Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Komatsu HD785-7

Caricato da

Muhammad FattahCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Komatsu HD785-7

Caricato da

Muhammad FattahCopyright:

Formati disponibili

ENGINE POWER

895 kW / 1.200 HP @ 1.900 rpm

MAXIMUM GVW

166.000 kg

BODY CAPACITY, HEAPED

60,0 m

HD785-7

HD

785

OFF-HIGHWAY TRUCK

HD785-7

HD785-7

O F F - H I G H W A Y TR U C K

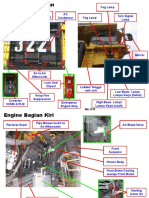

WALK-AROUND

Productivity features

High performance Komatsu SAA12V140E-3 engine

Variable horsepower control (VHPC)

Two-speed selective reverse gears of RH and RL

Anti-pitching 4-wheel oil-cooled multiple-disc retarder

Automatic Idling Setting System (AISS)

Auto Retard Speed Control (ARSC)

High strength body

Minimum turning radius: 10,1 m

ABS (Anti-Lock Braking System) (Option)

ASR (Automatic Spin Regulator) (Option)

Payload meter function

Environment-friendly

Meets EPA Tier 2

Low operating noise

Low fuel consumption

Lead-free radiator

Brake cooling oil recovery tank

OFF-HIGHWAY TRUCK

HD785-7

ENGINE POWER

895 kW / 1.200 HP

MAXIMUM GVW

166.000 kg

Operator environment

Wide, spacious cab with excellent visibility

Ergonomically designed cab

Easy-to-see instrument panel

Air suspension seat

Tiltable, telescoping steering wheel and low effort pedals

Electric body dump control lever

K-ATOMiCS transmission with Skip-Shift function

Synchronous control of engine and transmission

Hydropneumatic suspension for all terrains

Viscous cab mounts

Built-in ROPS/FOPS

Supplementary steering (Automatic)

Pedal-operated secondary brakes

Three-mode hydropneumatic suspension

(auto-suspension) (Option)

Front stairway with handrails

BODY CAPACITY, HEAPED

60,0 m

Reliability features

Fully hydraulic brake system

Reliable Komatsu manufactured major

components

High-rigidity frame

Wet multiple-disc brakes (front and rear)

Flat face-to-face O-ring seals

Sealed DT-connectors

Highly reliable hydraulic system

Easy maintenance

Long oil change interval

Centralized greasing points

Centralized arrangement of filters

Flanged type rims

KOMTRAX - Komatsu satellite

monitoring system

KOMTRAX Plus (Vehicle Health

Monitoring System)

Satellite communication system for

KOMTRAX Plus

3

HD785-7

O F F - H I G H W A Y TR U C K

PRODUCTIVITY & ECONOMY

High performance Komatsu SAA12V140E-3

engine

Variable horsepower control (VHPC) with

mode selection system

This engine delivers faster acceleration and higher

travel speeds with high horsepower per ton. Advanced

technology, such as High Pressure Common Rail injection system (HPCR), air-to-air aftercooler efficient turbocharger gives high torque at low speed, impressive

acceleration, and low fuel consumption for maximum

productivity.

The system allows selection of the appropriate mode

between two modes Power mode or Economy mode

according to each working condition. The mode is easily

selected with a switch in the operators cab. When the

key switch is turned on, Economy mode is selected

automatically. Select Power mode by using the switch

when needed.

VHPC (Variable horsepower control)

F7-R2 (RH/RL) fully automatic transmission

The transmission is configured with 7 forward and 2

reverse gears. Fully automatic control is applied to all

forward gears and an optimum gear is automatically

selected according to the

travel speed and engine

speed. The shifting point is

automatically selected depending on the acceleration

of the machine to reduce

excessive fuel consumption.

Both in Power and Economy modes, the VHPC system

detects whether machine condition is loaded or unloaded and selects optimum horsepower setting mode, providing both high production and low fuel consumption.

Power mode: Makes best use of the horsepower to attain optimal production. This mode is suitable for operation in job sites including uphill travel with load where

powerful hauling is top priority.

Economy mode: Sets the maximum horsepower at low

level to reduce fuel consumption. The machine maintains sufficient power for economical operation in this

mode.

Two-speed selective reverse gears (RH/RL)

In order to meet various operating conditions, two

reverse gears are provided. The switch on the panel

allows the operator to select optimum reverse gear of

RH or RL depending on the job site conditions. Furthermore, the reverse gear is equipped with a lockup clutch,

allowing the operator to reverse the machine without

overheating.

895 kW

(1.200 HP)

Power

mode

809 kW

(1.085 HP)

750 kW

(1.005 HP)

RH: Suitable for normal operation. Thanks to the lockup

clutch, the machine can be reversed at higher speed

RL: Suitable for operation in job sites where there are

steep grades.

Economy

mode

698 kW

(936 HP)

Automatic selection

Manual selection

OFF-HIGHWAY TRUCK

Anti-pitching 4-wheel oil-cooled multiple disc

retarder

The machine is equipped with an anti-pitching 4-wheel

oil-cooled multiple disc retarder that applies retarding

force on all four wheels. With this retarder, the retarding force is shared between four wheels. This reduces

the possibility of tire-lock and enables effective use of

retarder capacity, allowing stable downhill travel. The

machine descends slopes smoothly and comfortably

without machine pitching since retarding force on front

and rear wheels is controlled independently.

