Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

The Engineer's Companion - Fastener Design Manual, Part Two

Caricato da

Sebastián Castillo MorenoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

The Engineer's Companion - Fastener Design Manual, Part Two

Caricato da

Sebastián Castillo MorenoCopyright:

Formati disponibili

12/8/2015

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

TheEngineer'sCompanion

Home

Ethics

Failures

Fasteners

Innovation

OnJobs

Licensing

PIDTuning

Quality

Rhetoric

AboutRon

WhatEngineersAre

EngineerasHero

FastenerDesignManual,PartTwo

RichBarrett

Washers

BellevilleWashers

Bellevillewashers(Figure12)areconicalwashersusedmoreformaintainingauniformtension

loadonaboltthanforlocking.Iftheyarenotcompletelyflattenedout,theyserveasaspringin

theboltjoint.However,unlesstheyhaveserratedsurfaces,theyhavenosignificantlocking

capability.Thesesurfaces,ontheotherhand,willdamagethematingsurfacesunderthem.

ThesewasherscanbestackedincombinationsasshowninFigure13toeitherincreasethe

totalspringlength(Figure13(a)and(c))orincreasethespringconstant(Figure13(b)).

Lockwashers

ThetypicalhelicalspringwashershowninFigure14ismadeof

slightlytrapezoidalwireformedintoahelixofonecoilsothatthe

freeheightisapproximatelytwicethethicknessofthewasher

crosssection.Lockwashersareusuallymadeofhardenedcarbon

steel,buttheyarealsoavailableinaluminum,silicon,bronze,

phosphorbronzealloy,stainlesssteel,andKMonel.

Figure12.Typesof

Bellevillewashers.(a)

smooth(b)serrated

Thelockwasherservesasaspringwhiletheboltisbeing

tightened.However,thewasherisnormallyflatwhentheboltis

fullytorqued.Atthistimeitisequivalenttoasolidflatwasher,

anditslockingabilityisnonexistent.Insummary,alockwasherofthistypeisuselessfor

locking.

Figure13.Combinations

ofBellevillewashers.(a)

series(b)parallel(c)

parallelseries

Tooth(orStar)Lockwashers

Toothlockwashers(Figure15)areusedwithscrewsandnutsfor

somespringactionbutmostlyforlockingaction.Theteethare

formedinatwistedconfigurationwithsharpedges.Oneedge

bitesintothebolthead(ornut)whiletheotheredgebitesintothe

matingsurface.

Figure14.Helicalspring

washers.

Althoughthiswasherdoesprovidesomelockingaction,it

damagesthematingsurfaces.Thesescratchescancausecrackformationinhighly

stressedfasteners,inmatingparts,orboth,aswellasdecreasedcorrosionresistance.

SelfAligningWashers

Figure15.Tooth

lockwashers.(a)flat(b)

countersunk

Aselfaligningwasherisusedwithamatingnutthathasconical

facesasshowninFigure16.Becausethereisbothaweight

penaltyandaseverecostpenaltyforusingthisnut,itshouldbe

usedonlyasalastresort.Maintainingparallelmatingsurfaces

withinacceptablelimits(twofeet,perSAEHandbook(ref.4))is

normallythebetteralternative.

Inserts

Figure16.Selfaligning

washer.

Aninsertisaspecialtypeof

devicethatisthreadedoninsidediameterandlockedwith

threadsorprotrusionsonoutsidediameterinadrilled,

molded,ortappedhole.Itisusedtoprovideastrong,

wearresistanttappedholeinasoftmaterial(e.g.plastics,

nonferrousmetals),aswellastorepairstrippedthreadsin

atappedhole.

Figure17.Wirethread

insertinstallation.

Theaerospaceindustryusesinsertsintappedholesin

softmaterialsinordertotakeadvantageofweightsavings

providedbysmallhighstrengthfasteners.Thebigger

externalthreadoftheinsert(nominally1/8in.biggerin

diameterthantheinternalthread)gives,forexample,a10

32boltinanequivalent5/1618nut.

Ingeneral,therearetwotypesofinserts:thosethatarethreadedexternally,andthosethatarelockedbysomemethod

otherthanthreads(knurls,serratedsurfaces,grooves,orinterferencefit).Withinthethreadedinsertstherearethree

types:thewirethread,theselftapping,andthesolidbushing.

