Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluid Bed Systems: GPCG Lab System

Caricato da

sumit_waghmareTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fluid Bed Systems: GPCG Lab System

Caricato da

sumit_waghmareCopyright:

Formati disponibili

Fluid bed systems

G P C G 2 LabSystem

DRYING

GRANULATING

COATING

PELLETIZING

GPCG 2 LabSystem

We set the standard

The very best for your laboratory

Function and form taken to perfection

The innovative

GPCG 2 LabSystem

from Glatt

The innovative

GPCG 2 LabSystem

from Glatt

Absolute flexibility

Optimum process control

The full range of fluid bed processes. In top

quality. For new ideas and top products.

Customer expectations are high. Fast and

simple process control is what counts.

The solution: ProcessView from Glatt.

Drying (in the granulating insert).

Granulating (Top Spray in the

granulating insert).

Coating (Bottom Spray in the HS-Wurster*).

Pelletizing (Tangential Spray in

the rotor insert).

Optimum batch size - from 0.3 kg to 5 kg**.

With textile filter or metal filter and various

bottom screens. With Glatt single-arm spray

nozzle, powder-feed and other innovations.

In the standard version or customised to suit

your specific requirements. The perfect

equipment to ensure your success.

Swivelling operating panel

Excellent handling and

integrated technology

Perfect solutions and sophisticated design.

The GPCG 2 offers all the advantages of

integrated technology and top quality

processing.

Step up safety

Your safety is of utmost importance to us.

The PRO concept from Glatt. No compromises,

instead maximum safety.

Touch-screen control.

Swivelling operating panel.

Perfect ergonomics for the operator.

Integrated recipe handling.

Batch report.

No pressure relief.

Environmental and personal protection

with a contained system.

For all dusts up to an explosion pressure

of 10 bar and their hybrid mixtures.

New sealing system. Less weight

and better handling.

As a total containment version for

highly active substances.

Centralised process inserts, removeable

and rotatable for product discharging.

Simple filling and discharging.

Problem-free cleaning.

Plug & Play. Just connect it and youre off.

Ergonomically arranged connections.

Rotating mesh for contained emptying.

Removable product container.

Unique work surface made of synthetic

granite. Resistant to solvents, scratch-proof

and impact-proof. It still looks like new

even after years of use.

Support for laboratory

equipment

Removeable and rotatable product container

Modular design

Expect absolute flexibility. Integrated

modules offer you options now or in the future.

Top for clinical sample production

Batch sizes from 0.3 kg to 5 kg**

The highest of requirements apply in

the manufacture of clinical samples.

Problems are something you can do without.

What you need is the GPCG 2.

Easy-to-clean design.

Comprehensive process documentation.

Validation of processes.

Drying

Granulating

Coating

Pelletizing

Dehumidification of inlet air.

Downstream deduster for dust sensitive

coating processes.

Additional storage space for process

accessories.

* patented

** product dependent

Some of the features mentioned

in this brochure are optional

GPCG 2 LabSystem with storage modul

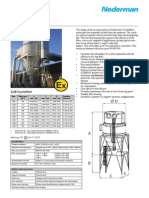

Technical Data / Addresses

GPCG 2 LabSystem

Batch sizes

small 1)

standard

large

1 - 3 l

2 - 6 l

5 - 12 l

Wurster insert (4" and 6") 2)

2 l

3.5 l

Rotor insert 2)

5 l

Granulating insert

Electrical power 3)

Operating voltage 1 x 230 V and 3 x 400 V

Frequency

Total connected load

Connector CEE form 3-pin / 5-pin

Compressed air

50 Hz

3.5 / 15 kW

Max. consumption

12 m3 / h

Pressure

6 bar(g)

Connection

Hose connection

Inlet air heater, electric

Max. inlet air temperature

120 C

Dimensions

Height

2427 mm

Width

1900 mm

Depth

987 mm

Weight

Spray pump 2) 3)

53 ml / min

Connection voltage

230 V

Frequency

50 Hz

(Subject to technical alternations)

964

1865

2427

1) Only together with the tower bypass for process air 2) Optional 3) Other voltages and frequencies on request

