appearance

Maintenance and storage of housekeeping equipment.

Common housekeeping tasks are:

Vacuum cleaning

Painting

Weeding

Maintenance.

Waste removal

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 3 of 25

What equipment is used in housekeeping?

A wide range of equipment can be used to help with housekeeping. Some

examples are:

Brooms and brushes

Safety equipment such as gloves, goggles, aprons, etc

Cleaning agents and associated items used to apply these agents

Ladders, ramps and scaffolding

Mechanical items such as vacuums, sweepers and high-pressure

cleaners.

As you work through the guide you will identify other equipment available for

use in housekeeping tasks.

What is the link between housekeeping and OH&S?

As you now know, housekeeping is essential to ensure a safe, clean and

healthy workplace. OH&S Regulations and Codes of Practice provide specific

instructions on:

Occupational Health and Safety

First Aid

Hazardous Substances

Labeling of Workplace Substances

Manual Handling.

All of these instructions apply to housekeeping duties. Remember, the

application of OH&S Regulations is mainly a management responsibility but

everyone is required to help and be involved.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 4 of 25

How is OH&S applied to housekeeping?

As mentioned in Section One, OH&S Regulations must be applied to

housekeeping duties. Although the main responsibility for safety in the

workplace belongs with the employer, you also have responsibilities.

You need to know and be able to apply these. You must:

Follow instructions in relation to the Regulations and the workplace

Use protective clothing and equipment provided to comply with the

Regulations

Not use drugs or alcohol that will endanger yourself or others in the

workplace

Undertake induction (training) prior to starting new or unfamiliar work.

The amount of training depends on the hazards involved

Obey the approved Codes of Practice, unless there is an alternative

which provides equal or better protection.

The Regulations are very detailed so all of the contents cannot be covered

here. There are many other matters that you will need to learn as you

progress in your career. It is important that you take the time to educate

yourself further on this subject. The main Codes of Practice that you need to

know about are:

Occupational Health and First Aid

Control of Workplace Hazardous Substances; ie: use of cleaning

agents and cleaning up spillages. More detail on this subject is given in

Handling Dangerous Goods

Labelling of Workplace Substances

Manual Handling. This covers:

Identification of risk factors likely to cause manual handling injuries

Detailed assessment of particular risk factors

An introduction to measures to remove or control risks.

In these Codes of Practice there are details you need to know about. Speak to

your supervisor to obtain the Codes and read them as soon as possible.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 5 of 25

What protective clothing and equipment is used?

A wide variety of protective clothing and equipment is available for use in your

housekeeping duties.

As you will have noticed in the Codes of Practice, use of protective clothing

and equipment is required when handling chemicals and using some

equipment. A list of items you might use is given below. This list is not

complete as there are many other examples in the industry:

Dust coat

Rubber apron

Goggles or glasses

Helmet

Noise protection

Gloves

Breathing filter or self contained breathing apparatus.

How do you use, maintain and store safety equipment

in a safe and secure way?

To ensure the safe use, maintenance and storage of safety equipment, you

will need to:

Choose the correct equipment for the task

Read warning labels and instructions and follow this information

Fit the equipment correctly

Follow the instructions when using equipment

Maintain the equipment correctly

Store the equipment correctly.

If the standard of safety equipment is suspect DO NOT USE IT.

Apply the three R’s:

Report it,

Repair it

Or replace it!

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 6 of 25

Cleaning the work site

Keeping the worksite clean reduces the risk of:

Workers tripping over waste material

Contamination of work in progress

Fire.

All materials should be assessed. Those still useable should be returned to a

suitable storage area, those which are unsuitable should be disposed of in an

approved environmentally safe way.

If possible, all open bags with raw material should be used on other

processing equipment. If this is not possible, ensure all materials are suitably

protected from risk of contamination and stored in designated storage areas

for later use.

Recyclable materials should be placed in appropriate bins or fed into

granulator/regrinding equipment.

Adequate waste bins should be available in your work area.

Tagging and isolating

When a piece of operating equipment is closed down, it must be properly

isolated and tagged. You must follow your company's standard operating

procedure for closing down equipment.

