Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Skoflo HighTurndown - 060712

Caricato da

edriceTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Skoflo HighTurndown - 060712

Caricato da

edriceCopyright:

Formati disponibili

HIGH TURNDOWN VALVE SERIES

ONLY ONE MOVING PART

ADJUSTABLE FLOW RATES

500:1 TURN DOWN

NO SCHEDULED MAINTENANCE

WILL PASS .04 INCH PARTICLES

CONSTANT FLOW REGARDLESS OF PRESSURE FLUCTUATIONS

Patents Pending

WHY PRESSURE INDEPENDENT CONTROL VALVES?

SkoFlo pressure independent control valves allow one pump to be shared

by several injection points, thereby reducing facility and maintenance

costs. SkoFlo valves are maintenance-free, while pumps may require

several seal changes over the life of the project.

WHY USE HIGH TURNDOWN CONTROL VALVES?

SkoFlo high turndown valves maintain constant flow rate by governing the

pressure drop across an internal restrictor. As of 2006, there are over 6,000

SkoFlo rate controllers operating using this principle, offering from 5:1 to

10:1 turndown. SkoFlo valves require access only to change the flow rate

range, which requires changing an internal restrictor.

The internal restrictor in the high turndown series is made up of a series of

cascading flow restrictors that are varied as the stem is adjusted to change

flow rate set point. When the stem is fully open, the valve will pass up to .04

inch spheres, producing a robust flush-through design that does not require

rate modification, as a 500:1 turndown flow will always be in range.

QUESTIONS & ANSWERS

Q. Why is this valve different from other flow

control valves?

A. This flow control valve maintains a constant flow

through it regardless of pressure changes across it.

Q. Does this valve have more than one setting?

A. Yes, it operates within a pre-determined flow

range. You just turn the rate adjustment handle to

change the flow.

Q. Can you supply valves to operate at less than

200 psi (13.8 bar) differential pressure?

Q. What is required to operate the unit?

A. No hands-on operation or maintenance are

required after intial start-up and calibration. No

scheduled maintenance is required. You change

the flow rate by turning the rate adjustment handle.

Q. What can go wrong with the unit?

A. It is possible to plug the orifice system. Fluid passing

through the unit must be filtered. We recommend

that a filter be installed at the inlet to each unit.

Q. How many moving parts are in the unit?

A. Yes, please contact the factory with your

requirements.

A. This unit has one moving part.

Q. What engineering principle does this valve use to

give constant flow regardless of pressure

fluctuations across it?

A. Yes, static O-rings and high pressure seals are used to

seal the unit. The unit is bolted together.

A. This unit uses a unique spring system to maintain a

constant differential pressure across an orifice.

A. Range 1 - 0.5 to 500 gpd

Q. What does the unit use for control power?

A. The fluid passing through the unit provides the

control power. The flow rate remains constant as

long as the minimum differential pressure is

maintained.

Q. Is this unit leak free?

Q. What flow rates can be provided?

Range 2 - 15 to 1500 gpd

Q. How many units can be installed on a single pump or

supply header system?

A. You can connect as many units as the pump or

supply source will satisfy.

THE VALVE

F

Square pattern;

M6 x 15/.59 deep

Valve Performance Curve

H

Square pattern;

M6 thru

FLOW (Li/day)

200 psi (13.8 bar)

N (Port flat)

Standard Valve

102 / 4.00

VALVE

at 100% FS

6 / 0.25

VALVE

below 100% FS

K (Outlet)

P ACROSS VALVE

C Max

Notes: (Assuming Cv remains constant for both valves)

1. Standard Valve: flow rate varies as the square root

of the differential pressure across the standard

control valve.

2. SkoFlo Valve: flow rate remains constant once the

minimum differential pressure is reached across the

SkoFlo valve.

L (Inlet)

E

J

Note: Inlet can be oriented

in 90 increments. Shown

as shipped

D

I

M (Port flat)

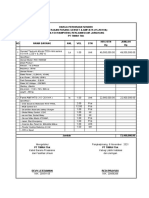

MODEL

HTD-10000

THE SYSTEM

HTD-5000

DIMENSIONS (mm/in)

C

D

E

F

G

H

I

157

184

269

88

113

41

31

57

88

6.18

7.25

10.60

3.48

4.44

1.62

1.20

2.25

3.48

184

269

75

113

41

31

57

88

156

6.15

7.25

10.60

2.96

4.44

1.62

1.20

2.25

3.48

A

K

3

13

0.50

13

0.50

AE MP

L

3

8

1

NPT

4

AE MP

M

42

8

1.64

35

1

NPT

1.68

4

N

43

1.69

43

1.69

Consult factory for current outline drawings

Multi-Point System Utilizing a Positive Displacement Pump

A single pump for multi-location

injection program

Local flow control chemical injection flow

controllers for individual location

rate control

No pneumatic or electric power sources

required for control

Continuous flow

Back Pressure

Regulator

chemical injection

control valve 3-Way

Valve

Filter

Check Isolation

Valve

Valve

SF

Isolation

Valve

Chemical Out

to Process*

To

Flow Meter

SF

Tank

BPR

PRV

Pump

Pressure

Gauge

EXP

SF

Chemical

to Valves

Filter

Pulsation

Damper

(Expansion

Compensator)

SF

*Any number of injection points can be served.

