Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Waterbar Application Manual

Caricato da

barouniamineDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Waterbar Application Manual

Caricato da

barouniamineCopyright:

Formati disponibili

Waterbar Application Manual

General description of Waterstops and their usage

Existing methods of sealing joints and problems associated with them

An explanation of Strip type waterbars

Advantage of Dr. Fixit Waterbars

Detailed instructions on how to lay Dr. Fixit Waterbars

from the makers of

BRANCH OFFICES Ph No.: INDIA +92-22-28357000 THAILAND +66-0-2722-8535 SINGAPORE +0065-67638681 / 6215 USA +561-775-9600

UNITED KINGDOM +44 208 42223111 CHINA +86 21 64430132 EGYPT +20-2-4186709 BRAZIL +55-11-96263661

DISCLAIMER The product information & application details given by the company & its agents has been provided in good faith & meant to serve only as a general guideline during

usage. Users are advised to carry out tests & take trials to ensure on the suitability of products meeting their requirement prior to full scale usage of our products. Since the correct

identification of the problems, quality of other materials used and on-site workmanship are factors beyond our control, there are no expressed or implied guarantee / warranty as to

the results obtained. The Company does not assume any liability or any consequential damage for unsatisfactory results, arising from the use of our products.

CC-DF-WF-WB-BK-07/13

Pidilite Industries Limited

Construction Chemicals Division

Ramakrishna Mandir Road, PO Box No. 17411, Andheri East, Mumbai 400 059 T 2835 7000 F 2835 7008

drfixit@pidilite.com, www.doctor-fixit.com

Frequently answered question (FAQ) on waterbars

Comparision table for different types of strip waterbars

Waterbar Application Manual

1] What are waterbars or waterstops and where are they

used in civil engineering?

Leakage occurs when there is a gap in the construction

joint. This gap occurs when it is not possible to vibrate

concrete properly and effectively within the construction

joint due to various difficulties under site conditions. Such a

gap can also occur due to shrinkage of concrete. Shrinkage

gaps may vary from 0.5 mm to 1mm. Gap due to

inadequate vibration may vary from 1-6mm.

All structures built of concrete have construction joints.

These may be horizontal joints, vertical joints, inclined joints

or curved joints. By themselves, they do not pose any

serious problems. However, if the structures are subject to

water pressure, improperly cast joints may cause problems

because of leakage. This may happen in water tanks,

basements, tunnels, swimming pools, water treatment

plants etc.

3] How do we solve this chronic problem?

Various attempts are made by engineers to solve this

problem.

Such structures include Water Tanks, Swimming Pools,

Basement Wall and Floor perimeter joint, Basement column

and floor slab joint, vertical joints in basement retaining

walls, Sewage Treatment Plants, Sump Tanks, Potable water

Reservoirs, Raft Slabs cast in more than one pour, final roof

slabs cast in more than one pour, pipe intrusions in

concrete walls, fish hatcheries, concrete lined storm water

and irrigation channels, precast structures such as box

culverts, septic tanks and utility vaults, pedestrian and

below grade tunnels, but joint between old roof and new

roof and other joints.

2] Why does leakage occur?

Some engineers suggest the use of PVC waterstops during

concreting. Some apply epoxy to the construction joint.

Some prefer to grout the joint with cement slurry or epoxy

injection. Let us evaluate all these systems one by one.

Nonswellable Waterbar

A noneswellable or compressible waterbar works on the

principle of compression and sealing the joint. When

concrete falls on the sealant, it gets compressed and by

virtue of this the gap or construction joint gets filled up.

For this, the essential properties are compressibility, i.e.

the waterbar should be slightly soft so that it gets

compressed. It should be able to change its shape and

squeeze itself to fill up the gap. It should be of fairly large

cross section so that there is enough material to get

squeezed. If for eg, the cross section is only 5 mm x 10

mm or 10 mmx 10 mm, there may not be enough material

to get compressed. Typically, compressible sealants

should be of 20 mm x 20 mm cross section minimum for

maximum effectiveness. If it is 25 mm x 25 mm, it is even

better.

Cement Grouting

Cement grouting into construction joints is one of the

methods which is used regularly by engineers in the

attempt to fill up construction joints. This works well if

there is a large amount of honeycombs in the concrete.

However, if there are no honeycombs and there is only

a thin gap in the joint, then it becomes very difficult

to grout since the slurry cannot find its way into the fine

gap. Moreover, drilling a number of holes directly into

a joint will actually make the joint weaker and not help

much in sealing the joint.

