Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Elasticity 1

Caricato da

Sesha Sai KumarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Elasticity 1

Caricato da

Sesha Sai KumarCopyright:

Formati disponibili

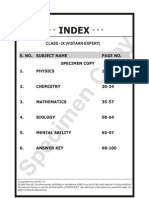

PHYSICS - I C

ELASTICITY

ELASTICITY

*

I nter atomic for ces

* Elastic M odulii

* Behaviour of wir e under str ess

* Elastic ener gy

1.1 I NTRODUCTI ON

Elasticity deals with property of a material, its

strength and ability to withstand against external

forces which are acting on it. While selecting a

suitable material for a project, an engineer is always

interested to know its strength. The strength of a

material may be defined as an ability to resist its

failure under the action of external forces. As a matter

of fact the properties of a material under the action

of external forces are very essential, for an engineer,

to enalbe him, in designing him all types of structures

and machines.The properties of matter like elasticity,

surface tension, viscocity, can be studied well with

the help of interatomic and intermolecular forces.

The for ces acting between the atoms due to

electr ostatic inter action between the char ges of

the atoms ar e called inter atomic for ces. Thus

interatomic forces are electrical in nature. The

interatomic forces are active if the distance between

the two atoms is of the order of atomic size

1010 m .

During interaction between the two atoms, the

following electrostatic forces will be active

(i)Attractive forces between the nucleus of one atom

AKASH MULTIMEDIA

lsion

1.2 I NTERATOM I C FORCES

repu

The forces acting among charged particles in

an atom are responsible for structure of atom. The

electromagnetic forces acting among atoms are

responsible for the structure of molecules. The

electromagnetic forces acting among the molecules

are responsible for the structure of matter and their

elastic behaviour.

and electrons of the other atom. These attractive

forces tend to decrease the potential energy of the

pair of atoms.

(ii) The repuslive forces between the nucleus

of one atom with the nucleus of another atom and

electrons of one atom with the electrons of the other

atom. These repulsive forces tend to increase the

potential energy of pair of atoms.

The potential energy U is related with the force

dU

F by the relations. F

. The variation of

dr

potential energy U(r) and interatomic force F(r) with

separation r between two atoms have been shown in

graphs (fig (1), fig (2))

x

O

r0

attraction

fig.(2)

From graphs the following points are observed.

(i)At large distances, the potential energy is

negative and becomes more negative as r decrease.

It implies that interatomic force in this region is

5

PHYSICS - I C

ELASTICITY

attractive. For a particular value of r denoted by x in

fig.(2), the attractive interatomic force becomes

maximum. After this distance x, the attractive force

starts decreasing rapidly with the further decrease in

the value of r

the force of attraction becomes maximum. After this

distance, the force of attraction decreases and

becomes zero at a distance r0. It is found that foce of

attraction between the molecules varies inversely as

the seventh power of intermolecular distance r, i.e.,

(ii) At a distance r0 the potential energy attains

minimum value (maximum negative value). At this

stage, the two atoms will be in a state of equilibrium.

The distance r0 is called as normal or equilibrium

distance. At this distance, the attractive force between

two atoms will become zero.

1

a

orFa 7 The negative sign indicates that

7

r

r

the force is attractive in nature.

(iii) As the distance is further decreased below

r0, the potential energy starts increasing, becomes

zero for a particular value of r and after this becomes

positive. In this region, the interatomic force is

repulsive, the repulsive force increases very rapidly

as the distance between the two atoms decreases.

So, the two atoms cannot be fused together easily.

therefore, atoms are regarded as hard elastic spheres.

1.3 I NTER M OL ECUL AR FORCES

The for ce between the molecules due to

electr ostatic inter action between the char ges of

the molecules ar e called inter molecular for ces.

