Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CASOSHISTORICOSEURONAVYES301

Caricato da

andradeinsuaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CASOSHISTORICOSEURONAVYES301

Caricato da

andradeinsuaCopyright:

Formati disponibili

EURONAVY S.A.

EURONAVY

REFERENCES

Marine & Offshore

List of relevant projects

and track record

information

June 2008

EURONAVY S.A.

EURONAVY REFERENCE LIST

Marine & Offshore

June 2008

SUMMARY

This document is attaching a list of main offshore and marine industries projects that adopted Euronavy

coating systems (Appendix 1). The listed projects account for more than six million square meters of

steel treated with over four million litres of ES301 solvent-free products since year 2000 only.

Accounting with older marine & offshore projects using ES301 since early 90s, with the dispersed sale of

these products for numerous OEMs and contractors and with the sales for on-shore industrial uses

(including oil & gas and energy industries, steel bridges and other steel structures), Euronavy estimates

that over eleven million square meters of steel have been protected with ES301 systems since this

type of products have been developed.

For each project, the table details the project type and data such as type and dimension (m2) of areas

coated, surface preparation method(s) and year and place of application. These projects include

maintenance & repair, conversion and new building jobs. All the projects used ES301 solvent-free surface

& humidity tolerant coatings as main anticorrosive system. Ultra High Pressure hydroblasting was widely

used as surface preparation method.

Apart from the attached reference list, a summary of the action that took place with Euronavy systems in

some major clients is given.

An ES301-based coating system as been Type Approved as IMO PSPC1 compliant. The IMO PSPC is the

new set of rules for the protective coatings selection and application for ballast tanks at new building

stage. Being one of the first coating systems being Type Approved under such stringent prequalification

rules enables Euronavy to positioning itself in the front row of the marine new building market for

protective coatings. The results of such positioning will surely be reflected in this reference list in a near

future.

IMO PSPC refers to the Resolution MSC.215(82) of IMOs Maritime Safety Committee adopted on 8 December 2006, designated

PERFORMANCE STANDARD FOR PROTECTIVE COATINGS FOR DEDICATED SEAWATER BALLAST TANKS IN ALL TYPES OF

SHIPSAND DOUBLE-SIDE SKIN SPACES OF BULK CARRIERS

Euronavy Tintas Martimas e Industriais S.A.

Estrada Vale de Mulatas, Quinta de S. Francisco

2914-516 Setbal * Portugal

Tel.: (351) 265739440 | Fax: (351) 265702711

sales@euronavy.net | www.euronavy.net

EURONAVY S.A.

EURONAVY REFERENCE LIST

Marine & Offshore

June 2008

US NAVY (USA)

ES301 coating system was one of the few coating systems going through extensive evaluation since

1994, when DoD Department NAVSEA 05M launched a Program aimed to review all blasting and painting

procedures for US Navy and US Coast Guard, in order to improve the service life of traditional coating

protection being applied so far. As a result, NAVSEA has already published extensive new specifications

for coating onboard US Navy and US Cost

Guard ships and is now trying to disseminate

the new standards through the US Navy fleet.

ES301 was approved for the most demanding

areas and is listed in the Advanced Coatings

List by Navsea. ES301 is approved as a 20

years service life coating system for ballast

tanks, is the only system approved for ballast

tanks when hydroblasting is to be used as

surface preparation and is approved by the

most stringent standard for coating

qualification for ships: the MIL-PRF 23236C

standard.

The information regarding the several ships

using ES301 (for ballast tanks, bilges and

other areas where it is approved for use) is

not available. Nevertheless, abundant

technical information and some inspection

reports by independent sources can be

supplied in separate.

PEMEX (MEXICO)

Euronavy products are included in PEMEX Standards &

Specifications for Anticorrosive Protection. Oil rig PSS

Chemul (Mobile, AL, USA, 2005) is a recent example, ES301

system being used for a full refurbishment and life extension

project. Pemex is also using ES301 for general maintenance

onboard ships and offshore platforms in Gulf of Mexico.

PSS Chemul

Euronavy Tintas Martimas e Industriais S.A.

Estrada Vale de Mulatas, Quinta de S. Francisco

2914-516 Setbal * Portugal

Tel.: (351) 265739440 | Fax: (351) 265702711

sales@euronavy.net | www.euronavy.net

EURONAVY S.A.

