Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Clock and Weather Station

Caricato da

- yAy3e -Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Clock and Weather Station

Caricato da

- yAy3e -Copyright:

Formati disponibili

Nautical Clock and

Weather Station

W hen we decided to move from a wild and windy

part of the coast to a relatively mild hills-and-dales

part of the country, we felt that we wanted to take a lasting

The wonderful thing about a design of this size, type

and character is its flexibility. There are any number of

amazingly exciting options. I say this because, as soon as

memento with us. As we both love the sea, we felt that I had made the sculpted and weathered board, Gill came

we wanted a reminder of our wonderful walks along the up with the beautiful idea of using one of our old mould-

rugged cliffs, of the picnics on the lonely beaches, and of ing planes to create a classic moulded board. Her thinking

the exciting times we had with our many boats. After a was that there must be thousands of woodworkers out

great deal of thought that took in such notions as collect- there who own an old plane and are just looking for an

ing sea shells and the like, it suddenly came to us. Why excuse to tune it up and get started! She also had the

not take a piece of driftwood—perhaps part of an old bright idea that with a more formal board, the various

boat—and turn it into a nautical clock and weather sta- instruments could be arranged so that the board could be

tion? To our way of thinking, the whole project would be mounted vertically or horizontally.

a lasting memento . . . of the beaches, the storms that

smashed up the boats, and the constant need to keep one MAKING THE FOUND WOOD BOARD

eye on the time, tide and weather. This project is slightly unusual in that your found wood

So if you, too, want to make a memento gift that uses needs the minimum of preparation. Okay, it needs to be

a piece of found wood, then this is a great project. clean and the like, but that's about it—no jointing, no

Copyright 2004 Martian Auctions 933

extensive marking out, just three drilled holes and a small much the better. For example, 1 knocked out two rusty

amount of planing and sanding. And, of course, there's old nails and wire brushed the resultant iron-stained holes

no reason why your piece of found wood can't be a branch so that they were big enough to take a piece of found

from a special tree, a part of an old house, a piece of wood rigging cordage, so that the clock and weather station

found in the desert or mountains, or by a river, as long could be hung on the wall.

as it has some particular significance. Use the wire brush to sculpt the form, to extend and

When you have found your piece of wood, set it down exaggerate the actions of nature. You can make contours

on the bench and consider how the instruments might that are rounded and rippled, much the same way as the

best be placed. Are you going to settle for the clock, the wind, rain, sand and sea scour out the soft part of the

thermometer and the hygrometer, (see page 73), or are grain, so that the hard gram and knots are left standing

you going to go for additional instruments like a tube in relief.

barometer or maybe a special tide-time clock? Of course, When you have achieved what you consider is a good

much depends on the size of your piece of found wood. form, use a plane and sandpaper to prepare a level seating

Though I wanted three matching brass dials, with a big enough for the instruments. Aim for a flat smooth

clock having Arabic numerals, I found it impossible to surface that is slightly bigger than the instruments. Make

get a good matchup. As you can see, I had to settle for a sure that there are no nails, grit or other matter in the

slightly nasty white-face clock with Roman numerals. areas that are going to be drilled.

Make sure that the instruments you choose are designed Having cleaned up the seating for the instruments so

to fit into a shallow recess or hole, with the brass surround that it resembles a level plateau, bore the recess holes out

or rim overlapping the edge of the hole. with the Forstner bits. Then seal with a coat of varnish

When you have decided where the instruments are and use beeswax to burnish the whole works to a rich

going to be placed, use a wire brush to scour the grit and sheen finish. Finally, push fit the instruments in the holes,

grime from the workpiece. If you see some part of the

fit the rope or chain, and the project is finished and ready

found wood that could be modified in some way, then so

for hanging.

Copyright 2004 Martian Auctions 934

STEP-BY-STEP STAGES

2 Remove the more obvious bits of rubbish—old

nails, bits of tar, embedded grit and such. Wipe the

wood with a damp cloth and leave it until it is good and

dry.

1 Having found your piece of wood, select a set

of instruments to fit.

3 Not forgetting to wear gloves and goggles, use a

power drill fitted with a wire brush attachment to scour

out the loose grain. The safest procedure is to have the

workpiece either screwed or clamped to the bench.

Copyright 2004 Martian Auctions 935

4 A close-up showing

how I have concent r a t e d

use of the wire brush

along the edges and

around the knots, so that

there is a smooth, level

central area.

5 If you have a drill bit

size that fits the in-

strument, then so much

the better; otherwise, you

have to drill the nearest

size hole. After drilling the

hole, painstakingly file it

to fit. I needed to remove

an all-round strip about

1/8" wide.

Note—as I said earlier

in the project, I don't

much like the clock as

shown. On consideration,

I would much prefer the

l i t t l e watch-clock as

shown in the miniature

mantle clock case project.