HD785-7

Auto Retard Speed Control (ARSC)

ARSC allows the operator to simply set the downhill

travel speed and go down slopes at a constant speed.

As a result, the operator can concentrate on steering.

The speed can be set at increments of 1 km/h per click

to match the optimum speed for the slope. Also, when it

is predicted that the retarder oil temperature becomes

overheated, since the retarder oil temperature is always

monitored, operator is informed this by warning lamp.

UP

SET

CANCEL

Front brake

Rear brake

DOWN

Go down

slope at

constant

speed

Anti-pitching 4-wheel oil-cooled

multiple disc retarder

F/R: Retarder (4-wheel)

Conventional

R: Retarder (2-wheel)

Retarder absorbing capacity (continuous descent):

1.092 kW (1.464 HP)

Brake surface

Front total: 37.467 cm

Rear total: 72.414 cm

5

HD785-7

O F F - H I G H W A Y TR U C K

PRODUCTIVITY & ECONOMY

Eliminating hydraulic losses & optimizing

transmission control

Hydraulic circuits such as brake cooling, steering, body

dump control, transmission control etc. are optimized

to reduce fuel consumption. As a result, the fuel consumption for operation with medium and light load is

improved.

Automatic Idling Setting System (AISS)

This system facilitates quick engine warmup and cab cooling/warming. When setting

the system ON, engine idle speed is kept at

945 rpm when coolant temperature is 50 C

or lower. Speed automatically returns to 750 rpm when

coolant temperature reaches 50 C.

Small turning radius

A-frame

The MacPherson strut type

front suspension has a special

10,1 m

A-frame between each wheel

and the main frame. The wider

space created between the

front wheels and the main

frame increases the turning

angle of the wheels. The larger this turning angle, the

smaller the turning radius of the truck.

Long wheelbase and wide tread

With an extra-long wheelbase, a wide tread and an

exceptionally low center of gravity, the HD785-7 hauls

the load at higher speed for greater productivity, and

delivers superior driving comfort over rough terrain.

Large body

A wide target area makes for easy loading with minimal

soil spillage and more efficient hauling.

Heaped capacity: 60,0 m

Target area (inside length x width):

7.065 mm 5.200 mm

OFF-HIGHWAY TRUCK

HD785-7

SAFETY FEATURES

Built-in ROPS/FOPS

Pedal-operated secondary

brake

These structures conform to ISO 3471 and

SAE J1040 standards

and ISO 3449 and SAE

J231 FOPS standards.

If there should be a failure on

the foot brake circuit, both front

and rear parking brakes are

activated as a pedal operated

secondary brake. In addition,

when hydraulic pressure drops

below the rated level, the parking brake is automatically

actuated.

Parking brakes on 4 wheels

ABS (Anti-Lock Braking System) (Option)

The machine is equipped with spring applied parking

brakes on 4-wheels. Wet multiple disc brakes built in

both front and rear axles apply braking force to all four

wheels. These brakes are highly reliable require no

periodic maintenance.

Using its outstanding electronics technology, Komatsu is

the first in the industry to introduce ABS on construction

machinery. This system prevents the tyres from locking,

thus minimizes skidding under slippery conditions while

applying the service brake.

ASR (Automatic Spin Regulator) (Option)

ASR automatically prevents the rear tyres on either side

from slipping on soft ground for optimal traction. The

steering angle is monitored in order to ensure smooth

turning.

Front brake

Rear brake

Supplementary steering and secondary brakes

Supplementary steering and secondary brakes are

standard features.

Steering: ISO 5010, SAE J1511, SAE J53

Brakes: ISO 3450, SAE J1473

Stairway

A stairway at the front of the radiator grill simplifies such

everyday operations as getting on and off the machine.

7

HD785-7

O F F - H I G H W A Y TR U C K

OPERATOR ENVIRONMENT

Wide, spacious cab with excellent visibility

The wide cab provides a comfortable space for the

operator and a full size trainers seat. A large electrically

operated window and the operators seat positioned on

the left hand side ensures superior visibility.

Ergonomically designed cab

The ergonomically designed operators compartment

makes it very easy and comfortable for the operator to

use all the controls. The result is more confident operation by operators and greater productivity. A rear view

camera and monitor system is supplied as standard.

Easy-to-see instrument panel

Steering wheel and pedals

The instrument panel makes it easy to monitor critical

machine functions. In addition, a caution light warns the

operator of any problems that may occur. This Komatsu

on-board monitoring system makes the machine very

friendly and easy to service.

Low effort pedals reduce operator fatigue when working

continuously for long periods. The tiltable, telescoping

steering column enables operators to maintain an optimum driving position at all times.

Electric body dump control lever

Air suspension seat is standard

The air suspension, fabric-covered seat which is adjustable to the operators weight is provided as standard.

The air suspension seat dampens vibrations transmitted

from the machine and reduces operator fatigue as well

as holding the operator securely to assure confident

operation.

The low effort lever makes dumping easier than ever.

A positioning sensor is

installed for dump body

control which significantly

reduces the shock made by

the lowering of the dump

body.

OFF-HIGHWAY TRUCK

HD785-7

K-ATOMiCS with Skip-Shift function

The MacPherson strut type front suspension

The K-ATOMiCS (Komatsu Advanced Transmission with

Optimum Modulation Control System) ensures proper

clutch modulation pressure when the clutch is engaged.