EURONAVY REFERENCE LIST

Marine & Offshore

June 2008

PETROBRAS AND TRANSPETRO (BRAZIL)

Petrobras tested and

thoroughly evaluated

EURONAVY products.

The result was the

recognition of the

superior performance

of the EURONAVY

products, and it

specification and use

in Petrobras Projects

in USA, Europe,

Singapore, Brazil, and

many other locations

in the world.

(Platforms, Ships,

Equipments, etc.).

More than 4 million

m2 were already

coated with ES301 at

Petrobras and

Transpetro projects.

Petrobras P52 FPU: the hull in the photo was built in Singapore (Keppel Fels) and totally

protected with Euronavy coating systems

Transpetro is the Petrobras-owned oil&gas products transportation company and manages a fleet of

product carriers. Transpetro is using ES301 coating system for a few years

now, mostly for ballast and cargo tanks repair. One good example is the

crude cargo tanks of MT Ataulfo Alves, fully refurbished in 2002 using

MT Cartola cargo tanks, after

hydroblasting and ES301 coating system. An inspection performed in 2008

treatment in 2002

by ABS, more than 5 years after coating application, found the surface in

pristine condition, proving the outstanding performance of Euronavy ES301

coating system for anticorrosive protection.

Euronavy Tintas Martimas e Industriais S.A.

Estrada Vale de Mulatas, Quinta de S. Francisco

2914-516 Setbal * Portugal

Tel.: (351) 265739440 | Fax: (351) 265702711

sales@euronavy.net | www.euronavy.net

EURONAVY S.A.

EURONAVY REFERENCE LIST

Marine & Offshore

June 2008

AKER

Aker Floating Production ASA, a subsidiary

of Aker Group, launched recently his FPSO

conversion program. The first FPSO being

converted by Aker is the Aker Smart 1. This

project started in 2007 at Jurong Shipyard

in Singapore and Euronavy was chosen as

single coating supplier for the hull

Aker Smart 1, deck coating

conversion. Thanks to the ES301 coating

with ES301 after hydroblasting:

tolerance in action.

system, hydroblasting is being used as the

main surface preparation method for this

project. The scope of supply includes

Aker Smart 1

modules fabrication in Malaysia and

Indonesia, apart from the activities in Singapore. The Aker Smart 1

FPSO is due to sail from Singapore in July 2008.

BP

BPs Thunder Horse semisub, offshore in the Gulf of

Mexico, used ES301 system for deck refurbishment. It was

applied in 2006 using UHP hydroblasting as surface

preparation method. The advantage of the system was

well perceived in such a situation: the painting job was

performed during the night, with very high humidity levels.

This humidity tolerance feature, together with the ability

of reaching effective adhesion values over surfaces with

reduced profile of roughness, have been the main causes

for the adoption of ES301 technology.

Euronavy Tintas Martimas e Industriais S.A.

Estrada Vale de Mulatas, Quinta de S. Francisco

2914-516 Setbal * Portugal

Tel.: (351) 265739440 | Fax: (351) 265702711

sales@euronavy.net | www.euronavy.net

Painting at night in the Gulf of

Mexico. Photo and title

extracted from Ken Judice Jrs

article in Coatings & Linings,

Feb07

EURONAVY S.A.

EURONAVY REFERENCE LIST

Marine & Offshore

June 2008

TRANSOCEAN (USA)

Transocean had chosen the ES301 system for the refurbishment of the

tanks of the Discoverer 534 drill ship in 2007 (Sembawang Shipyard,

Singapore), using

hydroblasting as

surface preparation

method. The quality

of the protection after

application (namely

the pull-off tests) and

the quality of

Nordic jack up

technical service from

Euronavy have been

praised by Transoceans project team. Thanks to the

good feedback obtained from the D534 project,

ES301&hydroblasting concept was again chosen for the

Discoverer 534 drill ship

refurbishment of the Seven Seas drill ship in 2008 (again

in Singapore) and for an extensive tank repair job at the

tanks of the Nordic jack up (Malaysia, 2008).

