Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Comparison of Design Procedures For Pre Engineering Buildings PEB A Case Study

Caricato da

Mohit NatuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Comparison of Design Procedures For Pre Engineering Buildings PEB A Case Study

Caricato da

Mohit NatuCopyright:

Formati disponibili

Comparison of Design Procedures for Pre Engineering Buildings

(PEB): A Case Study

by

Sai Kiran Gone, Kailash Rao, Pradeep Kumar Ramancharla

in

International Journal of Civil, Architectural, Structural and Construction Engineering

Report No: IIIT/TR/2014/-1

Centre for Earthquake Engineering

International Institute of Information Technology

Hyderabad - 500 032, INDIA

August 2014

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:8 No:4, 2014

Comparison of Design Procedures for Pre

Engineering Buildings (PEB): A Case Study

G. Sai Kiran, A. Kailasa Rao, R. Pradeep Kumar

International Science Index Vol:8, No:4, 2014 waset.org/Publication/9998849

AbstractIn recent years, the introduction of Pre Engineered

Building (PEB) concept in the design of structures has helped in

optimizing design. The adoptability of PEB in the place of

Conventional Steel Building (CSB) design concept resulted in many

advantages, including economy and easier fabrication. In this study,

an industrial structure (Ware House) is analyzed and designed

according to the Indian standards, IS 800-1984, IS 800-2007 and also

by referring MBMA-96 and AISC-89. In this study, a structure with

length 187m,width 40m,with clear height 8m and having R-Slope

1:10,isconsidered to carry out analysis& design for 2D frames (End

frame, frame without crane and frame with 3 module cranes). The

economy of the structure is discussed in terms of its weight

comparison, between Indian codes (IS800-1984, IS800-2007) &

American code (MBMA-96), & between Indian codes (IS800-1984,

IS800-2007).

having the dimensions length 187m, width 40m, eave height

8m(clear), &roof slope 1:10.Structure suited in seismic zone

IV with wind speed 47 m/sec considered life span of structure

as 5 years. Complete structure configuration details can be

found in Table I as follows [1]-[2], [10]-[11]:

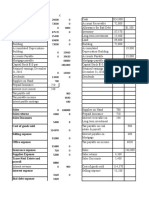

TABLE I

STRUCTURE CONFIGURATION DETAILS

Location

:

Rajasthan, India.

Length

:

187 m

Width

:

40 m

Eave height

:

8m (clear)

Seismic zone

:

IV

Wind speed

:

47 m/sec

Wind terrain category

:

2

Wind Class

:

C

Life Span

:

5 years

Slope of roof

:

1:10

Crane Capacity

:

10 t (for all 3- cranes)

Soil type

:

Medium

Importance factor

:

1

Response reduction factor :

5

Purlin spacing

:

1800 mm

Girt spacing

:

2200 mm

KeywordsAISC, Crane Beam, MBMA, Pre-EngineeredBuildings, Staad Pro, Utilization Ratio.

I. INTRODUCTION

TEEL is the material of choice for design because it is

inherently ductile and flexible. In structural engineering, a

pre-engineered building (PEB) is designed by a manufacturer,

to be fabricated using a pre-determined inventory of raw

materials and manufacturing methods that can efficiently

satisfy a wide range of structural and aesthetic design

requirements. PEB can be fitted with different structural

accessories including mezzanine floors, canopies, fasciae,

interior partitions, etc. The concept of PEB is the frame

geometry which matches the shape of the internal stress

(bending moment) diagram thus optimizing material usage and

reducing the total weight of the structure. The complete

designing is done at the factory and the building components

are brought to the site in knock down condition. These

components are then fixed/ jointed at the site and raised with

the help of cranes.

III. DEAD LOAD CALCULATION

Dead load calculation includes the weight calculation of

sheeting, sag angles, purlins and insulation material as follows

in Table II [2].

TABLE II

CALCULATION OF DEAD LOAD

Sheeting unit weight

: 4.78 kg/m2(5mm thick galvanized sheet)

: 4.71 kg/m(spacing of purlin = 1.8m)

Purlin wt.

: 4.71/1.8

: 2.61 kg/m2

: 1.2 kg/m

Sag rods wt.

: 1.2/1.8 :0.667 kg/m2

Insulation material wt.

: 2 kg/m2

: 4.78 + 2.61 + 0.667 + 2

Dead load

: 10kg/m2 : 0.1 KN/m2

II. STRUCTURE CONFIGURATION

Selected structure is located in Rajasthan, India. Structure

G. Sai Kiran(M.Tech) is Structural Engineer, with the PS Engineering

Consultancy, Nagole X roads, Hyderabad, (www.psec.in).

A. Kailash Rao is Associate vice president (AVP) with the Phenix

Construction Technologies, Plot No. 30 P, Village Naranpura, Taluka Sanand,

Dist. Ahmedabad 382213(Phone: +91 (02717) 612 500, Fax: +91 (02717)

612 501,(http://www.mbphenix.com).

R. Ramancharla Pradeep Kumar is Professor of Civil Engineering & Head,

Earthquake Engineering Research Centre,IIIT,Gachibowli, Hyderabad 500

032, India, (Ph: +91 (40) 6653 1187 (o), 93911 31199 (m),Fax: +91 (40) 6653

1413,e-mail: ramancharla@iiit.ac.in, url: http://eerc.iiit.ac.in/index.html).

