Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Welding QC 12 - MIG

Caricato da

Exsan OthmanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Welding QC 12 - MIG

Caricato da

Exsan OthmanCopyright:

Formati disponibili

rI

T\{/I

wot

THE \TELDING L\STmJTE

SECTION12

._tI

TWI

w7{

TH: WELDTNG UCS

IT|LT:

ilJ?.i Jlit;:;:'le[

t""::i':::":':'ti"l atte

mpteda]terati

on in arcIensth

i isniricant ;;.;s;';; #; iil i :":l-'"?fl

li,(J:l?.TI:|:;.,.J

i" ?lit J,

aolustlng arc,,.

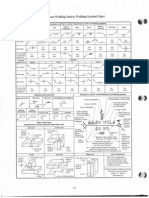

A ',FLAT'ARCpRocESS (CONSTANT)

' VOLTAGE

MErAL'ruE^rno5

lnarcl

f Uii

6un noztl.

6at

y:,,i,1:i:,,".::lylcr;

co,;Metar.ar

sasshielded;CrrlnW

(o9p.r aonlaal

luba

r aonn.clad lo the

toJ.? tupplf unll )

tNatd

Elaatroda rt a

Typjcaldefectsassociated

with this

process:

tncomplete

penetration.

Excessivepenetration.

. Undercut

Co.pI.t.d

J.(d

Type of Operation

Manual,mechanised

or automatic.

Mode of Operation

An arc is maintained

betweenthe end of

b..rg wire electrode

and the *o;k:;"

.lh.u j.d

at.aconsiantspeed,

setectedto

:l: ]:

p]::^l: requiredcurrent,and the

arc

controtJed

Oytir. po*"r-r-or"r"..

,_:i:

n operatoris not

tfrerefore."";;;;.

.r

w-rthcontrollingthe

arc tength

concentrareon depositing and can

ln .the correctmanner_ rn" *"ia i_r"or

#Ji"ffi:rTrbe

opherated

athish

Excessive

spatter.

Cracking.

. Porosity.

.Lack of rusion.

Strayffash.

In mechanisedMIG and submerged

arc welding the process may also

be operatedusing constantcunent

or drooping arc characteristics.

''

;n*retorm

oi-a",;;l:T,ffi:J":1?::",

technique

is confined

.:::T,Tt"T,this

wcrorng

in,rheflatandhorizontal to

ooJriln.

ror vertjcal and

overhead*"ldi";;;;.;r;

j::lY*"1,

techniquesmust De used,

,.e.

transferor pulsedarc.

The

.r.

,.orp'pool

"nj-.

werd

are shieldedby a stream

of gas.

The electrodecan be

solidor fiux cored.

WELDING TECHNOLOGY

Issue 0191

12_1

T\^/I

wof

TT{E WELDTNGTNSTIT TIE

GAS SH I E LDE DMETALARC WELDING

Welding sets

Wbe rec!

Setsare manufactured

in a rangeof sizes,identified

by current,similarto

metatarcwerding'currents.beiow

2o0A;;nrt

fiu" ,aipt.un"r"i"of,"rltion,

suitable for welding

steel only.

Larger sets may have the wire reel and

motor as a separate unit, so it can be

placed near the job. "."T:j:

th: set a_djustouipur vortage and may altow

a

choice of inductance:the wire :l

speed controi wit be on the wire feed unit.

17.2

WEAING TECHNOLOGY

lssue Olgl

:

T\VI

THE WET.DING TNSTTTLJTE

Electricalinput is from singie_phase24OVmains for

sma sets, or three_ohase

''-"

4.15v for rnediumsize upwards. output is a,ways

oc *itn " irit "ripri-"

cnaracteristic(semiautomatic),droopingoutput (mechanised).

Sets often have a built-inholderfor a gas cylinder.

A set will usuallybe suppliedcompletewith a suilablegun:

atso see

'Accessories'

below. Heavy duty guns may be water cooteo,and the

set may

have a water tank and coolingradiatorbuiit in.

