Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

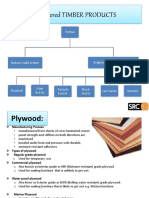

Plywood

Caricato da

sagar pajankarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Plywood

Caricato da

sagar pajankarCopyright:

Formati disponibili

Plywood - Wikipedia, the free encyclopedia

1 of 9

https://en.wikipedia.org/wiki/Plywood

Plywood

From Wikipedia, the free encyclopedia

Plywood is a sheet material manufactured from thin layers

or "plies" of wood veneer that are glued together with

adjacent layers having their wood grain rotated up to 90

degrees to one another. It is an engineered wood from the

family of manufactured boards which includes mediumdensity fibreboard (MDF) and particle board (chipboard).

All plywoods bind resin and wood fibre sheets (cellulose

cells are long, strong and thin) to form a composite material.

This alternation of the grain is called cross-graining and has

several important benefits: it reduces the tendency of wood

to split when nailed at the edges; it reduces expansion and

shrinkage, providing improved dimensional stability; and it

Softwood plywood made from spruce.

makes the strength of the panel consistent across all

directions. There are usually an odd number of plies, so that

the sheet is balancedthis reduces warping. Because plywood is bonded with grains running against one

another and with an odd number of composite parts, it is very hard to bend it perpendicular to the grain direction

of the surface ply.

Smaller thinner plywoods and lower quality plywoods (see Average-quality plywood photo below and right) may

only have their plies (layers) arranged at right angles to each other, though some better quality plywood

products will by design have five plies in steps of 45 degrees (0, 45, 90, 135, and 180 degrees), giving strength in

multiple axes.

Contents

1 History

2 Structural characteristics

3 Types

3.1 Softwood plywood

3.2 Hardwood plywood

3.3 Tropical plywood

3.4 Aircraft plywood

3.5 Decorative plywood (overlaid plywood)

3.6 Flexible plywood

3.7 Marine plywood

3.8 Other plywoods

4 Production

5 Sizes

6 Grades

7 Applications

7.1 Softwood plywood applications

7.2 Hardwood plywood applications

7.3 Tropical plywood applications

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

2 of 9

https://en.wikipedia.org/wiki/Plywood

8 See also

9 References

10 External links

History

In 1797 Samuel Bentham applied for patents covering several machines to produce veneers. In his patent

applications, he described the concept of laminating several layers of veneer with glue to form a thicker piece

the first description of what we now call plywood.[1] Samuel Bentham was a British naval engineer with many

shipbuilding inventions to his credit. Veneers at the time of Bentham were flat sawn, rift sawn or quarter sawn;

i.e. cut along or across the log manually in different angles to the grain and thus limited in width and length.

About fifty years later Immanuel Nobel, father of Alfred Nobel, realized that several thinner layers of wood

bonded together would be stronger than one single thick layer of wood ; understanding the industrial potential of

laminated wood he invented the rotary lathe.

There is little record of the early implementation of the rotary lathe and the subsequent commercialization of

plywood as we know it today, but in its 1870 edition, the French dictionary Robert describes the process of

rotary lathe veneer manufacturing in its entry Droulage.[2] One can thus presume that rotary lathe plywood

manufacture was an established process in France in the 1860s. Plywood was introduced into the United States

in 1865[3] and industrial production started shortly after. In 1928, the first standard-sized 4 ft by 8 ft (1.2 m by

2.4 m) plywood sheets were introduced in the United States for use as a general building material.[1]

Artists use plywood as a support for easel paintings to replace traditional canvas or cardboard. Ready-made

artist boards for oil painting in three-layered plywood (3-ply) were produced and sold in New York as early as

1880.[4]

Structural characteristics

A typical plywood panel has face veneers of a higher grade than the core veneers. The principal function of the

core layers is to increase the separation between the outer layers where the bending stresses are highest, thus

increasing the panel's resistance to bending. As a result, thicker panels can span greater distances under the

same loads. In bending, the maximum stress occurs in the outermost layers, one in tension, the other in

compression. Bending stress decreases from the maximum at the face layers to nearly zero at the central layer.

Shear stress, by contrast, is higher in the center of the panel, and zero at the outer fibres.