IV. LIVE LOAD CALCULATION

Calculation of live loads includes consideration of live

loads according to different codes (Indian, American) as

follows in Table III [2].

TABLE III

CALCULATION OF LIVE LOAD

As per IS: 875(part-2) -1987-Table-II (Imposed loads on various types of roofs).

Angle of roof truss ()

: tan-1(1/10) : 5.71 (<10)

As per Indian- LL

: 0.75 KN/m2

As per MBMA-96, Cl-1.3.2.

As per AISC - LL

: 0.57 KN/m2

480

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:8 No:4, 2014

V. WIND LOAD CALCULATION

Wind load calculation is done according to Indian code IS:

875(part-2)-1987-Cl.5.3, as follows in Table IV [2].

TABLE IV

CALCULATION OF WIND LOAD

Wind speed

(Vb)

: 47 m/sec

Risk coefficient

(K1)

: 0.71

Probability factor

(K2)

: 0.93

Topography factor (K3)

: 1.0

: K1*K2*K3*Vb

Design wind speed (VZ)

: 0.71*0.93*1*47

: 31.03 m/sec

:0.6*(Vz)2

: 0.6*31.032

Design wind pressure (PZ)

: 578 N/m2

: 0.578 KN/m2

Fig. 1 End frame with wind columns

International Science Index Vol:8, No:4, 2014 waset.org/Publication/9998849

VI. PRE-ENGINEERED BUILDINGS BY STAAD.PRO

The power tool for computerized structural engineering

STAAD Pro is the most popular structural engineering

software product for 2D, 3D model generation, analysis and

multi-material design. It has an intuitive, user-friendly,

visualization tools, powerful analysis and design facilities and

seamless integration to several other modeling and design

software products. The software is fully compatible with all

Windows operating systems. In STAAD Pro utilization ratio is

the critical value that indicates the suitability of the member as

per codes. Normally, a value higher than 1.0 indicates the

extent to which the member is over-stressed, and a value

below 1.0 tells us the reserve capacity available. Critical

conditions used as criteria to determine Pass/Fail status are

slenderness limits, Axial Compression and Bending, Axial

Tension and Bending, Maximum w/t ratios and Shear. For

static or dynamic analysis of Pre-engineered building, STAAD

Pro has been the choice of design professionals around the

world for their specific analysis needs [1]-[9].

VII. DRAWINGS

Following drawings includes drawings of frames which are

selected for analysis [11], [12].

AISC-89/MBMA-86

Limit State of Serviceability:

(DL+LL)

(DL+WL/EL)

(DL+CL)

(DL+ 0.5*WL/EL+CL)

Limit State of Strength:

(DL+LL)

(DL+ CL)

0.75*(DL+WL/EL)

0.75*(DL+WLRL-P)

0.75(DL+ 0.58*WL/EL+CL )

Fig. 2 Internal frame without crane

Fig. 3Internal main frame with cranes

VIII. LOAD COMBINATIONS

Load combinations include different combinations of loads

according to different codes (AISC-89/MBMA-86, IS8001984, IS800-2007) by considering serviceability and strength

criteria as follows in Table V [4]-[7].

TABLE V

LOAD COMBINATIONS ACCORDING TO DIFFERENT CODES

IS 800-1984

IS 800-2007

(DL+LL)

Limit State of Serviceability:

(DL+WL/EL)

(DL+LL)

(DL+LL+WL/EL)

(DL+WL/EL)

(DL+LL+CL)

(DL+LL+CL)

(DL+ LL + CL+ WL/EL)

(DL+0.8*LL+0.8*WL/EL+0.8*CL)

Limit State of Strength:

Limit State of Strength:

(DL+LL)

1.5*(DL+LL)

(DL+WL/EL)

1.5*(DL+WL/EL)

(DL+ LL+ CL)

(0.9*DL+1.5 WL/EL)

0.75* (DL+LL+WL/EL)

(1.5*DL+1.5*LL+1.05*CL)

0.75*(DL+ LL + CL+ WL/EL)

(1.5*DL+1.05*LL+1.5*CL)

(1.2*DL+1.2*LL+0.6*WL/EL+1.05*CL)

(1.2*DL+1.05*LL+0.6*WL/EL+1.2*CL)

(1.2*DL+1.2*LL+1.2 *WL/EL+0.53*CL)

(1.2*DL+1.2*LL+1.2*WL/EL+0.53*CL)

481

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:8 No:4, 2014

IX. DESIGN SPECIFICATIONS

Design specifications include limiting ratios of cross

sections and deflection limits according to different codes

(AISC-89/MBMA-86, IS800-1984, IS800-2007) as follows in

Tables VI & VII [4]-[7].

