Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

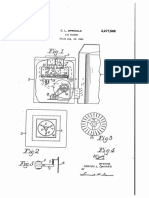

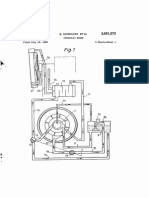

Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1

Caricato da

luiscremaschiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1

Caricato da

luiscremaschiCopyright:

Formati disponibili

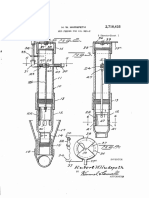

Jan.

16, 1962

J. A. LYNE

3:016w99l

HYDRAULIC TURBO BRAKE

Filed Jan. 26, 1959

2 Sheets-Sheet 1

ATTORNEY

Jan. 16, 19.62

J, A, LYNE

3,016,991

HYDRAULIC TURBO BRAKE

Filed Jan. 26, 1959

2 Sheets-Sheet 2

3%

//, Z

//.4

49

30

34a

47

35a

.33

49a

do 9

/I .

1

Z yne

IN VEN TOR.

BY QM

ATTORNEY

United States Patent O?ice

1

3,016,991

HYDRAULIQ TURBO BRAKE

Joe A. Lyne, 106 Ferndale, Bellaire, Tex.

Filed Jan. 26, 1959, Ser. No. 788,360

4 Claims. (Cl. 18t90)

3,016,991

Patented Jan. 16, 1962

2

centrifugal pump vanes and thereby increase ?uid de

livery to the working chamber of the brake.

In carrying out my invention, I provide a circumferen

tial series of nozzles opening into the stator pockets

from an annular reservoir or manifold extending around

the shaft. When the level of ?uid moves around and

up in the reservoir to approach the elevation of the shaft

This invention relates to hydraulic turbo brakes, and

more particularly, to a hydrodynamic brake having a wide

and meet the demands of load increases, the ?uid may

range of control over ?uid delivery therein for close

also enter the brake through a clearance provided be

control of resistance to varying loads.

10 tween the stator and the hub of the rotor. Certain of

Hydrodynamic brakes are commonly used to control

the rotor blades are extended to bridge this clearance so

or restrict shaft speeds and are particularly useful in con

as to terminate within the cross-sectional area of the

junction with oil ?eld hoisting equipment to limit the

stator and thus engage and centrifugally impel ?uid en

:speed at which pipe or tools are lowered into a well.

tering the brake chamber through the clearance. This

Hydrodynamic brakes generally have rotor and stator as 15 auxiliary pump effect of the rotor blades increases the

:semblies, each having radial vanes to form opposing

gpockets or cups. In brakes of this type water is generally

employed as the ?uid braking medium to circulate be

tween the pockets of the rotor and stator and resist rela

feed capacity of the brake by overcoming the resistance to

further intake caused by pressure build-up within the

brake chamber.

Other objects and advantages of my invention will

tive movement thereof. Consequently, it is extremely 20 become apparent from the speci?cation following when

important to control the amount of water in the brake

read in conjunction with the accompanying drawings

in accordance with the work load or resistance required.

wherein:

Moreover with the conversion of mechanical energy into

heat taking place within the water resulting from the

FIG. 1 is a diagrammatic view illustrating my com

plete hydrodynamic brake system;

resistance thereof, it is necessary to maintain circulation 25

FIG. 2 is a diametrical section view through the

through the brake in order to replace heated water with

brake;

'

cool Water. Frequently, water is introduced into the

FIG. 3 is a section view taken along line 33 of

brake through a series of nozzles extending into the brake

FIG. 2;

and disposed so that circulation of the ?uid already with

FIGS. 4 and 5 are perspective views of two different

in the brake past the nozzle discharge opening creates a

rotor vanes.

vacuum to draw water out of the nozzle and into the

Referring now to the drawings in particular, FIG. 1

brake.

illustrates the circulation of ?uid through my hydrody

With the nozzles arranged in a circular row concentric

to the brake shaft, the depth of water in a common

namic brake system and shows ?uid being delivered to

the brake 1 from a reservoir or surge tank 2.