Turn off all electrical power switches, including the main isolating switch.

If the equipment you are closing down is connected to a power socket with the

plug, remove the plug from the socket.

To ensure the equipment cannot be turned on, all remote electrical switches

must be tagged. The information recorded on the safety tag must show:

Your name

The date

The job task.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 7 of 25

Shutting down

When the work area is cleaned and the equipment tagged, the next tasks

involving preparing the equipment for an idle period.

One of the major tasks to perform during shutdown is to get the machine/work

area ready for a future production run so that as little as possible will have to

be done to put a piece of equipment or a work area back into production.

It is important that seals and hoses

be inspected as part of the

shutdown procedure and that

replacement hoses and seals be

fitted as necessary.

Preventing an accidental start up

There are a number of tasks to be completed that will stop any personnel from

mistakenly starting up the machinery.

Locks and guards can be used to keep workers away from the machines and

clearly show that the machines are not to be touched.

What terms are used to categorise chemicals and

dangerous goods?

Chemicals and dangerous goods are products or articles that may be

dangerous or have harmful effects on people, property or the environment.

They can be:

Gases

Liquids

Or solids.

They may be dangerous because they are:

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 8 of 25

Explosive

Flammable

Poisonous (toxic)

Corrosive

Radioactive

Infectious.

These effects can be either:

Acute toxicity (immediate)

- For example, an explosion has an immediate effect on people

and property (injure, kill or destroy)

Chronic toxicity (long term)

- For example, an oil spill has a long term effect on the

environment. (Contamination of waterways, soils and native

wildlife).

When handling chemicals and dangerous goods you will be faced with terms

that may, or may not be familiar to you. You will be expected to know the

meanings of these terms and to apply that knowledge when handling

chemicals and dangerous goods.

What are the sources of hazard information?

When handling chemicals and dangerous goods your safety and the safety of

others is of the utmost importance. To assist you in processing chemicals and

dangerous goods safely there are a number of sources where information can

be gained. These sources of information you need to familiar with could

include:

Acts of Legislation (Laws)

Australian Standards

Codes of Practice

Workplace procedures

Product label.

The type of information contained could include some of the following:

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 9 of 25

Product identification

Safe handling

Safe storage

Packaging

Transportation

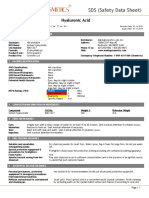

What are Material Safety Data Sheets (MSDS’s)?

MSDS’s are documents designed to provide information on hazardous

products. The purpose is to protect the handler or user by providing all the

information needed to allow safe handling and use of a specific product.

Who is responsible for providing MSDS’s?

The supplier (manufacturers) is responsible for providing MSDS’s for all

hazardous products that they supply. They are to be given to buyers or

prospective buyers of their products. They are also provided on request.

When does a MSDS need to be supplied?

A current MSDS is to be supplied before or with the first delivery of a

hazardous substance. When the MSDS has been revised a new MSDS is to

be sent with the next delivery or on request. There is no need to include a

MSDS with every delivery.

When does a MSDS need to be revised?

The MSDS must be revised and re-issued whenever the product is changed in

some way, for example a change in the composition or ingredients of the

product.

Who needs access to MSDS’s?

Every worker handling or using hazardous substances must have access to

MSDS’s. They may be located in the immediate worksite or work area or can

be held in a central location, provided that everybody knows where they are

and has access to them.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 10 of 25

What does "sanitize" mean?

Before we go much further, you should understand that sanitation is NOT the

same thing as cleaning or sterilization. Sanitizing means reducing or removing

bacteria and other undesirable micro-organisms via heat or chemical means.

Cleaning involves removing visible dirt and residue from your equipment,

while sterilization means that everything (germs, worms and personality) is

killed, and besides - it isn't realistic or even desirable to create a sterile state

during the winemaking process.

Achieving good sanitation isn't rocket science; just use some common sense.

For instance, don't use your mouth to start a siphon! Instead, use a sanitized

siphoning device or suction bulb and an uncontaminated piece of tubing.

The Sanitation Cycle

There are several methods you can employ to achieve sanitation, but the

cyclical process of cleaning and sanitizing should always follow this general

rule of thumb:

Wash everything just before use and then wash again when the job is

finished.