Thus intermolecular forces are also electrical in

origin. These forces are active if the separation

between two molecules is of the order of molecular

size 10 9 m

The variation of intermolecular forces with

distance is shown in fig.

repu

lsion

x

O

r0

r

attraction

fig.(2)

(i) For large distnace r, the intermolecular force is

neglisibly small. As the distance decreases, the force

of attraction increases. At a particular distance x,

AKASH MULTIMEDIA

Fa

(ii) When the distance between the molecules

becomes less than r0, the force becomes repulsive in

nature. The repulsive force increases very rapidly

with decrease in intermolecular distance. It is found

that repuslive force varies inversely as the ninth

power of r, ie. Fr

1

b

or Fr 9

9

r

r

1.4 : Some impor tant defimitions

(i)Defor ming For ce : When an exter nal for ce is

applied on a body which is not fr ee to move, the

molecules of the body ar e for ced to under go a

change in their r elative positions. Due to this

change, the body may suffer a change in length

(or ) volume (or ) shape. Such a body is said to be

deformed. The applied for ce is called defor ming

for ce.

(ii) Restor ing for ce : The for ce developed within

t he body on account of r elat ive molecular

displacement is called inter nal for ce (or ) elastic

for ce (or ) r estor ing for ce.

At equilibrium the restoring force developed in

a body is equal and opposite to the deforming force

applied on the body.

(iii) Rigid body : A body is said to be r igid if the

r elative positions of its constituent par ticles

r emain unchanged inspite of any amount of

defor ming force. There is no perfect rigid body. The

nearest approach to a rigid body is diamond.

(iv) Elasticity : I t is the pr oper ty of mater ial of a

body by vir tue of which the body r egains its

or iginal length, volume and shape after the

defor ming for ces have been r emoved.

6

PHYSICS - I C

If a body regains its original length, volume and

shape completely when the deforming forces are

removed, then the body is said to be a perfectly elastic

body. There is no perfectly elastic body in nature.

The nearest approach to a perfectly elastic body is

Quartz fiber.

(v) Reason for elasticity : In a solid, atoms and

molecules are arranged in such a way that each

molecule is acted upon by the forces due to

neighbouring molecules. These forces are known

as intermolecular forces. The two molecules in their

equilibrium positions are at certain separation (r =

r0) called inter molecular seperation. At this

separation the potential energy is minimum. On

applying the deforming forces, the molecules either

come closer or go far apart from each other. In both

the cases potential energy of molecules is greater

than the minimum. Since every system tends to

remain in the state of minimum potential energy, the

molecules has a tendency to come back to its original

position. Tendency of the body to recover its original

configuration can be interpreted as due to the

presence of some forces known as restoring forces

acting in a direction opposite to that of deforming

forces. This gives rise to the property of elasticity.

When the deforming forces are removed, these

restoring forces bring the molecules of solid to their

respective equilibrium positions (r = r0) and hence

the body regains its original form.

(vi) Plasticity : The pr operty of material of a body

by vir tue of which it does not r egain its or iginal

shape and size (i.e it r emains in the defor med

state) even after the r emoval of defor ming for ce

is called plasticity.

If a body does not have any tendency to recover

its original configuration on the removal of deforming

force, then the body is said to be a perfectly plastic

body. There is no perfectly plastic body in nature,

the nearest approach to a perfect plastic body is putty.

Note 1.1 : Most of the bodies are neither

perfectly elastic nor perfectly plastic. They are

partially elastic.

AKASH MULTIMEDIA

ELASTICITY

1.5 Str ess : When a deforming force is applied on a

body, there will be relative displacement of the

particles. Due to property of elasticity an internal

restoring force is developed which tends to restore

the body to its original state.

Definition :The internal r estoring force acting per

unit ar ea of cr osssection of the defor med body

is called str ess.

Stress

Re storing force

F

Area of cross section A

At equilibrium, as the restoring force is equal in

magnitude and opposite to external deforming force,

stress can also be equal to external deforming force

per unit area on a body.

If F is the external deforming force applied

on the Area A of the body then

Stress

Deforming force ( F )

Area ( A)

* Stress is a tensor quantity

* SI unit of stress is Pascal (N/m2)

* C.G.S. unit of stress is dyne cm2.

* Dimensional formula of stress is (ML1T2)

* The units and dimensions of stress are same

as that of pressure.

Stress developed in a body depends upon how

the external forces are applied over it. On this basis

there are two types of stresses. They are (a) Normal

stress (b) Tangential ( or) shearing stress.

(a) Nor mal Str ess : I f the str ess is nor mal to the

sur face, it is called nor mal str ess. The stress is

always normal in the case of change in length of a

wire (or) volume of a body.