QUEIROZ GALVAO (BRAZIL)

Queiroz Galvao Oleo e Gas is engaged in offshore drilling and oil & gas exploration since the 80s and

started using ES301 system in the 90s, for the repair

of the Alaskan Star oil rig. Today (June 2008) the

Olinda Star (ex-Petrobras P13)

being refurbished in Maua

ES301 coating system, together with hydroblasting

Shipyard, Brazil, May 2008

surface preparation, is being used as main

anticorrosive system for the oil rig Olinda Star

refurbishment project (Maua shipyard, Niteroi, Brazil).

This project is due to completion before the end of

2008 and uses Euronavy systems for all areas of the

platform (tanks, legs, deck, new steel structures, etc).

Discoverer 534 drill ship

Euronavy Tintas Martimas e Industriais S.A.

Estrada Vale de Mulatas, Quinta de S. Francisco

2914-516 Setbal * Portugal

Tel.: (351) 265739440 | Fax: (351) 265702711

sales@euronavy.net | www.euronavy.net

EURONAVY S.A.

EURONAVY REFERENCE LIST

Marine & Offshore

June 2008

HDW (GERMANY) AND PORTUGUESE NAVY

Euronavy coating systems had been

selected for the coating of most of the

areas of the new Type 209PN

submarines for the Portuguese Navy

being built in the HDW shipyard in Kiel,

Germany. Two submarines are now

being built, with a third one as option.

ES301 solvent free coating system is

being use for critical areas and was

submitted to extensive testing in

Germany.

SHIPYARDS

Euronavy coatings had been extensively applied by numerous shipyards world wide. Some examples are

presented below, listed by geographical location. This list is an excellent indication of the dissemination of

Euronavy concept.

North America

South America

Asia

Bender Shipyard (Mobile, USA)

Maua Shipyard (Niteroi, Brazil)

Jurong Shipyard (Singapore)

Atlantic Marine (Mobile, USA)

Brasfels (Angra dos Reis, Brazil)

Keppel Fels (Singapore)

Dynamics (New Iberia, USA)

Sermetal (Rio de Janeiro, Brazil)

Keppel Shipyard (Singapore)

Halifax Shipyard (Canada)

EISA (Rio de Janeiro, Brazil)

Sembawang (Singapore)

Norfolk Navy Shipyard (USA)

Mac Laren (Niteroi, Brazil)

MSE (Malaysia)

San Diego Shipyard (USA)

Bason Shipyard (Vietnam)

Hyundai Vinashin(Vietnam)

Europe

Middle East

Lisnave (Setubal, Portugal)

Dubai Dry Docks (UAE)

HDW (Kiel, Germany)

Asry Shipyard (Bahrein)

Euronavy Tintas Martimas e Industriais S.A.

Estrada Vale de Mulatas, Quinta de S. Francisco

2914-516 Setbal * Portugal

Tel.: (351) 265739440 | Fax: (351) 265702711

sales@euronavy.net | www.euronavy.net

Cam Rahn Shipyard (Vietnam)

Sasebo (Japan)

EURONAVY S.A.

EURONAVY REFERENCE LIST

Marine & Offshore

June 2008

MORE EXAMPLES

Apart from the examples mentioned above, Euronavy is supplying a growing number of marine and

offshore clients. The biggest ever seagoing ballast tank repair, for example, with over 500,000 m2 of steel

being treated since 2003, is being done using ES301 coating system, applied by a Norwegian contractor

and Mobil saw ES301 coating system being applied for the refurbishment of ballast tanks and cargo

tanks of their Zaphiro Producer FPSO, offshore West Africa. Many companies engaged in the supply chain

of marine and offshore projects (OEMs, steel

structures construction yards, etc) are also

joining the list of Euronavy clients at an

increasing pace. Euronavy coating materials

are being shipped to virtually every corner of

the earth, to be used by steel construction

yards in Brazil, Malaysia or Indonesia, valve

manufacturers in Europe or Navy suppliers in

USA or Japan. New clients are being

conquered, like SBM (using ES301 system for

the full refurbishment of two single buoys at

Brasfels shipyard in Brazil). The likes of Rolls

Royce, GE Oil&Gas (Nuovopignone), or

Halliburton are also part of Euronavy list of

clients. Its the Euronavy vision being

increasingly adopted by the marine & offshore

industries.