Here's a breakdown of what we mean...

Inspect equipment

Clean equipment, paying special attention to small crevices (like

scratches in plastic), nooks and crannies where bacteria and other

micro-organisms love to hide, grow and multiply

Sanitize equipment (see directions and methods below)

Rinse equipment (may not be necessary, depending upon sanitation

method used)

Use equipment

Rinse equipment immediately after use

Clean equipment

Sanitize equipment

Allow equipment to air dry

Store equipment (cover it or stopper it to keep dust and bugs out)

When ready to use equipment again, go back to step one and start

over

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 11 of 25

What Should I Sanitize?

Generally speaking, anything that comes in contact with the product must be

sanitized - and this especially includes your hands, which are a great source

of micro-organisms and lactic acid bacteria. The most common pieces of

equipment that require sanitation include:

Stoppers or bungs

Airlocks

Carboys

Bottles

Tubing

Thermometer

Sample jars

Hydrometers

Bottling wands or systems

Siphoning equipment

Measuring devices, such as measuring cups and spoons

Stirring paddles, rods, and spoons

What are some approved sanitation methods?

In the following paragraphs, we will explore the most common ways to sanitize

equipment. We will also provide you with directions to make one U.S. gallon of

sanitizing solution with each sanitizing agent described.

Boiling

The most basic way to sanitize equipment is to boil your equipment in water.

No chemicals are involved, and all you need is a source of heat, water, and a

large vessel to hold the water. As you learned in grade school, high

temperatures applied over a length of time will sanitize most anything. Home

canners have known this for years.... they dunk their glassware in boiling

water before filling them with food.

METHOD: Boil equipment in water for at least 5-10 minutes. Note: Minimum

sustained water temperature must be no less than 170 degrees for fifteen

minutes.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 12 of 25

Chlorine

Chlorine (free available chlorine, in the form of household bleach) is the most

universally accessible sanitizer and is an excellent cleaner and disinfectant.

However, if equipment is not rinsed well with copious amounts of hot water

after sanitation, you may inadvertently leave some chlorine residue behind. At

the very least, this will impart "off" tastes to your product - or worse, it can ruin

your product. We generally use chlorine for sanitation in emergencies only,

when we can't get other (more desirable) sanitizing chemicals.

METHOD: Mix 1/4 teaspoon unscented household bleach (Clorox or generic

brand) with one gallon of water. A little bit goes a long way. Strictly speaking,

it only takes 0.25 PPM (parts per million) of pure chlorine in distilled water to

create an effective sanitizing solution. Since most household bleach contains

a 5% solution of available chlorine, we generally err on the side of caution and

mix 1/4 tsp. with a gallon of water. This will create a batch of solution that

contains around 25 PPM of chlorine, which is more than ample for our

purposes. If making this solution, we always recommend pouring a little water

in the bottom of a gallon jug, adding the bleach and then shake the heck out

of it. Slowly add more water, shaking after each addition, until you reach 1

gallon of water.

Iodine

This chemical is also an effective sanitizing agent, and like chlorine, a little bit

goes a long way. Usually, an acid such as phosphoric acid has been added as

a cleaning agent.

METHOD: We've seen manufacturers recommend adding anywhere from 2 to

4 ml per gallon to get the desired strength. We stock the B-T-F Iodophor

Solution, which is effective at 12.5 PPM (0.3 oz diluted in 3 gallons of cool or

lukewarm water) with only 60 seconds of contact time required. You don't

even have to rinse or air dry your equipment after use; just drain well. Read

the label directions carefully to be sure. Not only can iodine stain your clothes

or skin, but it can be as toxic as chlorine (never add to hot water!), so please

handle with care.

B-Brite

B-Brite is a proprietary formulated sanitizing powder made specifically for the

winemaking and beer making industry. It cleans with active oxygen, and does

not contain chlorine or bisulfite. It also removes fermentation residues, so we

recommend it for its effective one-two punch (cleaning and sanitizing), a

combination that is hard to beat.