The normal stress can further be compressive

(or) tensile depending upon whether it produces a

decrease (or) increase in length or volume.

(i) L ongitudinal str ess : When a nor mal str ess

changes the length of a body then it is called

longitudinal str ess. (or )

7

PHYSICS - I C

ELASTICITY

When a force is applied nor mal to the cr osssectional ar ea of the body such that its length

changes then the r estor ing for ce developed per

unit cr oss-sectional ar ea is called longitudinal

stress.

Deforming force (F)

Longitudinal stress =

Area of cross - section (A)

It can be further divided into two types, they

are tensile stress and compressive stress.

1) If a rod is stretched by two equal forces

applied normal to its crosssectional area,the

restoring force developed per unit area in this case is

called tensile stress.

A

As shown in figure, a small solid sphere is placed

in a fluid such that it is compressed uniformly on all

sides. The force applied by the fluid acts in

perpendicular direction at each point of the surface

and the body is said to be under hydraulic

compression. This leads to decrease in its volume

without any change of its geometrical shape. The

internal restoring force per unit area in this case is

known as bulk stress and is equal to the hydraulic

pressure in magnitude (applied force per unit area)

F

V V

F

B ody subjected to tensile force

A

Volume stress

F

Force

=

=

(or)

surface area A

Bulk stress

F

Tensile stress

Ex : A string fixed at one end and stretched at

the other end experience tensile stress.

2) If a rod is compressed under the action of

applied forces, the restoring force per unit area is

called compressive stress.

A

F

Body subjected to compressive force

A

F

Com pressive stress

Ex: The pillars of a building experience

compressive stress.

(ii) Volume (or) Bulk stress : When a normal stress

changes the volume of a body then it is called

volume str ess.

When forces of equal magnitude act on a body

normally from all directions, the volume of the body

changes. The body develops internal restoring forces

that are equal and opposite to the forces applied. The

internal restoring force per unit area in this case is

known as volume stress.

AKASH MULTIMEDIA

F

F

= Pressure (P)

(b) Shear ing stress : When the str ess is tangential

to the sur face due to the application of for ces

par allel to the sur face, then the str ess is called

tangential (or ) shear ing stress.

F

Force

=

Shearing stress =

surface area A

If two equal and opposite deforming forces are

applied parallel to the two surfaces of the cube as

shown in the figure, there is relative displacement

between the opposite faces of the cube. The restoring

force per unit area developed due to the applied

tangential force is known as tangential (or) shearing

stress.

A

A

fixed

Note 1.2 : If deforming force is applied on a body

such that normal stress is developed in a body, then

the length or volume of the body may change.

8

PHYSICS - I C

ELASTICITY

Note 1.3 : If deforming force is applied tangential to

the surface, such that tangential stress is developed

in a body, then the shape of the body may change.

F

Note 1.4 :

n

er

When a force F acts at an angle ' q ' with

outward normal n to the area A as shown in figure.

In this case, the stress will have the normal and

tangential components.

To find the linear (or) longitudinal stress, take

the component of the force perpendicular to the plane

of a given area A, then divide this component ( Fer )

by the area A.

F

F cos q

Longitudinal stress =

A

A

To find the shearing stress, take the component

of force parallel to the plane of the given area and

then devide F by the area A.

F

F sin q

Shearing stress =

A

A

The total stress = longitudinal stress + shearing stress

Being the ratio of two similar quantities, strain

is a dimensionless quantity and has no unit. Like

stress, strain is a tensor.

Strain is classified into three types depending

upon the change produced in a body, they are

(i) Longitudinal strain

(ii) Volume strain

(iii) Shearing strain

(i) Longitudinal strain : It isthe ratio of the change

in length of a body to its or iginal length.

Consider a wire of length ' ' and is suspended

from a rigid support. Let a stretching force F be

applied normally to its face. Let the wire suffer a

change in its length.

F

er

el

el

But not F/A.

* Pr oblem 1.1

A steel wir e of 2mm in diameter is str etched

by applying a for ce of 72N. Find the str ess in the

wir e.

Solution :

r 1103 m; F=72N

F

F

72

The stress = 2

2

A pr

p 1103

72

2.292107 Nm2 .

p 106

1.6 Str ain :

When the forces (or) a torque acting upon a body

causes relative displacements of its particles, a

change in length (or) volume (or) shape is produced.