The total control system controls both the engine and

transmission by monitoring the vehicle conditions. This

system and newly added skip-shift function ensure

smooth shifting and responsive acceleration.

The MacPherson type independent suspension is

installed to the front wheels. The linkage arrangement

with less friction allows the front wheel to follow the

undulation of road surface smoothly, realizing excellent

riding comfort.

Skip-shift function

The optimum travel speed automatically selected in

response to the angle of ascent. Reduced frequency of

down shifts and smoother operation are provided.

Shift down

Skip-shift

Shift hold

Shift down

Current

Shift down

Shift down

Viscous cab mounts

Three-mode hydropneumatic suspension

(Auto-suspension) (Option)

Viscous mounts reduce the

noise transmitted to the cab

and achieve a quiet 75 dB(A)

noise level (SAE J1166).

For a comfortable and stable ride, the suspension mode

is automatically switched to one of three stages (soft,

medium and hard) according to load and operating

conditions.

HD785-7

O F F - H I G H W A Y TR U C K

ADVANCED MONITORING SYSTEM

Availability rate with vehicle monitoring system

The electronic display panel shows current vehicle condition and how to fix them with action codes and check

results with service codes. Thus, vehicle management is easier and the working rate is higher. At the same time the

monitoring data is saved to be used for later troubleshooting.

Equipment Management Monitoring System (EMMS)

Monitoring network

Monitoring system

Engine controller

Transmission controller

This window is normally used as the service meter/

odometer. If the dump truck has any abnormality or

needs to be inspected or serviced, a message of proper

remedy and an action code are displayed in this window. Each time the starting switch is turned on, the system is checked. If any filter or oil needs to be replaced

at this time, the maintenance caution lamp flashes or

lights up and the filter or oil to be replaced is displayed.

If any abnormality occurs in the dump truck, a message is dispayed on the character diplay to notify the

operator of what action to take. Accordingly, the operator can take that action immediately. The abnormality is

displayed as a fault code on the character display and

stored so that it will be available for quick troubleshooting to shorten downtime.

10

Retarder controller

OFF-HIGHWAY TRUCK

HD785-7

EASY MAINTENANCE

KOMTRAX Plus

(Vehicle Health Monitoring System)

Centralized greasing

points

The KOMTRAX Plus controller monitors the health

conditions of major components and enables analysis of

the machine and its operations. The KOMTRAX Plus

controller monitors and stores all data received from the

engine and transmission controller and various additional sensors on the major components. This way, its

possible to record the evolution of the machines health

condition. This data can be downloaded via a portable

computer or via satellite communication. In both cases,

customers and Komatsu specialists can analyse this

downloaded data and follow up trends in the machines

condition. When using the satellite communications, the

Komatsu specialist can inform you whenever an abnormal condition occurs. This way, repair and maintenance

costs can be optimised, and maximum machine availability can be maintained.

The Komatsu satellite monitoring system, KOMTRAX

lets you pin-point the precise location of your machines.

Greasing points are

centralized at three

locations.

Centralized arrangement

of filters

The filters are centralized

so that they can be serviced

easily.

Flange type rims

Flange type rims provide

easy removal/installation of

the tyres.

Satellite communication

Customer

job site

KOMATSU

Internet

WebCARE Server

Customer

Personal

computer

terminal

(for downloading

data)

Electric circuit breaker

A circuit breaker is adopted

in important electric circuits

that should be restored in

a short time when a problem occurs in the electrical

system.

Payload meter function on KOMTRAX Plus

Extended service intervals

The payload is indicated on the Equipment Management Monitor. This option allows the production volume

and the working conditions on the dump trucks to be

analyzed directly via a personal

computer. The system can store

up to 2.900 working cycles.

In order to minimize operating costs, service intervals

have been extended:

Engine oil 500 hours

Hydraulic oil 4.000 hours

Brake cooling oil recovery tank

To protect the environment, a tank is installed to recover

brake cooling oil in the event of brake floating seal leakage.

11

HD785-7

O F F - H I G H W A Y TR U C K

RELIABILITY FEATURES

Komatsu components

Flat face-to-face O-ring seals

Komatsu manufactures the engine, torque converter,

transmission, hydraulic units, and electrical parts on this

dump truck. Komatsu dump trucks are manufactured

with an integrated production system under a strict

quality control system.

Flat face-to-face O-ring

seals are used to securely seal all hydraulic

hose connections and

to prevent oil leakage.

Nipple

Hose

O-rings

High-rigidity frames

Front support is integrated with the

frame. The frame rigidity is increased drastically. As a result, flexural rigidity and torsional

rigidity that are indicators of

drivability and riding quality

are significantly improved.

Wet multiple-disc brakes and fully hydraulic

braking system

For lower maintenance costs and higher reliability. Wet

disc brakes are fully sealed. Contaminants are kept out,

reducing wear and maintenance. Brakes require no adjustments for wear, meaning even lower maintenance.

The new parking brake is also an adjustment- free, wet

multiple-disc for high reliability and long life. Added reliability is designed into the braking system by the use of

three independent hydraulic circuits. Provides hydraulic

backup should one of the circuits fail. Fully hydraulic

brakes system means no air system to bleed, or condensation of water that can lead to contamination, corrosion, and freezing.

12

Sealed DT-connectors

Main harnesses and

controller connectors are

equipped with sealed

DT-connectors providing high reliability, water

resistance and dust

resistance.