METHOD: Mix one tablespoon powder to one gallon water. Rinse equipment

with clear water after cleansing.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 13 of 25

Campden Tablets

These little tablets (Potassium Metabisulfite is the active ingredient) work

wonders; not only do they "clean" must prior to pitching yeast, but adding

crushed campden tablets to water also makes a great sanitizing solution for

equipment.

Each campden tablet supplies about 67 mg / litre (PPM) per gallon at pH

between 3.2 and 3.5. As it turns out, it's good to have a little free SO2

(between 40 - 60 PPM), so there's no need to rinse your equipment after

sanitizing with this agent.

METHOD: In order to obtain a sanitizing solution of 940 PPM SO2, crush 14

campden tablets and dissolve into 1 gallon of water.*

Potassium Metabisulfite Powder

You can also buy Potassium Metabisulfite in powder form, usually sold to

home winemakers in 4 ounce bottles or 1 pound bags. This chemical works

well as a sanitizing agent because it is a bacterial inhibitor. Since there's no

inert materials in this form (unlike campden tablets, which have some fillers

added), you don't need to add a lot of crystals to make a great sanitizing

solution.

METHOD: Dissolve 1 teaspoon of crystals in one gallon of water to make a

solution comprised of 940 PPM SO2.*

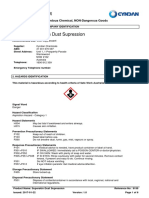

To help you visualize the differences between the methods of sanitizing

equipment, we've comprised a matrix of the various methods, listing the

advantages and disadvantages of each.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 14 of 25

Sanitation

Advantages Disadvantages

Method

Time consuming; need large vessels to

No chemicals are

Boiling wash equipment in; burn hazard; requires

required.

steady source of heat

Hard to remove from porous material; if

Common chemical,

not properly rinsed off with hot water,

readily available in the

residues can ruin the taste and smell of

Chlorine form of household

wine; potentially hazardous (chlorine gas,

bleach; inexpensive;

poisonous in high concentration); ruins

good cleaning agent

clothes and corrodes stainless steel.

Sulfites cause allergic reactions to some

Campden Easy to measure correct

people; must crush tablets before mixing.

Tablets amount. Long shelf life.

Same active ingredient, but more

(#2731) No rinsing necessary.

expensive than metabisulfite powders.

Iodine

(B-T-F Economical; a little Toxic in high concentrations; stains

Iodophor - dab'll do ya. clothes, skin and porous materials.

#2745)

Potassium

Long shelf life;

Metabisulfite Need to take care in measuring; some folks

economical. No rinsing

crystals are allergic to sulfites.

required.

(#2732)

Cleans with oxygen,

Must rinse equipment with clear water

B-Brite without the use of

after use. Slightly more expensive than

(#2721) chlorine. Cleans and

metabisulfite powder

sanitizes.

Note: Heat destroys the chemicals mentioned above, so store them in a cool, dry

place.

WARNING: Never, EVER mix any of these sanitizing agents with one another!

The gases that are released by the chemical reactions can be very toxic.

Here are some other chemical sanitizers we have not discussed, but they can

be used as well:

CTSP (Chlorinated TriSodium Phosphate)

Quaternary ammonia

Washing soda (sodium carbonate)

Conclusion

Sanitation, an extremely important step, is easy to accomplish if you follow a

few simple guidelines and take the time to do a complete and thorough job.

Before you use equipment, clean it and sanitize it.

After you use it, rinse, clean and sanitize equipment. It's very difficult to

clean out crevices once residue has dried.

Air dry and store covered to keep out contamination and bugs.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 15 of 25

How do you carry out waste removal?

When doing waste removal, the most important parts you need to think about

are:

The risk from chemical

Contamination (waterways and soil)

Slips, trips, sprains and falls

Removal of materials used to absorb spillage. These must be treated

under the same rules as the original product. An example would be

using sawdust or sand to absorb an oil spill. In this case the sawdust or

sand would have to be disposed of in the same way as the oil; i.e.; in a

contaminated waste site.