Types

Different varieties of plywood exist for different applications:

Softwood plywood

Softwood panel is usually made either of cedar, Douglas fir or spruce, pine, and fir (collectively known as

spruce-pine-fir or SPF) or redwood and is typically used for construction and industrial purposes.[5]

The most common dimension is 1.2 by 2.4 metres (3 ft 11 in 7 ft 10 in) or the slightly larger imperial

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

3 of 9

https://en.wikipedia.org/wiki/Plywood

dimension of 4 feet 8 feet. Plies vary in thickness from 1.4 mm to

4.3 mm. The number of plies depends on the thickness and grade of the

sheet but at least three are required as the minimum odd number of plies.

Roofing can use the thinner 5/8" (15 mm) plywood. Subfloors are at least

3/4" (18 mm) thick, the thickness depending on the distance between

floor joists. Plywood for flooring applications is often tongue and groove;

This prevents one board from moving up or down relative to its neighbor,

so providing a solid feeling floor when the joints do not lie over joists.

T&G plywood is usually found in the 1/2" to 1" (1225 mm) range.

Hardwood plywood

Average-quality plywood with 'show

veneer'

Hardwood plywood is made out of wood from angiosperm trees and used

for demanding end uses. Hardwood plywood is characterized by its

excellent strength, stiffness and resistance to creep. It has a high planar

shear strength and impact resistance, which make it especially suitable

for heavy-duty floor and wall structures. Oriented plywood construction

has a high wheel-carrying capacity. Hardwood plywood has excellent

surface hardness, and damage- and wear-resistance.[6]

Tropical plywood

Tropical plywood is made of mixed species of tropical wood. Originally

from the Asian region, it is now also manufactured in African and South

American countries. Tropical plywood is superior to softwood plywood

due to its density, strength, evenness of layers, and high quality. It is

usually sold at a premium in many markets if manufactured with high

standards. Tropical plywood is widely used in the UK, Japan, United

States, Taiwan, Korea, Dubai, and other countries worldwide. It is the

preferred choice for construction purposes in many regions due to its low

cost. However, many countries forests have been over-harvested,

including the Philippines, Malaysia and Indonesia, largely due to the

demand for plywood production and export.

Aircraft plywood

High-quality concrete pouring plate in

plywood

Birch plywood

High-strength plywood also known as aircraft plywood, is made from mahogany and/or birch, and uses

adhesives with increased resistance to heat and humidity. It was used for several World War II fighter aircraft.

Although the British-built Mosquito bomber, nicknamed "The Wooden Wonder", was constructed of a plywood

monocoque, this was formed in moulds from individual veneers of birch, balsa and birch, rather than machined

from pre-laminated plywood sheets.

Structural aircraft-grade plywood is more commonly manufactured from African mahogany or American birch

veneers that are bonded together in a hot press over hardwood cores of basswood or poplar or from European

Birch veneers throughout . Basswood is another type of aviation-grade plywood that is lighter and more flexible

than mahogany and birch plywood but has slightly less structural strength. Aviation-grade plywood is

manufactured to a number of specifications including those outlined since 1931 in the Germanischer Lloyd

Rules for Surveying and Testing of Plywood for Aircraft and MIL-P-607, the latter of which calls for shear

testing after immersion in boiling water for three hours to verify the adhesive qualities between the plies and

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

4 of 9

https://en.wikipedia.org/wiki/Plywood

meets specifications.

Decorative plywood (overlaid plywood)

Usually faced with hardwood, including ash, oak, red oak, birch, maple, mahogany, Philippine mahogany (often

called lauan, luan or meranti and having no relation to true mahogany), rose wood, teak and a large number of

other hardwoods. However, Formica, metal and resin-impregnated paper or fabric bonded are also added on top

of plywood at both side as a kind of ready for use in the decoration field. This plywood is a lot easier to dye and

draw on than any other plywoods.

Flexible plywood

Flexible plywood is very flexible and is designed for making curved parts. In the UK this is sometimes known as

"Hatters Ply" as it was used to make stovepipe hats in Victorian times . It is also often referred to as "Bendy

Ply" due to its flexibility. However these may not be termed plywood in some countries because the basic

description of plywood is layers of veneered wood laid on top of each other with the grain of each layer

perpendicular to the grain of the next. In the U.S.A, the terms "Bender Board" and "Wiggle Board" are

commonly used.