Reliable hydraulic system

A large capacity oil cooler is installed in each hydraulic

circuit, improving the reliability of the hydraulic units

during sudden temperature rises. Further, in addition

to the main filter, a 10-micron line filter is located at the

entrance to the transmission control valve. This system

helps to prevent secondary faults.

OFF-HIGHWAY TRUCK

HD785-7

Rugged and durable dump body design

The standard dump body is made of high-tensilestrength steel with a Brinell hardness of 400 for excellent rigidity and reduced maintenance cost. The V-shape

and V-bottom design also increase structural strength.

The side and bottom plates of the dump section are

reinforced with ribs for added strength.

A quarry body with a 25 mm Hardox bottom plate with a

Brinell hardness of 450 is also available.

13

HD785-7

O F F - H I G H W A Y TR U C K

SPECIFICATIONS

ENGINE

Model...........................................................Komatsu SAA12V140E-3

Type ................................. Common rail direct injection, water-cooled,

turbocharged, after-cooled diesel

Engine power

at rated engine speed ...................................................... 1.900 rpm

ISO 14396............................................................ 895 kW/1.200 HP

ISO 9249 (net engine power)............................... 879 kW/1.179 HP

No. of cylinders................................................................................ 12

Bore stroke ................................................................ 140 165 mm

Displacement.......................................................................... 30,48 ltr

Max. torque ......................................................................... 518 kgfm

Governor ....................................................... Electronically controlled

Lubrication system:

Lubrication method .............................Gear pump, force lubrication

Filter .................................................................................... Full flow

Air filter ....................... Dry type with double elements and precleaner

(cyclonpack type), plus dust indicator

TRANSMISSION

Torque converter................................... 3-elements, 1-stage, 2-phase

Transmission ........................................ Full-automatic, planetary type

Speed range ....................... 7 speeds forward and 2 reverse (RH/RL)

Lock-up clutch .............................................. Wet, multiple-disc clutch

Forward ......................................... Torque converter drive in 1st gear,

direct drive in 1st lockup and all higher gears

Reverse ..............................................Torque converter drive (lockup)

Shift control .............................. Electronic shift control with automatic

clutch modulation in all gears

Max. travel speed ................................................................... 65 km/h

STEERING SYSTEM

Type ......................................................Fully hydraulic power steering

with two double-acting cylinders

Supplementary steering ..........Automatically and manually controlled

(meets ISO 5010, SAE J1511 and SAE J53)

Minimum turning radius, centre of front tyre ............................. 10,1 m

Maximum steering angle (outside tyre) ..........................................41

BRAKES

Brakes meet ISO 3450 and SAE J1473 standards.

Service brakes:

Front.................. Full-hydraulic control, oil-cooled multiple-disc type

Rear .................. Full-hydraulic control, oil-cooled multiple-disc type

Parking brake Spring applied, multiple-disc type, acting on all wheels

Retarder ................................. Oil-cooled, multiple-disc front and rear

brakes act as retarder

Retarder capacity (continuous) .......................... 1.092 kW / 1.464 HP

Secondary brake ............................................Manual pedal operation

When hydraulic pressure drops below the rated level,

parking brake is automatically actuated.

Brake surface:

Front............................................................................... 37.467 cm

Rear ............................................................................... 72.414 cm

HYDRAULIC SYSTEM

Hoist cylinder ......................................... Twin, 2-stage telescopic type

Relief pressure .................................................. 20,6 MPa/210 kg/cm

Hoist time (at high idle)..............................................................13 sec

Lowing time (float) .....................................................................14 sec

AXLES

Final drive type .............................................................Planetary gear

Rear axle ........................................................................... Full floating

Ratios:

Differential............................................................................... 3,357

Planetary................................................................................. 6,333

SUSPENSION

Independent, hydropneumatic suspension cylinder with fixed throttle

to dampen vibration.

Effective cylinder stroke:

Front suspension ................................................................320 mm

Rear suspension .................................................................127 mm

Rear axle oscillation ..................................................................... 6,5

CAB

Dimensions comply with ISO 3471 and SAE J1040-1988c ROPS

(Roll-Over Protective Structure) standards and ISO 3449 and SAE

J231 FOPS (Falling Object Protective Structure) standard.

MAIN FRAME

Type .......................................................... Box-sectioned construction

Integral front bumpers

TYRES

Standard tyres .....................................................................27.00 R49

14

OFF-HIGHWAY TRUCK

BODY

Capacity:

Struck...................................................................................... 40 m

Heaped (2:1, SAE).................................................................. 60 m

Payload..........................................................................91 metric tons

Material............................................................................. 130 kg/mm

400 Brinell high tensile strength steel

Material thickness:

Bottom .................................................................................. 19 mm

Front...................................................................................... 12 mm

Sides ....................................................................................... 9 mm

Target area (inside length width) .................. 7.065 mm 5.200 mm

Dumping angle ...............................................................................48

Height at full dump ............................................................ 10.210 mm

Heating ...................................................................... Exhaust heating

HD785-7

WEIGHT (APPROX.)

Empty weight ....................................................................... 72.600 kg

Gross vehicle weight ......................................................... 166.000 kg

Not to exceed max. gross vehicle weight, including options, fuel and

payload.