International Science Index Vol:8, No:4, 2014 waset.org/Publication/9998849

TABLE VI

LIMITING WIDTH TO THICKNESS RATIO ACCORDING TO IS 800 -2007-TABLE-2

Compression

Ratio

Class of section

Class 1 (Plastic)

Class 2 (Compact)

Class 3 (Semi-Compact)

Outstanding element of compression

Rolled section

b/tf

9.4

10.5

15.7

flange

Welded section

b/tf

8.4

9.4

13.6

Internal element of compression flange

Compression due to bending

b/tf

33.5

42

29.3

Axial compression

b/tf

Not applicable

Web of an I,H or box section

Neutral axis at mid-depth

d/tw

84

105

126

d/tw

(105)/(1+r1)

(126)/(1+2r2)

(84)/(1+r1)

but 42

but 42

Generally If r1 is negative

If r1 is positive

d/tw

(105)/(1+1.5r1)

but 42

Axial compression

Web of a channel

Angle, compression due to bending (Both criteria should be satisfied)

Single angle, or double angles with the components separated, axial

compression (All three criteria should be satisfied)

Outstanding leg of an angle in contact back-to-back in a double angle member

outstanding leg of an angle with its back in continuous contact with another

component

Stem of a T-section, rolled or cut from a rolled I-or H- section

Circular hollow tube, including welded tube subjected to:

d/tw

d/tw

b/t

d/t

b/t

d/t

(b+d)/t

d/t

d/t

Not applicable

42

9.4

9.4

9.4

9.4

10.5

10.5

42

42

15.7

15.7

15.7

15.7

25

15.7

15.7

D/tf

8.4

9.4

18.9

42

10.5

10.5

Not applicable

D/t

422

522

a) Moment

D/t

Not applicable

b) Axial compression

NOTES

1. Elements which exceed semi-compact limits are to be taken as of slender cross-section.

2. = (250 /f y) 1/2.

3. The stress ratio r1 and r2are defined as:

r1 = (Actual average axial stress(negative if tensile)/(Design compressive stress of web alone)

r2 = (Actual average axial stress(negative if tensile)/(Design compressive stress of overall section)

S.No

2

3

4

5

6

7

8

TABLE VII

DEFLECTION LIMITS ACCORDING TO DIFFERENT CODES

Limiting Deflections

AISC-89/MBMA-86

IS 800:1984

Description

Vertical

Lateral

Vertical

Lateral

Main frame

L/180

H/60

L/325

H/325

Main frame with crane (pendent)

H/100

L/325

H/325

Main frame with crane (cab operated)

H/240

L/325

H/325

Electric<50t

L/600

L/400

L/750

Crane beam

Electric>50t

L/800

L/1000

Wind column

H/120

H/325

Mezzanine beam

L/240

L/325

Under slung crane

L/450

L/750

Purlin

L/180

L/180

Girt

L/120

L/180

Primary

4 mm

6 mm

Minimum thickness

Secondary

1.6 mm

2 mm

X. COMPARISON BETWEEN IS 800-1984, IS 800-2007, MBMA

Comparison includes comparison of frame weights from

STAAD.Pro and its variation of weight percentage according

to different codes (AISC-89/MBMA-86, IS800-1984, IS8002007) as follows in Table VIII [9]:

482

1462

882

Vertical

L/180

L/180

L/180

L/750

L/1000

IS 800:2007

Lateral

H/150

H/200

H/400

H/150

L/240

L/750

L/150

L/150

4 mm

1.6 mm

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:8 No:4, 2014

Description

GL-1

GL-2-3

GL-4-25

Total

TABLE VIII

FRAME WEIGHTS FROM STAAD.PRO & ITS PERCENTAGE VARIATION ACCORDING TO DIFFERENT CODES

Comparison (% of increase in Wt.)

MBMA/AISC

IS 800-2007

IS 800-1984

In IS 800-2007

In IS 800-1984 compared to

In IS 800-1984 compared

(Kgs)

(Kgs)

(Kgs)

compared to MBMA

MBMA (%)

to IS 800-1984(%)

2934

3334

3738

13.7

27.5

12.2

1908

2411

2538

26.4

33.1

5.3

2863

3599

3898

25.8

36.2

8.4

7705

9344

10174

21

32

9

XI. RESULTS

Following graph shows the % increase in wt. in IS8001984, 2007 compared to MBMA/AISC.

35

% of Increase in Wt compared to

MBMA

International Science Index Vol:8, No:4, 2014 waset.org/Publication/9998849

30

combinations and Serviceability according to MBMA 1996, IS800-1984, & IS800-2007 [2], [4]-[7].

2) Internal Pressure Coefficient is considered as +/-0.2.

(Since %of opening<5%) [2].

3) External column base considered as fixed support. (Sway

is not controlling with pinned connection).Internal column

base considered as fixed support.

4) Wall cover is full height sheeted all around the building.

32

XIII. CONCLUSION

25

20

21

15

10

5

0

IS 800-2007

IS 800-1984

.

Indian Codes

Fig. 4 Comparison between Indian codes (IS800-1984 &IS800-2007)

& American code (MBMA)

Following graph shows the % increase in wt. in IS800-1984

compared to IS 800-2007.

10

8

% of Increase in Wt compared to IS8002007

9

6

4

2

0

IS 800-1984

.