Marine plywood

Marine plywood is manufactured from durable face and core veneers, with few defects so it performs longer in

both humid and wet conditions and resists delaminating and fungal attack. Its construction is such that it can be

used in environments where it is exposed to moisture for long periods. More recently, tropical producers have

become dominant in the marine plywood market. Okoum from Gabon is now the accepted standard for marine

plywood, even though the wood is not very resistant to rot and decay. Each wood veneer will be from tropical

hardwoods, have negligible core gap, limiting the chance of trapping water in the plywood and hence providing

a solid and stable glue bond. It uses an exterior Water and Boil Proof (WBP) glue similar to most exterior

plywoods.

Marine plywood can be graded as being compliant with BS 1088, which is a British Standard for marine

plywood. There are few international standards for grading marine plywood and most of the standards are

voluntary. Some marine plywood has a Lloyd's of London stamp that certifies it to be BS 1088 compliant. Some

plywood is also labeled based on the wood used to manufacture it. Examples of this are Okoum or Meranti.

Marine plywood is frequently used in the construction of docks and boats. It is much more expensive than

standard plywood: the cost for a typical 4-foot by 8-foot 1/2-inch thick board is roughly $75 to $100 U.S. or

around $2.50 per square foot, which is about three times as expensive as standard plywood.

Other plywoods

Other types of plywoods include fire-retardant, moisture-resistant, wire mesh, sign-grade, and pressure-treated.

However, the plywood may be treated with various chemicals to improve the plywood's fireproofing. Each of

these products is designed to fill a need in industry.

Production

Plywood production requires a good log, called a peeler, which is generally straighter and larger in diameter than

one required for processing into dimensioned lumber by a sawmill. The log is laid horizontally and rotated about

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

5 of 9

https://en.wikipedia.org/wiki/Plywood

its long axis while a long blade is pressed into it, causing a thin layer of wood to peel off (much as a continuous

sheet of paper from a roll). An adjustable nosebar, which may be solid or a roller, is pressed against the log

during rotation, to create a "gap" for veneer to pass through between the knife and the nosebar. The nosebar

partly compresses the wood as it is peeled; it controls vibration of the peeling knife; and assists in keeping the

veneer being peeled to an accurate thickness. In this way the log is peeled into sheets of veneer, which are then

cut to the desired oversize dimensions, to allow it to shrink (depending on wood species) when dried. The sheets

are then patched, graded, glued together and then baked in a press at a temperature of at least 140 C (284 F),

and at a pressure of up to 1.9 MPa (280 psi) (but more commonly 200 psi) to form the plywood panel. The panel

can then be patched, have minor surface defects such as splits or small knot holes filled, re-sized, sanded or

otherwise refinished, depending on the market for which it is intended.

Plywood for indoor use generally uses the less expensive urea-formaldehyde glue, which has limited water

resistance, while outdoor and marine-grade plywood are designed to withstand moisture, and use a water

resistant phenol-formaldehyde glue to prevent delamination and to retain strength in high humidity.

Anti fungal additives such as Xyligen may sometimes be added to the glueline to provide added resistance to

fungal attack.

The adhesives used in plywood have become a point of concern. Both urea formaldehyde and phenol

formaldehyde are carcinogenic in very high concentrations. As a result, many manufacturers are turning to low

formaldehyde-emitting glue systems, denoted by an "E" rating ("E0" possessing the lowest formaldehyde

emissions). Plywood produced to "E0" has effectively zero formaldehyde emissions.[7]

In addition to the glues being brought to the forefront, the wood resources themselves are becoming the focus of

manufacturers, due in part to energy conservation, as well as concern for natural resources. There are several

certifications available to manufacturers who participate in these programs. Programme for the Endorsement of

Forest Certification (PEFC) Forest Stewardship Council (FSC), Leadership in Energy and Environmental Design

(LEED), Sustainable Forestry Initiative (SFI), and Greenguard are all certification programs that ensure that

production and construction practices are sustainable. Many of these programs offer tax benefits to both the

manufacturer and the end user.[8]

Sizes

The most commonly used thickness range is from 0.14 to 3.0 inches (0.36 to 7.62 cm). The sizes of the most

commonly used plywood sheets are 4 by 8 feet (1.2 by 2.4 m). Width and length may vary in 1-foot (30 cm)

increments.

In the United States, the most commonly used size is 4 8 feet (1,200 2,400 mm) or 5 5 feet

(1,500 1,500 mm).[9] A common metric size for a sheet of plywood is 1,220 2,440 millimetres

(4.00 8.01 ft).

Sizes on specialised plywood for concrete-forming can range from 6 to 21 mm (0.24 to 0.83 in), and a multitude

of formats exist, though 157501,500 mm (0.59 inch 2.464.92 ft) is very commonly used.