Cool

reservoir will determine the number of nozzles feeding 35 water is delivered from a source thereof (not shown)

?uid into the brake. In this way, the capacity of the

through a supply pipe 3, the ?ow being controlled by a

brake can be controlled closely to meet varying load re

suitable valve 4. The relatively cooler water at the

quirements. However, as the load increases and pres

bottom of the tank is then delivered through feed pipes

sure is built up within the brake the rate of feed, being

5 into the brake until the water level W.L. is reached.

dependent upon pressure diiferential, falls o? to the ex 40 Steam and hot water formed by the absorption of heat

tent that maximum brake capacity cannot be achieved.

energy within the brake 1 is removed by pipe 6 and

Moreover, another major disadvantage of present hy

carried back to the surge tank 1.

drodynamic brakes resides in the inefficient circulation

The desired water level W.L. is maintained by means

of ?uid in and between the stator and rotor pockets.

of an open pipe or hose 7, the open end of which is

Generally, the ?uid ?ows radially outward in the rotor 45 adjustable in elevation. While I have shown an ac

pockets across to the opposed stator pockets wherein it

cordion-like swing pipe 7, it is equally obvious that a

?ows radially inward. Usually, it is found desirable to

?exible hose, telescopically arranged pipes or any similar

?exible or extensible tubular member may be employed

terminate vanes of the rotor (and stator) radially out

ward from the hub to afford enough circumferential

with equal ei?cacy. In any event, the over?ow pipe 7

space throughout each pocket and thereby avoid entrap 50 removes the relatively hot water from the top of the tank

2 and discharges it through outlet pipe 8. A breather

ment of ?uid. However, the relatively ?at radial rotat

pipe 9 is preferably provided at the top of the tank 2

ing surface of the rotor before the vanes tends to throw

in order to equalize pressure in the tank and the brake 1

off ?uid impinging thereon from the stator, particularly

at atmospheric pressure.

at high speeds. Consequently, the e?iciency of circula

tion within the brake pockets themselves, is materially 55 Referring now to FIG. 2, my hydrodynamic brake is

retarded at advanced shaft speeds.

enclosed within a housing indicated generally at 11 and

comprising annular side plates 12 and a cylindrical cover

It is, therefore, an object of my invention to provide a

13. Couplings 14 are provided in the side walls 12 near

means for delivering ?uid under pressure to the work

the bottom of the housing 11 to receive the ?uid inlet

ing chamber of a hydrodynamic brake to achieve maxi

60 pipes 5 and a coupling 15 is provided through the top

mum capacity.

of the cylindrical cover 13 for the outlet pipe 6. Pref

It is a further object of my invention to provide a

erably, a drainage plug 16 is provided at the bot-tom of

?ne control variable ?uid feed combined with a pressure

the cylindrical cover 13.

fluid feed to achieve maximum brake capacity.

It is a further object of my invention to provide a

In my preferred construction, the side plates 12 are

means to increase circulation of brake ?uid between 65 welded or otherwise secured to rigid heavy duty rings 17

stator and rotor pockets.

of steel or the like having strength ribs 18 radiating there

It is a further object of my invention to provide a

from. Journal members 19 carrying suitable anti-friction

hydrodynamic brake having rotor vanes that function as

bearings 20 to rotatably receive a shaft 21 are in turn

impellers to implement circulation within and between

rigidly secured to the rings 17. The journal members 19

70 also carry suitable leak proof packing 22 in ?uid tight

the brake pockets.

It is a further object of my invention to provide rotor

sealing engagement with the shaft 21. The bearings 20

vanes that cooperate with the stator blades to function as

are protected by annular cover plates 23. One end 25

3,016,991

of the shaft 21 projects outwardly from the housing and

height of the water level in the surge tank 2 according to

the elevation of the open swing pipe 7. Since the water

has a keyway 26 or similar means for coupling to the

rises up and around the annular reservoirs or intake mani

folds 33 it is apparent that the height of the water level

in the tank and hence in the annular reservoir 33 will de

termine the number of nozzles 36 from the circular row

shaft the speed of which is to be controlled.