Compressible (Nonswellable Waterbars) require very less

cover in concrete. They can be used with cover as less as

25mm. The minimum strength of concrete can also be as

low as M15 since there is no danger of expansion of

sealant.

Epoxy, P. U, acrylic or other chemical

grouting

Existing Methods of Sealing Construction Joints and common problems

with such methods

PVC Waterstops

PVC waterstops are available in various sizes in width and

various thicknesses. One half of the waterstop is inserted

into fresh concrete during concreting.

The other half is normally concreted in the second phase

of concreting. It is believed that this waterstop helps in

increasing the flow path of water around it thus lowering

its pressure. Experience shows us that PVC waterstops do

not bond with the parent concrete due to

nonhomogenous nature of the PVC and the concrete.

It is very difficult to keep the PVC waterstop in position

while concreting is underway, especially if there is

obstructing reinforcement bars. When the second lift of

concrete is poured, the second half of the PVC waterstop

generally folds over and helps to form a passage through

which even more water may leak. It is difficult

to weld PVC waterstop on site if a welding machine is not

available.

TYPICAL

Epoxy Coatings in Construction Joints

WATER MAY LEAK ALONG

THE PATH SHOWN IN RED

the construction joint with a waterbar to prevent leakage,

your structural consultant may still recommend that you

apply epoxy coating above and below the waterbar so as

to ensure structural bonding.

Although some nonengineers have suggested epoxy

coating as a solution to the problem of sealing gaps in

construction joints, this system will not work since epoxy

forms only a thin coating and does not fill the gap. It is

useful only when structural bonding is required. Gaps in

construction joints may be quite large (upto 5-6 mm) and

cannot be filled up by epoxy coating. In addition to sealing

PVC WATERSTOP FOLDING

OVER WHEN CONCRETE

FALLS ON IT

PROBLEMS WITH PVC WATERSTOPS

Epoxy grouting also has the same problems as cement

grouting. If drilling and fixing a grout nipple can be

executed well, then this method has a higher degree of

success as compared with cement grouting. However,

epoxy or any other kind of chemical grouting is very

expensive and it is difficult to find experienced applicators

to carry out such jobs.

An important requirement of compressible waterbars is a

highly adhesive nature. This is required because freshly

poured concrete should adhere immediately with the

waterbar. When shrinkage of concrete occurs, the

waterbar is still stuck to the concrete and no gap occurs

because of the shrinkage.

The correct solution to sealing construction joints in

water contact structures is a STRIP WATERBAR OR STRIP

WATERSTOP.

Compressible waterstops are generally useful to stop

water leakage having a maximum head of about 15 to 20

mtrs.

Swellable Waterbars

A swellable waterbar works on the principle of swelling

upon coming into contact with water. If there is no water,

it does not swell at all. Typically, they are made of

hydrophilic rubber or are bentonite based materials.

Pure rubber Hydrophilic Waterbar

Let us look at such a waterbar which is commonly

available in the market today. Such a waterbar is of small

cross section say 5 mm x 10 mm or 10 mm x 10 mm and

expands to 200 percent of its volume on contact with

water. Such waterstops are fairly rigid before expansion

and also after expansion. They retain most of their cross

section even after expansion. If it is immersed in water

and then taken out after a few days, it is not possible to

squeeze it in your hand and change its shape. These

waterstops work well in straight joints and where there is

no irregularity in the gap.

High Expansion pressure: Because hydrophilic rubbers

expand so much (250-300 percent), they are generally

manufactured using small cross sections like 5 mm x 10

mm, 10 mm x 10 mm, or 5 mm x 20 mm. This ensures

that there is not too much expansion volume and

A strip waterstop looks like a rope. Strip Waterstops

typically have a square or rectangular cross section of

sizes like 5 mm x 20 mm, 10 mm x 10 mm, 10 mm x 20

mm, 19 mm x 25 mm, 20 mm x 20 mm, 25 mm x 25 mm

etc. They are made of different materials like

hydrocarbon based polymer , hydrophilic rubber,

bentonite base, butyl rubber and other materials.

Generally they are divided into two categories:

NonSwellable (Compressible) Waterstops and Swellable

Waterstops or Waterbars.

Waterbar Application Manual

LAYING DR. FIXIT WATERBAR-METHODOLOGY

consequently high pressures which may blow out

the joint.

freshly poured concrete. It is extremely difficult to

remove NSW2525 from set concrete. This property helps

when concrete shrinkage takes place. The waterstop is

pulled by the concrete and shapes itself into the new

space.

For the same reason, manufacturers advise that the

minimum cover required in concrete when you use such

materials is about 75 100 mm. Also the grade of

concrete should not be less than M20. Some

manufacturers even advise M25.