Gas noa.k

(opaanr rcnovable)

Vl'se

I nsulating b osslocatinz

nozzla ac

Conua dp

(opaaror rcpbcalbl.)

Swan-ncck

Gaspa.ssage

Trigga switch

Handle

Hose: Onc-piecc or

separae innqs in

Iusc slccve

- Wclding cable

- Wtc condtit

- Gashqc

- Triggo switch conaection

Whenweldingaluminium,

the wireis soft, and tends to kink when pushed

througha hose- a gun carryinga small reel of wire -'reel-on-gun, obviates

this.

WELDING TECHNOLOGY

tssue 0191

1?.3

TWI

WT

-fi

WELDTNG I}.TSTr|IJTE

Sets.whichsupplycurrent.inpulses(at 40_200per second)give

improved

resultson somejobs:as this'purse-MrG'

would

increase

tne

number

of

,synergic,

controls,.anelectronic

controlsystemvariesajl the pafametersin

stepto simplifyadjustments.

Accessories

Weldingcables

set

::_T-e:t:!s

:o

urampsor cltps

l

) simitarto manualmetatarc: one set usuailyinctuded

I

Gun and connecting

hoseassembry

to suit current,usua|ysuppriedwithset;

also see 'spares,below.

Gas regulatorsand hose,connections

to suit.

Vaporiserfor carbondioxidegas on industrialsets.

Cylinderstand

Spares

The followingpartscomeintocontactwith the wire- sparesare needed

to

replaceworn parts,or if wiresizeor type is changed.

Inletand outletguides)

) on driveassembly

Driverolls

)

wre co_nduit

liner- springsteelcoir,rikecurtainwire,for steererectrode

wire,

or plastictubefor aluminium.

Contacttip in gun - needsfairlyfrequentreplacement.

Gas shieldingnozzlefor gun - varioussizesto suitdifferentiobs.

17.4

WELDINGTECHNOLOGY

l

Issue0191

T\ryI

Wg

THE WEI.DINC INSTMJTE ' -

MIG/MAGWELDING

PROCESSCHARACTERTSTICS

The heatsourceusedto mertthe parentmetaris obtainedfrom

an eiectrcarc

whichis formedbetweenthe end of a consumabre

erectrodewireand the

work-piece. The arc mertsthe end of the erectrodewire which

is traisieneo

to the moltenweld pool. The electrodewire is fed from a spool

"

attachedto the wiredrivingsystemand passesthrough...rot il;

roris-'wnicn

are

drivenby a variabrespeederectricmotoi. By varyinglthespeed

oithe motor

we can adjustthe reverof the werdingcurrenl nigi iire reeospeeo-'gives

high

werdingcurrent. The arc rengthcan ajso be varied by aitering

the vo-rtage:

nigh

voltagesgive longerarc lengthsand vice versa.

rn orderto preventthe air reactingchemicallywiththe molten

metara shierding

gas of either CO, or argory'CO2

mi)atureis passedover the weldzone from a

nozzreaftachedto the weldinggun or torch. This protectstire

mortenoroprets

passingacrossthe arc and the moltenweld pool.

Electricalpower for the processis a direct curent which is obtained

from a

transformer-rectifier.The werdinggun or torch is connectedto

po"itiu"

fl.r"

pole of the powersupplyunitand eiectricalcontactto

the wireis.obtainedas

closeto the arc as possibieby meansof a coppercontacttip or

tube.

flrtrde

vin

Cdllocl lip

Shielding

gos

fleld p@(

WELDING TECHNOLOGY

lssue 019l

12.5

T\vI

Ttof

THE \TE[.DIN6 NSTITrJTE

QUESTIONS

MtG MAG AND CO, WELDING

(METALTNERTGAS WELDTNG)

Q1

State the main weldingparametersand variablesof the process.

4\

al

b)

d)

e)

lltt angte

s)

Q2

What polarity is normally used for welding applications ?

Q3

State the modes of transfer

4l

b)

c)

Spraytransfer

d)

Q4

State three (3) items of importancewhen inspectinga wire to be

used for MIG weldino.