Stator members shown generally at 30 are secured with

in the housing 11 and each comprises an annular wall 31

of curvilinear cross-section held within the housing 11 in

thereof that will be covered by the water. Consequently,

spaced relation with the side plates 12 by bolting, welding

a very close control over feed of water to the brake for

or otherwise rigidly securing the side plates to an annular

varying load conditions can be maintained by control of

?ange 32 integral with the wall 31. As shown in FIG. 2,

the stator wall 31 curves radially inward and away from 10 the height of the water in the tank 2. When increased

load conditions necessitates an increase in ?uid to bring

the side plates 12, the spaces 33 between the side plates

the level up near the shaft 21, the ?uid may also enter

12 and the stator walls 31 and extending to the shaft seals

between the rotor and stator members through the clear

22 forming annular reservoirs for ?uid being fed into the

ance 43. In this instance, feed of the ?uid is positive since

brake, as will hereinafter be explained.

A series of radial vanes 34a and 34b, each lying gen 15 the centrifugal pumping of the inner vane portions 49a

of the pump vanes 47 increase the feed pressure sufficiently

erally in an axial plane, are secured around the stator

to overcome the inherent resistance of pressure build-up

walls 31 to form the usual ?uid pockets. The outer por

in the Working chamber of the brake.

tion 35 of each stator vane 34a and 34b lies substantially

in a radial plane. However the inner portion 35a of most

As the ?uid absorbs mechanical energy and transforms

of the vanes terminates above the inner edge of the wall 20 it into heat energy, water heated within the brake chamber

31 so that their converging relationship does not trap or

is discharged through pipe 6, with the rotor itself function

con?ne the ?uid. Certain of the vanes 34b taper back

ing as an impeller to increase the discharge rate.

gradually at 35b so that its radially inner end is spaced

While I have described a preferred embodiment of my

just slightly from the inner annular edge 31a of the stator

invention,

it is apparent that many changes and modi?ca~

25

wall 31.

tions can be made therein without departing from the spirit

Extending through the stator wall 31 is a circumferential

and scope of my invention which is de?ned by the claims

series of nozzles 36 which deliver ?uid from the annular

appended hereto.

manifold reservoir 33 to discharge adjacent to the radial

Having described my invention, I claim:

edge 35 of the stator vanes 34a and 34b. Preferably, each

1. A ?uid brake comprising

30

nozzle 36 is disposed in a plane parallel to the shaft 21

a housing,

and may be angled somewhat in the direction of rotation

to increase the vacuum created by circulation of ?uid

a shaft extending through said housing and rotatable

thereby. Additionally, I may provide a shroud ring 37

therein and adapted to have impressed thereon torque

which it is desired to oppose by braking force,

secured in circumferentially aligned recesses in the stator

vanes 34 to insure proper circulation of the ?uid.

35

The rotor member 4% is keyed to the shaft 21 as at 41

and includes a hub portion or trunnion 42. The rotor

hub 42 is spaced from the inner edge 31a of the stator

wall so as to provide a clearance 43 in direct communica

tion with the annular reservoir 33 so that ?uid may be 40

fed therethrough into the chambers formed between the

rotor and stators. Integral with the rotor hub 42 is the

circular rotor wall 42 terminating in an annular ?ange

45. Between the hub and the ?ange is a circumferential

series of generally radial vanes 46 and 47. Since the

radial vanes naturally converge toward the axis of the

rotor the pockets tend to become more and more re

strictive to the impedance of ?uid circulation. Most of

the vanes 46 have outer radial edges 48 which lie closely

adjacent to the radial edges 35 of the stator vanes but 50

which are tapered back at their inner portions 48a (see

FIGS. 3 and 5) to afford more capacity for freedom of

circulation near the hub portion of the rotor. However,

by terminating the pockets 46a short of the hub a free

smooth, substantially radial surface 50 surrounding the 55

hub 42 is presented to water ?owing radially inward and

a rotor mounted on said shaft within said housing and

having a concave wall of annular form,

a stator Within said housing,

said stator having a concave annular wall spaced axially

from one end of said housing and cooperating with

said rotor annular wall to de?ne a ?uid chamber be

tween said stator annular wall and said rotor annular

wall,

the inner circular edge of said stator annular wall being

spaced radially from said shaft and axially from said

rotor to provide a clearance for ?uid ?ow into the

?uid chamber between said rotor and said stator,

the outer circular edge of said stator annular wall being

spaced axially from said rotor annular wall to afford

?uid ?ow from the ?uid chamber space between said

rotor and said stator;

a conduit from a source of ?uid opening into said

housing between said one end and said stator annular

wall,

a plurality of generally radial vanes carried within each

of said rotor and said stator concave annular walls

to form opposing ?uid pockets,

across in the direction of the arrows in FIG. 2 from the

stator 30. Such a surface rotating at high speeds tends

the radially inner termini of said stator vanes being

to throw ?uids off and circulation is materially impeded.