Weight distribution

Empty:

Front axle .................................................................................. 47%

Rear axle .................................................................................. 53%

Loaded:

Front axle ............................................................................... 31,5%

Rear axle ............................................................................... 68,5%

SERVICE REFILL CAPACITIES

ENVIRONMENT

Engine emissions ...............................Fully complies with EPA Tier II

exhaust emission regulations

Noise levels:

LpA operator ear ...........................................75 dB(A) (SAE J1166)

Vibration levels (EN 12096:1997)*

Hand/arm .............................. 2,5 m/s (uncertainty K = 0,65 m/s)

Body...................................... 0,5 m/s (uncertainty K = 0,21 m/s)

* for the purpose of risk assessment under directive 2002/44/EC,

please refer to ISO/TR 25398:2006.

Fuel tank................................................................................. 1.308 ltr

Engine oil................................................................................... 129 ltr

Torque converter, transmission and retarder cooling................. 205 ltr

Differentials (total) ..................................................................... 137 ltr

Final drives (total) ...................................................................... 128 ltr

Hydraulic system ....................................................................... 175 ltr

Brake control ............................................................................... 36 ltr

Suspension (total) ....................................................................... 93 ltr

15

HD785-7

O F F - H I G H W A Y TR U C K

SPECIFICATIONS

Power Mode

GROSS WEIGHT

EMPTY

LOADED

RIMPULL

TOTAL RESISTANCE (GRADE + ROLLING) (%)

LOADED

UNLOADED

TRAVEL SPEED

TRAVEL PERFORMANCE

To determine travel performance: Read from gross weight down to the percent of total resistance. From

this weight-resistance point, read horizontally to the curve with the highest obtainable speed range, then

down to maximum speed. Usable rimpull depends upon traction available and weight on drive wheels.

GRADE DISTANCE: CONTINOUS DESCENT

RETARDER PERFORMANCE

20

40

60

80

100

120

140

EMPTY

160

180

200 x103 kg

LOADED

Optional exhaust retarder

F1

F2

-20

-15

F3

F4

-10

F5

F6

TOTAL RESISTANCE (GRADE + ROLLING) (%)

To determine brake performance:

These curves are provided to

establish the maximum speed and

gearshift position for safer descents

on roads with a given distance.

Read from gross weight down to the

percent of total resistance. From this

weight resistance point, read horizontally to the curve with the highest obtainable speed range, then

down to maximum descent speed

the brakes can safely handle without

exceeding cooling capacity.

GROSS WEIGHT

0

-5

F7

10

20

30

40

50

60

TRAVEL SPEED

16

70

80

90

100 km/h

HD785-7

OFF-HIGHWAY TRUCK

GRADE DISTANCE: 450 m

GRADE DISTANCE: 600 m

40

60

80

100

120

140

EMPTY

160

180

200

20

40

LOADED

F2

-20

F3

-15

F4

F5

60

80

100

120

140

EMPTY

Optional exhaust retarder

F1

kg

-10

F6

F7

10

20

30

40

50

60

70

80

90

Optional exhaust retarder

F2

-20

F3

-15

F4

-10

F5

F6

F7

100 km/h

10

20

30

60

70

80

GRADE DISTANCE: 900 m

GRADE DISTANCE: 1.500 m

40

60

80

100

120

160

180

200 x103 kg

F2

F3

-15

F4

-10

F5

F6

F7

40

20

40

50

60

TRAVEL SPEED

70

60

80

100

120

100 km/h

90

100 km/h

160

180

200 x103 kg

LOADED

Optional exhaust retarder

F1

F2

-20

F3

-15

F4

-10

F5

F6

F7

-5

80

140

EMPTY

-20

30

LOADED

Optional exhaust retarder

20

90

GROSS WEIGHT

140

F1

10

50

TRAVEL SPEED

EMPTY

40

-5

TRAVEL SPEED

TOTAL RESISTANCE (GRADE + ROLLING) (%)

20

200 x103 kg

F1

GROSS WEIGHT

0

180

LOADED

-5

160

10

20

30

40

50

60

70

TOTAL RESISTANCE (GRADE + ROLLING) (%)

20

TOTAL RESISTANCE (GRADE + ROLLING) (%)

GROSS WEIGHT

x103

TOTAL RESISTANCE (GRADE + ROLLING) (%)

GROSS WEIGHT

-5

80

90

100 km/h

TRAVEL SPEED

17

HD785-7

O F F - H I G H W A Y TR U C K

MACHINE DIMENSIONS

18

OFF-HIGHWAY TRUCK

HD785-7

SERVICEABILITY AND CUSTOMER SUPPORT

The Komatsu dealer network guarantees you the lowest

operating costs

When you purchase Komatsu equipment, you gain access to a broad range of programmes and services that have

been designed to help you get the most from your investment. These all support substantial productivity, long and

useful equipment lifetime, low operating costs, and a high trade-in or resale value.

Many of the vital components in the HD785-7 have

been installed and proven totally reliable in other

heavy-duty Komatsu earthmoving equipment.

Komatsus extensive parts warehouses and logistics

system across Europe and around the globe ensure

unparalleled parts availability.

Continuous training programmes for Komatsu service

personnel guarantee that your equipment is serviced

properly and maintained in top running condition.

The Komatsu Oil Wear Analysis (KOWA) programme

offers sophisticated oil analysis to identify problems to

be followed up during preventative, scheduled

maintenance.

KFWP (Komatsus Flexible Warranty Programme) is

available, providing a range of extended warranty options on the machine and its components. These can

be chosen, based on individual needs and activities.

This programme is designed to help reduce total

operating costs.