The body is then said to be strained.

Def : The r at io of change pr oduced in t he

dimensions of a body by a system of for ces or

couples in equilibr ium to its or iginal dimensions

is called str ain.

AKASH MULTIMEDIA

change in length

Longitudinal strain =

original length

I f the length incr eases due to tensile str ess,

the cor r esponding str ain is called tensile str ain.

I f the length decr eases due to compressive str ess,

the strain is called compr essive str ain.

(ii) Volume str ain : I t is the r atio of change in

volume of body to its or iginal volume.

Let v be the volume of a given body. Under

the action of a normal stress, let the change in volume

of the body be V .Then

F

V- V

change in volume V

Volume strain = original volume V

9

PHYSICS - I C

ELASTICITY

(iii) Shear ing str ain : I t is defined as angle q in

r adians thr ough which a plane per pendicular to

the fixed sur face of the cubical body gets tur ned

under the effect of tangential for ce .

I t is also the r atio of the displacement of a

x

layer to its distance from the fixed layer. q

Consider a cube of material fixed at its lower

face and acted upon by a tangential force F at its

upper surface as shown in figure (a). The upper

surface is displaced relative to lower surface by x

as show in the figure (b). The perpendicular distance

between upper and lower fixed layer is ' ' . Then

F

G

F

Fixed

Surface

fig (a)

E

D

q

C

Fixed

fig (b)

Shearing strain = q

* Pr oblem 1.2

A copper wir e of length 1m is str etched by

1cm. Find the str ain on the wir e

Solution : The strain

e 1102

0.01

L

1

* Pr oblem 1.3

If a platinum wir e is stretched by 0.5% what

is the str ain on the wir e?

Solution :

e

Fractional increase in the length = strain

L

0.5

0.005 .

The strain =0.5% =

100

AKASH MULTIMEDIA

1.8 Hookes law: Hookes law states that within

elastic limit, the str ess is dir ectly pr opor tional to

the strain

stress strain (for small deformations)

stress = E x (strain)

stress

E

strain

Where E is proportionality constant and it is also

called modulus of elasticity.

Def : M odulus of elasticity of the mater ial of a

body is the str ess in the body to pr oduce unit

str ain (within the elastic limit).

1.7 Elastic limit : The maximum str ess within

which a body can r egain its or iginal size and

shape after the r emoval of the deforming for ce is

called elastic limit. If the stress developed in a body

excedes this limit, then it will not get the initial size

and shape completely, even after the removal of

deforming force.

E depends on the nature of the material, temperature

and impurities. It is independent of dimentions of

the body.

SI unit of E is Pascal (Pa) 1pa 1N / m 2

C.G.S. unit is dyne / cm2

Dimensional formula is ML1T 2

1.9 Factor s effecting Elasticity:

(i) ANNEAL I NG : The processes responsible for

making uniform structures from a given sample

reduce the elasticity of a material while those

responsible for generating smaller regular units inside

the sample increase the elasticity. Hence annealing

decreases elasticity while hammering and rolling

increases it.

(ii)I M PURI TI ES: The impurity having higher

elasticity than the sample to which it is added

increases the elasticity while the impurity with smaller

elasticity decreases the elasticity of the sample.

(iii)TEM PERATURE: Normally, elasticity of the

material gets decreased with rise in temperature.

10

PHYSICS - I C

ELASTICITY

However, INVAR STEEL is a material whose elastic

behaviour is not affected by rise in temperature.

1.10 Types of modulii

Depending on the type of str ess developed

and the r esulting str ain, we have the following

three modulii of elasticity.

(i) Youngs modulus

(ii) Bulk modulus

(iii) Modulus of Rigidity

1.11 Youngs modulus (Y) : I t is the r atio of

longitudinal str ess to the longitudinal str ain

within elastic limit.

longitudinal stess

i.e., Y

longitudinal strain

F

Pr oblem 1.5

A load (M ) suspended fr om a wir e pr oduces

an elongation (e) in the wir e then find the r ise in

temperature required to produce same elongation

in the same wir e.

Consider a wire of length ' ' and cross sectional area A. One end of the wire fixed to rigid

support and a stretching force F is applied normally

to its face as shown in the figure. Due to the

stretching force, the length of the wire changes by

. Then at equilibrium.