500

1900

The innovative

GPCG 2 LabSystem

from Glatt

Drying

Granulating

500

600

987

Glatt Maschinen- & Apparatebau AG

Kraftwerkstrasse 6

4133 Pratteln / Switzerland

Phone: +41 61 8 26 47 47

Fax: +41 61 8 26 48 48

eMail: info@glatt.com

Glatt Ingenieurtechnik GmbH

Nordstrae 12

99427 Weimar / Germany

Phone: +49 3643 47 0

Fax: +49 3643 47 12 31

eMail: info@glatt-weimar.de

1000 kg

Max. output

Glatt GmbH Process Technology

Werner-Glatt-Strae 1

79589 Binzen / Germany

Phone: +49 7621 6 64 0

Fax: +49 7621 6 47 23

eMail: info@glatt.com

Glatt Air Techniques Inc.

20 Spear Road

Ramsey, NJ 07446 / USA

Phone: +1 201 8 25 87 00

Fax: +1 201 8 25 03 89

eMail: info@glattair.com

Glatt Norden ApS.

Skjtevej 27 - 31

2770 Kastrup / Denmark

Phone: +45 48 14 22 44

Fax: +45 48 14 22 55

eMail: info@glattnorden.dk

Glatt Pharmatech SASU

Parc Technologique

6, rue Louis Nel

21000 Dijon / France

Phone: +33 3 80 74 32 64

Fax: +33 3 80 74 43 95

eMail: info@glatt-pharmatech.fr

Glatt Protech Ltd.

Swannington Road

Cottage Lane Ind. Est.

Broughton Astley

Leicester LE9 6TU / Great Britain

Phone: +44 1455 28 58 58

Fax: +44 1455 28 55 10

eMail: info@glatt-protech.co.uk

www.glatt.com

Coating

Pelletizing

We set the standard

Glatt GMBH Binzen GPCG 2 7221_314 November 2005 EN 2.000 Color-Offset Neuberger.Design

Potrebbero piacerti anche

- Ficha Tecnica Equipos para LaboratorioDocumento6 pagineFicha Tecnica Equipos para LaboratorioGustavoNessuna valutazione finora

- 01t0h00000602frAAA-A1v0h000006IudlAAC-Glatt GPCG2 Fluid Bed Dryer BrochureDocumento20 pagine01t0h00000602frAAA-A1v0h000006IudlAAC-Glatt GPCG2 Fluid Bed Dryer BrochureRisto PanovskiNessuna valutazione finora

- WWW Gericke Net 5Documento1 paginaWWW Gericke Net 5Mashudi FikriNessuna valutazione finora

- KMB FL Ze28 en NewDocumento8 pagineKMB FL Ze28 en Newvantuan17792Nessuna valutazione finora

- Glatt BRO PTP 227 TwinPro 2018-03 ENDocumento12 pagineGlatt BRO PTP 227 TwinPro 2018-03 ENJose Luis HuamanNessuna valutazione finora

- 2935 0969 40 GV18-300Documento6 pagine2935 0969 40 GV18-300Yacine CherifiNessuna valutazione finora

- GDS134Documento4 pagineGDS134Saurabh VermaNessuna valutazione finora

- Fluid Bed Systems: P Ro / P Lu SDocumento20 pagineFluid Bed Systems: P Ro / P Lu SmarciojunkNessuna valutazione finora

- Portable Dust Extraction SystemDocumento1 paginaPortable Dust Extraction Systemswakinjesu100% (1)

- KM BR Powerprint EnuDocumento8 pagineKM BR Powerprint EnuAndrzej FrasekNessuna valutazione finora

- Catalogo Horno Tamglastamglass ProEDocumento8 pagineCatalogo Horno Tamglastamglass ProEДушан СлијепчевићNessuna valutazione finora

- Arburg Freeformer 680836 en GBDocumento20 pagineArburg Freeformer 680836 en GBclingon29Nessuna valutazione finora

- Christian Pfeiffer Maschinenfabrik GMBHDocumento5 pagineChristian Pfeiffer Maschinenfabrik GMBHPeyman KhNessuna valutazione finora