NSW 2525 is larger than most other waterstops in the

market. It his highly flexible and therefore can be

moulded into the construction joint when concrete falls

on it, thus filling up the construction joint completely and

making the joint waterproof.

Premature Expansion Problem: It is important to see that

expansion does not take place even before you place

concrete. To solve this problem, some manufacturers

coat their waterstop with a Delay Coating which slows

down the rate of swell of the waterstop. This means that

the waterstop expands slowly.

site conditions cause problems and the waterstop

expands even before you concrete it. In that case, the

SW2020 waterstop behaves like a flexible compressible

waterstop. Its large cross section again comes into play

and the material squeezes itself into the construction

joint and again makes the joint watertight. This is why it is

called a 2 in 1 Waterbar.

CLEAN THE JOINT

APPLY PRIMER 20mm WIDE

NSW 2525 is completely unaffected by water and hence

can be used in situations where there is a danger of

curing water or rain affecting the work. It can be used

even when the cold joint is wet or curing water has

stagnated. However, loose mortar and laitance should be

removed physically before using NSW 2525.

Bentonite based Swellable Waterstop: Such a waterstop

relies highly on its considerable bentonite content to

expand. This is uncontrolled expansion. If immersed in

water, it will expand to the point that it will change its

shape completely and may even fall apart. If water

pressure is high, sometimes there is a chance that it

might even get washed away.

NSW 2525 is recommended to be used where it is

necessary to resist water heads of upto 15 to mtrs.

UNCOIL DR. FIXIT WATERBAR

Dr. Fixit's Swellable Waterbar SW 2020

Swellable waterstops are designed for higher waterheads.

They are typically used when you want to resist water

heads of about 50 to 100 mtrs.

PLACE IN POSITION

SW 2020 is the hydrophilic swellable waterbar of Dr. Fixit.

It is also known as a 2 in 1 Waterbar

SW2020 first acts like a compressible waterstop because

of its large cross section and because of its flexible

nature. It immediately makes the joint water resistant to a

waterhead of about 20 mtrs. Next, it starts expanding

when it comes into contact with water and then increases

the resistance to water leakage upto a head of 60-80

mtrs. This is why it is called a 2 in 1 Waterbar.

SW 2020 is a Controlled Expansion waterstop. It does

not swell to the point of deterioration. It is designed to

swell upto a maximum of 150 percent over and above its

original volume. By this, it ensures that there is no

unnecessary pressure generated inside the joint due to

high expansion. Hence concrete cover can be as less as

50 mm when using SW2020. It also ensures that it does

not expand so much that it gets washed out from the

joint in case there is a large gap.

SW 2020 has a large cross section of 20 mm x 20 mm.

Thus, it has the great advantage that compressible

waterbars have. A large cross section which ensures that

there is enough volume to begin with which can get

compressed. SW 2020 is a flexible material unlike regular

hydrophilic rubber waterstops which are rigid. Note that

rigid waterstops cannot be compressed easily.

Badly compacted concrete above or below a construction

joint can still leak in spite of using the best quality

waterbar

Advantages of Dr. Fixit Waterbars

Unlike other hydrophilic Rubber waterbars which are

commonly available, SW 2020 is highly adhesive in

nature. This nature allows it to bond by adhesion to

freshly poured concrete. It is extremely difficult to

remove SW2020 from set concrete. This property helps

when concrete shrinkage takes place. The waterstop is

pulled by the concrete and shapes itself into the new

space.

SW 2020 is fault tolerant waterstop. Let us assume that

Dr. Fixit Nonswellable Waterbar NSW2525

Dr. Fixit Nonswellable Waterbar NSW 2525 is a

compressible waterbar with a large cross section.

Unlike other hydrophilic Rubber waterbars which are

commonly available, NSW 2525 is highly adhesive in

nature. This nature allows it to bond by adhesion to

4

POUR CONCRETE

Effect of SW 2020

placed in a pipe &

immersed in water

Before swelling

After swelling

Detailed laying instructions

(READ CAREFULLY BEFORE USING DR.FIXIT WATERBAR)

Positioning of waterstop in the joint is very important.

Please refer to the section on SKETCHES in the waterbar

application manual to see exactly how waterstop is to be

placed.

Cleaning of joint of loose concrete, debris, dust and loose

mortar is very important.

ALWAYS CHECK the carton to make sure which waterbar

you are using Swellable or Nonswellable. Please note that

instructions for laying Swellable and Nonswellable

waterbar are different. Please refer SPECIFICATION in the

TECHNICAL DATA SHEET.