Therefore, certain of the rotor vanes operate as impeller

a plurality of said rotor vanes having portions thereof

extending axially across said clearance and into the

concavity of said stator annular wall to rotate adja

cent said stator annular wall and said radially inner

blades 4-7.

For example, every ?fth vane, has its outer

radial edges 49 tapering outward at 94a (FIGS. 3 and 4)

to follow the contour of the outer edges 35 of stator vanes

34a and 34b and the entire length of the edges 35, 35b of

the vanes 34]), and, more signi?cantly, to bridge the clear 65

ance 43 between the inner annular edge 31a of the stator

wall 31 and the rotor hub 42 and actually extend into the

axial cross-section area of the stator 30. In this way, the

rotor vanes 47 function as impellers and increase delivery

of ?uid through the clearance 43 under pumping action 70

and to pick up ?uid ?owing from the stator as soon as it

leaves the wall 31 and the vanes 34 to impell it into in

creased circulation.

In operation of my apparatus ?uid (probably water) is

fed to the brake 1 through intake lines 5 by adjusting the

spaced axially from said inner circular edge,

termini, and

a plurality of annularly spaced nozzles extending

through said stator annular Wall affording ?uid com

munication between said ?uid chamber and the space

between said housing one end and said stator annular

wall.

2. In a ?uid brake comprising

a rotatable shaft adapted to have impressed thereon

torque which it is desired to oppose by braking force,

a rotor mounted on said rotatable shaft and carrying

a plurality of vanes which form rotor pockets open

on one side thereof,

8,016,991

5

and a stator carrying a plurality of vanes which form

stator pockets open on one side thereof,

4. In a ?uid brake comprising

a rotatable shaft adapted to have impressed thereon

torque which it is desired to oppose by braking force,

said open sides of said rotor and stator pockets being

positioned opposite each other whereby said rotor

and stator pockets together de?ne a ?uid chamber

of annular form divided by said vanes into pockets,

and

passage means a?ording ?uid discharge from the radi

a rotor mounted on said rotatable shaft and carrying

ally outward portion of said ?uid chamber;

the further combination therewith of

10

a plurality of ?uid conduits positioned in and annularly

spaced around said stator, said conduits opening at

one end into communication with said ?uid chamber

and being connectable at the other end to a source

of ?uid,

15

a ?uid passage into said annular ?uid chamber at the

radially inward portion thereof,

and rotor vane portions adjacent said ?uid passage for

elfecting movement of ?uid through said ?uid passage

into said chamber when said rotor vane portions are 20

in motion.

3. A ?uid brake comprising the combination of

a rotatable shaft adapted to have impressed thereon

torque which it is desired to oppose by braking force,

a rotor mounted on said rotatable shaft and having a 25

wall of concave form with a plurality of vanes therein

whereby rotor pockets open on one side are formed,

a stator having a wall of concave form with a plurality

of stator vanes therein whereby stator pockets open

on one side are formed,

a plurality of vanes which form rotor pockets open

on one side thereof,

and a stator carrying a plurality of vanes which form

stator pockets open on one side thereof,

said open sides of said rotor and stator pockets being

positioned opposite each other whereby said rotor

and stator pockets together de?ne a ?uid chamber

of annular form divided by said vanes into pockets,

and

passage means a?ording ?uid discharge from the radi

ally outward portion of said fluid chamber;

the further combination therewith of

a plurality of ?uid conduits positioned in and annularly

spaced around said stator, said conduits opening at

one end into communication with said ?uid chamber

and being connectable at the other end to a source

of ?uid,

a ?uid passage into said annular ?uid chamber at the

radially inward portion thereof,

and rotor vane portions adjacent said ?uid passage for

effecting movement of ?uid through said ?uid pas

sage into said chamber when said rotor vane portions

are in motion;

at least one of said rotor vanes extending across the

30

said stator pockets and said rotor pockets being posi

line of separation of rotor from stator and into the

portion of said ?uid chamber de?ned by the radially

inward portion of the stator.

tioned opposite each other whereby said concave

walls de?ne a ?uid brake chamber with said vanes

References Cited in the ?le of this patent

therein;

said combination being further characterized by said 35

rotor vanes protruding from the rotor into the con

cavity of said stator wall at the radially inward end

of said stator concavity.