- P-Usg: Underwater Strand Pelletizing Systems For Cost-Eff Ective ProductionDocumento8 pagineP-Usg: Underwater Strand Pelletizing Systems For Cost-Eff Ective Productionruk1921Nessuna valutazione finora

- Mann+Hummel Protec GMBH: ConveyingDocumento8 pagineMann+Hummel Protec GMBH: ConveyingMUHAMMAD SHARIFNessuna valutazione finora

- Heinkel Centrifuges Pharma enDocumento8 pagineHeinkel Centrifuges Pharma enRavi Kiran CharugullaNessuna valutazione finora

- Pipe ExtrusionDocumento21 paginePipe ExtrusionSummer Spencer100% (2)

- Modular CleanroomDocumento6 pagineModular CleanroomMohamed EidNessuna valutazione finora

- Gkf3000s enDocumento6 pagineGkf3000s enPiotrSikoraNessuna valutazione finora

- Deduster® Anthology - : The Complete GuideDocumento16 pagineDeduster® Anthology - : The Complete GuidePetros IosifidisNessuna valutazione finora

- Biofuge Fresco 100V-120V Green EnglishDocumento70 pagineBiofuge Fresco 100V-120V Green EnglishAndrew Holmes80% (5)

- SEAL 62 ProDocumento2 pagineSEAL 62 ProAlberto SundayNessuna valutazione finora

- Vs 90Documento6 pagineVs 90Mari PrunaNessuna valutazione finora

- A:Gran: Patented by NGRDocumento8 pagineA:Gran: Patented by NGRAkhilesh KumarNessuna valutazione finora

- Tkis-Polytrack-Factsheet-210 X 297-WebpdfDocumento2 pagineTkis-Polytrack-Factsheet-210 X 297-WebpdfHa Kim BJNessuna valutazione finora

- 14 EXT BR Conical Profile enDocumento12 pagine14 EXT BR Conical Profile enPankaj KushwahaNessuna valutazione finora

- Welcome at Commercial Establishment Mikro-Met ® Grzegorz KłosowskiDocumento25 pagineWelcome at Commercial Establishment Mikro-Met ® Grzegorz KłosowskiVarun BaxiNessuna valutazione finora

- HFD Catalog IL8Documento12 pagineHFD Catalog IL8PartsGopher.comNessuna valutazione finora

- EJ 9-21 204 EVS LoDocumento2 pagineEJ 9-21 204 EVS Lojhony0294km5Nessuna valutazione finora

- Polytrack Clinker Cooler: Proven, Reliable, Future-Proof - Step Up Your Plant ProductivityDocumento2 paginePolytrack Clinker Cooler: Proven, Reliable, Future-Proof - Step Up Your Plant ProductivityemadsabriNessuna valutazione finora

- Multinject PDFDocumento32 pagineMultinject PDFkfaravNessuna valutazione finora

- Double-Clip Machine: Innovative Reliable LeadingDocumento2 pagineDouble-Clip Machine: Innovative Reliable LeadingAvneet MaanNessuna valutazione finora

- ProTec Polymer ProcessingDocumento12 pagineProTec Polymer ProcessingSaber Abdel MoreidNessuna valutazione finora

- GEA Convair: Empty PET Bottle Air Conveying SystemDocumento4 pagineGEA Convair: Empty PET Bottle Air Conveying SystemАндрій МагденккоNessuna valutazione finora

- Ficha Tecnica Hepa 24x48x5 Tm2Documento4 pagineFicha Tecnica Hepa 24x48x5 Tm2EDWLYCANNessuna valutazione finora

- Flowshield SL: Standard Colour ChartDocumento2 pagineFlowshield SL: Standard Colour ChartManjunath HrmNessuna valutazione finora

- GyratoryDocumento4 pagineGyratoryFrancisco M. RamosNessuna valutazione finora

- Arburg-Micro Injection MouldingDocumento12 pagineArburg-Micro Injection Mouldingweb312_twNessuna valutazione finora

- Brochure Quadro Comil GeneralDocumento12 pagineBrochure Quadro Comil Generaljuditherrera_11100% (2)

- Glascroft Equipment PDFDocumento2 pagineGlascroft Equipment PDFA MahmoodNessuna valutazione finora