APPENDIX

The table of Appendix 1 presents detailed data about projects using Euronavy systems. The information

is not exhaustive and includes projects since the year 2000 only.

Euronavy Tintas Martimas e Industriais S.A.

Estrada Vale de Mulatas, Quinta de S. Francisco

2914-516 Setbal * Portugal

Tel.: (351) 265739440 | Fax: (351) 265702711

sales@euronavy.net | www.euronavy.net

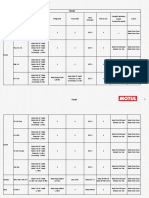

APPENDIX1

REFERENCELISTJUNE2008

MainMarine&OffshoreProjectssinceyear2000

CLIENT

COUNTRY

PROJECT

TYPE

SITE&LOCATION

YEAR

USNAVY&USCOAST

GUARD

USA

Allapplications

Severaltypes

MostlyUSA,Japan,

MidleEast

19942008

USNAVY

USA

USSBelleawWood

AircraftCarrier(repair)

Sasebo,Japan

2000

Ballasttanks

USNAVY

USA

USSDetroit

SupportShip(repair)

NWS,USA

2000

Bilges

TRANSPETRO

BRAZIL

O/OMAFRA

Tanker(repair)

DubaiDryDocks,UAE

2000

BallastTanks.

TRANSPETRO

BRAZIL

N/TNORMA

Tanker

Renavy(Brazil)

2001

TRANSPETRO

BRAZIL

O/OMARAC

Tanker

AsryShipyard(Bahrain)

FPSO

JurongShipyard

(Singapore)

PETROBRAS

BRAZIL

P43

SCOPE

Mostlytanksandbilges

SURFACEPREPARATION

Hydroblasting,abrasive,

powertooling

ESTIMATEDAREAS

(m2)

CONSUMPTION

ES301(Lt.)

300,000

180,000

Hydroblasting

undisclosed

undisclosed

Hydroblasting

undisclosed

undisclosed

Gritblasting

12,500

7,300

CargoTanks.

HydroBlasting

3,600

2,200

2001

BallastTanks.

Gritblasting

8,000

5,300

2002

CargoOilTanks,DieselOilTanksand

DoubleBottoms.

Gritblasting

120,000

70,000

40,000

28,000

13,000

7,000

Hydroblasting

Gritblasting

Hydroblasting

Gritblasting

PETROBRAS

BRAZIL

P17

FSU

Brasfels(Brazil)

2002

Generalmaintenanceandconversion.

TRANSOCEAN

USA

HARVEYWARD

OILRIG

SembawangShipyard

(Singapore)

2002

Drillwatertanks.

TRANSPETRO

BRAZIL

ATAULFOALVES

Tanker

SembawangShipyard

(Singapore)

2002

CargoOilTankBottoms.

Hydroblasting

11,000

5,350

TRANSPETRO

BRAZIL

CARTOLA

Tanker

SembawangShipyard

(Singapore)

2002

CargoOilTankBottoms.

Hydroblasting

11,000

5,200

PETROBRAS

BRAZIL

P43

FPSO

MauaJurong(Brazil)

2003

Modules.

Gritblasting

20,000

14,000

PETROBRAS

BRAZIL

P48

FPSO

Brasfels(Brazil)

2003

Modules.FullAreas.

Gritblasting

550,000

335,000

PETROBRAS

BRAZIL

P40

FPSO

OffshoreBrazil

2003

Maindeck.Onlyprimer.

HydroBlasting

11,000

2,500

PETROBRAS

BRAZIL

P50

FPSO

DinamicShipyard(USA)

2003

Gritblasting

70,000

55,000

PETROBRAS

BRAZIL

P50

FPSO

JurongShipyard

(Singapore)

20032004

650,000

450,000

PETROBRAS

BRAZIL

P47

FPSO

Ultratec(Brazil)

2003

46,000

25,000

PETROBRAS

BRAZIL

P50

FPSO

MauaJurong(Brazil)

20032005

Hydroblasting

180,000

134,000

PEMEX

MXICO

CHEMUL

FPU

BenderShipyard

2004

Gritblasting

80,000

85,000

ModulesPO2A&BandPO3A&B,

equipmentandpiping.