If you are involved in waste removal plans and tasks you need to think

about:

Reduction - this means having no more waste than possible or

reducing the amount of waste being produced

Re-use - wherever possible, use waste material in the operations

Recover - this means to reproduce a useable product from the waste

Segregation - separate waste in clearly defined areas and containers

Specialised removal - specialists may need to be called in to handling

dangerous waste product

Applying hazardous waste removal regulations and codes of practice.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 16 of 25

Work area maintenance

Housekeeping not only entails clean up and disposal of waste, but regular and

routine inspections so that housekeeping standards can be maintained.

Vigilance is the key to a safe and clean workplace.

HOUSEKEEPING PAYS

IF YOU USE IT –

PUT IT AWAY

DON’T WAIT FOR SOMEONE ELSE

Housekeeping is a continual process that is everyone’s responsibility.

Personnel should not assume that someone else will clean up a mess or put

away equipment.

In some plants, housekeeping audits are performed by designated personnel

to check on the effectiveness of the housekeeping program.

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 17 of 25

TLIV507C CLEAN AND INSPECT PALLETS

TRAINING AND ASSESSMENT ACTIVITIES AND QUESTIONS

The Trainee will be required to demonstrate competence on the job, in

practical demonstration; observation, question/answer and role-play

situations, incorporating verbal questions and written work, including

completing workplace forms, either to the RTO Trainer or Supervisor, under

the guidance of the RTO Trainer.

Element of competency:

1. Identify workplace procedures, resources and requirements for cleaning

pallets

2. Inspect and clean pallets

3. Monitor and maintain cleanliness and tidiness of pallet cleaning and storage

areas

4. Complete assigned pallet cleaning and inspection duties

1. When is protective equipment and clothing required to be used?

2. What are material safety data sheets?

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 18 of 25

3. How do you prevent accidental equipment start-up?

4. What does sanitising mean?

Assessment task

Your workplace assessor will observe your performance as you demonstrate

your ability to:

Identify workplace procedures, resources and requirements for

cleaning pallets

Inspect and clean pallets

Monitor and maintain cleanliness and tidiness of pallet cleaning and

storage areas

Complete assigned pallet cleaning and inspection duties

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 19 of 25

ASSESSMENT MODE A - Oral questioning

Trainee name:

Name of Workplace:

RTO Trainer name:

Unit/s of competency: TLIV507C

Unit Name: CLEAN AND INSPECT PALLETS

Date of training/

assessment visit:

Instructions: In addition to written answers provided above, the trainee is required to

provide verbal answers to the following questions that will be asked by the RTO Trainer.

Read the questions prior to the Trainer’s visit, and be prepared to answer them, obtaining

help where necessary.

Did the trainee satisfactorily answer the following questions: Yes No

1. When is protective equipment and clothing required to be used?

2. What are material safety data sheets?

3. How do you prevent accidental equipment start-up?

4. What does sanitising mean?

5. How do you maintain cleaning equipment supplies?

6. How are pallets sorted and stored?

The trainee’s underpinning knowledge was:

Satisfactory Not Satisfactory

Notes/comments :

Question 1:

Question 2:

Question 3:

Question 4:

Question 5:

Question 6:

RTO Trainer signature:

Trainee signature:

Date of assessment:

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 20 of 25

ASSESSMENT MODE B - Skills observation checklist

Trainee name:

Name of workplace:

RTO Trainer name:

Unit/s of competency: TLIV507C

Unit Name: CLEAN AND INSPECT PALLETS

Date of training/

assessment visit:

During the demonstration of skills, did the trainee: Yes No N/A

Workplace operating procedures, including occupational health and

safety requirements for pallet cleaning, were identified and read

Equipment (including appropriate engineering controls and personal

protection equipment) and consumables were selected in accordance

with work area requirements

Specific requirements for pallet inspection and cleaning were identified

and used in the planning of work activities

Requirements for the organisation of pallet storage before and after

cleaning were identified to meet workplace requirements

Information on serviceability requirements of pallets for required

purposes was accessed and read

Pallet design features were noted and pallet types were identified for

particular purposes

Pallets were inspected prior to, and during, cleaning to ensure that

condition was appropriate for required use

Damaged pallets were tagged for repair or recycling

Pallets were cleaned following workplace procedures

Pallets were sorted and stacked in appropriate storage areas

Work was carried out following workplace practices and safe work

procedures

Initiative was used to continuously monitor the cleanliness, safety and

tidiness of the pallet cleaning and storage area

Housekeeping issues were raised with designated personnel in

accordance with workplace procedures

Cleaning equipment and supplies were maintained and stored

Assigned pallet cleaning and inspection duties were conducted in

accordance with workplace requirements

Documentation concerning cleaning operations was completed in

accordance with workplace procedures

The trainee’s performance was: Not Satisfactory Satisfactory

Trainee signature:

