Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Plunge Router Mortising Jig

Caricato da

Ian ForemanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Plunge Router Mortising Jig

Caricato da

Ian ForemanCopyright:

Formati disponibili

Building a Simple:

Plunge Router

Mortising Jig

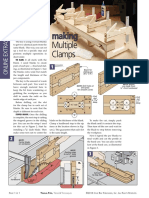

One of the best ways

to get the biggest

bang from a plunge

router is to put it to

work routing mortises. The technique,

explained in Shopnotes No. 90, is easy

to master and the

results are topnotch.

And the clincher is

that, from setup to

completion, the whole process takes only

a few minutes. The key is the simple-tobuild and easy-to-use mortising jig you

see in the photos.

Overview A Simple Jig. So before

you can start routing mortises, youll need

to build the jig. My emphasis here was on

keeping things very simple, so this wont

keep you away from the work for long.

Take a look at the drawing below and

youll see that the working parts of the jig

consist of an auxiliary baseplate and two

adjustable guides. The baseplate is simply

a slotted piece of hardboard that rides

along the workpiece. The guides are the

Page 1 of 1

heart of the jig and serve two purposes.

First, theyre used to easily and accurately position the mortise in the workpiece

by allowing you to reference the cut off one

edge. Second, the two guides sandwich

the workpiece snugly to give you steady

control of the router as the mortise is being

cut. This makes it possible to cut accurate

mortises in even very narrow stock.

First, the Baseplate. Now let me give

you the short course on how to build the

jig. As shown in the drawing, the auxiliary

ShopNotes No. 90

baseplate is cut to size from 14" hardboard.

(You could substitute 14" plywood or phenolic.) The long rectangular shape gives

you more stability and allows for longer

guides. I used the standard baseplate to

locate the countersunk holes for the attachment screws and a centered hole for the

bit. Youll want to use the largest Forstner

bit in the shop to drill the center hole. This

will give you a better field of view around

the bit while routing.

Two slots in the baseplate, along with

carriage bolts and wing nuts, allow you to

adjust and tighten down the guides. The 5"long slots let the jig accommodate a wide

range of workpieces. After routing the

slots with a straight bit in the router table, I

screwed the baseplate to the router.

The Guides. Next, I cut the two guides

from "-thick hardwood. Youll notice that

theyre a little longer than the baseplate.

This simply makes them easier to grasp

and adjust when the router and jig are

resting on the workpiece.

Once the guides are cut to size, youll

need to drill a pair of counterbored bolt

holes through each one. The spacing of the

holes in the guides should precisely match

that of the slots in the baseplate. When

installed, you want be able to adjust them

easily on the baseplate.

And that brings us to the final step. Sink

a carriage bolt firmly into each hole, pass

the ends through the slots in the baseplate

and add washers and wingnuts. All you

need is a bit in the router and youre ready

to go to work.

2006 August Home Publishing. All rights reserved.

Potrebbero piacerti anche

- How To Make A Stopped Dado Jig For Any Router: InstructablesDocumento11 pagineHow To Make A Stopped Dado Jig For Any Router: InstructablesTroy100% (1)

- Popular Woodworking No 76 January 1994Documento100 paginePopular Woodworking No 76 January 1994aleksandar.omasystemsNessuna valutazione finora

- Racket EET: Nline XtrasDocumento5 pagineRacket EET: Nline XtrasRafishfullNessuna valutazione finora

- 41 Scollsaw FINALDocumento5 pagine41 Scollsaw FINALDeco de SousaNessuna valutazione finora

- Long Langstroth HiveDocumento7 pagineLong Langstroth HiveWolfgangNessuna valutazione finora

- Glass-Panel: This Certainly Run-Of-The-Mill and Worl Might Add A New DimensionDocumento10 pagineGlass-Panel: This Certainly Run-Of-The-Mill and Worl Might Add A New Dimensionrayane ouzmihNessuna valutazione finora

- Sliding Bookrack: Woodworks: Intermediate ProjectDocumento8 pagineSliding Bookrack: Woodworks: Intermediate ProjectEucap Mdz100% (1)

- Adjustable Taper Ripping JigDocumento6 pagineAdjustable Taper Ripping Jiggmand68Nessuna valutazione finora