F

Longitudinal stress =

A

Longitudinal strain =

F

longitudinal stress A F

Y = longitudinal strain = A

If a force is applied on a wire of radius r

by hanging a load of mass M as shown in figure

AKASH MULTIMEDIA

Y

1 , Hence

A

But as

F

A

Y

sol :

Mg

2

pr

Mg

Y 2

then Y

p r

Pr oblem 1.4

Show that str ess r equir ed to double the

length of wire (or) to pr oduce 100% longitudinal

str ain is numer ically equal to Youngs modulus.

Sol : 1 , 2 2

F

A

2 , Y

F

.......1

AY

at.......2

But from given data

F

F

at t

AY

AYa

Note 1.5 : If two wires having lengths 1 , 2 ; crosssectional areas A1, A2 and Youngs modulii Y1, Y2

are stretched by forces F1, F2 then

F

Y1

F1 1 A2 e2

As Y Ae Y F A e

2

2

2

2

1

Note 1.6 : In terms of volume V of a wire.

As

F

F

F 2

F2

Y

y

Ae

Ve

A e Ve

Where V is the volume of the wire

m

m

as d V

V

d

2

F d

y

me

11

PHYSICS - I C

ELASTICITY

m mass of the wire

d density of material of the wire

In the above formula If V, F, Y are same for two

e1 12

2

e

a

wires then

e2 22

In the above formula if Y, d, F are same for two wires

2

2

e1 1 m2

then e a

m

e2 2 m1

Note 1.7 : As Y

Pr oblem 1.7

Two wires of same length and r adius are

j oined end to end and loaded. The Youngs

modulii of the mater ials of the two wires are Y 1

and Y 2. I f the combination behaves as a single

wire then its Youngs modulus is

e1

F F A FV

2 2

Ae

Ae

Ae

FV

FV

Y 2 4

2

Ae

pr e

m

m

as d V

V

d

Y1 A

e

Y2 A

e2

2

AY

Fm

Fm

Y

dA e

d p 2 r 4e

In the above formula if F, V, Y are same for

two wires then ea

1

1

ea 4

(or)

A

r

Pr oblem 1.6

When a body of mass m, density dB is

suspended from a wir e, its elongation is ewhen

the body is in air. I f the body is completely

immer sed in a non viscous liquid of density d

then its elongation is

In liquid

In air

F = Wa = mg

as e

F

AY

d

F 1 W mg 1

d B

e a F (as , A, Y are same in both cases)

d

1

mg

d

1

1

1

dB

1

e

F

e

dB

e

F

mg

AKASH MULTIMEDIA

e e1 e2

F 2

F

F

e

, e1

, e2

but

AYeq

AY1

AY2

F 2 F

F

AYeq

AY1 AY2

2

1

1

Yeq Y1 Y2

Yeq

2Y1Y2

Y1 Y2

Pr oblem 1.8

Two wires of same length and r adius are

j oined in par allel and loaded. The Youngs

modulii of the mater ial of the wires areY 1 & Y 2.

I f the combination is taken as a single wir e then

itsYoungs modulus is

Y1

y2

A

A

W

Yeq

2A

W

F = F1 + F2

Y 2 A e Y1 Ae Y2 Ae

2Yeq Y1 Y2

Yeq

Y1 Y2

2

12

PHYSICS - I C

ELASTICITY

* Pr oblem 1.9

The length of a metal wir e is 1 when the

tension in it is T 1 and is 2 when the tension is

T 2. Then the actual length of the wire is

Sol : Let its original length be ' ' .

Solution :

r = 0.5 x 103m; L=1m

F = 10N ; e=0.064 x 103m

10

F

F

i) Stress = 2 = p 2 =

A pr

We know e T 1 T1 .... (1)

2 T2 ...... (2)

From (1) & (2)

1

T

1 T2 1 T2 T1 2 T1

2 T2

T T

T2 1 T1 2 T2 T1 2 1 1 2

T2 T1

Pr oblem 1.10

The length of a r ubber cor d is 1 metr es

when the tension in it is 4N and 2 metr es when

the tension is 5N. Then the length in meters when

the tension is 9 N is

sol : Let ' ' be the original length and 3 be

the length of the wire when the tension is 9N.