RTO Trainer signature:

I confirm competence for this unit TLIV507C _________________

(Manager signature)

_________________

(Date)

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 21 of 25

COMPETENCY RECORD – TLIV507C

After assessment the assessor, the supervisor and participant should sign the competency record. If competency is not achieved at the first attempt, strategies to

address the performance gaps need to be identified and a time for re-assessment organized.

Assessment Strategies Assessor Comments

C U R R E N T

C O M P E T E N C I E S

Oral/written questions _____________________________________________

Activities

_____________________________________________

Workplace project

_____________________________________________

Supervisor/3rd party report

_____________________________________________

Self-Assessment _____________________________________________

Other _____________________________________________

Valid Sufficient Authentic Current

The evidence supplied is:

The participant is competent has shown competence in all of the

following elements:

Identify workplace procedures, resources and

requirements for cleaning pallets

Inspect and clean pallets

Monitor and maintain cleanliness and tidiness of pallet

cleaning and storage areas

Complete assigned pallet cleaning and inspection duties

Trainee Signature: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

D A T E _ _ _ _ _ _ _ _ _

Supervisor Signature:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

D A T E _ _ _ _ _ _ _ _ _

Trainer Signature

The Trainee is _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

D A T E _ _ _ _ _ _ _ _ _

NOT YET COMPETENT:

Strategies to address gaps in D A T E F O R R E A S S E S S M E N T : _ _ _ _ _ _ _ _ _ _ _

trainee performance:

TLIV507C Clean and inspect pallets February 2008 Version 1 Page 22 of 25

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Trane Chiller Purge Unit ManualDocumento40 pagineTrane Chiller Purge Unit Manualivyspell80% (5)

- TLII207D - Apply Customer Service Skills - Learner GuideDocumento54 pagineTLII207D - Apply Customer Service Skills - Learner Guideromerofred100% (1)

- Sample Paint EmcalcDocumento46 pagineSample Paint EmcalctlchrisNessuna valutazione finora

- TLIG107C - Work Effectively With Others - Learner GuideDocumento35 pagineTLIG107C - Work Effectively With Others - Learner Guideromerofred67% (3)

- TLIL107C - Complete Workplace Orientation Induction Procedures - Learner GuideDocumento109 pagineTLIL107C - Complete Workplace Orientation Induction Procedures - Learner GuideromerofredNessuna valutazione finora

- TLIH107D - Interpret Road Maps and Navigate Pre-Determined Route - Learner GuideDocumento48 pagineTLIH107D - Interpret Road Maps and Navigate Pre-Determined Route - Learner GuideromerofredNessuna valutazione finora

- TLIG207C - Lead A Work Team or Group - Learner GuideDocumento57 pagineTLIG207C - Lead A Work Team or Group - Learner GuideromerofredNessuna valutazione finora

- ADEADV1047 - Quick Facts & T&C - 12 Hour Heavy Combination UNFUNDEDDocumento2 pagineADEADV1047 - Quick Facts & T&C - 12 Hour Heavy Combination UNFUNDEDromerofredNessuna valutazione finora

- ADEADV1030 - Quick Facts & T& C - Light RigidDocumento2 pagineADEADV1030 - Quick Facts & T& C - Light RigidromerofredNessuna valutazione finora

- ADEADV1042 Quick Facts & T& C - Forklift 1 Day Licence CourseDocumento2 pagineADEADV1042 Quick Facts & T& C - Forklift 1 Day Licence CourseromerofredNessuna valutazione finora

- ADEADV1048 - Quick Facts & T&C - 5 Hour Light Rigid UNFUNDEDDocumento2 pagineADEADV1048 - Quick Facts & T&C - 5 Hour Light Rigid UNFUNDEDromerofredNessuna valutazione finora