UNITED STATES PATENTS

1,985,889

1,992,911

2,226,558

2,790,518

2,889,013

Mater et a1. __________ __ Jan. 1,

Mater ______________ __ Feb. 26,

Fitzpatrick __________ __ Dec. 31,

Wilson ______________ __ Apr. 30,

Schneider ______________ __ June 2,

1935

1935

1940

1957

1959

Potrebbero piacerti anche

- Scientific American Supplement, No. 365, December 30, 1882Da EverandScientific American Supplement, No. 365, December 30, 1882Nessuna valutazione finora

- Scientific American Supplement, No. 623, December 10, 1887Da EverandScientific American Supplement, No. 623, December 10, 1887Nessuna valutazione finora

- GT LL: NN W///, WM)Documento5 pagineGT LL: NN W///, WM)lfilippiniNessuna valutazione finora

- Buoyancy: The "Hidro" Self-Powered Generator of James KwokDocumento14 pagineBuoyancy: The "Hidro" Self-Powered Generator of James KwokAlboresha RafidNessuna valutazione finora

- 1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpDocumento7 pagine1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpRenier SnymanNessuna valutazione finora

- Once Through Boiler Recirculation PumpDocumento6 pagineOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்Nessuna valutazione finora

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocumento4 pagineSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNessuna valutazione finora

- Carburador de Hidrógeno PatE8Documento7 pagineCarburador de Hidrógeno PatE8Maximo CozzettiNessuna valutazione finora

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Documento4 pagineH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNessuna valutazione finora

- What is a draft tubeDocumento4 pagineWhat is a draft tubeMuhammad Umar100% (1)

- OpenDocumento9 pagineOpenchristian1777Nessuna valutazione finora

- S Chapter 27Documento14 pagineS Chapter 27jesusalbeirourbanoviverosNessuna valutazione finora

- Hydraulic DynamometerDocumento26 pagineHydraulic DynamometerhelderlpNessuna valutazione finora

- Friction clutch control through hydrostatic pressureDocumento4 pagineFriction clutch control through hydrostatic pressurebelchior alvaroNessuna valutazione finora

- Nov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Documento5 pagineNov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Anggara T NugrahaNessuna valutazione finora

- Rotating double shell heat exchange drumDocumento5 pagineRotating double shell heat exchange drumaegosmithNessuna valutazione finora

- Jan-1, 1935 - R. G. de La Mater Er Al 1,985,889Documento8 pagineJan-1, 1935 - R. G. de La Mater Er Al 1,985,889lfilippiniNessuna valutazione finora

- United States Patent: BittnerDocumento8 pagineUnited States Patent: BittneronlyaqmalNessuna valutazione finora

- Charts For Water Hammer in Low Head Pump Discharge PDFDocumento26 pagineCharts For Water Hammer in Low Head Pump Discharge PDFotilem1992Nessuna valutazione finora

- Us 2109297Documento6 pagineUs 2109297lfilippiniNessuna valutazione finora

- Wash and Humidify Air with Early Air Washer DesignDocumento3 pagineWash and Humidify Air with Early Air Washer DesignPriya TiwariNessuna valutazione finora

- 20080012322-Vortex Flow ControlDocumento10 pagine20080012322-Vortex Flow Controlozland9Nessuna valutazione finora

- CE 2040 Hydraulic Engineering Assignment ProblemsDocumento4 pagineCE 2040 Hydraulic Engineering Assignment ProblemsAsh0% (1)

- Rotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowDocumento4 pagineRotor Rim-Ventilated Generator with Turning Vanes for Rotor Inlet Coolant Gas FlowHamedJamshidiNessuna valutazione finora