Notes: For systems not using a positive displacement pump the pulsation damper and back pressure regulator are not required.

FLOW TABLES

HOW TO ORDER - NAMEPLATE MARKING

HTD 5000

Working Pressure

Current Model

500

Lowest Flow

V = Viton

K = Kalrez Equivalent

E = EPDM

A

SN

Highest Water Flow

Range 1:

1.0 to 500 GPD

3.8 to 1893 l/day

Range 2:

15 to 1500 GPD

56.8 to 5678 l/day

Consult factory for flow rates beyond range 1 and 2

PREDICTING FULL SCALE CHEMICAL FLOW

Qfluid

Qwater x V

Sgfluid

Where:

Qwater = water rate, Gal/day

Qfluid = fluid flow rate, Gal/day

Sgfluid = specific gravity of fluid

V = viscosity correction factor (from table)

Example: Full Scale Water = 500 gpd (1930 l)

Fluid specific gravity = 0.9

Fluid viscosity = 250 cs

V = 0.58 (from table)

Qfs fluid =

500 x 0.58

= 306 Gal/day

0.9

Note: For fluid thicker than water,

the full scale flow of the actual

fluid needs to be converted.

www.skoflo.com

Patents Pending

Ver. 060712

Viscosity

CS

Factor

V

1

10

20

30

40

50

60

70

80

90

100

200

300

400

500

600

700

800

900

1000

1.00

1.00

0.97

0.92

0.89

0.86

0.83

0.81

0.79

0.77

0.74

0.63

0.53

0.44

0.39

0.34

0.30

0.26

0.24

0.23

PO BOX 1728, 14241 NE 200th , Bldg A, Suite B

Woodinville Wa, 98072 USA

425.485.7816

FAX 425.368.1696

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Royal Dutch Shell PLC: IndexDocumento16 pagineRoyal Dutch Shell PLC: IndexedriceNessuna valutazione finora

- (Package Description) (Extra Line For Package Description)Documento24 pagine(Package Description) (Extra Line For Package Description)edriceNessuna valutazione finora

- Welcome: Slide Notes Have Been Added For Additional Content/reference or Speaker SuggestionsDocumento25 pagineWelcome: Slide Notes Have Been Added For Additional Content/reference or Speaker SuggestionsedriceNessuna valutazione finora

- IATA - Australia Passport, Visa and Health AdviceDocumento2 pagineIATA - Australia Passport, Visa and Health AdviceedriceNessuna valutazione finora

- Selected Financial Data Shell Ar19Documento170 pagineSelected Financial Data Shell Ar19edriceNessuna valutazione finora

- CFIHOS Reference Data Library V1.4 1Documento1.113 pagineCFIHOS Reference Data Library V1.4 1edrice100% (1)

- Hexagon PPM - Concurrent Engineering Rev0Documento8 pagineHexagon PPM - Concurrent Engineering Rev0edriceNessuna valutazione finora

- Novatek FS ENG 12m2019 FINALDocumento76 pagineNovatek FS ENG 12m2019 FINALedriceNessuna valutazione finora

- Enviroline 405HT UKDocumento17 pagineEnviroline 405HT UKedriceNessuna valutazione finora

- Incose Sep OverviewDocumento49 pagineIncose Sep OverviewedriceNessuna valutazione finora

- ABB VFD Tech+Guide - DriveDocumento4 pagineABB VFD Tech+Guide - DriveedriceNessuna valutazione finora

- Factories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulation 1970Documento115 pagineFactories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulation 1970bevarsiNessuna valutazione finora

- Pacific Coast Oil Trust Ups Its Distribution - Pacific Coast Oil Trust (NYSE - ROYT) - Seeking AlphaDocumento2 paginePacific Coast Oil Trust Ups Its Distribution - Pacific Coast Oil Trust (NYSE - ROYT) - Seeking AlphaedriceNessuna valutazione finora

- 10MW Solar Power Farm GebengDocumento1 pagina10MW Solar Power Farm GebengedriceNessuna valutazione finora

- OE AUG08 Sizing Up Tree Planting (HCLS)Documento3 pagineOE AUG08 Sizing Up Tree Planting (HCLS)edriceNessuna valutazione finora

- ABB VFD Tech+Guide - DriveDocumento4 pagineABB VFD Tech+Guide - DriveedriceNessuna valutazione finora

- Act 139 Factories and Machinery Act 1967 (Revised - 1974) (Reprint - 2000)Documento113 pagineAct 139 Factories and Machinery Act 1967 (Revised - 1974) (Reprint - 2000)edriceNessuna valutazione finora

- 2011.03.30 FaberDocumento3 pagine2011.03.30 FaberedriceNessuna valutazione finora