Aircraft plywood is available in thicknesses of 0.4mm (3 ply construction) and upwards, typically Aircraft

plywood uses veneers of 0.5mm thickness although much thinner veneers such as 0.1mm are also used in

construction of some of the thinner panels.

Grades

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

6 of 9

https://en.wikipedia.org/wiki/Plywood

Grading rules differ according to the country of origin. Most popular standard is the British Standard (BS) and

American Standard (ASTM). Joyce (1970), however, list some general indication of grading rules:[10]

Grade

Description

Face and back veneers practically free from all defects.

A/B

Face veneers practically free from all defects. Reverse veneers with only a few small knots or

discolorations.

A/BB Face as A but reverse side permitting jointed veneers, large knots, plugs, etc.

B

Both side veneers with only a few small knots or discolorations.

B/BB

Face veneers with only a few small knots or discolorations. Reverse side permitting jointed veneers,

large knots, plugs, etc.

BB

Both sides permitting jointed veneers, large knots, plugs, etc.

C/D

For structural plywood, this grade means that the face has knots and defects filled in and the reverse

may have some that are not filled. Neither face is an appearance grade, nor are they sanded smooth.

This grade is often used for sheathing the surfaces of a building prior to being covered with another

product like flooring, siding, concrete, or roofing materials.

WG

Guaranteed well glued only. All broken knots plugged.

Knots, knotholes, cracks, and all other defects permitted.

JPIC Standards

Grade

Description

Face as BB, back as CC. BB as very little knots of less than 1/4 inches, slight discoloration, no decay,

BB/CC split and wormholes mended skillfully, matched colors, no blister, no wrinkle. Most popular choice for

most applications.

Applications

Plywood is used in many applications that need high-quality, high-strength sheet material. Quality in this context

means resistance to cracking, breaking, shrinkage, twisting and warping.

Exterior glued plywood is suitable for outdoor use, but because moisture affects the strength of wood, optimal

performance is achieved in end uses where the wood's moisture content remains relatively low. On the other

hand, subzero conditions don't affect plywood's dimensional or strength properties, which makes some special

applications possible.

Plywood is also used as an engineering material for stressed-skin applications. It has been used for marine and

aviation applications since WWII. Most notable is the British de Havilland Mosquito bomber, which was

primarily made using a moulded sandwich of two layers of birch plywood around a balsa core. Plywood was

also used for the hulls in the hard-chine Motor Torpedo Boats (MTB) and Motor Gun Boats (MGB) built by the

British Power Boat Company and Vosper's. Plywood is currently successfully used in stressed-skin applications.

The American designers Charles and Ray Eames are known for their plywood-based furniture, as is Finnish

Architect Alvar Aalto and his firm Artek, while Phil Bolger has designed a wide range of boats built primarily of

plywood. Jack Kper of Cape Town designed the plywood Dabchick sailing dinghy, which as of 2015 is still

sailed by large numbers of teenagers.

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

7 of 9

https://en.wikipedia.org/wiki/Plywood

Plywood is often used to create curved surfaces because it can easily bend with the grain. Skateboard ramps

often utilize plywood as the top smooth surface over bent curves to create transition that can simulate the

shapes of ocean waves.

Softwood plywood applications

Typical end uses of spruce plywood are:

Floors, walls and roofs in home constructions

Wind bracing panels

Vehicle internal body work

Packages and boxes

Fencing

There are coating solutions available that mask the prominent grain structure of spruce plywood. For these

coated plywoods there are some end uses where reasonable strength is needed but the lightness of spruce is a

benefit e.g.:

Concrete shuttering panels

Ready-to-paint surfaces for constructions

Hardwood plywood applications

Phenolic resin film coated (Film Faced) plywood is typically used as a ready-to-install component e.g.:

Panels in concrete form work systems

Floors, walls and roofs in transport vehicles

Container floors

Floors subjected to heavy wear in various buildings and factories

Scaffolding materials

("Wire" or other styles of imprinting available for better traction)

Birch plywood is used as a structural material in special applications e.g.:

Wind turbine blades

Insulation boxes for liquefied natural gas (LNG) carriers

Smooth surface and accurate thickness combined with the durability of the material makes birch plywood a

favorable material for many special end uses e.g.:

High-end loud speakers

Die-cutting boards

Supporting structure for parquet

Playground equipment

Furniture

Signs and fences for demanding outdoor advertising

Musical instruments

Sports equipment

Tropical plywood applications

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

8 of 9

https://en.wikipedia.org/wiki/Plywood

Tropical plywood is widely available from the South-East Asia region, mainly from Malaysia and Indonesia.