We know e F

1 4.......1 , 2 5....... 2

3 9.......3

1 4

From (1) & (2) 5 51 5 4 2 4

2

5 1 4 2 ....... 4

-2

1.27310 7 N m

e 0.064 103

(ii) Strain =

L

1

= 0.064 x 103

Stress 1.27310 7

(iii) Y=

Strain 0.064103

= 1.989x1011Nm2

* Pr oblem 1.12

A steel wir e of diameter 1 mm and length

2m is str etched by applying a for ce of 2kg wt.

Calculate (i) the incr ease in length of the wir e,

(i i ) t he st r ai n and (i i i ) t he st r ess.

(g = 9.8 ms2, Y = 2 x 1011 N m2)

1

3

Sol: r 10 m; L 2m;

2

F = 2kg wt = 2 x 9.8N; Y = 2 x 1011 Nm2

i)

1 5 1 4 2 4

1 4

From (1) & (3) 9 5 4 9

1

3

3

2

51 4 2 4

4 2 4 1

4

1

3 51 4 2 9

3 51 4 2 9

36 2 361 4 3 201 16 2

20 2 16 1 4 3 3 5 2 4 1

* Pr oblem 1.11

A steel wir e of 1mm diameter and of length

1m is str etched by applying for ce of 10N. I f the

incr ease in length is 0.064mm, find (i) the str ess,

(ii) the strain and (iii) theYoungs modulus of the

wir e.

AKASH MULTIMEDIA

Y

e

F L

r 2 e

FL

2 9.8 2

2

2

r Y

1

3

10 2 1011

2

= 2.495x104m

ii)

The strain=

e 2.495104

L

2

= 1.248104

iii) The stress = Y x strain

4

11 2.49510

10

= 2.49510 7 Nm 2

13

PHYSICS - I C

ELASTICITY

* Pr oblem 1.13

What mass must suspended fr om the fr ee

end of a steel wir e of length 2m and diameter

1mm to str etch it by 1mm? (Y=2x1011Nm2)

1

Mg L

3

Sol: r 10 m; L 2m; Y 2

2

r e

Y r 2 e

gL

1

2

3

210 10 1103

2

9.82

11

102 100

8.015kg

9.8 4

39.2

* Pr oblem 1.14

A br ass wir e of length 5m and cr oss section

1mm2 is hung fr om a r igid suppor t, with a br ass

weight of volume 1000 cm3 hanging fr om the

other end. Find the decr ease in the length of the

wir e, when t he br ass weight is complet ely

immer sed in water.

(Ybrass=1011 Nm2; g=9.8ms2; water 1gcm 3 )

Sol:

When a weight is hung in air from the other

end of a wire, F = Mg. The increase in length of the

wire, e = ?

FL

Young's modulus, Y

Ae

MgL

e

.

AY

When weight hung in a liquid,

Weight of the body in the liquid = Mg - V g

where V is the volume of the body

This is the force, F acting on the wire i.e.,

F = Mg V g

Increase in length of the wire,

e/

Mg vg L

AY

which is less than the increase in length of the

wire when the weight is in air.

Decrease in length = e in air - e| in liquid

AKASH MULTIMEDIA

MgL Mg Vg L

AY

AY

VgL

AY

Here, V = 1000cm3 = 1000 x 10-6m3

=1gcm3=1x103kgm3;g=9.8ms2;L=5m

A 1mm2 1106 m2 ;Y 11011 Nm2

The decrease in length

1000106 110 3 9.8 5

=

1106 11011

= 49 x 10-5 m = 0.49 mm

* Pr oblem 1.15

A copper wir e and a steel wir e of r adii in

the r atio 1:2, lengths in the r atio 2:1 ar e stretched

by the same force. I f the Young's modulus of

copper = 1.1 x 1011Nm2 find the r atio of their

extensions

(youngsmodulus of steel = 2 x 1011 N/m2).