ThreadedInserts

http://www.designnotes.com/companion/manual2.html

1/8

12/8/2015

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

Wirethread.Thewirethreadtypeofinsert(Helicoil10)(a)isaprecisioncoilofdiamond

shapedCRESwirethatformsbothexternalandinternalthreadsasshowninFigure17.Thecoil

ismadeslightlyoversizesothatitwillhaveaninterferencefitinthetappedhole.Inaddition,

thisinsertisavailablewithadeformedcoil(Figure18)foradditionallocking.Thetangisbroken

offatthenotchafterinstallation.

Thewirethreadinsertisthemostpopulartypeforrepairofatappedholewithstrippedthreads,

sinceitrequirestheleastamountofholeenlargement.However,thesolidbushinginsertis

preferredifspacepermits.

Figure19.Selftapping

inserts.(a)Slotted(b)

Nylok

Figure18.Wirethread

Selftapping.Mostoftheselftappinginsertsarethesolidbushing

inserttypes.(a)free

typemadewithataperedexternalthreadsimilartoaselftapping

running(b)locking

screw(Figure19).Thereareseveraldifferentlocking

combinations,suchastheNylokplug(Figure19(b))orthethread

formingSpeedsertdeformedthread(Figure20).Anadditional

advantageofthethreadforminginsertisthatitgeneratesnocuttingchips,sinceitdoes

notcutthethreads.Itcanonlybeused,however,insoftermaterials.[RexnordSpecialty

FastenersDivision,Torrance,California.]

Solidbushing.Solidbushinginsertshaveconventionalthreads

bothinternallyandexternally.ApopulartypeistheKeensert

[Rexnord]showninFigure21.Thelockingkeysaredriveninafter

theinsertisinplace.Anothermanufacturerusesatwoprongringforlocking.Theseinsertsare

alsoavailablewithdistortedexternalthreadorNylokplugsforlocking.

NonthreadedInserts

Plasticexpandable.Themostfamiliarofthenonthreadedinserts

istheplasticexpandabletypeshowninfigure22.Thisinserthas

barbsontheoutsideandlongitudinalslitsthatallowittoexpand

outwardasthethreadedfastenerisinstalled,pushingthebarbs

intothewallofthedrilledhole.(Seeref.5.)

Figure20.Speedsert.

Moldedinplace.Thistypeofinsert(Figure23)isknurledor

seffatedtoresistbothpulloutandrotation.Itiscommonlyused

withceramics,rubber,andplastics,sinceitcandevelophigher

resistancetobothpulloutandrotationinthesematerialsthanselftappingor

conventionallythreadedinserts.(Seeref.5.)

Ultrasonic.Ultrasonicinserts(Figure24)havegroovesinvarious

directionstogivethemlockingstrength.Theyareinstalledina

preparedholebypushingtheminwhiletheyarebeing

ultrasonicallyvibrated.Theultrasonicvibrationmeltsthewallof

theholelocallysothattheinsertgroovesare"welded"inplace.Sincetheareameltedissmall,

theseinsertsdonothavetheholdingpowerofthosethataremoldedinplace.Ultrasonicinserts

arelimitedtouseinthermoplastics.(Seeref.5.)

Figure21.Keensert.

Threads

TypesofThreadsSincecompleteinformationonmostthreads

canbefoundintheANSIstandards(ref.6),theSAEHandbook

(ref.4),andtheNationalInstituteofStandardsandTechnology

Figure22.Plastic

HandbookH28(ref.7)nothreadstandardswillbeincludedhere.

expandableinsert.

Thegoalhereistoexplainthecommonthreadtypes,alongwith

theiradvantagesanddisadvantages.Thecommonthreadtypes

areunifiednationalcoarse(UNC),unifiednationalfine(UNF),

unifiednationalextrafine(UNEF),UNJC,UNJF,UNR,UNK,andconstantpitchthreads.

Figure23.Moldedinplace

insert.

Unifiednationalcoarse.UNCisthemostcommonlyusedthread

ongeneralpurposefasteners.Coarsethreadsaredeeperthan

finethreadsandareeasiertoassemblewithoutcrossthreading.

Themanufacturingtolerancescanbelargerthanforfinerthreads,

allowingforhigherplatingtolerances.UNCthreadsarenormally

easiertoremovewhencorroded,owingtotheirsloppyfit.