Do not stretch or pull the Dr. Fixit Waterbar and make it

longer than its existing length. If you do this, then the

effectiveness of the waterbar will reduce drastically and it

will not be able to seal the joint properly.

FINISHED WATERPROOF JOINT

Waterbar Application Manual

(Sketches)

SECOND

POUR

Cut away view showing Dr. Fixit Waterbar inside a typical

horizontal construction joint

SECOND

POUR

FIRST

POUR

Vertical Joints in raft slab

VERTICAL JOINT - HANGING WATERBAR

USING BINDING WIRE OR STRING

IF IT DOES NOT STICK TO PRIMER

TYPICAL PLACEMENT OF WATER BAR IN

CONSTRUCTION JOINTS OF BASEMENT OR CELLAR

Waterbar Application Manual

products

Question: In hot weather, will Dr. Fixit waterbar become

soft and melt?

Answer: No, the unique structure of Dr. Fixit Waterstop

ensures that it does not melt and flow in hot weather,

unlike other waterstops.

DR. Fixit Waterbar SW 2020 is the only hydrophilic

rubber swellable waterbar having such a large cross

section. Cross section of SW 2020 is 20mm x 20 mm =

400 sq mm. Other waterbars are of much smaller cross

section.

Dr. Fixit Waterbar NSW 2525 is made of superior

material made with the latest technology in the USA in

international standard extruding machines. The

manufacturing process complies fully with ISO 9001.

Comparision with other similar

process which exerts less pressure on the surrounding

concrete and is the preferred specification today.

Frequent questions

Question: Will the Waterbar become hard or deteriorate

with time?

Answer: Dr. Fixit Waterbar is designed to remain flexible

for the lifetime of the concrete. It will not deteriorate

with time. It will last the lifetime of the structure.

Question: You have two types of waterbars. One is

swellable and the other is nonswellable. Which should I

choose for my project?

Answer: The choice of waterbar depends on various

factors. The first and primary characteristic is the

waterhead that it has to resist in your structure. If you

have a high waterhead, you will choose the swellable

type. If you have a low waterhead, you will choose the

nonswellable type. If you are not sure how well you will be

able to vibrate in the construction joint area, you will

choose the swellable type. If you are fairly certain about

your concrete quality compaction just below and just

above the construction joint, you will choose the

nonswellable type. However, in view of the fact that the

price difference is very less between the swellable and

the nonswellable waterbar in Pidilite, it may be advisable

to choose the swellable type since it offers significantly

more benefits.

Question: Is it compulsory to make a keyway or groove

and then place the waterbar?

Answer: No, it is not. The waterstop will work effectively

even if there is no keyway as long as there is enough

head of concrete on top to press the waterbar. This is

especially important in the case of the nonswellable

waterbar. For best results, the recommended head of

concrete for nonswellable waterbar is 400 mm and for

swellable waterbar, the head can be as low as 150 mm.

Question: How do I know if the waterstop I have used

in my project is the original patented Dr. Fixit Waterbar

or not?

Answer: It is always advisable to buy from any of our

registered dealers. That way, you are assured of getting

the original waterbar. There are instances when fake

waterbars made of cheap black material will be shown as

Dr. Fixit waterbar or equivalent. Only when the waterbar

fails will you know that the product has caused you

enormous problems. But by then, it may be too late. It is

always advisable to buy the original product and be 100

percent sure.

Question: Some waterstop companies claim that their

waterstop is better because it resists a waterhead of 100

mtrs. Is that of better quality?

Answer: You need to buy a waterstop that fits your need

and your budget. If your structure has to resist only 15

mtrs waterhead throughout its entire life, there is no

need to pay a very high price and buy a waterstop which

can resist 100 mtrs waterhead. However, if you are able

to get a waterstop which will resist a very high pressure

and at the same time costs very less, then buy it.

Question: Is Dr. Fixit waterbar competitive in price

compared to other waterbars in India?

Answer: Compare our product with any other waterstop

available in the market. When others give smaller cross

sections of 10 mm x 10 mm or 5 mm x 20 mm, Pidilite is

offering a cross section of 20mm x 20 mm for the same

price as others. i.e. you are getting a waterstop which has

three times the volume which also means that the price

is nearly one third that of competitors for the same

category.

Question: Our consultant has specified that the waterstop

has to expand in volume by 300 percent so that it will

work well. Does your swellable waterstop swell by 300

percent?