FL

Sol: we know e 2

r Y

e1 L1

r

2

r1

e 2 L 2

Y2 F

Y F

1

Here r1:r2= 1:2, L1:L2 = 2:1 Y1=1.1x1011

Nm2; Y2 = 2.0x1011Nm2

2

e1 2 2 2.01011 16 160

e 2 1 1 1.11011 1.1 11

e1:e2 = 160:11

* Pr oblem 1.16

An aluminium wir e and a steel wir e of the

same length and cr oss-section ar e j oined end to

end. The composite wir e is hung fr om a r igid

suppor t and a load is suspended fr om the fr ee

end. I f the incr ease in the length of the composite

wir e is 2.7mm, find the incr ease in the length of

each wir e.

(Y A1=2x1011Nm2, Y steel =7x1011Nm2)

Sol: Total increase in length, e = e1 + e2.

e1 + e2 = 2.7 mm

14

PHYSICS - I C

ELASTICITY

FL

AY

1

As F, A, L are same for both the wires. So, e

Y

e1 Y2 21011 20

20

e1 e 2

=

,

11

e 2 Y1 710

7

7

substituting in e1 + e2 = 2.7 mm

we know e

20

e1 e 2 2.7mm

7

e2 = 0.7 mm

e1

27e 2

2.7mm

7

* Pr oblem 1.18

A steel wire of length 2 m and cross sectional

ar ea 2 mm2 is fixed at one end and str etched by

suspending a block of mass 2 kg on the sur face

of the moon. I f theYpungs modulus of steel is 2

x 1011 N m2 find the increase in the length of the

steel wir e.

1

(g on the moon of the g on the earth)

6

Sol: L = 2 m ; A = 2 mm2 = 2 x 106 m2;

20

20

e 2 0.7 2.0mm

7

7

M = 2 kg ; g on the moon =

* Pr oblem 1.17

A block of mass 1 kg is fastended to one end

of a wir e of cr oss - sectional ar ea 2 mm2 and is

r otated in a ver tical cir cle of r adius 20 cm. The

speed of the block at the bottom of the cir cle is

3.5 m s1. Find the elongation of the wir e when

the block is at the bottom.

Sol: i) Tension at the bottom of the circle,

mv

13.5

mg

19.8

r

0.2

2

= 61.25 + 9.8 = 71.05 N

This tension in the string is equal to the force,

F i.e. F = 71.05N, L =r = 0.2m.

The increase in length ,

FL

71.050.2

e

AY 2106 21011

= 3.553 x 105m

ii)

Tension at the top of the circle,

T = Tension at the bottom 6 mg

= 71.05 6 x1x9.8 = 71.05 58.8 = 12.25 N.

F = 12.25 N; L = 0.2 m.

The increase in length

e

FL

12.25 0.2

AY 2106 21011

g 9.8 2

ms

6

6

N

;e ?

m2

The increase in length ,

Y 21011

FL MgL

29.82

AY

AY

62106 21011

= 1.633 x 105m

Pr oblem 1.19

One end of a unifor m wire of length Land

mass M is attached r igidly to a point in the r oof

and a load of mass mis suspended from its lower

end. I f A is the area of cross - section of the wire

then find the str ess in the wir e at height xfr om

its lower end (x < L )

Tension in the string at point P is

(L-x)

T = wt of load + wt of wire of length x

M

x T mg

xg

L

mg Mxg

m

Stress at P = T/A = A AL

Pr oblem 1.20

A metal ring of radius rand cross- sectional

area A is to be fitted on to a wooden circular

disc of r adius R (R > r ). I f the Youngs modulus

of the mater ial of the r ing is Y the force with

which the metal r ing expands is

P

L

(R > r)

= 0.6125105 m

AKASH MULTIMEDIA

15

PHYSICS - I C

ELASTICITY

Initial length of wire 2p r

for it to be fitted onto a wodden disc, its final

length must be 1 2p R

F

Ae

YA R r

e 1 2p R r , Y

F

YAe YA2 p R r

2pr

YA R r

Pr oblem 1.21

I f two wir es ar e ar r anged as shown in the

figur e. What ar e the elongations of upper and

lower wir es

Sol :