However,aUNCfastenercanbeprocuredwithaclass3(tighter)

fitifneeded(classestobecoveredlater).

Figure24.Ultrasonic

inserts.

Unifiednationalfine.UNFthreadhasalargerminordiameterthanUNCthread,whichgivesUNF

fastenersslightlyhigherloadcarryingandbettertorquelockingcapabilitiesthanUNCfasteners

ofthesameidenticalmaterialandoutsidediameter.Thefinethreadshavetightermanufacturing

tolerancesthanUNCthreads,andthesmallerleadangleallowsforfinertensionadjustment.UNFthreadsarethemost

widelyusedthreadsintheaerospaceindustry.

Unifiednationalextrafine.UNEFisastillfinertypeofthreadthanUNFandiscommontotheaerospacefield.This

threadisparticularlyadvantageousfortappedholesinhardmaterialsandforthinthreadedwalls,aswellasfortapped

holesinthinmaterials.

UNJCandUNJFthreads."J"threadsaremadeinbothexternalandinternalforms.Theexternalthreadhasamuch

largerrootradiusthanthecorrespondingUNC,UNR,UNK,orUNFthreads.Thisradiusismandatoryanditsinspection

isrequired,whereasnorootradiusisrequiredonUNC,UNF,orUNEFthreads.Sincethelargerrootradiusincreasesthe

minordiameter,aUNJForUNJCfastenerhasalargernettensileareathanacorrespondingUNForUNCfastener.This

rootradiusalsogivesasmallerstressconcentrationfactorinthethreadedsection.Therefore,highstrength(180ksior

more)boltsusuallyhave"J"threads.

http://www.designnotes.com/companion/manual2.html

2/8

12/8/2015

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

UNRthreads.TheUNRexternalthreadisarolledUNthreadinallrespectsexceptthattherootradiusmustberounded.

However,therootradiusandtheminordiameterarenotcheckedortoleranced.ThereisnointernalUNRthread.

UNKthreads.TheUNKexternalthreadissimilartoUNR,exceptthattherootradiusandtheminordiameterare

tolerancedandinspected.ThereisnointernalUNKthread.

AccordingtoasurveyofmanufacturersconductedbytheIndustrialFastenersInstitute,nearlyallmanufacturersof

externallythreadedfastenersmakeUNRrolledthreadsratherthanplainUN.Theonlyexceptionisforgroundorcut

threads.

Constantpitchthreads.Thesethreadsofferaselectionofpitchesthatcanbematchedwithvariousdiameterstofita

particulardesign.Thisisacommonpracticeforboltsof1in.diameterandabove,withpitchesof8,12,or16threads

perinchbeingthemostcommon.

AgraphicalandtabularexplanationOfUN,UNR,UNK,andUNJthreadsisgivenonpageM6ofreference8.Acopy

(Figure25)isenclosedhereforreference.AccordingtotheIndustrialFastenersInstitute,"[thefollowing]isnotascrew

threadstandard,shouldnotbeusedasaworkingsheet,andshouldonlyreferthereadertotheproperANSIStandards

documentwhereinthefullthreaddetailsonworkingdataarecontained."

http://www.designnotes.com/companion/manual2.html

3/8

12/8/2015

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

Figure25.ExplanationofUN,UNR,UNK,andUNJthreads.ReprintedwithpermissionofIndustrialFastenersInstitute.

ClassesofThreads

Threadclassesaredistinguishedfromeachotherbytheamountsoftoleranceandallowance.Thedesignationsrunfrom

IAto3AandIBto3Bforexternalandinternalthreads,respectively.AclassIisalooserfitting,generalpurposethread

aclass3istheaerospacestandardthread,andhasatightertolerance.(Theindividualtolerancesandsizesforthe

variousclassesaregivenintheSAEHandbook(ref4).)

FormingofThreads

Threadsmaybecut,hotrolled,orcoldrolled.Themostcommonmanufacturingmethodistocoldformboththehead

andthethreadsforboltsuptooneinchindiameter.Forboltsoflargerdiameterandhighstrengthsmallerbolts,the

headsarehotforged.Thethreadsarestillcoldrolleduntiltheboltsizeprohibitsthematerialdisplacementnecessaryto

formthethreads(uptoaconstantpitchofeightthreadsperinch).Threadsarecutonlyatassemblywithtapsanddies

orbylathecutting.