Vessel.

FullArea.

Generalmaintenanceinsidecargo

tanks.

Vessel.Assemblyandrepairs.

FullArea.

Externalhull.FullArea.

Hydroblasting

Gritblasting

Hydroblasting

MechanicalTreat

Appendix 1

Page 1/3

APPENDIX1

REFERENCELISTJUNE2008

MainMarine&OffshoreProjectssinceyear2000

PROJECT

TYPE

SITE&LOCATION

YEAR

TRANSPETRO

BRAZIL

N/TPIRAJUI

Tanker

SELMETALSHIPYARD

2004

BallastTanks.

Hydroblasting

5,000

2,200

PETROBRAS

BRAZIL

PIII

FSO

MauaJurong(Brazil)

2004

Externalhull.FullArea.

Hydroblasting

5,000

3,200

PETROBRAS

BRAZIL

P52

FPU

KeppelFels(Singapore)

20042006

220,000

BRAZIL

P51

FPU

KeppelFels(Singapore)

2005

Hydroblasting

Gritblasting

Hydroblasting

Gritblasting

350,000

PETROBRAS

60,000

48,000

PETROBRAS

BRAZIL

P34

FPSO

GDK(Brazil)

2005

Pontoonandcolumnsbelowmain

deck.FullArea.

Nodesfrompontoon.

FullArea.

Generalmaintenance,skidsfrom

chemicalmodulesandpiping.

Hydroblasting

50,000

30,000

2005

BallastTanks.

Hydroblasting

45,000

31,000

2005

BallastTanks.

Hydroblasting

45,000

29,000

2005

BallastTanks,CargoTanksandHull.

Gritblasting

42,000

30,000

Hull,legs,underdeck.

Hydroblasting

4,500

2,500

Gritblasting

5,000

3,000

410,000

280,000

10,000

6,500

650,000

480,000

900,000

750,000

Gritblasting

200,000

140,000

Gritblasting

100,000

60,000

TRANSPETRO

BRAZIL

M/VBicas

Tanker

TRANSPETRO

BRAZIL

M/VBrotas

Tanker

AULAC

VIETNAM

AulacAngel

Tanker

QUEIROZGALVO

BRAZIL

ALASKASTAR

FPU

OffshoreBrazil

2005

PETROBRAS

BRAZIL

PRA1

FSO

MacLarenShipyard

(Brazil)]

2005

PETROBRAS

BRAZIL

P51

FPU

Brasfels(Brazil)

20052007

PETROBRAS

BRAZIL

P52

FPU

Brasfels(Brazil)

20052006

PETROBRAS

BRAZIL

P54

FPSO

PETROBRAS

BRAZIL

P53

FPU

PETROBRAS

BRAZIL

P53

FPU

PETROBRAS

BRAZIL

P54

FPSO

TRANSOCEAN

USA

DISCOVER534

DRILLSHIP

JurongShipyard

(Singapore)

KeppelShipyardTuas

(Singapore)

EstaleiroRioGrande

(Brazil)

20052006

MauaJurong(Brazil)

20052006

SembawangShipyard

(Singapore)

SembawangShipyard

(Singapore)

20052006

20052008

Ibeamsandpanelsfrommodule.

Moduleassembly.

Pontoon,columns,maindeck,

modulesandequipment.Assembly.

Pontoonandcolumnsbelowmain

deck.Assembly.FullArea.

Vessel.

FullArea.

Vessel.

FullArea.

Modules01,02,03,05,06,07,08,09,

11,12andassembly.

Modules01,02,03,05,06,07,08,09,

11,12andassembly.

SURFACEPREPARATION

CONSUMPTION

ES301(Lt.)

COUNTRY

SembawangShipyard

(Singapore)

SembawangShipyard

(Singapore)

HyundaiVinashin

(Vietname)

SCOPE

ESTIMATEDAREAS

(m2)

CLIENT

Hydroblasting

Gritblasting

Hydroblasting

Gritblasting

Hydroblasting

Gritblasting

Hydroblasting

Gritblasting

2006

Maintenanceoftheentireship.

Hydroblasting

25,000

17,000

2006

BallastTanks,PumpRoomandFore

PeakTank.