05

Whichdefectcan be quitecommonwhenusingthe shortcircuiting

modeof transfef

a)

b)

c)

d)

Lackof penetration

Undercut

Lackof fusion

Porosity

os11

Potrebbero piacerti anche

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- TUBE INSPECTION SOLUTIONS: SELECTION GUIDEDocumento28 pagineTUBE INSPECTION SOLUTIONS: SELECTION GUIDEAkhileshNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- A-Health Advance - Application Form With InstructionsDocumento14 pagineA-Health Advance - Application Form With InstructionsExsan OthmanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDocumento1 paginaApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- PETRONAS Employee Medical Top-Up PlanDocumento2 paginePETRONAS Employee Medical Top-Up PlanExsan OthmanNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Farris Series 2600Documento96 pagineFarris Series 2600johngoff100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- SSI Guideline V3 PDFDocumento34 pagineSSI Guideline V3 PDFSyed Mohd FirdausNessuna valutazione finora

- Senarai Nama Arkitek BerdaftarDocumento150 pagineSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- RFET Technique Detects Local and Gradual DefectsDocumento4 pagineRFET Technique Detects Local and Gradual DefectsExsan OthmanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Farris Valve ManualDocumento11 pagineFarris Valve ManualsumsolcaggNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- AWS Specifications For Filler MaterialDocumento9 pagineAWS Specifications For Filler MaterialExsan OthmanNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- P91 T91 Engl PDFDocumento3 pagineP91 T91 Engl PDFparmodrtkNessuna valutazione finora

- Engineering Your Future PDFDocumento605 pagineEngineering Your Future PDFExsan OthmanNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- MetrodeHandbook - ZavarivanjeDocumento416 pagineMetrodeHandbook - ZavarivanjetonicmiraNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Astm C 871Documento5 pagineAstm C 871Exsan Othman100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Asmt C 795Documento4 pagineAsmt C 795Exsan OthmanNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Astm C 692 PDFDocumento7 pagineAstm C 692 PDFExsan Othman100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- AWS Weld Symbol ChartDocumento1 paginaAWS Weld Symbol ChartExsan OthmanNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Piping CalDocumento13 paginePiping CalglazetmNessuna valutazione finora

- EPA RMP OSHA PSM State Law SummaryDocumento1 paginaEPA RMP OSHA PSM State Law SummaryExsan OthmanNessuna valutazione finora

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Documento6 pagineCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNessuna valutazione finora

- MaterialsDocumento181 pagineMaterialsExsan OthmanNessuna valutazione finora

- Calculation Minimum Required Thickness For Bending Pipe r2Documento11 pagineCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNessuna valutazione finora

- Pipeline DataDocumento4 paginePipeline DataExsan OthmanNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Nozzle Design Tool AnalysisDocumento2 pagineNozzle Design Tool AnalysisArt G. EnziNessuna valutazione finora

- Material CharacteristicsDocumento4 pagineMaterial CharacteristicsExsan OthmanNessuna valutazione finora

- Mechanical Design SpreadsheetDocumento1 paginaMechanical Design SpreadsheetHoney TiwariNessuna valutazione finora

- 300 - F&D Head Design Tool Ver E4.01Documento1 pagina300 - F&D Head Design Tool Ver E4.01Honey TiwariNessuna valutazione finora

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- LH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionsDocumento304 pagineLH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionshadensandorNessuna valutazione finora

- Biology (Paper I)Documento6 pagineBiology (Paper I)AH 78Nessuna valutazione finora

- LAST CARGOES AND CLEANINGDocumento1 paginaLAST CARGOES AND CLEANINGAung Htet KyawNessuna valutazione finora

- Workplace Hazard Analysis ProcedureDocumento12 pagineWorkplace Hazard Analysis ProcedureKent Nabz60% (5)

- Nutrition During PregnancyDocumento8 pagineNutrition During PregnancyHalliahNessuna valutazione finora

- Human Capital FormationDocumento9 pagineHuman Capital Formationtannu singh67% (6)

- Endocrown Review 1Documento9 pagineEndocrown Review 1Anjali SatsangiNessuna valutazione finora