Coldrollinghastheadditionaladvantageofincreasingthestrengthoftheboltthreadsthroughthehighcompressive

surfacestresses,similartotheeffectsofshotpeening.Thisprocessmakesthethreadsmoreresistanttofatigue

cracking.

FatigueResistantBolts

Ifaboltiscycledintension,itwillnormallybreakneartheendofthethreadedportionbecausethisistheareaof

maximumstressconcentration.Inordertolessenthestressconcentrationfactor,theboltshankcanbemachineddown

totherootdiameterofthethreads.Thenitwillsurvivetensilecyclicloadingmuchlongerthanastandardboltwiththe

shankdiameterequaltothethreadoutsidediameter.

Fatigue(Cyclic)LoadingofBolts

http://www.designnotes.com/companion/manual2.html

4/8

12/8/2015

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

Figure26.Fatigueloadingofbolts.(a)boltedflangeswithexternalload(b)freebodywithnoexternalload(c)freebody

withexternalload

TheboltedjointinFigure26(fromref.9)ispreloadedwithaninitialloadFi,whichequalstheclampingloadFCbeforethe

externalloadFEisapplied.Theequation(fromref.11)forthisassemblyis

FB=Fi+FEKB/(KB+KC)

whereFBisthetotalboltload.InthisequationKBisthespringconstantoftheboltandKCisthespringconstantofthe

clampedfaces.Toseetheeffectsoftherelativespringconstants,letR=KC/KB.Then(fromref.10)

FB=Fi+FE/(1+R)

InanormalclampedjointKCismuchlargerthanKB(R=5.0forsteelboltandflanges),sothattheboltloaddoesnot

increasemuchastheinitialexternalloadisapplied.(NotethattheboltloaddoesnotincreasesignificantlyuntilFE

exceedsFi.)

Aseriesoftriangulardiagrams(Figure27,fromref.11)canbeusedtoclarifytheeffectofexternallyappliedloads.

TriangleOABisidenticalinallfourdiagrams.TheslopeofOArepresentstheboltstiffnesstheslopeofABrepresents

thejointstiffness(jointisstifferthanboltbyratioOC/CB.)InFigure27(a)theexternallyappliedloadFE(a)doesnotload

thebolttoitsyieldpoint.InFigure27(b)theboltisloadedbyFE(b)toitsyieldpoint,withthecorrespondingdecreasein

clampingloadtoFCL.InFigure27(c)theexternalload(c)hascausedthebolttotakeapermanentelongationsuchthat

theclampingforcewillbelessthanFiwhenFE(c)isremoved.InFigure27(d)thejointhascompletelyseparatedonits

waytoboltfailure.NotethattheflattertheslopeofOA(orthelargertheratioOC/OBbecomes),thesmallertheeffectFi

hasonboltload.Therefore,usingmoresmalldiameterfastenersratherthanafewlargediameterfastenerswillgivea

morefatigueresistantjoint.ReferringtoFigure27(a),notethatthecyclic(alternating)loadisthatportionaboveFi.This

isthealternatingload(stress)tobeusedonastressversusloadcyclesdiagramoftheboltmaterialtopredictthe

fatiguelifeofthebolts.NotethataninitialpreloadFineartheboltyieldsminimizescyclicloading.

Figure27.Boltexternalloading.

ThermalCyclicLoadingofBolts

Iftheboltandjointareofdifferentmaterials,anoperatingtemperaturehigherorlowerthantheinstallationtemperature

cancauseproblems.Differentialcontractioncancausethejointtounload(orseparate)differentialexpansioncancause

overloadingofthefasteners.Inthesecasesitiscommonpracticetouseconicalwashers(seewashersectionofthis

manual)togiveadditionaladjustmentsinfastenerandjointloading.

http://www.designnotes.com/companion/manual2.html

5/8

12/8/2015

http://www.designnotes.com/companion/manual2.html

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

6/8

12/8/2015

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

Table4.Coefficientsofstaticandslidingfriction.