Hydroblasting

14,000

7,500

TESMA

INDONESIA

BROTOJOYO

FPSO

TRANSPETRO

BRAZIL

N/TCARIOCA

Tanker

(Argentina)

2006

CargoTanks.

Hydroblasting

4,300

2,600

TRANSPETRO

BRAZIL

N/TPOTI

Tanker

ASRY(Bahrain)

2006

BallastTanks.

Gritblasting

8,000

4,300

Appendix 1

Page 2/3

APPENDIX1

REFERENCELISTJUNE2008

MainMarine&OffshoreProjectssinceyear2000

CLIENT

COUNTRY

PROJECT

TYPE

SITE&LOCATION

YEAR

BP

UK/USA

THUNDERHORSE

OffshoreGulfofMexico

2006

TECO

NORWAY

IranNoah,IranNabi,IranNoor,

IranNessa,IranNajm

FiveVLCCTankers

Seagoing

Since2003

TRANSPETRO

BRAZIL

N/TPIRAJU

Tanker

ASRY(Bahrain)

2007

JurongShipyard

(Singapore)

AKERFLOATING

PRODUCTIONS

NORWAY

AKERSMART1

FPSO

PETROBRAS

BRAZIL

MEXILHAO

GasRig

JURONGSHIPYARD

SINGAPORE

SKIDTRUSS

SupportStructure

TRANSOCEAN

USA

DISCOVERERSEVENSEAS

DRILLSHIP

TRANSOCEAN

USA

NORDIC

JACKUPRIG

PETROBRAS

BRAZIL

GAROUPA

FLOTEL

QUEIROZGALVO

BRAZIL

OLINDASTAR

20072008

BTEngineering(Singapore) 20072008

JurongShipyard

(Singapore)

SembawangShipyard

(Singapore)

SCOPE

Helydeckandstructures.

BallastTanks.

BallastTanks.

VesselFullAreasincludingmodules

andstructures

ModuleandEquipment

SURFACEPREPARATION

ESTIMATEDAREAS

(m2)

CONSUMPTION

ES301(Lt.)

Hydroblasting

16,000

11,000

WetGritBlasting

Hydroblasting

500,000

350,000

Gritblasting

11,500

5,880

Hydroblasting

Gritblasting

400,000

250,000

Gritblasting

20,000

15,000

20072008

Maintenanceofsteelstructure

Hydroblasting

10,000

6,500

20072008

Ballasttanks

Hydroblasting

20,000

10,000

JohorPort(Malaysia)

20072008

Ballasttanks

Hydroblasting

30,000

19,000

OffshoreBrazil

20072008

Fullrefurbishment.

Hydroblasting

44,000

85,000

56,000

FPU

MauaShipyard(Brazil)

20072008

FullAreas.

Hydroblasting

Gritblasting

CamRanhShipyard

(Vietname)

20072008

FullAreas

Gritblasting

110,000

70,000

Brasfels(Brazil)

20072008

Fullrefurbishment.

Hydroblasting

Gritblasting

21,000

16,000

FullAreas(quantitiesuptoJune2008

only)

Gritblasting

16,400

11,800

SHINPETROL

VIETNAM

VSP01

SBM

MONACO

SBMIMODICOSO17480

1e2

Tanker22,500DWT(new

building)

Singlebuoysx2

(refurbishment)

PORTUGUESENAVY

PORTUGAL

SUBMARINES209PN

Submarines(newbuilding)

HDW(Germany)

20062008

TRANSPETRO

BRAZIL

N/TPEDREIRAS

Tanker

ASRY(Bahrain)

2008

BallastTanks.

Gritblasting

8,500

4,340

TRANSPETRO

BRAZIL

N/TBICAS

Tanker

ASRY(Bahrain)

2008

BallastTanks.