A Komatsu Repair & Maintenance Contract is a way

to establish a fixed operating cost and ensure optimal

machine availability for the duration of the contract.

19

HD785-7

OFF-HIGHWAY TRUCK

STANDARD EQUIPMENT

ENGINE

Komatsu SAA12V140E-3 engine,

EPA Tier II compliant

AISS (Automatic Idling Setting

System)

Engine power mode selection

system with VHPC

Alternator 90 A/24 V

Batteries 4 12 V/170 Ah

Starting motor 2 7,5 kW

CAB

ROPS cab with FOPS,

sound suppression type

Two doors, left and right

Air conditioner

Electronic maintenance display/

monitoring system

Electronic hoist control system

Operator seat, reclining, air

suspension type with retractable

78 mm width seat belt

Passenger seat with seat belt

Power window (l.h.)

Steering wheel, tilt and telescopic

Sun visor

Sun visor, additional

Tinted glazing

Pre radio installation

Cigarette lighter, ashtray, cup holder,

space for lunch box

Windshield washer and wiper (with

intermittent feature)

LIGHTING SYSTEM

Back-up light

Hazard lights

Headlights with dimmer switch

Indicator, stop and tail lights

GUARDS AND COVERS

Exhaust thermal guard

Fire prevention covers

Engine underguard

TM underguard

Drive shaft guard (front and rear)

Engine side covers

Lockable fuel cap and covers

SAFETY EQUIPMENT

Anti-pitching 4-wheel oil-cooled

multiple-disc retarder (AP-FOUR)

Back-up alarm

Horn, electric

Coolant temperature alarm and light

Hand rails for platform

Ladders, left and right hand side

Supplementary steering, automatic

Overrun warning system

ARSC (Auto Retard Speed Control)

Rearview mirrors

Underview mirrors

Rear view camera and monitor

Front stairway with handrails

KOMTRAX Plus (Vehicle Health

Monitoring System)

Satellite communication system for

KOMTRAX Plus

Payload meter function on

KOMTRAX Plus

OTHER

Centralized greasing

Electric circuit breaker, 24 V

PM service connections

Poor fuel arrangement

(water and dust)

Fuel tank with fast ll coupler

KOMTRAX - Komatsu satellite

monitoring system

TYRES

27.00-R49

REGULATIONS

Complies with EC requirements

BODY

Body exhaust heating

Cab guard (left hand side)

Spill guard, 300 mm

Platform guard (right hand side)

OPTIONAL EQUIPMENT

CAB

Heater and defroster

Cassette-radio

Power window (r.h.)

BODY

Body liners

Mufer without body heating

Mufer with body heating

Quarry body

LIGHTING SYSTEM

Rear working lights, left and right

Fog lights

Back-up light, additional

LED combination lights, rear

ARRANGEMENTS

High-capacity batteries

Cold area arrangement

(-30 C to 40 C)

Sandy and dusty area arrangement

SAFETY EQUIPMENT

ABS (Anti-lock Braking System)

ASR (Automatic Spin Regulator)

Exhaust retarder

Tyre stopper block

OTHER

Auto greasing system

Engine coolant heater

Engine oilpan heater

Three-mode automatic

hydropneumatic suspension

TYRES

31/90 R49

Komatsu Europe

International NV

Mechelsesteenweg 586

B-1800 VILVOORDE (BELGIUM)

Tel. +32-2-255 24 11

Fax +32-2-252 19 81

www.komatsueurope.com

EESS018603

11/2010

Materials and specifications are subject to change without notice.

is a trademark of Komatsu Ltd. Japan.

Printed in Europe This specification sheet may contain attachments and optional equipment that are not available in your area.

Please consult your local Komatsu distributor for those items you may require. Materials and specifications are subject to change without notice.

Potrebbero piacerti anche

- HD785-7Documento8 pagineHD785-7Dani Wijaya50% (2)

- Of F-Highway Truck: FeaturesDocumento8 pagineOf F-Highway Truck: Featuresmario palondonganNessuna valutazione finora

- PC1250Documento16 paginePC1250Gavin Li100% (1)

- Komatsu Hd785-7 Rigid Dump TrucksDocumento20 pagineKomatsu Hd785-7 Rigid Dump Truckswahyu100510Nessuna valutazione finora

- 773E Introduction MasterDocumento46 pagine773E Introduction MasterRicardo Manríquez100% (1)

- Komponen HD 785-7Documento23 pagineKomponen HD 785-7Wahyu IskandarNessuna valutazione finora

- PC2000 11Documento6 paginePC2000 11arun_anuNessuna valutazione finora

- SANY SRT95C Rigid Dump TruckDocumento4 pagineSANY SRT95C Rigid Dump TruckTLK Channel100% (1)

- KOMPONEN - HD785-7 SippDocumento23 pagineKOMPONEN - HD785-7 Sippziky dun100% (1)

- Coh Hoist System HD 785-7Documento21 pagineCoh Hoist System HD 785-7Fata AlbanaNessuna valutazione finora

- Taufik Hidayat Gultom PS3 D375Documento26 pagineTaufik Hidayat Gultom PS3 D375Dava JrNessuna valutazione finora

- Periodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamDocumento28 paginePeriodic Service 1000 Hours PC 200-8: Present By: Muh Arif Budiawan SyamMuh Arief Budiawan Arief100% (1)

- Master Form Standar PPM PC 2000-8Documento3 pagineMaster Form Standar PPM PC 2000-8Burhan Mburine UdinNessuna valutazione finora