Fig. 5 Comparison between Indian codes(IS800-1984 & IS800-2007)

XII. CONSIDERATIONS

1) Wind Load application as per IS 875 (Part-3) -1987

(reaffirmed 1997), Design According to ASIC -1989,

IS800-1984, & IS800-2007 for Built-up Members& Load

Following are the conclusions which are observed:

1) One of the main reason to increase in weight in IS 8001984 compared to IS 800-2007 is Serviceability

Criteria. Deflection limits by IS code are higher than

deflection limits by MBMA.

2) Reason for higher wt. in IS 800-2007 compared to

AISC/MBMA is limiting ratios of the sections (Table 2 of

IS800-2007).

3) Live load is 0.75 KN/m2 in IS code & whereas it is 0.57

KN/m2 in MBMA. Thus, concluded that loading as per

Indian codes is greater than MBMA code.

4) The main difference between the Indian Code (IS8002007) to the other equivalent American Codes are in the

classification of the cross-section of the steel member. As

per Indian code, the classes of section considered for

design are Plastic, Compact and Semi- compact, slender

cross-section. It is well known that many PEB

manufacturers use sections with very thin webs in order to

reduce the weight of the section and be

economical/competitive in their commercial offers, and

these thin webs do not satisfy the codal provisions of IS

800: 2007.

5) It was observed in industries most of the projects done

with AISC/MBMA. Reasons to preferring AISC/MBMA

Code are IS 800:2007 has not considered slender sections

which are often encountered in cold formed thin sections,

because there is another code IS 801 for this. Hence

people using cold formed sections cannot use IS 800.May

be that is the reason people are using AISC code &the

main reason to use the AISC code for PEB structures is

due the fact that it leads to an economical structural

solution as compared to the Indian Code.

6) It is observed that crane Impact load allowance is similar

in case of vertical loads whereas in case of horizontal

loads (surge, barking loads) the impact allowance is more

in MBMA compared to IS codes.

483

World Academy of Science, Engineering and Technology

International Journal of Civil, Architectural, Structural and Construction Engineering Vol:8 No:4, 2014

REFERENCES

International Science Index Vol:8, No:4, 2014 waset.org/Publication/9998849

[1]

Indian Standard: 1893 (Part1); 2002. Criteria for Earthquake Resistant

Design Structures: New Delhi: BIS; 2002.

[2] IS 875: Part 1 to 5 Code Of Practice For Design Loads (Other Than

Earthquake) For Buildings and Structures,1st Revision, New Delhi:

BIS..

[3] Indian Standard: 801 1975; Code Of Practice For Use Of Cold-Formed

Light Gauge Steel Structural Members In General Building

Construction, 1st Revision, New Delhi: BIS.

[4] Indian Standard: 800 2007; General Construction in Steel Code of

Practice; 3rd S Revision, New Delhi: BIS.

[5] Indian Standard: 800 1984; Code of Practice for General Construction,

In Steel; 1st Revision, New Delhi: BIS.

[6] MBMA: Metal Building Manufacturers Association-2006, Metal

Building Systems Manual, http://www.mbma.com.

[7] AISC: American Institute of Steel Construction-1989, Manual of Steel

Construction, Allowable Stress Design.

[8] Syed Firoz (2012), Design Concept of Pre-engineered Building,

International Journal of Engineering Research and Applications

(IJERA), Vol. 2, Issue 2, 267-272.

[9] C. M. Meera (2013),Pre-Engineered Building Design of an Industrial

Warehouse, international journal of engineering sciences & emerging

technologies, volume 5, issue 2, pp: 75-82.

[10] Indian Standard: 807 1976; Code Of Practice For Design,

Manufacture, Erection And Testing (Structural Portion) Of Cranes and

Hoists, 1st Revision, New Delhi: BIS.

[11] Technical Manual, Zamil Steel, Saudi Arabia, Pre-Engineered Buildings

Division.

[12] Technical Hand Book, Kirby Building Systems-INDIA.LTD.

G. Sai Kiran completed M.Tech Structural Engineer from

IIIT-Hyderabad, Telangana in the year 2014 & he completed

B.Tech Civil Engineering from TRR College of Engineering

& Technology (TRRCET), Patancheru, Telangana, in the year

2012. He is now working as structural Engineer at PS

Engineering Consultancy (www.psec.in), Nagole X roads,

Hyderabad, Telangana, India. His research interest is Seismic

Behavior of Structures. (E- mail:saikiran.gone@gmail.com).

484

Potrebbero piacerti anche

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Comparing Design Procedures for Pre-Engineered BuildingsDocumento6 pagineComparing Design Procedures for Pre-Engineered BuildingsAdnan AdilNessuna valutazione finora

- Seismic Instrumentation Design: Selected Research Papers on Basic ConceptsDa EverandSeismic Instrumentation Design: Selected Research Papers on Basic ConceptsNessuna valutazione finora

- Comparison of Design Procedures For Pre Engineering Buildings (PEB) : A Case StudyDocumento1 paginaComparison of Design Procedures For Pre Engineering Buildings (PEB) : A Case StudyMuhammad FarhanNessuna valutazione finora

- Elastic, Plastic and Yield Design of Reinforced StructuresDa EverandElastic, Plastic and Yield Design of Reinforced StructuresNessuna valutazione finora