Answer: Generally the gap in construction joints varies

from 0 mm to 4 mm. More the waterstop swells, more

the pressure that is exerted inside the concrete. For this

reason, uncontrolled expansion is generally not preferred

by knowledgable engineers. Dr. Fixit Waterbars are

designed to swell by 150 percent more than original

volume which is the specified standard in many advanced

countries. This Controlled

Swelling property of Dr. Fixit Waterbar is a patented

Question: How is it that Dr. Fixit waterbar is priced lesser

than other competitor's products?

Answer: Pidilite is able to give this technically advanced

Controlled Expansion Waterbar at such a low price by

manufacturing it in large quantities.

8

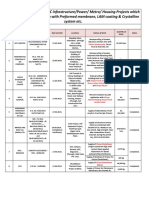

Comparision of Different types of Strip Waterbars (User Guide)

No. Property

Compressible

(Nonswellable Waterbar)

Other Regular

SwellableWaterbar

Pidilites special 2 in 1

Controlled Expansion

Waterbar

SW 2020

1.

Concrete Grade

Can be used in concrete grade

as low as M15 or M20

Preferable to use in concrete

grade M 25 and above only

Can be used in concrete grade

from M20 to M40

2.

Cover required

20 mm

75 mm

50 mm

3.

Size available

(Bigger the better)

Generally 20 mm x 25 mm

(500 sq. mm.)

Typically

5mmx10mm

10mmx10mm

5mmx20mm

Big size

20mmx20mm (400 sq. mm)

Value for money

4.

Expansion

(More need not

necessarily be

better, please read

detailed literature

on this)

None

250 to 300

150 over and above

original volume

5.

Technology

Proven technology. Has been

used for many years.

Swelling technology better

than compressible waterbars

Next higher level in

technology after swelling

technology

6.

Water Head which

it can resist

15-20 mtrs

50-100 mtrs

60-80 mtrs

7.

Flexibility and

compressbility

Very good

Fairly rigid

Very good

8.

Dual Role of

compressible and

swelling waterstop

No

No

Yes

9.

Availability

Available always

Not available always

Available always

10.

Technical Backup

Not available always

11.

Offering Full range

of waterstop

Always available from Pidilite.

Separate division formed to

service this market

Pidilite offers entire range

Always available from Pidilite.

Separate division formed to

service this market

Pidilite offers entire range

Competitors do not offer

entire range

9

Notes

Potrebbero piacerti anche

- Internship CompanyDocumento19 pagineInternship CompanySourNessuna valutazione finora

- Sika Vietnam Tunnel ProjectsDocumento12 pagineSika Vietnam Tunnel ProjectsNguyen Thanh BinhNessuna valutazione finora

- Portrait of an Industrial City: 'Clanging Belfast' 1750-1914Da EverandPortrait of an Industrial City: 'Clanging Belfast' 1750-1914Nessuna valutazione finora

- Banglore Master PlanDocumento6 pagineBanglore Master Planshahnidhi1407Nessuna valutazione finora

- IMC Product ListDocumento4 pagineIMC Product ListjosebejoyNessuna valutazione finora

- Techdrain Td5020f SpecificationDocumento1 paginaTechdrain Td5020f SpecificationcmthebossNessuna valutazione finora

- Construction Chemicals 17.06.08Documento27 pagineConstruction Chemicals 17.06.08Kanupriya JainNessuna valutazione finora

- Roofing and Waterproofing Product Catalog 2015 16 2014 - 11 - 04Documento44 pagineRoofing and Waterproofing Product Catalog 2015 16 2014 - 11 - 04Liondo PurbaNessuna valutazione finora

- LTHEARDocumento125 pagineLTHEARLaxmi BharuchaNessuna valutazione finora

- Company BrochureDocumento16 pagineCompany BrochureGer Shortt0% (1)

- The Singapore Engineer - September 2018 IssueDocumento27 pagineThe Singapore Engineer - September 2018 Issuekrpt0tytNessuna valutazione finora

- NWR - Company Profile Updated 2022Documento189 pagineNWR - Company Profile Updated 2022dolceovenby AGNessuna valutazione finora

- Bituplus GDocumento4 pagineBituplus GNicholas WashingtonNessuna valutazione finora

- List of Accrediated 149 New MaterialsDocumento9 pagineList of Accrediated 149 New MaterialsjoyNessuna valutazione finora

- Sales Blitz List VSIP2 ADocumento22 pagineSales Blitz List VSIP2 AHồ Vy100% (1)

- CHRYSO CredentialsDocumento8 pagineCHRYSO CredentialsAbhisheK MishrANessuna valutazione finora

- Product Submittal: Mastertop 1205Documento61 pagineProduct Submittal: Mastertop 1205Nagendra BurabattulaNessuna valutazione finora