Tropical plywood boasts premium quality, and strength. Depending on machinery, tropical plywood can be made

with high accuracy in thickness, and is a highly preferable choice in America, Japan, Middle East, Korea, and

other regions around the world.

Common plywood

Concrete panel

Floor base

Structure panel

Container flooring

Lamin board

Laminated veneer lumber (LVL)

See also

BS 1088

Engineered wood

Fiberboard

Glued laminated timber

Hardboard

Masonite

Medium-density fiberboard

Oriented strand board

Particle board

Pressed wood

Wikimedia Commons has

media related to Plywood.

References

1. "Plywood" (http://www.answers.com/topic/plywood). Gale's How Products are Made. The Gale Group Inc.

Retrieved 26 November 2013.

2. "Drouler" (http://historique.fracademic.com/18379d%C3%A9rouler). Le Robert historique de la langue

franaise. Dictionnaires Robert. Retrieved 26 November 2013.

3. "Plywood" (http://www.answers.com/topic/plywood). Columbia Encyclopedia. Retrieved 26 November 2013.

4. Muller, Norman E. "An early example of a plywood support for painting" (http://www.jstor.org/discover/10.2307

/3179496?uid=3738016&uid=2129&uid=2&uid=70&uid=4&sid=21102998036157). Journal of the American

Institute for Conservation. American Institute for Conservation of Historic and Artistic Works. Retrieved

26 November 2013.

5. O'Halloran, p. 221.

6. Handbook of Finnish plywood, Finnish Forest Industries Federation, 2002, ISBN 952-9506-63-5 [1]

(http://www.forestindustries.fi/infokortit/handbookplywood/Documents/HandbookOfFinnishPlywood.pdf)

7. Engineered Wood Products Association of Australasia (http://www.ewp.asn.au/newsandmedia/downloads

/media_release_-_formaldehyde_emissions.pdf). (PDF). Retrieved on 2012-02-10.

8. Pro Woodworking Tips.com (http://www.prowoodworkingtips.com/Plywood.html). Pro Woodworking Tips.com.

Retrieved on 2012-02-10.

9. Metric conversions, Canadian government publication (http://www.cps.gov.on.ca/english/plans/E9000/9011/M9011L.pdf). (PDF). Retrieved on 2012-02-10.

10. Joyce, Ernes. 1970. The Technique of Furniture Making. London: B. T. Batsford Limited.

External links

8/11/2015 3:50 PM

Plywood - Wikipedia, the free encyclopedia

9 of 9

APA The Engineered Wood Association

(http://www.apawood.org/level_b.cfm?content=prd_ply_main)

Material Uses (http://www.prowoodworkingtips.com

/Material_Uses_Index.html) Pro Woodworking Tips.com

Canadian Plywood Association (http://www.canply.org/english/)

Plywood (http://www.technologystudent.com/joints/plywood1.html)

https://en.wikipedia.org/wiki/Plywood

Look up plywood in

Wiktionary, the free

dictionary.

Retrieved from "https://en.wikipedia.org/w/index.php?title=Plywood&oldid=675396794"

Categories: Plywood Engineered wood Composite materials

This page was last modified on 10 August 2015, at 09:41.

Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may

apply. By using this site, you agree to the Terms of Use and Privacy Policy. Wikipedia is a registered

trademark of the Wikimedia Foundation, Inc., a non-profit organization.

8/11/2015 3:50 PM

Potrebbero piacerti anche

- Particle Board and Hardboard: Pergamon Series of Monographs on Furniture and TimberDa EverandParticle Board and Hardboard: Pergamon Series of Monographs on Furniture and TimberValutazione: 5 su 5 stelle5/5 (1)

- Wood Product (Interior Design)Documento36 pagineWood Product (Interior Design)trupti0% (1)

- Particle BoardDocumento4 pagineParticle BoardAssassin's j :uNessuna valutazione finora

- Fiber Board & Particle Board: Presented by - Azleen KaziDocumento31 pagineFiber Board & Particle Board: Presented by - Azleen KaziRUSHALI SRIVASTAVA100% (1)

- PlywoodDocumento50 paginePlywoodNeha Agrawal83% (12)

- What Is VeneerDocumento45 pagineWhat Is Veneeraliyah khalidNessuna valutazione finora