Copyright 2004 Martian Auctions 936

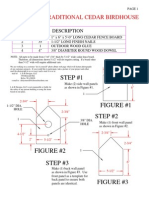

MAKING A TRADITIONAL STEP-BY-STEP STAGES

BEAD-MOULDED BOARD

Having measured and marked out the board and cut it to

size, use the bench plane to bring it to a smooth finish.

When you are happy that the board is square and true,

secure it to the bench so that one long side is hanging

over the edge.

Set your moulding plane up with 3/8"-wide beading

iron. If like me, you are using a single-bead cutter to plane

two beads side by side—a double reed—then adjust the

fence to the position for the bead that is furthest in from

the edge. The procedure is: First cut the bead that is fur-

thest in from the edge. Then reset the fence and cut the

bead nearest the edge. You repeat the procedure for the

other edge of the board.

Finally, having used a block plane to chamfer the ends

of the board, drill out the three large-diameter holes as

already described in step 5.

SPECIAL TIP

If you are looking to bore out clean-sided, flat-bottomed

holes—relatively shallow holes as in this project—then

you can't do better than using Forstner drill bits in con-

junction with a drill press. We use a large Delta bench drill

press. It doesn't wobble, or make odd noises, or require a

great deal of attention. It just gets on with the job. As for

the drill bits, we have a set of Forstner bits made by Freud.

They do a beautiful job every single time. They bore down

through end grain and hard knots, and just about any-

thing we care to throw at them. Best of all, we like the

fact that we can use them to bore out overlapping holes.

Yes, they do cost about twice as much as most bits, but

they last longer, stay sharp and are a pleasure to use.

1 When you have used the plane to cut the two beads

side by side, reset the blade to the very finest of

skimming cuts and burnish the surface of the wood to a

sheen finish. Be careful not to force the pace. Just let the

weight of the plane do the work.

Copyright 2004 Martian Auctions 937

Potrebbero piacerti anche

- Childrens Play StructureDocumento7 pagineChildrens Play Structure- yAy3e -100% (1)

- Children's Bunkhouse LoftDocumento7 pagineChildren's Bunkhouse Loft- yAy3e -100% (3)

- Chest of Drawers 2Documento6 pagineChest of Drawers 2khunchaiyai100% (3)

- CandlelabraDocumento3 pagineCandlelabrakhunchaiyai100% (1)

- Cabinet BathroomDocumento4 pagineCabinet Bathroom- yAy3e -Nessuna valutazione finora

- Crotch-Grained Chess Table: Walnut, PoplarDocumento5 pagineCrotch-Grained Chess Table: Walnut, Poplarkhunchaiyai100% (2)

- Cherry End TableDocumento5 pagineCherry End TablekhunchaiyaiNessuna valutazione finora

- Cappucino BarDocumento3 pagineCappucino Bar- yAy3e -100% (1)

- Chattahoochee ChairDocumento1 paginaChattahoochee Chair- yAy3e -Nessuna valutazione finora

- Chairside BookcaseDocumento3 pagineChairside Bookcasekhunchaiyai100% (2)

- Carved Fruit BowlDocumento5 pagineCarved Fruit Bowlkhunchaiyai100% (1)

- Candle Stands PDFDocumento2 pagineCandle Stands PDFBenivaldo Do Nascimento JuniorNessuna valutazione finora

- Classic Bow SawDocumento6 pagineClassic Bow Saw- yAy3e -Nessuna valutazione finora

- Bungalow MailboxDocumento3 pagineBungalow Mailbox- yAy3e -Nessuna valutazione finora

- Candle BoxDocumento4 pagineCandle Box- yAy3e -Nessuna valutazione finora

- Blanket ChestDocumento3 pagineBlanket ChestkhunchaiyaiNessuna valutazione finora

- Bunk BedsDocumento5 pagineBunk Bedskhunchaiyai100% (4)

- Build A Toy BoxDocumento10 pagineBuild A Toy BoxkhunchaiyaiNessuna valutazione finora

- Book Case 1Documento6 pagineBook Case 1khunchaiyaiNessuna valutazione finora

- Bread BoxDocumento3 pagineBread Box- yAy3e -Nessuna valutazione finora

- Bookcase 2Documento3 pagineBookcase 2mhdridhuanNessuna valutazione finora

- Brydcliffe CabinetDocumento3 pagineBrydcliffe CabinetkhunchaiyaiNessuna valutazione finora

- Bookcase PlansDocumento7 pagineBookcase PlansBrenda LeeNessuna valutazione finora

- Book Case (Mission Style)Documento8 pagineBook Case (Mission Style)khunchaiyai100% (3)