- Sany Excavators SY75C Tier 3Documento8 pagineSany Excavators SY75C Tier 3csbersama0% (1)

- Hydraulic OilDocumento4 pagineHydraulic Oilwaleedatif0% (1)

- Form Standar PPM PC1250 SP-7Documento2 pagineForm Standar PPM PC1250 SP-7Afrizal Bee Mei AeNessuna valutazione finora

- 785-5 Instrument Familiarization & AssessmentDocumento61 pagine785-5 Instrument Familiarization & AssessmentCrispin Cris Nspm100% (1)

- Arti Kode Engine: D375A-5 SAA6D170E-3Documento17 pagineArti Kode Engine: D375A-5 SAA6D170E-3Akbar WijayaNessuna valutazione finora

- Materi TrainingDocumento66 pagineMateri TrainingMuhammad IsalNessuna valutazione finora

- Kajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Documento8 pagineKajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Devi RahmaditaNessuna valutazione finora

- PM PC1250SP-8Documento25 paginePM PC1250SP-8Teguh Imam AdriNessuna valutazione finora

- PC1250-8 PC1250SP-8Documento20 paginePC1250-8 PC1250SP-8Banu Agus Hartoyo100% (1)

- 02 HD785-7 Presentation For Pama All 06may15Documento20 pagine02 HD785-7 Presentation For Pama All 06may15Bima Dwi Utomo83% (6)

- Small Catalog OHT CAT 773E PDFDocumento4 pagineSmall Catalog OHT CAT 773E PDFSupriyono Abdullah100% (1)

- Modul Cooling System OBH KomatsuDocumento24 pagineModul Cooling System OBH KomatsuYUDI WAHYUDI 172490% (1)

- PC3000 6 PDFDocumento8 paginePC3000 6 PDFRocioSanchezCalderonNessuna valutazione finora

- CAT 777G FiltersDocumento3 pagineCAT 777G FiltersettoscarNessuna valutazione finora

- Maintenance Fowa - Oil - 50312 PDFDocumento16 pagineMaintenance Fowa - Oil - 50312 PDFdarwin100% (2)

- HM400-3R Leaflet Cen00510-01 - 86997 PDFDocumento9 pagineHM400-3R Leaflet Cen00510-01 - 86997 PDFKevin Andrian0% (1)

- Introducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmDocumento120 pagineIntroducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmGerardo Marín100% (2)

- HD785 7 2007nov18 Compacted 51902Documento118 pagineHD785 7 2007nov18 Compacted 51902Jheison Valencia100% (2)

- PC1250-8 Eess018304 1011Documento20 paginePC1250-8 Eess018304 1011Ioannis Zorzos100% (2)

- Spec Loader Hitachi Ex2600-6Documento16 pagineSpec Loader Hitachi Ex2600-6Zdulkurnain MuhamadNessuna valutazione finora

- Powerroc T50: Surface Drill Rig For Quarrying and Open Pit MiningDocumento5 paginePowerroc T50: Surface Drill Rig For Quarrying and Open Pit MiningWikileak CenterNessuna valutazione finora

- Komponen HD 785-7-1 PDFDocumento23 pagineKomponen HD 785-7-1 PDFHacker TampabNessuna valutazione finora

- 330 GC ExcavadoraDocumento13 pagine330 GC ExcavadoraAndres Felipe Marquez GiraldoNessuna valutazione finora

- Coolant KomatsuDocumento16 pagineCoolant Komatsusmallfire100% (3)

- New Meca Sheet - Ver.0.0: Komatsu Motor Grader Gd825Documento69 pagineNew Meca Sheet - Ver.0.0: Komatsu Motor Grader Gd825Akhmad Shohibul FadilahNessuna valutazione finora

- II. ENGINE DIESEL (Komponen Engine) PDFDocumento34 pagineII. ENGINE DIESEL (Komponen Engine) PDFJoko SukarionoNessuna valutazione finora

- Product Knowledge: Nama: Satria Pamayung Adji Kelas: 4MCDocumento8 pagineProduct Knowledge: Nama: Satria Pamayung Adji Kelas: 4MCSatria SpaNessuna valutazione finora

- PC350 350LC-7Documento7 paginePC350 350LC-7bellatobingNessuna valutazione finora

- HD465 7E0 (English)Documento12 pagineHD465 7E0 (English)Ed OrtizNessuna valutazione finora

- Bab III Power LineDocumento54 pagineBab III Power Linenauza getstar100% (1)

- D375A-6 Work EquipmentDocumento42 pagineD375A-6 Work Equipmentalcowo100% (3)

- Pm-Clinic Service Inspection Sheet For GD825A-2 #12001 and Up Base InformationDocumento10 paginePm-Clinic Service Inspection Sheet For GD825A-2 #12001 and Up Base InformationLucio Valderrama100% (1)

- 320C Vs Deere200EnglishDocumento52 pagine320C Vs Deere200EnglishFernando Omar ArenaNessuna valutazione finora

- 773E Hydraulic SystemDocumento2 pagine773E Hydraulic SystemDipendra BhattacharyaNessuna valutazione finora

- HD785 7 OperationDocumento51 pagineHD785 7 OperationSang Sang Barongan100% (10)

- Qa-4 Assembling Work Sheet: Hour MeterDocumento8 pagineQa-4 Assembling Work Sheet: Hour Meteredi Supriyono100% (1)