- MDF (Medium Density Fibreboard) Made by A Process Which Glues WoodDocumento3 pagineMDF (Medium Density Fibreboard) Made by A Process Which Glues WoodJensenNessuna valutazione finora

- Veneers and LaminatesDocumento31 pagineVeneers and LaminatesVijaya Ratna MNessuna valutazione finora

- Market Sorvey On PlywoodDocumento19 pagineMarket Sorvey On PlywoodEduardo MafraNessuna valutazione finora

- Plywood ManufacturingDocumento11 paginePlywood ManufacturingNeeraj Kamboj100% (2)

- Particle BoardDocumento15 pagineParticle BoardYadhu Sankar100% (1)

- GCSE Woods Paper & Card TheoryDocumento6 pagineGCSE Woods Paper & Card TheoryMissparish8Nessuna valutazione finora

- BT5 - WoodsDocumento34 pagineBT5 - WoodsHatdugNessuna valutazione finora

- Construction Materials: Interior Design 2Nd Semester 9782134439/9024262644Documento45 pagineConstruction Materials: Interior Design 2Nd Semester 9782134439/9024262644DARSHAN SAVSAIYANessuna valutazione finora

- Wood AnatomyDocumento73 pagineWood AnatomyJay_ntNessuna valutazione finora

- Plywood ManufacturingDocumento32 paginePlywood ManufacturingRichner Juan100% (1)

- Special Woods and Wood AlternativesDocumento61 pagineSpecial Woods and Wood AlternativesnadiajmiNessuna valutazione finora

- Wood JointsDocumento2 pagineWood JointsRosalinda AtunNessuna valutazione finora

- LaminatesDocumento20 pagineLaminatesSandi Prashanth ReddyNessuna valutazione finora

- VeneersDocumento23 pagineVeneersyashaswini100% (2)

- Plywood ManufacturingDocumento54 paginePlywood Manufacturingarcha agrawalNessuna valutazione finora

- Roof TileDocumento10 pagineRoof TileAshutosh PrateekNessuna valutazione finora

- Wood JointsDocumento34 pagineWood JointsJefforyNessuna valutazione finora

- Learn Everything About Plywood - Bonito DesignsDocumento8 pagineLearn Everything About Plywood - Bonito DesignsFiky SanjayaNessuna valutazione finora

- Wooden (Disambiguation) Heartwood (Disambiguation) Woodland Commodity Lumber Wood (Disambiguation)Documento19 pagineWooden (Disambiguation) Heartwood (Disambiguation) Woodland Commodity Lumber Wood (Disambiguation)Ashutosh OjhaNessuna valutazione finora

- Plywood User's GuideDocumento6 paginePlywood User's Guidejindi100% (16)

- Engineered TIMBER PRODUCTSDocumento9 pagineEngineered TIMBER PRODUCTSAr Ayoushika Abrol0% (1)

- AHEC-India Wood Sector Market Study-2016reduced 550865 7Documento44 pagineAHEC-India Wood Sector Market Study-2016reduced 550865 7Aijaz Haider Hussaini100% (1)

- Wooden Windows CatalogueDocumento17 pagineWooden Windows CatalogueVIJAY VATSALNessuna valutazione finora

- Wood Plastic CompositesDocumento12 pagineWood Plastic CompositesMadhusudhan SrinivasNessuna valutazione finora

- Introduction To Plywood IndustryDocumento9 pagineIntroduction To Plywood IndustryShakeel AhamedNessuna valutazione finora

- Furniture SpecsDocumento57 pagineFurniture SpecsShandy PrimadaniNessuna valutazione finora

- Capentry and JoineryDocumento5 pagineCapentry and JoineryKunbi Santos-ArinzeNessuna valutazione finora

- Wood Technology Design Form 1 4 MinDocumento91 pagineWood Technology Design Form 1 4 MinTanaka Mudekwe100% (1)

- Wood Preservation - 101Documento37 pagineWood Preservation - 101melanioNessuna valutazione finora

- Plywood Manufacturing ProcessDocumento40 paginePlywood Manufacturing Processanon_61481338750% (2)

- Furniture Materials and CharacteristicsDocumento2 pagineFurniture Materials and CharacteristicsKathleen Anne CabreraNessuna valutazione finora

- Powerpoint of Plywood ManufacturingDocumento33 paginePowerpoint of Plywood Manufacturingmikogonzalve100% (4)