- Bookcase End TableDocumento3 pagineBookcase End Tablekhunchaiyai100% (1)

- Bird House2Documento3 pagineBird House2khunchaiyai100% (1)

- Book Case 2Documento5 pagineBook Case 2khunchaiyai100% (1)

- Bird HouseDocumento3 pagineBird Housekhunchaiyai100% (3)

- Bit ShelfDocumento2 pagineBit Shelf- yAy3e -100% (1)

- Bentwood Box With Snap-Fit Lid: Walnut, Hard MapleDocumento4 pagineBentwood Box With Snap-Fit Lid: Walnut, Hard MaplekhunchaiyaiNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Lorain Schools CEO Finalist Lloyd MartinDocumento14 pagineLorain Schools CEO Finalist Lloyd MartinThe Morning JournalNessuna valutazione finora

- July 4th G11 AssignmentDocumento5 pagineJuly 4th G11 Assignmentmargo.nicole.schwartzNessuna valutazione finora

- Interview Question SalesforceDocumento10 pagineInterview Question SalesforcesomNessuna valutazione finora

- Timoshenko Beam TheoryDocumento8 pagineTimoshenko Beam Theoryksheikh777Nessuna valutazione finora

- Understanding The Self Metacognitive Reading Report 1Documento2 pagineUnderstanding The Self Metacognitive Reading Report 1Ako Lang toNessuna valutazione finora

- Resistance and ResisivityDocumento2 pagineResistance and ResisivityDeddy KismanaNessuna valutazione finora

- Mathematics Specimen Papers and Mark Schemes UG013054Documento102 pagineMathematics Specimen Papers and Mark Schemes UG013054minnie murphy86% (7)

- Tipolo WH Gantt ChartDocumento15 pagineTipolo WH Gantt ChartMayeterisk RNessuna valutazione finora

- Catalogue MinicenterDocumento36 pagineCatalogue Minicentermohamed mahdiNessuna valutazione finora

- Color TheoryDocumento28 pagineColor TheoryEka HaryantoNessuna valutazione finora

- Types of Ego?Documento2 pagineTypes of Ego?S.UdhayakumarNessuna valutazione finora

- Educating The PosthumanDocumento50 pagineEducating The PosthumanCatherine BrugelNessuna valutazione finora

- Educational Leadership Platform PaperDocumento4 pagineEducational Leadership Platform Paperapi-273087939Nessuna valutazione finora

- Big Band EraDocumento248 pagineBig Band Erashiloh32575% (4)

- Njhs Application EssayDocumento4 pagineNjhs Application Essaycjawrknbf100% (2)

- Double Burden of Malnutrition 2017Documento31 pagineDouble Burden of Malnutrition 2017Gîrneţ AlinaNessuna valutazione finora

- I Am Sharing 'Pregnancy Shady' With YouDocumento48 pagineI Am Sharing 'Pregnancy Shady' With YouNouran AlaaNessuna valutazione finora

- AWS S3 Interview QuestionsDocumento4 pagineAWS S3 Interview QuestionsHarsha KasireddyNessuna valutazione finora

- Fire Pump System Test ReportDocumento12 pagineFire Pump System Test Reportcoolsummer1112143100% (2)

- OJT Form 03 Performance EvaluationDocumento2 pagineOJT Form 03 Performance EvaluationResshille Ann T. SalleyNessuna valutazione finora

- Operation Manual 11-3000psi Shear Ram BopDocumento30 pagineOperation Manual 11-3000psi Shear Ram BopBoedi SyafiqNessuna valutazione finora

- About Topsøe - and What We DoDocumento20 pagineAbout Topsøe - and What We DoAbhishek ChaudharyNessuna valutazione finora

- Tender Evaluation Template GuideDocumento15 pagineTender Evaluation Template GuideKhalid NaeemNessuna valutazione finora

- All Types of Switch CommandsDocumento11 pagineAll Types of Switch CommandsKunal SahooNessuna valutazione finora

- EJC H2 Math P1 With Solution PDFDocumento23 pagineEJC H2 Math P1 With Solution PDFKipp SohNessuna valutazione finora

- IntegrityDocumento5 pagineIntegrityPritam Kumar100% (1)

- Case Analysis of CriminologyDocumento12 pagineCase Analysis of CriminologyinderpreetNessuna valutazione finora

- Sustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Documento408 pagineSustaining The Metropolis: LRT and Streetcars For Super Cities, Presented by The Transportation Research Board of The National Academies (Circular E-C177)Randall WestNessuna valutazione finora

- RISO MZ Servicemanual EnglDocumento438 pagineRISO MZ Servicemanual Englkuvalda2000_8645336367% (3)

- Seismic Design Guide (2010)Documento102 pagineSeismic Design Guide (2010)ingcarlosgonzalezNessuna valutazione finora