- Performance of Multi-Layers Coil PumpDocumento15 paginePerformance of Multi-Layers Coil PumpsupermarioprofNessuna valutazione finora

- Us 2409624Documento6 pagineUs 2409624Giovanni BlancoNessuna valutazione finora

- Electrolytic Carburetor Breaks Water Into Hydrogen and Oxygen for FuelDocumento11 pagineElectrolytic Carburetor Breaks Water Into Hydrogen and Oxygen for Fuelmax386Nessuna valutazione finora

- Controlling Pressure in Oil WellsDocumento16 pagineControlling Pressure in Oil WellsluiscremaschiNessuna valutazione finora

- Hydrant system reduces aircraft refueling pressure surgesDocumento4 pagineHydrant system reduces aircraft refueling pressure surgessqmiNessuna valutazione finora

- Water flow calculations and pipe bend forceDocumento4 pagineWater flow calculations and pipe bend force翁shuaiNessuna valutazione finora

- Liquid Control Jet Reduces Pressure Fluctuations in Hydraulic TurbinesDocumento15 pagineLiquid Control Jet Reduces Pressure Fluctuations in Hydraulic TurbinesromeoresigaNessuna valutazione finora

- Clem Engine Paper PresentationDocumento6 pagineClem Engine Paper PresentationDankamialNessuna valutazione finora

- Draft Tube and CavitationDocumento8 pagineDraft Tube and Cavitationasn90100% (1)

- Reciprocating pump flow separation and air vesselsDocumento7 pagineReciprocating pump flow separation and air vesselsAnkush JainNessuna valutazione finora

- June 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951Documento3 pagineJune 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951محمود محمدNessuna valutazione finora

- Measuring Ullage of a Vessel Using Air Pressure DropDocumento6 pagineMeasuring Ullage of a Vessel Using Air Pressure DropAamir Shahzad100% (2)

- Boiler MountingsDocumento15 pagineBoiler MountingsBishwajit MahatoNessuna valutazione finora

- CN205423574 (U) EnglishDocumento2 pagineCN205423574 (U) EnglishGabriel PhilippiNessuna valutazione finora

- Expansion Valve ReportDocumento22 pagineExpansion Valve ReportAniket GunjalNessuna valutazione finora

- July 5, 1966 P. H. Koch 3,259,111 : Filed June 25, 1964Documento3 pagineJuly 5, 1966 P. H. Koch 3,259,111 : Filed June 25, 1964Anonymous KzJcjGCJbNessuna valutazione finora

- Siled Sept. 8, 1966: T, N. NccomeDocumento5 pagineSiled Sept. 8, 1966: T, N. NccomeliNessuna valutazione finora

- Practice Problems Set 3Documento5 paginePractice Problems Set 3Shashwat Singh JamwalNessuna valutazione finora

- Stepless Variable Capacity ControlDocumento7 pagineStepless Variable Capacity Controlswapneel_kulkarniNessuna valutazione finora

- Study Pelton WheelDocumento5 pagineStudy Pelton WheelAnonymous MuYBV2WNessuna valutazione finora

- IMPACT OF A JET ReportDocumento11 pagineIMPACT OF A JET ReportKyra Claire Zaharr100% (6)

- Novel pile extracting device using steel sleeve water-gas injection methodDocumento7 pagineNovel pile extracting device using steel sleeve water-gas injection methodVivek SharmaNessuna valutazione finora

- V-shaped engine cylinder block designDocumento8 pagineV-shaped engine cylinder block designLalit KumarNessuna valutazione finora

- 1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????Documento3 pagine1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????fernando Ancaya AncayaNessuna valutazione finora

- Boiler CirculationDocumento7 pagineBoiler CirculationaruntpeNessuna valutazione finora

- Hyper Valve PatentDocumento15 pagineHyper Valve PatenttonytayicNessuna valutazione finora

- Chapter 2. Hydraulic PumpsDocumento44 pagineChapter 2. Hydraulic PumpsrasolisrNessuna valutazione finora