- WOOD Part 1Documento83 pagineWOOD Part 1Elaiza Ann TaguseNessuna valutazione finora

- Soft Toys MakingDocumento3 pagineSoft Toys MakingRahul ChauhanNessuna valutazione finora

- Timber ConversionDocumento15 pagineTimber ConversionAsitha Rathnayake100% (1)

- Some Market Trends of Wood Products Exports in Ghana and Their Implications For Stakeholders PDFDocumento8 pagineSome Market Trends of Wood Products Exports in Ghana and Their Implications For Stakeholders PDFRichard Nkosuo AcquahNessuna valutazione finora

- Wood Composite SeminarDocumento25 pagineWood Composite SeminarsriNessuna valutazione finora

- Wood PPT (Material)Documento12 pagineWood PPT (Material)pratiksha singhNessuna valutazione finora

- Lumber Grading ChartDocumento2 pagineLumber Grading ChartKeith BibelhausenNessuna valutazione finora

- TimberDocumento93 pagineTimberHarshita MittalNessuna valutazione finora

- UNIT - IV CarpentryDocumento14 pagineUNIT - IV CarpentryAjay SonkhlaNessuna valutazione finora

- Comfort in A Morris Chair: Craftsman-StyleDocumento5 pagineComfort in A Morris Chair: Craftsman-Stylegromov.kirill1Nessuna valutazione finora

- Miscellaneous Materials PDFDocumento10 pagineMiscellaneous Materials PDFPriyanka BasuNessuna valutazione finora

- Indroduction To CarpentryDocumento9 pagineIndroduction To CarpentryArun Pravin APNessuna valutazione finora

- Module 5 Compressive and Flexural Strength of Wood NewDocumento31 pagineModule 5 Compressive and Flexural Strength of Wood NewEUREKA JANAH MENDOZANessuna valutazione finora

- Identify The Available Construction Materials in The Laboratory On The Basis of Their SourceDocumento32 pagineIdentify The Available Construction Materials in The Laboratory On The Basis of Their SourceR 34 Arya RoyNessuna valutazione finora

- Wallpaper and VeneerDocumento6 pagineWallpaper and VeneerYogirajsinh GohilNessuna valutazione finora

- Timber and Industrial TimberDocumento140 pagineTimber and Industrial TimberKinjal Harpavat100% (1)

- Builders Guide To PlywoodDocumento12 pagineBuilders Guide To PlywoodNiallburke100% (1)

- IKEA in IndiaDocumento23 pagineIKEA in IndiaTang GuanxinNessuna valutazione finora

- Plywood PDFDocumento4 paginePlywood PDFaulad999Nessuna valutazione finora

- Plywood - Wikipedia, The Free EncyclopediaDocumento9 paginePlywood - Wikipedia, The Free EncyclopediaApoorva JainNessuna valutazione finora

- PlywoodsDocumento23 paginePlywoodsNavya ShreeNessuna valutazione finora

- Plywood Is A Type of Manufactured Wood Made From Thin Sheets of WoodDocumento4 paginePlywood Is A Type of Manufactured Wood Made From Thin Sheets of WoodSarinKumarNessuna valutazione finora

- DarjeelingDocumento7 pagineDarjeelingsagar pajankarNessuna valutazione finora

- Chennai Super KingsDocumento38 pagineChennai Super Kingssagar pajankarNessuna valutazione finora

- Great Wall Motors Company LimitedDocumento10 pagineGreat Wall Motors Company Limitedsagar pajankarNessuna valutazione finora

- Hitman Hitman Is An Episodic Stealth Video Game Developed by IODocumento13 pagineHitman Hitman Is An Episodic Stealth Video Game Developed by IOsagar pajankarNessuna valutazione finora

- SamsungDocumento26 pagineSamsungsagar pajankarNessuna valutazione finora

- Colored PencilDocumento4 pagineColored Pencilsagar pajankarNessuna valutazione finora

- Bajirao IDocumento9 pagineBajirao Isagar pajankarNessuna valutazione finora

- 8 Qualities That Make Great Bosses Unforgettable: Jeff HadenDocumento22 pagine8 Qualities That Make Great Bosses Unforgettable: Jeff Hadensagar pajankarNessuna valutazione finora

- CrayonDocumento11 pagineCrayonsagar pajankarNessuna valutazione finora

- Oil Paint: Oil Paint Is A Type of Slow-Drying Paint That ConsistsDocumento5 pagineOil Paint: Oil Paint Is A Type of Slow-Drying Paint That Consistssagar pajankarNessuna valutazione finora