- Term 2 2010Documento1 paginaTerm 2 2010romerofredNessuna valutazione finora

- 2009 ATV BrochureDocumento14 pagine2009 ATV Brochureromerofred100% (1)

- ADEADV1044 - Quick Facts & T&C - 5 Hour Medium Rigid UNFUNDEDDocumento2 pagineADEADV1044 - Quick Facts & T&C - 5 Hour Medium Rigid UNFUNDEDromerofredNessuna valutazione finora

- ADEADV1046 - Quick Facts & T&C - 12 Hour Heavy Rigid Synch Rome SH UNFUNDEDDocumento2 pagineADEADV1046 - Quick Facts & T&C - 12 Hour Heavy Rigid Synch Rome SH UNFUNDEDromerofredNessuna valutazione finora

- ADEADV1045 - Quick Facts & T&C - 12 Hour Heavy Rigid Non Synch Rome SH UNFUNDEDDocumento2 pagineADEADV1045 - Quick Facts & T&C - 12 Hour Heavy Rigid Non Synch Rome SH UNFUNDEDromerofredNessuna valutazione finora

- ADEADV1040 Quick Facts & T&C - Container Side LoaderDocumento2 pagineADEADV1040 Quick Facts & T&C - Container Side LoaderromerofredNessuna valutazione finora

- Off Road Brochure 2010Documento24 pagineOff Road Brochure 2010romerofred100% (1)

- TLIO207D - Follow Security Procedures - Learner GuideDocumento41 pagineTLIO207D - Follow Security Procedures - Learner Guideromerofred100% (1)

- Road Range 2010Documento28 pagineRoad Range 2010romerofred100% (1)

- Gold Wing AccessoriesDocumento17 pagineGold Wing Accessoriesromerofred100% (1)

- ADEADV1039 - Quick Facts & T& C - Heavy Combination Saturday Course NONDocumento2 pagineADEADV1039 - Quick Facts & T& C - Heavy Combination Saturday Course NONromerofredNessuna valutazione finora

- ADEADV1038 - Quick Facts & T&C - Motorcycle Licence Short CourseDocumento2 pagineADEADV1038 - Quick Facts & T&C - Motorcycle Licence Short CourseromerofredNessuna valutazione finora

- TLIL307C - Conduct Induction Process - Learner GuideDocumento57 pagineTLIL307C - Conduct Induction Process - Learner GuideromerofredNessuna valutazione finora

- TLIM308A - Develop Safe Motorcycle Riding Behaviours in Others - Learner GuideDocumento12 pagineTLIM308A - Develop Safe Motorcycle Riding Behaviours in Others - Learner GuideromerofredNessuna valutazione finora

- TLIL807C - Complete Routine Administrative Tasks - Learner GuideDocumento42 pagineTLIL807C - Complete Routine Administrative Tasks - Learner Guideromerofred100% (1)

- General Terms and Conditions of SaleDocumento2 pagineGeneral Terms and Conditions of SaleromerofredNessuna valutazione finora

- TLIM107A - Develop Safe Driving Habits in Others - Learner GuideDocumento85 pagineTLIM107A - Develop Safe Driving Habits in Others - Learner GuideromerofredNessuna valutazione finora

- TLIK107C - Use Information Technology Devices and Computer Applications in The Workplace - Learner GuideDocumento84 pagineTLIK107C - Use Information Technology Devices and Computer Applications in The Workplace - Learner GuideromerofredNessuna valutazione finora

- TLIH207D - Plan and Navigate Routes - Learner GuideDocumento50 pagineTLIH207D - Plan and Navigate Routes - Learner GuideromerofredNessuna valutazione finora

- TLIG707B - Work in A Culturally Diverse Environment - Learner GuideDocumento45 pagineTLIG707B - Work in A Culturally Diverse Environment - Learner Guideromerofred67% (3)

- Sds Hyaluronic AcidDocumento3 pagineSds Hyaluronic AcidAry SukmaNessuna valutazione finora