- A Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingDocumento6 pagineA Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingIJIRSTNessuna valutazione finora

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresDa EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNessuna valutazione finora

- Comparison of Design Procedures For Pre Engineering Buildings (PEB) : A Case StudyDocumento4 pagineComparison of Design Procedures For Pre Engineering Buildings (PEB) : A Case StudyMETEY DesignsNessuna valutazione finora

- A Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingDocumento7 pagineA Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingAyush GargNessuna valutazione finora

- Analysis and Design of PEB Using IS800 and International StandardDocumento5 pagineAnalysis and Design of PEB Using IS800 and International StandardPratik R. AtwalNessuna valutazione finora

- Structural Behavior of Steel Structures On The Basis of Computer Simulation SoftwareDocumento11 pagineStructural Behavior of Steel Structures On The Basis of Computer Simulation SoftwareIJRASETPublicationsNessuna valutazione finora

- Nov163513 PDFDocumento3 pagineNov163513 PDFravi maskeNessuna valutazione finora

- Ijsrst Shearwall Etabs StaadDocumento6 pagineIjsrst Shearwall Etabs StaadAli Asghar LangahNessuna valutazione finora

- Wind ForcesDocumento6 pagineWind ForcesJournalNX - a Multidisciplinary Peer Reviewed JournalNessuna valutazione finora

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Documento8 pagineInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Parth DaxiniNessuna valutazione finora

- Comparative Analysis of The Building Components in Staad Pro & Ansys SoftwareDocumento4 pagineComparative Analysis of The Building Components in Staad Pro & Ansys SoftwarekNessuna valutazione finora

- A Structural Analysis of Solid and Hollow Rectangular Building A ReviewDocumento5 pagineA Structural Analysis of Solid and Hollow Rectangular Building A ReviewInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Analysis and Design of Multi Storey Building by Using STAAD Pro V8iDocumento3 pagineAnalysis and Design of Multi Storey Building by Using STAAD Pro V8iInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Study and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. BhaskarDocumento3 pagineStudy and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. Bhaskarshashank adigaNessuna valutazione finora

- Analysis and Design of (G+100) Storied Building by Using SoftwareDocumento3 pagineAnalysis and Design of (G+100) Storied Building by Using SoftwareInternational Journal of Innovations in Engineering and ScienceNessuna valutazione finora

- Seismic study of buildings with roof top telecom towersDocumento4 pagineSeismic study of buildings with roof top telecom towersHamOdy SadeqNessuna valutazione finora

- Irjet V5i6276Documento5 pagineIrjet V5i6276Vinit KondapureNessuna valutazione finora

- Irjet V5i6276 PDFDocumento5 pagineIrjet V5i6276 PDFAkula VeerrajuNessuna valutazione finora

- Analysis of Residential Building With STAAD. Pro & ETABS: Materials Today: Proceedings October 2020Documento9 pagineAnalysis of Residential Building With STAAD. Pro & ETABS: Materials Today: Proceedings October 2020Ahmed EmadNessuna valutazione finora

- Irjet V7i9576Documento4 pagineIrjet V7i9576umashankaryaligarNessuna valutazione finora

- Comparison of Design Procedures For Pre Engineering Buildings (PEB) : A Case StudyDocumento6 pagineComparison of Design Procedures For Pre Engineering Buildings (PEB) : A Case StudyHari SankerNessuna valutazione finora

- Interview Question 1Documento9 pagineInterview Question 1mtech structuresNessuna valutazione finora

- Technical Performance Analysis of RSS and Mud Motors - A Case StudyDocumento5 pagineTechnical Performance Analysis of RSS and Mud Motors - A Case StudyM. Fadhli Cesar KNessuna valutazione finora

- Multi-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmDocumento8 pagineMulti-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmAusbel Joab Cuyo TtitoNessuna valutazione finora

- Non Liner Dynamic Analysis of RCC Chimney: Amit Nagar Shiva Shankar. MDocumento6 pagineNon Liner Dynamic Analysis of RCC Chimney: Amit Nagar Shiva Shankar. MIsha PatelNessuna valutazione finora

- IJCRT2207440Documento3 pagineIJCRT2207440Sarmad AlwardiNessuna valutazione finora

- Review On Design and Analysis of Residential Building by Using Different MaterialsDocumento6 pagineReview On Design and Analysis of Residential Building by Using Different MaterialsBiniNessuna valutazione finora

- SSRN Id3376351Documento6 pagineSSRN Id3376351Hema Chandra Reddy KarimireddyNessuna valutazione finora

- Design and Analysis of Multistorey G14 ResidentialDocumento13 pagineDesign and Analysis of Multistorey G14 ResidentialKhushboo Raj KhushiNessuna valutazione finora

- Comparison Between Manual Analysis and Software Analysis of A Shopping ComplexDocumento5 pagineComparison Between Manual Analysis and Software Analysis of A Shopping Complexoluwaluyi danielNessuna valutazione finora

- Structural Analysis and Design of Steel Transmission Tower in Wind Zones II and IVDocumento10 pagineStructural Analysis and Design of Steel Transmission Tower in Wind Zones II and IVAr G S YadavNessuna valutazione finora