- SIX-CANDLE CENTERPIECE - Woodsmith ShopDocumento5 pagineSIX-CANDLE CENTERPIECE - Woodsmith ShopEricsNessuna valutazione finora

- Coffe TableDocumento15 pagineCoffe TableJun Vargas100% (1)

- 103 - Table Saw Panel SledDocumento2 pagine103 - Table Saw Panel SledRob PierceNessuna valutazione finora

- Spliced Puzzle Joint - Australian Woodsmith #177, 2023 - 복사본Documento6 pagineSpliced Puzzle Joint - Australian Woodsmith #177, 2023 - 복사본김동원Nessuna valutazione finora

- Cove CalculationsDocumento1 paginaCove CalculationsflerziNessuna valutazione finora

- Plywood EdgeDocumento2 paginePlywood EdgeE100% (1)

- Router Table Micro-AdjusterDocumento2 pagineRouter Table Micro-Adjustergmand68100% (1)

- 5 Spline Miters JointDocumento2 pagine5 Spline Miters JointtomNessuna valutazione finora

- Picture BoxDocumento3 paginePicture BoxEmilian BalutaNessuna valutazione finora

- Jig For Threaded Inserts: Nline XtrasDocumento1 paginaJig For Threaded Inserts: Nline XtrasJd Diaz100% (1)

- Cortar CirculosDocumento7 pagineCortar CirculosarenasrubenNessuna valutazione finora

- How To Make A Wooden Bar Clamp PDFDocumento13 pagineHow To Make A Wooden Bar Clamp PDFAldrin DejumoNessuna valutazione finora

- Modular Planter Bench: Woodworks: Intermediate ProjectDocumento7 pagineModular Planter Bench: Woodworks: Intermediate ProjectEucap MdzNessuna valutazione finora

- Pocket Hole JoineryDocumento2 paginePocket Hole JoineryFrancois Vaaltyn100% (1)

- Wood Joint Work Part 4Documento2 pagineWood Joint Work Part 4Lo M'hNessuna valutazione finora

- Computer Desk - 002pdfDocumento12 pagineComputer Desk - 002pdfShahin R KrishnaNessuna valutazione finora

- Hank Ou: Get More From Your Table SawDocumento6 pagineHank Ou: Get More From Your Table Sawasg0401Nessuna valutazione finora

- Finger Joints: Fast and EasyDocumento4 pagineFinger Joints: Fast and EasyIlberto FortunaNessuna valutazione finora

- FinishDocumento4 pagineFinishGsmHelpNessuna valutazione finora

- 5 Shop Made Clamps - SSCDocumento1 pagina5 Shop Made Clamps - SSCjuan olivaNessuna valutazione finora

- ShopNotes Issue 05Documento32 pagineShopNotes Issue 05benignoNessuna valutazione finora

- Woodsmith Magazine - Plans Now - Router Table ReviewDocumento6 pagineWoodsmith Magazine - Plans Now - Router Table ReviewPaweł JamrożekNessuna valutazione finora

- Wooden ClampDocumento10 pagineWooden ClampzlobiulNessuna valutazione finora

- Router Table BasicsDocumento7 pagineRouter Table BasicskelvinchanNessuna valutazione finora

- Adega ModularDocumento15 pagineAdega ModularJairoViolinistaNessuna valutazione finora

- Homemade Edge Band Clamps: InstructablesDocumento4 pagineHomemade Edge Band Clamps: InstructablesJasmine VaaltynNessuna valutazione finora

- Bowl Basics 2Documento5 pagineBowl Basics 2api-522254901Nessuna valutazione finora

- Plansnow MilkpaintDocumento3 paginePlansnow MilkpaintTa JavoNessuna valutazione finora

- Loose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsDocumento6 pagineLoose-Tenon Options: Spend A Little, Spend A Lot: Three Great Ways To Make Loose-Tenon JointsFausto Martin Vicente MoralesNessuna valutazione finora

- Woodsmith Magnetic StopDocumento1 paginaWoodsmith Magnetic Stopr521999Nessuna valutazione finora

- 94 Shooting-BoardDocumento6 pagine94 Shooting-Boardbjørn vidar andersenNessuna valutazione finora