- Ab Cutrine Ultra Algicide MsdsDocumento2 pagineAb Cutrine Ultra Algicide MsdsSouth Santee AquacultureNessuna valutazione finora

- Hach 5500scDocumento384 pagineHach 5500scsurya chandraNessuna valutazione finora

- Student Assessment Tasks: Student Name: Student NumberDocumento32 pagineStudent Assessment Tasks: Student Name: Student NumberAmandeep KarwalNessuna valutazione finora

- Co2 Gas MSDSDocumento7 pagineCo2 Gas MSDSK SubramaniNessuna valutazione finora

- IBI Biochar Standards V2.1 Final2Documento61 pagineIBI Biochar Standards V2.1 Final2hphuc1707Nessuna valutazione finora

- Chemical Hazards-Lec 6Documento34 pagineChemical Hazards-Lec 6Amelia RamkissoonNessuna valutazione finora

- Potassium Carbonate (Anhydrous All Grades) MTR Ansi enDocumento14 paginePotassium Carbonate (Anhydrous All Grades) MTR Ansi enRay RichalmyNessuna valutazione finora

- (Tawas) Sodium Aluminate High Performance CoagulantDocumento3 pagine(Tawas) Sodium Aluminate High Performance CoagulantANNaNessuna valutazione finora

- F-14 Feed Safety Data Sheet (FSDS) ENGDocumento6 pagineF-14 Feed Safety Data Sheet (FSDS) ENGNikola StanićNessuna valutazione finora

- Premalube Red Material Safety Data SheetDocumento3 paginePremalube Red Material Safety Data Sheetfreddy william montalban palaciosNessuna valutazione finora

- Urethane Foam MSDSDocumento3 pagineUrethane Foam MSDSSIZ1400Nessuna valutazione finora

- Superskin Dust Supression-SDSDocumento6 pagineSuperskin Dust Supression-SDSIrelena RomeroNessuna valutazione finora

- 140070H1 TIFF YELLOW - United States-EnglishDocumento10 pagine140070H1 TIFF YELLOW - United States-Englishdedi munardiNessuna valutazione finora

- MSDS Dolomite Plus Soil AmendmentDocumento4 pagineMSDS Dolomite Plus Soil AmendmentLABORATORIUM FERTILINDONessuna valutazione finora

- SDS - Astm P 127 02Documento7 pagineSDS - Astm P 127 02Omar SaaedNessuna valutazione finora

- Johnson Paste Wax SDSDocumento13 pagineJohnson Paste Wax SDSMark LionNessuna valutazione finora

- Sds Sodium HydroxideDocumento11 pagineSds Sodium HydroxideusenuyaNessuna valutazione finora

- SF-650 Spray ArranqueDocumento3 pagineSF-650 Spray ArranqueNazareno Roca100% (1)

- RTHD SVX01G en - 08302016 PDFDocumento104 pagineRTHD SVX01G en - 08302016 PDFDione SilvaNessuna valutazione finora

- Huntex Or-27: Identification of The Substance/ Mixture and of The Company/ UndertakingDocumento8 pagineHuntex Or-27: Identification of The Substance/ Mixture and of The Company/ UndertakingHồ Nhã Mai PhươngNessuna valutazione finora

- Viton Fluoroelastomer: Safety Data SheetDocumento8 pagineViton Fluoroelastomer: Safety Data SheetRaghu SubranNessuna valutazione finora

- Colaliquid DO - SDSDocumento5 pagineColaliquid DO - SDSmndmattNessuna valutazione finora

- Chemicals Zetag MSDS LDP Zetag 7869 - 0710Documento6 pagineChemicals Zetag MSDS LDP Zetag 7869 - 0710PromagEnviro.comNessuna valutazione finora

- Sikaflex® 221: Safety Data SheetDocumento12 pagineSikaflex® 221: Safety Data SheetHakan KuruoğluNessuna valutazione finora

- Safety Sheet For Caco3Documento5 pagineSafety Sheet For Caco3Vaibhav D RavalNessuna valutazione finora

- Tankguard HB Classic Jotun PaintDocumento5 pagineTankguard HB Classic Jotun PaintGurdeep Sungh AroraNessuna valutazione finora