- Design of Industrial Warehouse IJERTV7IS020170Documento5 pagineDesign of Industrial Warehouse IJERTV7IS020170Anonymous Uf0LDX6GNessuna valutazione finora

- Effect of Rooftop Mounted TelecommunicatDocumento6 pagineEffect of Rooftop Mounted Telecommunicatindian royalNessuna valutazione finora

- Journal PDFDocumento10 pagineJournal PDFD.B. NiranjanNessuna valutazione finora

- Design T Girder BridgeDocumento1 paginaDesign T Girder BridgeBasu UdupiNessuna valutazione finora

- Comparative Analysis of Composite Structure by STADD Pro SoftwareDocumento6 pagineComparative Analysis of Composite Structure by STADD Pro SoftwareIJRASETPublicationsNessuna valutazione finora

- Analysis and Design of Reinforced Concrete Solid Slab BridgeDocumento4 pagineAnalysis and Design of Reinforced Concrete Solid Slab BridgeEditor IJTSRDNessuna valutazione finora

- Blade DesignDocumento9 pagineBlade DesignMuhammad ZahidNessuna valutazione finora

- Study of Multistoried Buildings With Oblique ColumDocumento10 pagineStudy of Multistoried Buildings With Oblique ColumAlex CarrilloNessuna valutazione finora

- Ext 71593Documento6 pagineExt 71593Md. Mizanur RahamanNessuna valutazione finora

- Badal and Sinha (2019) - Selection of Archetypical Building Configuration For Special Reinforced Concrete Moment-Resisting FramesDocumento161 pagineBadal and Sinha (2019) - Selection of Archetypical Building Configuration For Special Reinforced Concrete Moment-Resisting FramesSuman BanerjeeNessuna valutazione finora

- Ijet 17730Documento5 pagineIjet 17730Angelina AjengNessuna valutazione finora

- Comparative Study On Materials Used in Various Codes For Design of RC and Steel StructuresDocumento7 pagineComparative Study On Materials Used in Various Codes For Design of RC and Steel StructuresMohammad AslamNessuna valutazione finora

- BunkerDocumento7 pagineBunkerSrinivasan GanesanNessuna valutazione finora

- Ijert Ijert: Design and Development of Material Handling CraneDocumento8 pagineIjert Ijert: Design and Development of Material Handling CraneAnonymous PufNjgNessuna valutazione finora

- Design of Conical Roof Structure for Liquid Sulphur Storage TankDocumento7 pagineDesign of Conical Roof Structure for Liquid Sulphur Storage TankSaravanan Silamban100% (1)

- Effect of Bracings On The Behaviour of Industrial Buildings With Different Framing Configuration Subjected To Wind LoadDocumento10 pagineEffect of Bracings On The Behaviour of Industrial Buildings With Different Framing Configuration Subjected To Wind LoadIJRASETPublicationsNessuna valutazione finora

- Comparative Analysis of PEB Structure With Varying Ridge AngleDocumento11 pagineComparative Analysis of PEB Structure With Varying Ridge AngleIJRASETPublicationsNessuna valutazione finora

- Bharati Vidyapeeth's Institute of Computer Applications and Management (Bvicam)Documento8 pagineBharati Vidyapeeth's Institute of Computer Applications and Management (Bvicam)Sristi GuptaNessuna valutazione finora

- Analysis and Design of Reinforced Concrete Solid Slab BridgeDocumento6 pagineAnalysis and Design of Reinforced Concrete Solid Slab BridgeEditor IJTSRDNessuna valutazione finora

- Seismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentDocumento11 pagineSeismic Analysis and Design of RCC Chimney: International Journal of Advance Engineering and Research DevelopmentIsha PatelNessuna valutazione finora

- Comparision of Is 875part 31987 and Is 875part 32015 For Tall Junction TowerDocumento3 pagineComparision of Is 875part 31987 and Is 875part 32015 For Tall Junction Towerabhay_joshi2002Nessuna valutazione finora

- Irjet V5i5569 PDFDocumento5 pagineIrjet V5i5569 PDFPramod RaghuNessuna valutazione finora

- Major ProjectDocumento7 pagineMajor ProjectPradeep BodireNessuna valutazione finora

- Seismic Study of Building With Roof Top Telecommunication TowersDocumento4 pagineSeismic Study of Building With Roof Top Telecommunication TowersSyed Ehtesham aliNessuna valutazione finora

- 50243-16-2p-Commented FileDocumento2 pagine50243-16-2p-Commented FilePrem KumarNessuna valutazione finora

- L G PI E PC E: 2 - Station VPI Station VPCDocumento2 pagineL G PI E PC E: 2 - Station VPI Station VPCPrem KumarNessuna valutazione finora

- Therefore, The 220 Feet Radio Tower Will Be Considered As Obstruction To Air Navigation by FAADocumento1 paginaTherefore, The 220 Feet Radio Tower Will Be Considered As Obstruction To Air Navigation by FAAPrem KumarNessuna valutazione finora

- 16 111Documento1 pagina16 111Prem KumarNessuna valutazione finora

- Calculate rail curve super elevation and spiral lengthDocumento1 paginaCalculate rail curve super elevation and spiral lengthPrem KumarNessuna valutazione finora