- Info RASCHIG-JAEGER Wire Mesh Entrainment SeparatorsDocumento16 pagineInfo RASCHIG-JAEGER Wire Mesh Entrainment Separatorsperrychem100% (1)

- Special Closures Literature2Documento2 pagineSpecial Closures Literature2ruben'sNessuna valutazione finora

- Toaz - Info Capitulo 11c Metodo Por Triangulacion PRDocumento12 pagineToaz - Info Capitulo 11c Metodo Por Triangulacion PRJose Luis HuamanNessuna valutazione finora

- Cyclo FilterDocumento2 pagineCyclo FilterjnmanivannanNessuna valutazione finora

- A4 Depliant Gradoadroit EngDocumento3 pagineA4 Depliant Gradoadroit Engductoan32Nessuna valutazione finora

- Delta6rc FinalDocumento2 pagineDelta6rc FinalsarvottamNessuna valutazione finora

- URS 01 - Rotary Press Tablet Machine SPLDocumento18 pagineURS 01 - Rotary Press Tablet Machine SPLrosy0171057% (7)

- Multi Pan CoaterDocumento4 pagineMulti Pan CoaterTorben Richard PedersenNessuna valutazione finora

- Hanil Catalogue (2012)Documento100 pagineHanil Catalogue (2012)Soma GhoshNessuna valutazione finora

- Pulveriseren Atriton PDFDocumento8 paginePulveriseren Atriton PDFAntonNessuna valutazione finora

- Battenfeld - Blown Film 2003Documento12 pagineBattenfeld - Blown Film 2003J Díaz SalaverríaNessuna valutazione finora

- Industrial Washing MachineDocumento10 pagineIndustrial Washing MachineDiêm Công ViệtNessuna valutazione finora

- Rotary ValvesDocumento6 pagineRotary ValvesGelorawan AditNessuna valutazione finora

- Film Recycling Processes With Alpine Granulators (En)Documento4 pagineFilm Recycling Processes With Alpine Granulators (En)DIEGO2109Nessuna valutazione finora

- Lauffer Broschuere LCL AnsichtDocumento4 pagineLauffer Broschuere LCL AnsichtRaul CostiniucNessuna valutazione finora

- Inert SystemsDocumento56 pagineInert Systemsnkvd134Nessuna valutazione finora

- Manual Sigma Centrifuge 2-6 EngDocumento71 pagineManual Sigma Centrifuge 2-6 EngDavid Huamán GastelúNessuna valutazione finora

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationDa EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNessuna valutazione finora

- Bottles, Preforms and Closures: A Design Guide for PET PackagingDa EverandBottles, Preforms and Closures: A Design Guide for PET PackagingValutazione: 4.5 su 5 stelle4.5/5 (3)

- Pi 014 3 Recommendation On IsolatorsDocumento22 paginePi 014 3 Recommendation On IsolatorsMostofa Rubal0% (1)

- Building Innovation CompetenciesDocumento5 pagineBuilding Innovation Competenciessumit_waghmareNessuna valutazione finora

- 3rd Annual QBD ConferenceDocumento582 pagine3rd Annual QBD Conferencesumit_waghmareNessuna valutazione finora

- Assignment Booklet PGDAST Jan-Dec 2018Documento35 pagineAssignment Booklet PGDAST Jan-Dec 2018sumit_waghmareNessuna valutazione finora

- Root Cause Analysis: Jeremy Jay LimDocumento20 pagineRoot Cause Analysis: Jeremy Jay Limsumit_waghmareNessuna valutazione finora

- Guidance-Ergonomics en PDFDocumento28 pagineGuidance-Ergonomics en PDFsumit_waghmareNessuna valutazione finora

- TN Leak Rate v2Documento2 pagineTN Leak Rate v2sumit_waghmareNessuna valutazione finora

- Alkermes High Potency Whitepaper 2014Documento11 pagineAlkermes High Potency Whitepaper 2014sumit_waghmareNessuna valutazione finora

- Decision Tree For Case StudyDocumento1 paginaDecision Tree For Case Studysumit_waghmareNessuna valutazione finora