- Acc101Q7CE 5 3pp187 188 1Documento3 pagineAcc101Q7CE 5 3pp187 188 1Haries Vi Traboc MicolobNessuna valutazione finora

- Sub Erna RekhaDocumento2 pagineSub Erna Rekhasurabhi mandalNessuna valutazione finora

- AYUSHMAN BHARAT Operationalizing Health and Wellness CentresDocumento34 pagineAYUSHMAN BHARAT Operationalizing Health and Wellness CentresDr. Sachendra Raj100% (1)

- Mabuhay Wedding Package2006Documento3 pagineMabuhay Wedding Package2006Darwin Dionisio ClementeNessuna valutazione finora

- Job Satisfaction RRLDocumento39 pagineJob Satisfaction RRLMarie Tiffany100% (1)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Aço X6NiCrTiMoVB25!15!2 - 1.4980 Austenitic SteelDocumento2 pagineAço X6NiCrTiMoVB25!15!2 - 1.4980 Austenitic SteelMoacir MachadoNessuna valutazione finora

- Akshaya Trust NgoDocumento24 pagineAkshaya Trust NgodushyantNessuna valutazione finora

- Slaked Lime MSDS Safety SummaryDocumento7 pagineSlaked Lime MSDS Safety SummaryFurqan SiddiquiNessuna valutazione finora

- Carpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesDocumento105 pagineCarpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesVinod KumarNessuna valutazione finora

- Heat Exchanger Sodium SilicateDocumento2 pagineHeat Exchanger Sodium SilicateChristopher BrownNessuna valutazione finora

- The Danger of Microwave TechnologyDocumento16 pagineThe Danger of Microwave Technologyrey_hadesNessuna valutazione finora

- EO On Ban of Fireworks (Integrated)Documento2 pagineEO On Ban of Fireworks (Integrated)Mario Roldan Jr.Nessuna valutazione finora

- Soal Upk B Inggris PKBM WinaDocumento11 pagineSoal Upk B Inggris PKBM WinaCuman MitosNessuna valutazione finora

- Grab Go Porter S 5 ForcesDocumento2 pagineGrab Go Porter S 5 ForcesUtkarsh SharmaNessuna valutazione finora

- Stress and FilipinosDocumento28 pagineStress and FilipinosDaniel John Arboleda100% (2)

- Piping Material Classes GuideDocumento98 paginePiping Material Classes GuideLuis Pottozen VillanuevaNessuna valutazione finora

- Abortion and UtilitarianismDocumento4 pagineAbortion and UtilitarianismBrent Harvey Soriano JimenezNessuna valutazione finora

- 559 Fault CodeDocumento4 pagine559 Fault Codeabdelbagi ibrahim100% (1)

- Micdak BackgroundDocumento3 pagineMicdak Backgroundappiah ernestNessuna valutazione finora

- Rapid Cycling in Bipolar DisorderDocumento1 paginaRapid Cycling in Bipolar Disorderdo leeNessuna valutazione finora

- 7 Surprising Cyberbullying StatisticsDocumento4 pagine7 Surprising Cyberbullying StatisticsJuby Ann Enconado100% (1)

- Laboratorio 1Documento6 pagineLaboratorio 1Marlon DiazNessuna valutazione finora

- Circulatory System Packet BDocumento5 pagineCirculatory System Packet BLouise SalvadorNessuna valutazione finora

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetDa EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetValutazione: 3.5 su 5 stelle3.5/5 (4)

- The Martha Manual: How to Do (Almost) EverythingDa EverandThe Martha Manual: How to Do (Almost) EverythingValutazione: 4 su 5 stelle4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiDa Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiValutazione: 5 su 5 stelle5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!Da EverandCrochet Impkins: Over a million possible combinations! Yes, really!Valutazione: 4.5 su 5 stelle4.5/5 (9)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeDa EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNessuna valutazione finora

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesDa EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesValutazione: 2 su 5 stelle2/5 (12)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastDa EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastValutazione: 5 su 5 stelle5/5 (1)