- 520367-9-6P Aid: 30951 - 03/03/2019Documento1 pagina520367-9-6P Aid: 30951 - 03/03/2019Prem KumarNessuna valutazione finora

- 111Documento1 pagina111Prem KumarNessuna valutazione finora

- Therefore The Average Vehicle Speed Reduces and Roadway Capacity Increases As The Level of Services Varies From A To FDocumento1 paginaTherefore The Average Vehicle Speed Reduces and Roadway Capacity Increases As The Level of Services Varies From A To FPrem KumarNessuna valutazione finora

- 500,000 FT W 500000 64 32,000, 000 LB 32,000,000 .031081 Slug 994590. 40 SlugDocumento1 pagina500,000 FT W 500000 64 32,000, 000 LB 32,000,000 .031081 Slug 994590. 40 SlugPrem KumarNessuna valutazione finora

- Hazard Assessment Matrix Developed to Determine Risk IndexDocumento1 paginaHazard Assessment Matrix Developed to Determine Risk IndexPrem KumarNessuna valutazione finora

- 8 3PDocumento1 pagina8 3PPrem KumarNessuna valutazione finora

- Fender PerDocumento1 paginaFender PerPrem KumarNessuna valutazione finora

- 12 8PDocumento1 pagina12 8PPrem KumarNessuna valutazione finora

- 9 6PDocumento1 pagina9 6PPrem KumarNessuna valutazione finora

- Design ExtractsDocumento14 pagineDesign ExtractsPrem KumarNessuna valutazione finora

- Fender PerDocumento1 paginaFender PerPrem KumarNessuna valutazione finora

- It 1Documento5 pagineIt 1Prem KumarNessuna valutazione finora

- 2 35PDocumento2 pagine2 35PPrem KumarNessuna valutazione finora

- Construction fixes for cladding, flashing, skylights and moreDocumento12 pagineConstruction fixes for cladding, flashing, skylights and morePrem KumarNessuna valutazione finora

- 12 7PDocumento1 pagina12 7PPrem KumarNessuna valutazione finora

- 100 Speed Wind Total Speed Wind of Duration Wind %Documento2 pagine100 Speed Wind Total Speed Wind of Duration Wind %Prem KumarNessuna valutazione finora

- 12 8PDocumento1 pagina12 8PPrem KumarNessuna valutazione finora

- KSS Roofing Project Inspection ReportDocumento4 pagineKSS Roofing Project Inspection ReportPrem KumarNessuna valutazione finora

- ITC Driver's RoomDocumento9 pagineITC Driver's RoomPrem KumarNessuna valutazione finora

- It 1Documento5 pagineIt 1Prem KumarNessuna valutazione finora

- Weld Joint Rust. Aluminum Paint To ApplyDocumento10 pagineWeld Joint Rust. Aluminum Paint To ApplyPrem KumarNessuna valutazione finora

- 12 7PDocumento1 pagina12 7PPrem KumarNessuna valutazione finora

- Polymer Block Snag ListDocumento5 paginePolymer Block Snag ListPrem KumarNessuna valutazione finora

- Weld Joint Rust. Aluminum Paint To ApplyDocumento10 pagineWeld Joint Rust. Aluminum Paint To ApplyPrem KumarNessuna valutazione finora

- Best Corrugators Final InspectionDocumento14 pagineBest Corrugators Final InspectionPrem KumarNessuna valutazione finora

- Selection, Installation and Maintenance of Electrical Apparatus for Hazardous LocationsDocumento29 pagineSelection, Installation and Maintenance of Electrical Apparatus for Hazardous Locationskieran43100% (1)

- CD Deluxe New PDFDocumento109 pagineCD Deluxe New PDFSANTOSH KUMAR100% (3)

- Introduction To Fe Modeling of Composite Beam To CFST Column Connection - Phase - 1Documento60 pagineIntroduction To Fe Modeling of Composite Beam To CFST Column Connection - Phase - 1Harshil DevaniNessuna valutazione finora

- Online System, Functions, and PlatformsDocumento28 pagineOnline System, Functions, and PlatformsJules Gajes80% (5)

- 7447 TurbinDocumento3 pagine7447 Turbinfachrul rozziNessuna valutazione finora

- Testing Tilted Flanges and Nozzles Without Retesting the Entire TankDocumento3 pagineTesting Tilted Flanges and Nozzles Without Retesting the Entire TankCarlos MolinaNessuna valutazione finora

- MTL Product OverviewDocumento56 pagineMTL Product OverviewAries dNessuna valutazione finora

- EXTENSION PROPOSAL 2015 (First Sem)Documento14 pagineEXTENSION PROPOSAL 2015 (First Sem)Arnold Magdalita FranciscoNessuna valutazione finora

- Types of BricksDocumento5 pagineTypes of BricksMian M KhurramNessuna valutazione finora

- UT Dallas Syllabus For Mech3350.001.11s Taught by Wooram Park (wxp103020)Documento2 pagineUT Dallas Syllabus For Mech3350.001.11s Taught by Wooram Park (wxp103020)UT Dallas Provost's Technology GroupNessuna valutazione finora