- Process and Instrumentation Diagram DevelopmentDocumento14 pagineProcess and Instrumentation Diagram DevelopmentBaroszNessuna valutazione finora

- Appendix 5 PDFDocumento9 pagineAppendix 5 PDFjanelle ramdahinNessuna valutazione finora

- Trike BayThreat 2010Documento17 pagineTrike BayThreat 2010sumit_waghmareNessuna valutazione finora

- Aquionics Case StudyDocumento2 pagineAquionics Case StudyChaudhry KhurramNessuna valutazione finora

- Better: TypographyDocumento33 pagineBetter: TypographyDavid ElihúNessuna valutazione finora

- TD Staugitter DLT8000 13 BEN 019Documento12 pagineTD Staugitter DLT8000 13 BEN 019sumit_waghmareNessuna valutazione finora

- Refrigerant Dehumidification TechnologyDocumento4 pagineRefrigerant Dehumidification TechnologyUmarraj SaberwalNessuna valutazione finora

- Gamification As An Employee Engagement Strategy For Gen Y Employees in 2017 in IndiaDocumento1 paginaGamification As An Employee Engagement Strategy For Gen Y Employees in 2017 in Indiasumit_waghmareNessuna valutazione finora

- Bosch XRay WeightMEasurementDocumento8 pagineBosch XRay WeightMEasurementsumit_waghmareNessuna valutazione finora

- Butterfly Valve With Rotary Actuator: As Per AWWA: C504 and BS: 5155Documento1 paginaButterfly Valve With Rotary Actuator: As Per AWWA: C504 and BS: 5155sumit_waghmareNessuna valutazione finora

- Tablet TemplateDocumento12 pagineTablet TemplateRigoberto Huerta LaraNessuna valutazione finora

- Form 12: (See Rule 34) Application For Licence To Import Drugs For Purpose of Examination, Test or AnalysisDocumento1 paginaForm 12: (See Rule 34) Application For Licence To Import Drugs For Purpose of Examination, Test or Analysissumit_waghmareNessuna valutazione finora

- MA Staugitter DLT8005 15 AEN 001Documento4 pagineMA Staugitter DLT8005 15 AEN 001sumit_waghmareNessuna valutazione finora

- 238 TTC Containment Workshop WebDocumento8 pagine238 TTC Containment Workshop Websumit_waghmareNessuna valutazione finora

- Air Flow Sensor M16CC0406Documento2 pagineAir Flow Sensor M16CC0406sumit_waghmareNessuna valutazione finora

- BuffyFish 5000kms ProposalDocumento4 pagineBuffyFish 5000kms Proposalsumit_waghmareNessuna valutazione finora

- Best Quotes of All Time.Documento25 pagineBest Quotes of All Time.Abhi SharmaNessuna valutazione finora

- Steam SystemsDocumento32 pagineSteam SystemsmodulofrikiNessuna valutazione finora

- Ansi Valve Leakage StandardsDocumento1 paginaAnsi Valve Leakage StandardsSHAHgan1Nessuna valutazione finora

- Volume II - Ericsson Field Guide For UTRAN P1-Lite: Feature Parameters and Best PracticesDocumento71 pagineVolume II - Ericsson Field Guide For UTRAN P1-Lite: Feature Parameters and Best Practicessara y santi becerra barreto100% (2)

- Automatic Water Level Control in Overhead Tanks A Project Report Submitted in Partial Fulfillment of PDF FreeDocumento37 pagineAutomatic Water Level Control in Overhead Tanks A Project Report Submitted in Partial Fulfillment of PDF FreeSounds of Peace100% (1)

- 2238 Radio DescriptionDocumento10 pagine2238 Radio DescriptionKrustytfeNessuna valutazione finora

- Coa TechtalkDocumento27 pagineCoa TechtalkAnanya MajetiNessuna valutazione finora

- Fisher Fieldvue Dvc6200F Digital Valve Controller PST Calibration and Testing Using Valvelink SoftwareDocumento24 pagineFisher Fieldvue Dvc6200F Digital Valve Controller PST Calibration and Testing Using Valvelink SoftwareKram Alim VillonNessuna valutazione finora