- List of Enlisted Vendors Civil /electrical / Miscellaneous WorksDocumento72 pagineList of Enlisted Vendors Civil /electrical / Miscellaneous WorksTushar SharmaNessuna valutazione finora

- Aac Block Project by Aerocon Buildwell Pvt. Ltd. (Ekiesl-June 2016-02)Documento76 pagineAac Block Project by Aerocon Buildwell Pvt. Ltd. (Ekiesl-June 2016-02)esha108Nessuna valutazione finora

- Sowa Company Profile PDFDocumento37 pagineSowa Company Profile PDF2050978Nessuna valutazione finora

- Manual Samsung Washing WD18J7 English-ArabicDocumento124 pagineManual Samsung Washing WD18J7 English-ArabicJUSUFNessuna valutazione finora

- Loch Jiji LongDocumento4 pagineLoch Jiji Longmuth sokvisalNessuna valutazione finora

- Small Construction Company ProfileDocumento17 pagineSmall Construction Company ProfileMajaya JonasiNessuna valutazione finora

- S.No Category Name of Bidder Email Id Contact Number Capex A (1-3 KWP)Documento2 pagineS.No Category Name of Bidder Email Id Contact Number Capex A (1-3 KWP)Sharafat AliNessuna valutazione finora

- Internship Report ContentDocumento50 pagineInternship Report ContentHarshan HsNessuna valutazione finora

- Geosynthetic ProductsDocumento1 paginaGeosynthetic ProductsSharief ShaikNessuna valutazione finora

- 44 Anchor Bolts For Brick MasonryDocumento11 pagine44 Anchor Bolts For Brick MasonryNelson Eduardo Zárate SalazarNessuna valutazione finora

- TDS - Mastertop 300Documento3 pagineTDS - Mastertop 300Venkata RaoNessuna valutazione finora

- Waterproofing System For Building Standard in Vietnam CondtionDocumento18 pagineWaterproofing System For Building Standard in Vietnam CondtionNguyễn Việt LongNessuna valutazione finora

- Appendix - 9 - List of MakesDocumento105 pagineAppendix - 9 - List of MakesRamesh BabuNessuna valutazione finora

- SAE Catalogue Nov21Documento52 pagineSAE Catalogue Nov21SalahSangkaNessuna valutazione finora

- Grofers Market Sizing - Ripan - DuttaDocumento3 pagineGrofers Market Sizing - Ripan - DuttaKapil Rampal0% (1)

- Top 250 International ContractorsDocumento10 pagineTop 250 International ContractorsVankokhNessuna valutazione finora

- SUNANDA - Epoxy BrochureDocumento8 pagineSUNANDA - Epoxy BrochureGuru PrasathNessuna valutazione finora

- Cement and Steel in UAE - Dubai Chamber of CommerceDocumento28 pagineCement and Steel in UAE - Dubai Chamber of Commercesonia87Nessuna valutazione finora

- ENR TOP 250 Global Contractors in 2019Documento72 pagineENR TOP 250 Global Contractors in 2019yoonhkimNessuna valutazione finora

- Effects of Broken Clay Bricks in Treatment of Grey Water To Be Used For IrrigationDocumento33 pagineEffects of Broken Clay Bricks in Treatment of Grey Water To Be Used For IrrigationFred BamwineNessuna valutazione finora

- Main Panel: Agarwall VillaDocumento15 pagineMain Panel: Agarwall VillaEr.AROCKIA STEPHAN VSGNessuna valutazione finora

- HE Project 2Documento20 pagineHE Project 2Vinayak Gani100% (1)

- Technical Data Sheet: Krystol T1 Waterproofing SystemDocumento24 pagineTechnical Data Sheet: Krystol T1 Waterproofing Systemsri projectssNessuna valutazione finora

- Geostructurals Client Database - Business DevelopmentDocumento140 pagineGeostructurals Client Database - Business DevelopmentABOOBAKKERNessuna valutazione finora

- Sanctionslistfor Settlement Agreement 134Documento84 pagineSanctionslistfor Settlement Agreement 134Avisheak PalNessuna valutazione finora

- Vacuum DewateringDocumento34 pagineVacuum DewateringRkmanish CoolNessuna valutazione finora

- Sunanda Waterproofing - Product Summary Guide 2021Documento12 pagineSunanda Waterproofing - Product Summary Guide 2021GuruNessuna valutazione finora

- SK Ipt F3Documento22 pagineSK Ipt F3Karthic SKNessuna valutazione finora

- Fieo March Final - 2023Documento44 pagineFieo March Final - 2023Imran KhanNessuna valutazione finora