Gritblasting

7,000

3,520

Appendix 1

Page 3/3

Potrebbero piacerti anche

- A Funny DayDocumento1 paginaA Funny DayandradeinsuaNessuna valutazione finora

- Bike Julio 2011 - PERUDocumento125 pagineBike Julio 2011 - PERUandradeinsuaNessuna valutazione finora

- Drilled Shaft 2Documento126 pagineDrilled Shaft 2andradeinsuaNessuna valutazione finora

- Ko ZarazDocumento15 pagineKo Zarazspippol0Nessuna valutazione finora

- Technical Manual 1Documento118 pagineTechnical Manual 1Homero Silva100% (14)

- Diseño Pasajuntas 1Documento37 pagineDiseño Pasajuntas 1dorbarel100% (2)

- 4 Elephants Feet FerrulesDocumento17 pagine4 Elephants Feet FerrulesandradeinsuaNessuna valutazione finora

- DabateDocumento1 paginaDabateandradeinsuaNessuna valutazione finora

- FootingsDocumento8 pagineFootingsRebecca LeysonNessuna valutazione finora

- Building A Solid Foundation For Your Mill: Author: Jeff BelkeDocumento5 pagineBuilding A Solid Foundation For Your Mill: Author: Jeff BelkeandradeinsuaNessuna valutazione finora

- Design For Edge Lifting of Precast Concrete PanelsDocumento10 pagineDesign For Edge Lifting of Precast Concrete PanelsandradeinsuaNessuna valutazione finora

- Design Capacity Table - Part 1Documento32 pagineDesign Capacity Table - Part 1andradeinsuaNessuna valutazione finora

- Design For Edge Lifting of Precast Concrete PanelsDocumento10 pagineDesign For Edge Lifting of Precast Concrete PanelsandradeinsuaNessuna valutazione finora

- Technical Manual 1Documento118 pagineTechnical Manual 1Homero Silva100% (14)

- Building A Solid Foundation For Your Mill: Author: Jeff BelkeDocumento5 pagineBuilding A Solid Foundation For Your Mill: Author: Jeff BelkeandradeinsuaNessuna valutazione finora

- Volume ComputationDocumento4 pagineVolume ComputationJackiee1983Nessuna valutazione finora

- NSA - IN Anchorage Seminar 3-11 - 3 SlidesDocumento47 pagineNSA - IN Anchorage Seminar 3-11 - 3 SlidesMohamed AlyNessuna valutazione finora

- 4 Plate With Shear & Anchor BoltsDocumento5 pagine4 Plate With Shear & Anchor BoltsadnanNessuna valutazione finora

- Aisc PernosDocumento4 pagineAisc PernosandradeinsuaNessuna valutazione finora

- Designing Foundations With Piles For Vibrating Machinery: M. Gohnert, I. Luker and C. MorrisDocumento7 pagineDesigning Foundations With Piles For Vibrating Machinery: M. Gohnert, I. Luker and C. MorrisAmir Hooshang Ghadymi MahaniNessuna valutazione finora

- Bike Julio 2011 - PERU PDFDocumento125 pagineBike Julio 2011 - PERU PDFandradeinsuaNessuna valutazione finora

- 12 0002Documento234 pagine12 0002andradeinsuaNessuna valutazione finora

- Seismic Design of Structural Steel Pipe RacksDocumento5 pagineSeismic Design of Structural Steel Pipe Racksandradeinsua0% (1)

- Design of Structural Steel Pipe Racks PDFDocumento12 pagineDesign of Structural Steel Pipe Racks PDFmobin1978100% (3)

- Tabla 137 C0016Documento22 pagineTabla 137 C0016andradeinsuaNessuna valutazione finora

- Full Paper Balint KarolyDocumento8 pagineFull Paper Balint KarolyandradeinsuaNessuna valutazione finora

- Structural Plate Design GuidelinesDocumento100 pagineStructural Plate Design GuidelinesandradeinsuaNessuna valutazione finora

- Abhr Septoct 70 73Documento4 pagineAbhr Septoct 70 73andradeinsuaNessuna valutazione finora

- Technical Manual 1Documento118 pagineTechnical Manual 1Homero Silva100% (14)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 90 250 Single Stage Horizon Domestic PDFDocumento6 pagine90 250 Single Stage Horizon Domestic PDFherrerafaridNessuna valutazione finora

- PT. PANA OIL INSPECTION FORMDocumento1 paginaPT. PANA OIL INSPECTION FORMD Wahyu BawonoNessuna valutazione finora

- Case Study - Loyalty CardDocumento8 pagineCase Study - Loyalty Carddeepakgoyal85Nessuna valutazione finora

- Plate Cooling TechnologyDocumento8 paginePlate Cooling TechnologyVivek SharmaNessuna valutazione finora