- EN Calibration Source M340 - DatasheetDocumento2 pagineEN Calibration Source M340 - DatasheetMansour AchaourNessuna valutazione finora

- Novel Low Cost Green-Power PWM Controller: FeaturesDocumento15 pagineNovel Low Cost Green-Power PWM Controller: FeaturesmehmoodNessuna valutazione finora

- ULN2001, ULN2002 ULN2003, ULN2004: DescriptionDocumento17 pagineULN2001, ULN2002 ULN2003, ULN2004: DescriptionAlberto CorralesNessuna valutazione finora

- FNS 420 RDocumento2 pagineFNS 420 RJesus FabelaNessuna valutazione finora

- DTR100Documento56 pagineDTR100SUNYAOZONGNessuna valutazione finora

- DisplayPort Technical OverviewDocumento83 pagineDisplayPort Technical OverviewMorgan Yang100% (1)

- APC200 ECM-ECI Error Codes Ver1.1.Documento9 pagineAPC200 ECM-ECI Error Codes Ver1.1.Giovani PardinhoNessuna valutazione finora

- Polymer Memory: Bachelor of Technology IN Electronics and Communication EngineeringDocumento25 paginePolymer Memory: Bachelor of Technology IN Electronics and Communication EngineeringSateesh Kuna100% (1)

- AC-AC Voltage ControllersDocumento21 pagineAC-AC Voltage ControllersLai Yon PengNessuna valutazione finora

- Applications of PN Junction Diode PDFDocumento8 pagineApplications of PN Junction Diode PDFZain Ul AbedinNessuna valutazione finora

- PDU For TMA Catalog (Add 3DT) - Add CEQ V3.0 - 001 PDFDocumento3 paginePDU For TMA Catalog (Add 3DT) - Add CEQ V3.0 - 001 PDFpandavision76Nessuna valutazione finora

- Valliammai Enginering College Department of Mechanical EngineeringDocumento6 pagineValliammai Enginering College Department of Mechanical EngineeringMani KandanNessuna valutazione finora

- Automatic Generation Control in A Deregulated Power SystemDocumento6 pagineAutomatic Generation Control in A Deregulated Power SystemamaytaNessuna valutazione finora

- TTC 1000Documento2 pagineTTC 1000svismaelNessuna valutazione finora

- Company Profile - RELAYS ENG.Documento92 pagineCompany Profile - RELAYS ENG.mNessuna valutazione finora

- FSN140019 eDocumento84 pagineFSN140019 etehnicancomNessuna valutazione finora

- Innolux V500HJ1-ME1 Datasheet, Specification, Stocks, Overview - Lcd-SourceDocumento2 pagineInnolux V500HJ1-ME1 Datasheet, Specification, Stocks, Overview - Lcd-SourceJackeline MosquedaNessuna valutazione finora

- Balluff BES 516-325-S4-C BES01C8Documento2 pagineBalluff BES 516-325-S4-C BES01C8celsocarneiroNessuna valutazione finora

- ZN551Documento2 pagineZN551Darnell GracenNessuna valutazione finora

- Study On The Jamming To Synthetic Aperture RadarDocumento4 pagineStudy On The Jamming To Synthetic Aperture Radarapi-19919509Nessuna valutazione finora

- Chapter 9: 8086/8088 Hardware SpecificationsDocumento105 pagineChapter 9: 8086/8088 Hardware Specificationssapna_eng4080Nessuna valutazione finora

- A Simple Method To Measure Unknown InductorsDocumento4 pagineA Simple Method To Measure Unknown InductorsDiogo CarvalhoNessuna valutazione finora

- Edson - Vacuum Tube Oscillators 1953 PDFDocumento494 pagineEdson - Vacuum Tube Oscillators 1953 PDFrichi78yobsNessuna valutazione finora

- Pulse Delay Ranging PDFDocumento12 paginePulse Delay Ranging PDFMilorad PavlovicNessuna valutazione finora

- GS70 - MSI-1771 Disassembly GuideDocumento17 pagineGS70 - MSI-1771 Disassembly GuideCatalin FinkelsteinNessuna valutazione finora