- CENG 197 - CE Competency Appraisal II Problem Set 3b Fluid Statics 2 - Hydrostatic Forces On Plane and Curved SurfacesDocumento13 pagineCENG 197 - CE Competency Appraisal II Problem Set 3b Fluid Statics 2 - Hydrostatic Forces On Plane and Curved SurfacesApple AterradoNessuna valutazione finora

- Fluid Mechanics ÇENGELDocumento5 pagineFluid Mechanics ÇENGELNameis GhoffarNessuna valutazione finora

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDocumento3 pagineFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNessuna valutazione finora

- Tutorial 1 2014Documento7 pagineTutorial 1 2014sotdeNessuna valutazione finora

- United States Patent: ABSTRACT: Boundary Layer Separation in Surface Ships IsDocumento4 pagineUnited States Patent: ABSTRACT: Boundary Layer Separation in Surface Ships IsArthur HugenNessuna valutazione finora

- Lab Guide - Francis TurbineDocumento14 pagineLab Guide - Francis TurbineBonifacioNessuna valutazione finora

- The Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827Da EverandThe Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827Nessuna valutazione finora

- Scientific American Supplement, No. 611, September 17, 1887Da EverandScientific American Supplement, No. 611, September 17, 1887Nessuna valutazione finora

- EP0159813A2Documento16 pagineEP0159813A2luiscremaschiNessuna valutazione finora

- Us 2749078Documento12 pagineUs 2749078luiscremaschiNessuna valutazione finora

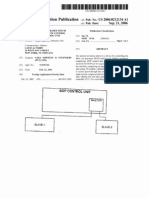

- Us 20060212134Documento9 pagineUs 20060212134luiscremaschiNessuna valutazione finora

- Us 3015975Documento9 pagineUs 3015975luiscremaschiNessuna valutazione finora

- Us 4018276Documento7 pagineUs 4018276luiscremaschiNessuna valutazione finora

- Controlling Pressure in Oil WellsDocumento16 pagineControlling Pressure in Oil WellsluiscremaschiNessuna valutazione finora

- United States Patent (191: RandallDocumento6 pagineUnited States Patent (191: RandallluiscremaschiNessuna valutazione finora

- Controlling Pressure in Oil WellsDocumento16 pagineControlling Pressure in Oil WellsluiscremaschiNessuna valutazione finora

- States Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexDocumento19 pagineStates Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexluiscremaschiNessuna valutazione finora

- USRE37167Documento16 pagineUSRE37167luiscremaschiNessuna valutazione finora

- Us 4018276Documento7 pagineUs 4018276luiscremaschiNessuna valutazione finora

- Us 2749078Documento12 pagineUs 2749078luiscremaschiNessuna valutazione finora

- States Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexDocumento19 pagineStates Atent (191: (11) (45) (54) (75) (73) (21) (22) (51) (52) (53) Assignee: Koomey, Inc., Houston, TexluiscremaschiNessuna valutazione finora

- United States Patent (191: RandallDocumento6 pagineUnited States Patent (191: RandallluiscremaschiNessuna valutazione finora

- Rig-E???': Gill!Documento6 pagineRig-E???': Gill!luiscremaschiNessuna valutazione finora

- Us 3051273Documento7 pagineUs 3051273luiscremaschiNessuna valutazione finora

- Us 3311200Documento10 pagineUs 3311200luiscremaschiNessuna valutazione finora

- Us 20060212134Documento9 pagineUs 20060212134luiscremaschiNessuna valutazione finora

- Us 3319746Documento31 pagineUs 3319746luiscremaschi0% (1)

- Jib TextDocumento36 pagineJib Textluiscremaschi100% (2)

- Principal Crane CapacityDocumento12 paginePrincipal Crane CapacityluiscremaschiNessuna valutazione finora

- F170a 23Documento108 pagineF170a 23luiscremaschi100% (1)

- WSH Manual Marine IndustriesDocumento360 pagineWSH Manual Marine IndustriesluiscremaschiNessuna valutazione finora

- DS350 1318 OperatorsDocumento61 pagineDS350 1318 Operatorsluiscremaschi100% (1)

- Crane 8012 LoadChartDocumento12 pagineCrane 8012 LoadChartluiscremaschiNessuna valutazione finora