- QuatroDocumento1 paginaQuatrosagar pajankarNessuna valutazione finora

- DodgeballDocumento6 pagineDodgeballsagar pajankarNessuna valutazione finora

- ChocolateDocumento20 pagineChocolatesagar pajankarNessuna valutazione finora

- Www.engineershandbook.comDocumento3 pagineWww.engineershandbook.comsagar pajankarNessuna valutazione finora

- Supreme Court of The United StatesDocumento296 pagineSupreme Court of The United StatesABC News PoliticsNessuna valutazione finora

- Mobile Based IVR SystemDocumento17 pagineMobile Based IVR SystemIndraysh Vijay [EC - 76]Nessuna valutazione finora

- CH 2 Nature of ConflictDocumento45 pagineCH 2 Nature of ConflictAbdullahAlNoman100% (2)

- Sign Language To Speech ConversionDocumento6 pagineSign Language To Speech ConversionGokul RajaNessuna valutazione finora

- Lecture 1Documento11 pagineLecture 1Taniah Mahmuda Tinni100% (1)

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Documento7 pagineAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudNessuna valutazione finora

- Descriptive Statistics - SPSS Annotated OutputDocumento13 pagineDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHINessuna valutazione finora

- PanasonicDocumento35 paginePanasonicAsif Shaikh0% (1)

- CPE Cisco LTE Datasheet - c78-732744Documento17 pagineCPE Cisco LTE Datasheet - c78-732744abds7Nessuna valutazione finora

- Bea Form 7 - Natg6 PMDocumento2 pagineBea Form 7 - Natg6 PMgoeb72100% (1)

- Leeka Kheifets PrincipleDocumento6 pagineLeeka Kheifets PrincipleAlexandreau del FierroNessuna valutazione finora

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDocumento2 pagineBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiNessuna valutazione finora

- 1.mukherjee - 2019 - SMM - Customers Passion For BrandsDocumento14 pagine1.mukherjee - 2019 - SMM - Customers Passion For BrandsnadimNessuna valutazione finora

- AutoCAD Dinamicki Blokovi Tutorijal PDFDocumento18 pagineAutoCAD Dinamicki Blokovi Tutorijal PDFMilan JovicicNessuna valutazione finora

- Chat Application (Collg Report)Documento31 pagineChat Application (Collg Report)Kartik WadehraNessuna valutazione finora

- SC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Documento5 pagineSC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Sanjeev kumarNessuna valutazione finora

- Random Variable N N Mean or Expected Value: Number of Ducks Type of Duck AmountDocumento2 pagineRandom Variable N N Mean or Expected Value: Number of Ducks Type of Duck AmountAngie PastorNessuna valutazione finora

- Marley Product Catalogue Brochure Grease TrapsDocumento1 paginaMarley Product Catalogue Brochure Grease TrapsKushalKallychurnNessuna valutazione finora

- Document 3Documento3 pagineDocument 3AdeleNessuna valutazione finora

- Canopy CountersuitDocumento12 pagineCanopy CountersuitJohn ArchibaldNessuna valutazione finora

- TOEFLDocumento6 pagineTOEFLSekar InnayahNessuna valutazione finora

- Hitt PPT 12e ch08-SMDocumento32 pagineHitt PPT 12e ch08-SMHananie NanieNessuna valutazione finora

- Fr-E700 Instruction Manual (Basic)Documento155 pagineFr-E700 Instruction Manual (Basic)DeTiEnamoradoNessuna valutazione finora

- Amazon Case StudyDocumento22 pagineAmazon Case StudySaad Memon50% (6)

- LICDocumento82 pagineLICTinu Burmi Anand100% (2)

- Bismillah SpeechDocumento2 pagineBismillah SpeechanggiNessuna valutazione finora

- Certification and LettersDocumento6 pagineCertification and LettersReimar FerrarenNessuna valutazione finora

- 87 - Case Study On Multicomponent Distillation and Distillation Column SequencingDocumento15 pagine87 - Case Study On Multicomponent Distillation and Distillation Column SequencingFranklin Santiago Suclla Podesta50% (2)

- Home Guaranty Corp. v. Manlapaz - PunzalanDocumento3 pagineHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- Econ 1006 Summary Notes 1Documento24 pagineEcon 1006 Summary Notes 1KulehNessuna valutazione finora