- Method Statement Supercast SW30Documento5 pagineMethod Statement Supercast SW30Gry Ardiansyah100% (1)

- Precast Concrete and Its Allied ProductsDocumento29 paginePrecast Concrete and Its Allied Productsvishwasrbhat100% (2)

- Hengshui Jingtong Rubber Co.,LtD - Waterstop Series TDS PDFDocumento74 pagineHengshui Jingtong Rubber Co.,LtD - Waterstop Series TDS PDF李倩Nessuna valutazione finora

- CICO Thermoseal XLDocumento2 pagineCICO Thermoseal XLsanjayNessuna valutazione finora

- Ink202210 DLDocumento76 pagineInk202210 DLFabio Enrique Gomez RamirezNessuna valutazione finora

- Bca St11 Submission 28 JAN 2020 00: General Notes & Structure Drawing List (For Pontoon)Documento25 pagineBca St11 Submission 28 JAN 2020 00: General Notes & Structure Drawing List (For Pontoon)Gunawan IwanNessuna valutazione finora

- Porcellan Presentation 3Documento19 paginePorcellan Presentation 3Sameer ShahidNessuna valutazione finora

- IRC Accredited ProductsDocumento8 pagineIRC Accredited Productss pradhanNessuna valutazione finora

- Progress 742 Leads 2021Documento57 pagineProgress 742 Leads 2021putri pertiwiNessuna valutazione finora

- Ankit FastenersDocumento4 pagineAnkit FastenersKarthik AbhiNessuna valutazione finora

- The Effect of Using Board Games in Reducing Language AnxietyDocumento65 pagineThe Effect of Using Board Games in Reducing Language AnxietyWandi huangNessuna valutazione finora

- 344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel StructureDocumento327 pagine344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel Structurej f100% (1)

- Nirmiti Word PresentationDocumento70 pagineNirmiti Word Presentationshreyas kulkarniNessuna valutazione finora

- E T 500Documento5 pagineE T 500Anup PrakashNessuna valutazione finora

- Sismotectonique TunisieDocumento1 paginaSismotectonique TunisiebarouniamineNessuna valutazione finora

- VSL Construction SystemsDocumento29 pagineVSL Construction SystemsbarouniamineNessuna valutazione finora

- 6 e 91 D 330Documento32 pagine6 e 91 D 330barouniamineNessuna valutazione finora

- VSL Construction SystemsDocumento26 pagineVSL Construction SystemsbarouniamineNessuna valutazione finora

- ASCE 7-05 Table 15-4-2Documento1 paginaASCE 7-05 Table 15-4-2barouniamineNessuna valutazione finora

- Col 713824Documento16 pagineCol 713824barouniamineNessuna valutazione finora

- Amiantit Polyolefin Piping Systems Co.: Product Guide Hdpe Pipe SystemsDocumento2 pagineAmiantit Polyolefin Piping Systems Co.: Product Guide Hdpe Pipe SystemsbarouniamineNessuna valutazione finora

- Guard Post Installation For: CertifiedDocumento1 paginaGuard Post Installation For: CertifiedbarouniamineNessuna valutazione finora

- Abandonment of Sewer MainsDocumento5 pagineAbandonment of Sewer MainsbarouniamineNessuna valutazione finora

- Concrete For Industrial Floors: Specifying Concrete To BS EN 206-1/BS 8500Documento4 pagineConcrete For Industrial Floors: Specifying Concrete To BS EN 206-1/BS 8500barouniamineNessuna valutazione finora

- APPSCoDocumento36 pagineAPPSCoshafeeqm3086Nessuna valutazione finora

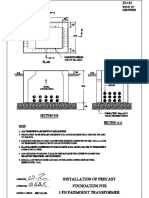

- Installation of Precast Foundation For 1 PH Padmount TransformerDocumento1 paginaInstallation of Precast Foundation For 1 PH Padmount TransformerbarouniamineNessuna valutazione finora

- Ada 240629Documento75 pagineAda 240629barouniamineNessuna valutazione finora

- Prefabricated Manhole Detail: CertifiedDocumento1 paginaPrefabricated Manhole Detail: CertifiedbarouniamineNessuna valutazione finora

- Fire Damaged Concrete StructuresDocumento11 pagineFire Damaged Concrete StructuresbarouniamineNessuna valutazione finora

- Industrial Floors 1Documento3 pagineIndustrial Floors 1barouniamineNessuna valutazione finora

- Foundation Analysis and Design: Fifth EditionDocumento1 paginaFoundation Analysis and Design: Fifth EditionbarouniamineNessuna valutazione finora