- Introduction Od Dump Truck Model HD785-7Documento4 pagineIntroduction Od Dump Truck Model HD785-7AbdulKarimAbbasNessuna valutazione finora

- D375a-6r Feature (Nxpowerlite)Documento130 pagineD375a-6r Feature (Nxpowerlite)Harry Wart Wart50% (2)

- 777 D Test ChartsDocumento41 pagine777 D Test ChartsAlejandro Alberto Robalino Mendez100% (1)

- 773 HarnesDocumento35 pagine773 HarnesMuhammad NovanNessuna valutazione finora

- HD1500-5 OmmDocumento162 pagineHD1500-5 OmmMunkhmanlai Chuluunbaatar100% (1)

- 04 Komatsu GD825 Engine SystemDocumento34 pagine04 Komatsu GD825 Engine SystemLucyan Ionescu100% (3)

- Trakindo Lifting Jacking BlockingDocumento80 pagineTrakindo Lifting Jacking BlockingVin YonisraNessuna valutazione finora

- Cooling System OBH KomatsuDocumento55 pagineCooling System OBH KomatsuYUDI WAHYUDI 17249Nessuna valutazione finora

- OMM WA600-3 # 62001 Up PEN00070-01Documento269 pagineOMM WA600-3 # 62001 Up PEN00070-01Mulyadi TarchaniNessuna valutazione finora

- Komatsu HD465Documento20 pagineKomatsu HD465gesoulixNessuna valutazione finora

- HD325 6Documento8 pagineHD325 6Tara Ayu CendaniNessuna valutazione finora

- Oracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JDocumento10 pagineOracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JLuis YañezNessuna valutazione finora

- New Microsoft Word DocumentDocumento3 pagineNew Microsoft Word DocumentAditya ShanbhagNessuna valutazione finora

- RS2 Stress Analysis Verification Manual - Part 1Documento166 pagineRS2 Stress Analysis Verification Manual - Part 1Jordana Furman100% (1)

- Baby DedicationDocumento3 pagineBaby DedicationLouriel Nopal100% (3)

- Kingroon ConfiguracoesDocumento3 pagineKingroon ConfiguracoesanafrancaNessuna valutazione finora

- Operator's ManualDocumento110 pagineOperator's ManualAdam0% (1)

- AN44061A Panasonic Electronic Components Product DetailsDocumento3 pagineAN44061A Panasonic Electronic Components Product DetailsAdam StariusNessuna valutazione finora

- Iso 22301 2019 en PDFDocumento11 pagineIso 22301 2019 en PDFImam Saleh100% (3)

- DOT RequirementsDocumento372 pagineDOT RequirementsMuhammadShabbirNessuna valutazione finora

- Penelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Documento25 paginePenelitian Tindakan Kelas - Alberta Asti Intan Sherliana 20220049Asti SherlyanaNessuna valutazione finora

- Cella Di Carico Sartorius MP77 eDocumento3 pagineCella Di Carico Sartorius MP77 eNCNessuna valutazione finora

- Catalogue - Central Battery SystemDocumento12 pagineCatalogue - Central Battery SystemarifzakirNessuna valutazione finora

- Final Lesson PlanDocumento3 pagineFinal Lesson Planapi-510713019Nessuna valutazione finora

- Product Handbook Arendal 1961 Series SubwoofersDocumento44 pagineProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicNessuna valutazione finora

- Mossbauer SpectrosDocumento7 pagineMossbauer SpectroscyrimathewNessuna valutazione finora

- Pizza Restaurant PowerPoint TemplatesDocumento49 paginePizza Restaurant PowerPoint TemplatesAindrila BeraNessuna valutazione finora

- Bullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceDocumento174 pagineBullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceAlexandre AndréNessuna valutazione finora

- Off Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesDocumento1 paginaOff Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesFadi Ramadan100% (1)

- Nationalism, Feminism, and Modernity in PalestineDocumento26 pagineNationalism, Feminism, and Modernity in PalestinebobandjoerockNessuna valutazione finora

- Using Your Digital Assets On Q-GlobalDocumento3 pagineUsing Your Digital Assets On Q-GlobalRemik BuczekNessuna valutazione finora

- S4 Computer Sciences Exercises PDFDocumento2 pagineS4 Computer Sciences Exercises PDFHenriette Desanges UwayoNessuna valutazione finora

- Big Brother Naija and Its Impact On Nigeria University Students 2 PDFDocumento30 pagineBig Brother Naija and Its Impact On Nigeria University Students 2 PDFIlufoye Tunde100% (1)

- CryptogrophyDocumento37 pagineCryptogrophyFarah EssidNessuna valutazione finora

- MC4 CoCU 6 - Welding Records and Report DocumentationDocumento8 pagineMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- X Lube Bushes PDFDocumento8 pagineX Lube Bushes PDFDavid TurnerNessuna valutazione finora

- Gigabyte Ga b85m Ds3h A r10 PDFDocumento30 pagineGigabyte Ga b85m Ds3h A r10 PDFMartha Lorena TijerinoNessuna valutazione finora

- Chapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Documento27 pagineChapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Masum ZamanNessuna valutazione finora

- Swiss Army Triplet 1Documento2 pagineSwiss Army Triplet 1johnpwayNessuna valutazione finora

- Unit-5 Harmonics & FiltersDocumento25 pagineUnit-5 Harmonics & FiltersBhanu100% (1)