- Workbench User Manual For TranscribersDocumento6 pagineWorkbench User Manual For TranscribersDiab MehdiNessuna valutazione finora

- Woodsmith 135Documento36 pagineWoodsmith 135Aditya Rajendran100% (1)

- Materials, Supplies, & Cutting Diagram: Large Craftsman TableDocumento1 paginaMaterials, Supplies, & Cutting Diagram: Large Craftsman TableDavid TuaineNessuna valutazione finora

- The Shabby Craftsman Kitchen Cabinet PricingDocumento47 pagineThe Shabby Craftsman Kitchen Cabinet PricingSamuel Martin McCallNessuna valutazione finora

- 2 - Woodworking Plans - OakplateDocumento6 pagine2 - Woodworking Plans - OakplatemacpatorNessuna valutazione finora

- Little Table: The Woodworking Resource LibraryDocumento6 pagineLittle Table: The Woodworking Resource LibraryAmanjot100% (1)

- Deluxe Router TableDocumento27 pagineDeluxe Router Tableiacob_gilberto6473100% (1)

- Moxon Vise Instructions-BC0317Documento12 pagineMoxon Vise Instructions-BC0317Cameron RiosNessuna valutazione finora

- Plansnow FlatstockjointerDocumento3 paginePlansnow FlatstockjointerFelipe AltamiranoNessuna valutazione finora

- JCM-1H and JCM-1C: Owner'S ManualDocumento4 pagineJCM-1H and JCM-1C: Owner'S ManualLothar MüllerNessuna valutazione finora

- Adding An Epoxy InlayDocumento2 pagineAdding An Epoxy InlayarenasrubenNessuna valutazione finora

- WS15620 Candle-HoldersDocumento6 pagineWS15620 Candle-HoldersJasmine VaaltynNessuna valutazione finora

- SN 100 - Reducing Rod DiameterDocumento1 paginaSN 100 - Reducing Rod DiameterHomerSimsonnakisNessuna valutazione finora

- Thank You!: WOOD StoreDocumento10 pagineThank You!: WOOD StoreLibrado Morales ZamoraNessuna valutazione finora

- EZPine Wall ShelfDocumento3 pagineEZPine Wall ShelfBSulliNessuna valutazione finora

- Woodworking Plans - Tavern TableDocumento2 pagineWoodworking Plans - Tavern TableBob Kowalski100% (1)

- Wooden Bar Clamps PlansDocumento14 pagineWooden Bar Clamps PlansWalter RamirezNessuna valutazione finora

- Beveled MitresDocumento1 paginaBeveled MitresRandallBergerudNessuna valutazione finora

- WOOD Magazine Workshop Floor Plan: Mor Cla Ra W A Planer PDocumento1 paginaWOOD Magazine Workshop Floor Plan: Mor Cla Ra W A Planer PZERONessuna valutazione finora

- Digital Patterns: Designed by Steve GoodDocumento4 pagineDigital Patterns: Designed by Steve GoodRichard PerezNessuna valutazione finora

- Freud Test Table PDFDocumento3 pagineFreud Test Table PDFalinupNessuna valutazione finora

- Fingerpicking Guitar Exercises & Hot Licks (Stefan Grossman, Mel Bay, July 1999)Documento28 pagineFingerpicking Guitar Exercises & Hot Licks (Stefan Grossman, Mel Bay, July 1999)Lothar MüllerNessuna valutazione finora

- Benson, George - in Session With George BensonDocumento83 pagineBenson, George - in Session With George BensonLothar MüllerNessuna valutazione finora

- Ac DCDocumento28 pagineAc DCLothar Müller100% (1)

- Sinumerik 840D SL NCU: ControllerDocumento116 pagineSinumerik 840D SL NCU: ControllerLothar MüllerNessuna valutazione finora

- Hummusbar Kiraly WebDocumento4 pagineHummusbar Kiraly WebLothar MüllerNessuna valutazione finora

- Catalogo Savinelli 2015 PDFDocumento187 pagineCatalogo Savinelli 2015 PDFLothar MüllerNessuna valutazione finora

- Section 5.4:: Factoring by Grouping and Special FormsDocumento6 pagineSection 5.4:: Factoring by Grouping and Special FormsLothar MüllerNessuna valutazione finora