- LECTURE 9 - Building Envelope With Green Building CodeDocumento38 pagineLECTURE 9 - Building Envelope With Green Building CodeKhyverAndreiAmadorNessuna valutazione finora

- M2U Bridge Lengthening, Widening and Other Modifications (Henry Ah Cann)Documento16 pagineM2U Bridge Lengthening, Widening and Other Modifications (Henry Ah Cann)TaiCheong LeeNessuna valutazione finora

- RDSO Drawing ListDocumento42 pagineRDSO Drawing Listkaushik96040% (5)

- Functional Competency Directory For Civil Roles: Damodar Valley CorporationDocumento9 pagineFunctional Competency Directory For Civil Roles: Damodar Valley Corporationlaloo01Nessuna valutazione finora

- RESUME - FIRE FIGHTING - OthersDocumento4 pagineRESUME - FIRE FIGHTING - OthersAseer Ahmed0% (1)

- IPT ManualDocumento19 pagineIPT ManualAarif07Nessuna valutazione finora

- Desyne Variance: Cost EstimateDocumento2 pagineDesyne Variance: Cost EstimateAzrael OrtegaNessuna valutazione finora

- Civil Engineering Design of G Plus Two FloorsDocumento49 pagineCivil Engineering Design of G Plus Two FloorsMubeen Akhtar100% (1)

- Presentation Permeation Grouting Prof - Dr. HanifiDocumento31 paginePresentation Permeation Grouting Prof - Dr. HanifiChalakAhmedNessuna valutazione finora

- Mogas TankDocumento4 pagineMogas Tankrhannie garciaNessuna valutazione finora

- DensElement Technical GuideDocumento16 pagineDensElement Technical GuideRed BarnNessuna valutazione finora

- The Minico2 Houses in Nyborg: - Valuable LessonsDocumento23 pagineThe Minico2 Houses in Nyborg: - Valuable Lessonsand.simonescuNessuna valutazione finora

- 15eng 3.5 Building Structures - IiiDocumento2 pagine15eng 3.5 Building Structures - IiiRakeshNessuna valutazione finora

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysis (Blanked) PDFDocumento5 pagineGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysis (Blanked) PDFljv004Nessuna valutazione finora

- Phase2 Analysis Information Tajeo Esperanza NV 920: Project SummaryDocumento5 paginePhase2 Analysis Information Tajeo Esperanza NV 920: Project SummarysanchezmendozaaNessuna valutazione finora

- SPE 184702 Cement Displacement FinalDocumento20 pagineSPE 184702 Cement Displacement FinalMauricio TrebilcockNessuna valutazione finora

- Analysis and Design of Underpass RCC BridgeDocumento6 pagineAnalysis and Design of Underpass RCC Bridgekashi BhojiaNessuna valutazione finora

- Api 579Documento60 pagineApi 579rastogi_rohit91% (23)

- 02 Berth Scouring ProtectionDocumento39 pagine02 Berth Scouring ProtectionMobile LegendsNessuna valutazione finora

- Typical Plan of Box Drain Outlet in Rain Water Harvesting (RWH) PitDocumento1 paginaTypical Plan of Box Drain Outlet in Rain Water Harvesting (RWH) PitDipNessuna valutazione finora

- Sikament - 163: High Range Water - ReducingDocumento2 pagineSikament - 163: High Range Water - ReducingBoby culiusNessuna valutazione finora

- 3d Stability Analysis of Gravity DamsDocumento10 pagine3d Stability Analysis of Gravity DamsCan EryilmazNessuna valutazione finora

- Glamping Pods A (Layouts & Costings)Documento15 pagineGlamping Pods A (Layouts & Costings)rajnish kumarNessuna valutazione finora

- Agitation MixingDocumento23 pagineAgitation MixingvicdejoNessuna valutazione finora

- IRC-SP-89 (Part II) - 2018 - Guideline For Design of Stabilised PavementDocumento37 pagineIRC-SP-89 (Part II) - 2018 - Guideline For Design of Stabilised PavementSachin TagdeNessuna valutazione finora

- Technical Data Homogeneous Bronze: BenefitsDocumento3 pagineTechnical Data Homogeneous Bronze: BenefitsEjang GutNessuna valutazione finora

- Cracks: in BuildingsDocumento25 pagineCracks: in BuildingsZhiwar oramari100% (1)

- Review Questions Utilities Part 5 PlumbingDocumento12 pagineReview Questions Utilities Part 5 PlumbingDhanna Mae ManluluNessuna valutazione finora

- Pump HP Calculation LSGD WssDocumento4 paginePump HP Calculation LSGD Wssapi-320179740100% (3)