- A Good Year For Malaysian Stocks - Benchmark Index Up 19%: Bursa MalaysiaDocumento4 pagineA Good Year For Malaysian Stocks - Benchmark Index Up 19%: Bursa MalaysiaedriceNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Basic Thermodynamics Prof. S. K. Som Department of Mechanical Engineering Indian Institute of Technology, KharagpurDocumento24 pagineBasic Thermodynamics Prof. S. K. Som Department of Mechanical Engineering Indian Institute of Technology, KharagpurAshutosh ShuklaNessuna valutazione finora

- Pumy Sp100ykmDocumento1 paginaPumy Sp100ykmJacky LaiNessuna valutazione finora

- PT Poeser IndonesiaDocumento13 paginePT Poeser Indonesiaqdod_waffiNessuna valutazione finora

- Welcome To The Test and Production Separation Production Separation PresentationDocumento73 pagineWelcome To The Test and Production Separation Production Separation PresentationhamdiiiiiiiiiiiiiiiiNessuna valutazione finora

- Basic Mechanical EngineeringDocumento13 pagineBasic Mechanical EngineeringJaysun Lanario PacrisNessuna valutazione finora

- Project Id Project Ref No Project TitleDocumento1 paginaProject Id Project Ref No Project TitleSagar JadhavNessuna valutazione finora

- Pneu Actuator Diaph ReplaceDocumento1 paginaPneu Actuator Diaph ReplaceKEL INessuna valutazione finora

- Sprezarka Embraco Aspera T2180GK Karta-ProduktuDocumento4 pagineSprezarka Embraco Aspera T2180GK Karta-Produktucarlosmochima100% (1)

- Pttep ZawtikaDocumento3 paginePttep ZawtikaSARAVANANessuna valutazione finora

- Fmea of Co Air Conditioning Systems: by Dr.-Ing. Ulrich Hussels Risa Sicherheitsanalysen GMBH, GermanyDocumento13 pagineFmea of Co Air Conditioning Systems: by Dr.-Ing. Ulrich Hussels Risa Sicherheitsanalysen GMBH, GermanykaimanwatsoNNessuna valutazione finora

- Lec 2 - ME 101 - BUETDocumento15 pagineLec 2 - ME 101 - BUETShaumik RahmanNessuna valutazione finora

- CMT 47 TR Manual.: Shaft & Wheel BalancingDocumento3 pagineCMT 47 TR Manual.: Shaft & Wheel BalancingjdcuevasNessuna valutazione finora

- Manual of 06naDocumento35 pagineManual of 06naKannan Krishnamoorthy100% (8)

- Dual Functional Roof VentilatorDocumento7 pagineDual Functional Roof VentilatorIJRASETPublicationsNessuna valutazione finora

- Smoke TesterDocumento1 paginaSmoke TesterashtaxNessuna valutazione finora

- C.Mill 3 Motor ListDocumento5 pagineC.Mill 3 Motor ListIrfan AhmedNessuna valutazione finora

- Slay The Pe - Mechanical - Tfs Practice Exam Questions 2020Documento59 pagineSlay The Pe - Mechanical - Tfs Practice Exam Questions 2020Ankit KumarNessuna valutazione finora

- Temperature Conditions: Type of Solar ModuleDocumento2 pagineTemperature Conditions: Type of Solar ModuleEhsan Ur RehmanNessuna valutazione finora

- Chiller Air - Cooled Daikin - Applied Scroll (075 100 - Ton) PumpPkg MPP (AGZ E)Documento1 paginaChiller Air - Cooled Daikin - Applied Scroll (075 100 - Ton) PumpPkg MPP (AGZ E)Trương Ngọc TrọngNessuna valutazione finora

- Balingt - Prelim ExamDocumento21 pagineBalingt - Prelim ExamRene Niño Macamay BalingitNessuna valutazione finora

- DD13 Engine HarnessDocumento1 paginaDD13 Engine Harnessalejandro sanchez100% (5)

- Ebara 200 X 150 Fsla CurveDocumento6 pagineEbara 200 X 150 Fsla CurveWahyudi SiregarNessuna valutazione finora

- HPS Genset K3lh Air Jangkang - KosongDocumento4 pagineHPS Genset K3lh Air Jangkang - KosongAndira ElectrikNessuna valutazione finora

- 4 BasicEngineandCompressorAnalysis PDFDocumento133 pagine4 BasicEngineandCompressorAnalysis PDFalvaroinc04Nessuna valutazione finora

- Jenbacher Type 6 Fs en Metric 2016Documento2 pagineJenbacher Type 6 Fs en Metric 2016laiquz zamanNessuna valutazione finora

- A320 NEO Abbreviations LEAP-1ADocumento5 pagineA320 NEO Abbreviations LEAP-1AwenjukwaxNessuna valutazione finora

- Fire Safetyquestion Paper CIE-2Documento3 pagineFire Safetyquestion Paper CIE-2mohan hsNessuna valutazione finora

- Plant Report FinalDocumento19 paginePlant Report FinalMalik Hafeez AwanNessuna valutazione finora

- MAYEKAWA Heat Pump System 09 09Documento12 pagineMAYEKAWA Heat Pump System 09 09alejandro obregonNessuna valutazione finora

- Floating Head Heat Exchanger-MaintainanceDocumento15 pagineFloating Head Heat Exchanger-MaintainanceEDY PRASETYONessuna valutazione finora