- Foster Wheeler Process Engineering Practices IndexDocumento86 pagineFoster Wheeler Process Engineering Practices Indexchemiesm94% (16)

- Greenhouse Effect-QuizDocumento4 pagineGreenhouse Effect-Quizlindsay tanNessuna valutazione finora

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFDocumento321 pagine(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManNessuna valutazione finora

- GRUNDFOS DATA BOOKLET FOR HYDRO MULTI-S BOOSTER SYSTEMSDocumento32 pagineGRUNDFOS DATA BOOKLET FOR HYDRO MULTI-S BOOSTER SYSTEMSHeri SulasionoNessuna valutazione finora

- Installation Instructions: Mico Basic 8.6Documento2 pagineInstallation Instructions: Mico Basic 8.6Servizio TecnicoNessuna valutazione finora

- Solar Air HeaterDocumento2 pagineSolar Air HeaterriyaNessuna valutazione finora

- Chlorosorb Ultra Case StudiesDocumento5 pagineChlorosorb Ultra Case StudiesWitta Kartika RestuNessuna valutazione finora

- 240-56063867 Transformer and Reactor Rapid Pressure Rise RelayDocumento6 pagine240-56063867 Transformer and Reactor Rapid Pressure Rise RelayMichael NgubaneNessuna valutazione finora

- Solex Adj ProcedureDocumento6 pagineSolex Adj Procedureprivate 2Nessuna valutazione finora

- Brazil's ratification adds momentum to Paris climate agreementDocumento3 pagineBrazil's ratification adds momentum to Paris climate agreementlauro sNessuna valutazione finora

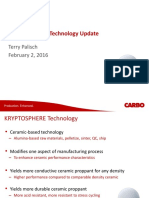

- KRYPTOSPHERE TechnologyDocumento20 pagineKRYPTOSPHERE TechnologySoniale Sánchez GómezNessuna valutazione finora

- 3 Instant Ways To Make Money From People Around You: by Oluwatoyin OmotosoDocumento21 pagine3 Instant Ways To Make Money From People Around You: by Oluwatoyin Omotosoobisesan phillipNessuna valutazione finora

- TSP-408L-1 P/N 32441-002: ApplicationDocumento2 pagineTSP-408L-1 P/N 32441-002: ApplicationSajjad ShamimNessuna valutazione finora

- Utilization of Waste From Rice ProductionDocumento17 pagineUtilization of Waste From Rice ProductionEmilia_P100% (2)

- V. Ganapathy On Calculation of Flue Gas DensityDocumento2 pagineV. Ganapathy On Calculation of Flue Gas DensityRi KoNessuna valutazione finora

- Wind Energy - University QuesDocumento2 pagineWind Energy - University QuesKsn Hari100% (2)

- Energy Manipulation and MeditationDocumento6 pagineEnergy Manipulation and Meditationapi-246292178100% (1)

- IPM 200 Series: Internal Permanent Magnet MotorsDocumento7 pagineIPM 200 Series: Internal Permanent Magnet MotorsLuu JosNessuna valutazione finora

- GH G ConversionDocumento146 pagineGH G ConversionjorgeNessuna valutazione finora

- Symmetry & Crystal StructuresDocumento37 pagineSymmetry & Crystal StructuresNurnajihah Sukimi JiehaNessuna valutazione finora

- Test RDCDocumento88 pagineTest RDCWan SahNessuna valutazione finora

- Yuken HydraulicDocumento24 pagineYuken HydraulicDian Pramadi100% (1)

- VS1-2 Manual PDFDocumento284 pagineVS1-2 Manual PDFJorge InostrozaNessuna valutazione finora

- Torsional Vibration in CrankshaftsDocumento10 pagineTorsional Vibration in Crankshaftscharans100% (4)

- Section 08 - ECD ManagementDocumento75 pagineSection 08 - ECD ManagementRicardo VillarNessuna valutazione finora

- Arcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingDocumento12 pagineArcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingRaajNessuna valutazione finora

- 6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHDocumento22 pagine6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHsrikanthc8550% (2)

- Quality Policy and Quality ObjectivesDocumento2 pagineQuality Policy and Quality ObjectivesrabiulfNessuna valutazione finora

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFDocumento181 pagine320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)