- Sample: Insert Company Name/Logo HereDocumento4 pagineSample: Insert Company Name/Logo Herealdi HaldiatnoNessuna valutazione finora

- Cibes Catalogue PDFDocumento31 pagineCibes Catalogue PDFNold AlburoNessuna valutazione finora

- Treasury Report EskomDocumento210 pagineTreasury Report EskomPrimedia Broadcasting100% (2)

- PG&E 500 KV Protection Standard Design and DevelopmentDocumento15 paginePG&E 500 KV Protection Standard Design and DevelopmentSheraz KhanNessuna valutazione finora

- Gotang Primary School science reportDocumento5 pagineGotang Primary School science reportLeonorBagnisonNessuna valutazione finora

- Company Profile Aditya - REVISEDDocumento4 pagineCompany Profile Aditya - REVISEDNandkumar Chinai100% (1)

- Europa Valve Non Slam Check ValvesDocumento16 pagineEuropa Valve Non Slam Check ValvesBryan KellyNessuna valutazione finora

- Flyback SMPS Design GuideDocumento16 pagineFlyback SMPS Design GuideRevathy100% (1)

- Proceedings of National Seminar On Etdg-12Documento189 pagineProceedings of National Seminar On Etdg-12Ayush SagarNessuna valutazione finora

- Case Study: Capacity Expansion For Transportation Project - San Antonio's Project, BoliviaDocumento3 pagineCase Study: Capacity Expansion For Transportation Project - San Antonio's Project, BoliviaMuhammad ImranNessuna valutazione finora

- Dhiraj Kumar: in Project Management/ Maintenance Operations/ Procurement & Vendor ManagementDocumento3 pagineDhiraj Kumar: in Project Management/ Maintenance Operations/ Procurement & Vendor ManagementVikas NarangNessuna valutazione finora

- Saunders S360 Presentation - A4Documento31 pagineSaunders S360 Presentation - A4MeanRatNessuna valutazione finora

- Availablility Based Tariff (ABT) : An OverviewDocumento41 pagineAvailablility Based Tariff (ABT) : An OverviewSamNessuna valutazione finora

- Bhatinda O&m TGDocumento897 pagineBhatinda O&m TGDeepak Gupta100% (2)

- 207D Summary 15 UK S03Documento20 pagine207D Summary 15 UK S03najibNessuna valutazione finora

- Guía de Lubricación de Motos Honda PDFDocumento3 pagineGuía de Lubricación de Motos Honda PDFMartin LabatNessuna valutazione finora

- eNGEL DUODocumento19 pagineeNGEL DUOBudoi Octav-Aurel100% (1)

- XE70 Fan-Coil Thermostats Control SpecsDocumento4 pagineXE70 Fan-Coil Thermostats Control Specsoutlander2008Nessuna valutazione finora

- Can A Pill Extend Life?: October 2007Documento116 pagineCan A Pill Extend Life?: October 2007lyvanhanhNessuna valutazione finora

- Compact Air and Gas Insulated SSDocumento25 pagineCompact Air and Gas Insulated SSPartha Sarathi MannaNessuna valutazione finora

- Marine LED LightsDocumento7 pagineMarine LED LightsSagar TanksaliNessuna valutazione finora

- Saif Power Initial Public OfferingDocumento6 pagineSaif Power Initial Public OfferingDebbie JacobsonNessuna valutazione finora

- Sylvania Guide To Energy Saving Lamps Brochure 1986Documento12 pagineSylvania Guide To Energy Saving Lamps Brochure 1986Alan MastersNessuna valutazione finora

- Canon's CSR Profile and ConflictsDocumento11 pagineCanon's CSR Profile and ConflictsJzevonimher C. EjeraNessuna valutazione finora

- Marnay Et Al 2008 Optimal Technology Selection and Operation of Commercial Building MicrogridsDocumento8 pagineMarnay Et Al 2008 Optimal Technology Selection and Operation of Commercial Building MicrogridselectrotehnicaNessuna valutazione finora

- Controls and Instrument Engineer or Automation Engineer or DcsDocumento3 pagineControls and Instrument Engineer or Automation Engineer or Dcsapi-79252446Nessuna valutazione finora