- Io s4.6 en 0407Documento2 pagineIo s4.6 en 0407Vasudev AgrawalNessuna valutazione finora

- BCS100 Capacitive Height Controller User ManualDocumento43 pagineBCS100 Capacitive Height Controller User Manualodhiles1100% (1)

- Exploring Cusco Peter Frost PDFDocumento2 pagineExploring Cusco Peter Frost PDFLiz0% (2)

- High Performance Glass PDFDocumento4 pagineHigh Performance Glass PDFBrajesh MishraNessuna valutazione finora

- MAN 48 60 Engine ExternDocumento688 pagineMAN 48 60 Engine Externlubangjarum100% (2)

- Workstation Assembly Instructions PDFDocumento1 paginaWorkstation Assembly Instructions PDFChris EfstathiouNessuna valutazione finora

- Hazchem Codes: StorageDocumento3 pagineHazchem Codes: StoragePleaase Annd DontNessuna valutazione finora

- 170904-Nokia 5G Technology Components White PaperDocumento13 pagine170904-Nokia 5G Technology Components White PaperMuhammad Jamil AwanNessuna valutazione finora

- Slope Stability Analysis Analiza Interna Input DataDocumento22 pagineSlope Stability Analysis Analiza Interna Input DatananesculNessuna valutazione finora

- Arci Ar 2016 17 Eng PDFDocumento158 pagineArci Ar 2016 17 Eng PDFMeenakshiNessuna valutazione finora

- Dexter Axles Light-Duty-600-8k - (Lit-001-00)Documento99 pagineDexter Axles Light-Duty-600-8k - (Lit-001-00)gearhead1Nessuna valutazione finora

- KBJNL Erm NLBC PresentationDocumento62 pagineKBJNL Erm NLBC PresentationPraveen PrakashNessuna valutazione finora

- Strato 35 Series and 70 Series :: ROAL Living EnergyDocumento1 paginaStrato 35 Series and 70 Series :: ROAL Living EnergyMinhNessuna valutazione finora

- Efficient Mould Cooling MethodsDocumento48 pagineEfficient Mould Cooling MethodsVinayak Aryan100% (1)

- Pre-Load Disc Springs: Plain TypeDocumento3 paginePre-Load Disc Springs: Plain TypeJEORJENessuna valutazione finora

- EV charging standards guideDocumento30 pagineEV charging standards guidejoacochacoman100% (2)

- Electrical Load Calculations for Building ConstructionDocumento16 pagineElectrical Load Calculations for Building ConstructionKitz DerechoNessuna valutazione finora

- Centrifugal ForceDocumento11 pagineCentrifugal Forceno oneNessuna valutazione finora

- Application of Materials in Interior DesignDocumento2 pagineApplication of Materials in Interior DesignInternational Educational Applied Scientific Research Journal (IEASRJ)Nessuna valutazione finora

- Durlon HandbookDocumento26 pagineDurlon HandbookFranco TadayNessuna valutazione finora

- Transmission Pipeline Calculations and Simulations ManualDa EverandTransmission Pipeline Calculations and Simulations ManualValutazione: 4.5 su 5 stelle4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (137)

- Advanced Modelling Techniques in Structural DesignDa EverandAdvanced Modelling Techniques in Structural DesignValutazione: 5 su 5 stelle5/5 (3)

- Matrix Methods for Advanced Structural AnalysisDa EverandMatrix Methods for Advanced Structural AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Pile Design and Construction Rules of ThumbDa EverandPile Design and Construction Rules of ThumbValutazione: 4.5 su 5 stelle4.5/5 (15)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDa EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNessuna valutazione finora

- Marine Structural Design CalculationsDa EverandMarine Structural Design CalculationsValutazione: 4.5 su 5 stelle4.5/5 (13)

- Offshore Pipelines: Design, Installation, and MaintenanceDa EverandOffshore Pipelines: Design, Installation, and MaintenanceValutazione: 4.5 su 5 stelle4.5/5 (2)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDa EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNessuna valutazione finora

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareDa EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareValutazione: 4.5 su 5 stelle4.5/5 (15)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDa EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsValutazione: 4 su 5 stelle4/5 (16)

- Built: The Hidden Stories Behind Our StructuresDa EverandBuilt: The Hidden Stories Behind Our StructuresValutazione: 4 su 5 stelle4/5 (27)

- Design and Construction of Soil Anchor PlatesDa EverandDesign and Construction of Soil Anchor PlatesValutazione: 5 su 5 stelle5/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesDa EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraValutazione: 4.5 su 5 stelle4.5/5 (4)

- Structural Analysis: In Theory and PracticeDa EverandStructural Analysis: In Theory and PracticeValutazione: 4.5 su 5 stelle4.5/5 (24)

- Concrete Structures: Repair, Rehabilitation and StrengtheningDa EverandConcrete Structures: Repair, Rehabilitation and StrengtheningNessuna valutazione finora

- Topology Design Methods for Structural OptimizationDa EverandTopology Design Methods for Structural OptimizationValutazione: 2 su 5 stelle2/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDa EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresValutazione: 1 su 5 stelle1/5 (2)

- Computational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignDa EverandComputational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignValutazione: 3.5 su 5 stelle3.5/5 (2)