Oncoefficientsofstaticandslidingfriction(fromreference12)

a. Oleicacid

1. Campbell,Trans.ASME,1939.

b. Atlanticspindleoil(lightmineral)

2. Clarke,Lincoln,andSterrett,Proc.API,1935.

c. Castoroil

3. BeareandBowden,Phil.Trans.Roy.Soc.,1985.

d. Lardoil

4. Dokos,Trans.ASME,1946.

e. Atlanticspindleoilplus2%oleic

5. BoydandRobertson,Trans.ASME,1945.

acid

6. Sachs,zeitf.angew.Math.AndMech.,1924.

f. Mediummineraloil

7. HondaandYamada,Jour.IofM,1925.

g. Mediummineraloilplus0.5%oleic

8. Tomlinson,Phil.Mag.,1929.

9. Morin,Acad.Roy.desSciences,1838.

10. Claypoole,Trans.ASME,1943.

11. Tabor,Jour.AppliedPhys.,1945.

12. Eyssen,GeneralDiscussiononLubrication,ASME,1937.

13. BrazierandHollandBowyer,GeneralDiscussiononLubrication,

ASME,1937.

acid

h. Stearicacid

i. Grease(zincoxidebase)

j. Graphite

k. Turbineoilplus1%graphite

l. Turbineoilplus1%stearicacid

m. Turbineoil(mediummineral)

14. Burwell,Jour.SAE,1942.

n. Oliveoil

15. Stanton,"Friction",Longmans.

o.

16. ErnstandMerchant,ConferenceonFrictionandSurfaceFinish,MIT,

p. Palmiticacid

1940.

q. Ricinoleicacid

17. Gongwer,ConferenceonFrictionandSurfaceFinish,MIT,1940.

r. Drysoap

18. HardyandBircumshaw,Proc.Roy.Soc.,1925.

s. Lard

19. HardyandHardy,Phil.Mag.,1919.

t. Water

20. BowdenandYoung,Proc.Roy.Soc.,1951.

u. Rapeoil

21. HardyandDoubleday,Proc.Roy.Soc.,1923.

v. 3in1Oil

22. BowdenandTabor,"TheFrictionandLubricationofSolids,"Oxford.

w. Octylalcohol

http://www.designnotes.com/companion/manual2.html

7/8

12/8/2015

TheEngineer'sCompanion/FastenerDesignManual,PartTwo

23. Shooter,Research,4,1951.

x. Triolein

y. 1%lauricacidinparaffinoil

FastenerTorque

Determiningthepropertorqueforafasteneristhebiggestprobleminfastenerinstallation.Someofthemanyvariables

causingproblemsare

1. Thecoefficientoffrictionbetweenmatingthreads

2. Thecoefficientoffrictionbetweenthebolthead(ornut)anditsmatingsurface

3. Theeffectofboltcoatingsandlubricantsonthefrictioncoefficients

4. Thepercentageofbolttensilestrengthtobeusedforpreload

5. Onceagreementisreachedonitem4,howtoaccuratelydeterminethisvalue

6. Relativespringratesofthestructureandthebolts

7. Interactionformulastobeusedforcombiningsimultaneousshearandtensionloadsonabolt(shouldfrictionloadsdue

toboltclampingactionbeincludedintheinteractioncalculations?)

8. Whether"runningtorque"foralockingdeviceshouldbeaddedtothenormaltorque

Gobacktopartone.

Theconscientious,effectiveengineerisavirtuousengineer.SamuelFlorman,TheCivilizedEngineer

TheEngineer'sCompanionisCopyright1995presentbyRonGrahamLastupdated11/14/200817:38:20

rongraham01@gmail.com

http://www.designnotes.com/companion/manual2.html

8/8

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Controls Electrical (ACS) - S630Documento3 pagineControls Electrical (ACS) - S630Luisa RocaNessuna valutazione finora

- Proper Bolt Axial Tightening Force and Proper Tightening TorqueDocumento1 paginaProper Bolt Axial Tightening Force and Proper Tightening TorqueNaufal JuveNessuna valutazione finora

- Gording ConnectionDocumento9 pagineGording ConnectionRicho MSNessuna valutazione finora

- VXN150 Vixion Stand & Footrest PDFDocumento2 pagineVXN150 Vixion Stand & Footrest PDFHarris Jum'aniandaNessuna valutazione finora

- Seat Hardware, Trim, and UpholsteryDocumento66 pagineSeat Hardware, Trim, and UpholsteryKing EwaNessuna valutazione finora

- Tapping ParametersDocumento2 pagineTapping ParametersVlastimir PejićNessuna valutazione finora

- Safe Rigging Handbook - OptimozedDocumento30 pagineSafe Rigging Handbook - OptimozedParthasarathi Dalai90% (20)

- Dimensions of Metric Hex NutsDocumento2 pagineDimensions of Metric Hex Nutsdidik sNessuna valutazione finora

- All Thread ChartsDocumento6 pagineAll Thread ChartsSHANENessuna valutazione finora

- 3265542-J M12 Pe BomDocumento3 pagine3265542-J M12 Pe BomYair CorredorNessuna valutazione finora

- Bolt Shear Strength - MetricDocumento1 paginaBolt Shear Strength - MetricK.S.MAYILVAGHANANNessuna valutazione finora

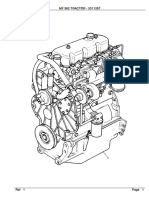

- Massey Ferguson MF 3655 TRACTOR Service Parts Catalogue Manual (Part Number 1637214)Documento21 pagineMassey Ferguson MF 3655 TRACTOR Service Parts Catalogue Manual (Part Number 1637214)qlb898316Nessuna valutazione finora

- Standard Bolt Torques For Imperial and For Metric BoltsDocumento2 pagineStandard Bolt Torques For Imperial and For Metric BoltsDefly GustiNessuna valutazione finora

- Aircraft HardwareDocumento103 pagineAircraft HardwareJuly Tade100% (1)

- Attachment 3 - Bolt Tensioning Task PlanDocumento4 pagineAttachment 3 - Bolt Tensioning Task Planchancele nguepdjopNessuna valutazione finora

- Connections in CLT AssembliesDocumento59 pagineConnections in CLT AssembliesRadekNessuna valutazione finora

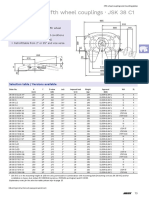

- Heavy Duty - Fifth Wheel Couplings JSK 38 C1: Advantages at A GlanceDocumento2 pagineHeavy Duty - Fifth Wheel Couplings JSK 38 C1: Advantages at A GlanceAhmad setiadiNessuna valutazione finora

- 9802/6220 B1-8-2 Bonnet & SidepanelsDocumento3 pagine9802/6220 B1-8-2 Bonnet & SidepanelsGarcia CruzNessuna valutazione finora

- Stub Achme-6.000-8Documento2 pagineStub Achme-6.000-8ananda_beloshe75Nessuna valutazione finora

- Spare Parts List: Drilling Stand DD-HD 30 AssyDocumento9 pagineSpare Parts List: Drilling Stand DD-HD 30 Assyblinkesku100% (1)

- Nut Washer DimensionsDocumento1 paginaNut Washer DimensionszfrlNessuna valutazione finora

- 02-04-01 Tilt Cylinder (L.H.) (6 Degrees - 10 Degrees, 6 Degrees - 6 Degrees)Documento2 pagine02-04-01 Tilt Cylinder (L.H.) (6 Degrees - 10 Degrees, 6 Degrees - 6 Degrees)Gustavo RodriguezNessuna valutazione finora

- Field Service Manual: Title: Tightening Torque For Cap ScrewsDocumento3 pagineField Service Manual: Title: Tightening Torque For Cap ScrewsPuchit Spk100% (1)

- Cable Glands Cross ReferenceDocumento8 pagineCable Glands Cross ReferenceUrip S. Setyadji100% (1)

- Lista Częśco Neptun MH 4MDocumento45 pagineLista Częśco Neptun MH 4MMirosław MroczkowskiNessuna valutazione finora

- 07 Rawlbolts Plugs Anchors PDFDocumento1 pagina07 Rawlbolts Plugs Anchors PDFRIFASNessuna valutazione finora

- Swing Drive 330LDocumento2 pagineSwing Drive 330LJuan AcostaNessuna valutazione finora

- Massey Ferguson MF 363 TRACTOR Service Parts Catalogue Manual (Part Number 3311357)Documento15 pagineMassey Ferguson MF 363 TRACTOR Service Parts Catalogue Manual (Part Number 3311357)qlb898316Nessuna valutazione finora

- Installation Guide MagFan 3,5 - WebDocumento24 pagineInstallation Guide MagFan 3,5 - Webjack.rendersNessuna valutazione finora

- en 14399 3 2015 e 1 PDFDocumento8 pagineen 14399 3 2015 e 1 PDFPramod WattamwarNessuna valutazione finora