for lower wire F = m2g

Pr oblem 1.23

A copper wire of negligible mass, length ,

cr oss - sectional ar ea (A) is kept on a smooth

horizontal table with one end fixed, a ball of mass

m is attached at other end. The wir e and the

ball are rotated with angular velocity w . If wire

elongates by then find Youngs modulus of

wir e. I f on incr easing the angular velocity fr om

w to w 1 the wir e br eakdown, obtain br eaking

str ess

Sol : a) r

F = T = mrw2

m w 2

F

as in small , F mw 2 y

Ae

F2

m g

e

e 2 2

Ay2

Ay2

A y1

1

m1

A 2

For upper wire F = (m1 +m2)g y2

m2

e

m m2 g 1

F 1

e 1

Ay1

Ay1

elongation of 2nd wire

3

A y3

mg 2

e2

D

Ay2

m

elongation of 3rd wire

mg 3

e3

Ay3

displacement of B is e1

displacement of C is e1 + e2

displacement of D is e1 + e2 + e3

b) We know Breaking stress

Breaking force

= Area of cross sec tion

m w 1

= A

Pr oblem 1.22

As shown in adjucent figur e if a load of mass

(m) is attached at lower end of lower wir e. Then

find the displacements of the points B, C, D ar e

Sol : As shown in figure

elongation of first wire

A y1

1

mg 1

B

e1

2

Ay1

A y2

AKASH MULTIMEDIA

mw 2

Pr oblem 1.24

A stone of mass (m) is attached to one end of

a small wir e of length and cr oss - sectional

area (A) suspended ver tically. The stone is now

r otated in hor izontal plane such that the wir e

mak es an angle ' q ' with ver t ical. Find the

increase in length of wire if itsYoungs modulus

is Y.

mg

Sol : From fig. T cos q mg T

cos q

S

T sin q mRw 2

q

L

F T

AY AY

mg

AY cos q

T

T cos q

q

T sin q

mg

16

PHYSICS - I C

ELASTICITY

Note : If ' q ' was not given but R, w and m was

given then in such case

T 2 cos 2 q T 2 sin 2 q mg mRw

2

T mg mRw

2

and use e

2 2

ii) equal str ains in both wir es

Youngs modulus of br ass = 1 x 1011 N/m2

Youngs modulus of steel = 2 x 1011 N/m2

Brass

wire

Steel

wire

T2

B

As the whole system is in equilibrium, so

t = 0. Taking moment of all the forces acting on

T1 x T2 2 x 0

Pr oblem 1.25

A light r od of length 2 m is suspended fr om

the ceiling hor izontally by means of two ver tical

wir es of equal length tied to its ends. One of the

wir es is made of steel and is of crosssection 103

m2 and the other is of br ass of cr oss section 2 x

103m2. Find out the position along the r od at

which a weight may be hung to pr oduce; i) equal

str ess in both wir es

C

(2 x)

Sol : Suppose a1 and a2 are the cross - sectional

areas, and Y1 and Y2 are the Youngs moduli of steel

and brass wire respectively. Let T 1 and T 2 are

tensions in the steel and brass wires respectively.

Let x is distance of the position of the hanging

weight from the steel wire.

i) First case : For equal stress in both wires, we

have

T1 T2

a1 a2

T

T2

(or) 13

10

2103

......... (ii)

Solving equations (i) and (ii), we get

4

x m

3

ii) Second case : For equal strains in both the wires

e1 = e2

T1

T

2

a1Y1 a 2 Y2

T1

T2

11

3

10 210

210 1011

(or) T1 = T2

........... (iii)

(or)

From equations (ii) and (iii) , we get

x=1m

Pr oblem 1.26

A steel wire of area of cross-section A and

length 2Lis clamped fir mly between two points

seper ated by a distance ' 2L' . A body is hung from

the middle point of the wir e such that the middle

point sags by a distance x. Calculate the mass of

the body and the angle made by the str ing with

the horizontal

AKASH MULTIMEDIA

......... (i)

the rod about C, we have

T

Ay

T1

(or) T2 2T1

x

T

T

Mg

Since ' ' is small

sin tan

x

L

F L

.

A e

YAe YA 2

2 1/ 2

L x L

L

L

17

PHYSICS - I C

ELASTICITY

So tension in the wire (due to elasticity)

1pa 1N / m 2

YA

YA

x 2

x2

F

L

1

L

L

L 2 L

L

2L

YAx 2

2 L2

for small angles sin

2F mg

2.

2 YAx2 x

. mg ,

2L2 L

x Mg

L YA

Mg

Tan

YA

1/ 3

So at lowest point

, Tan

So 8pv 2 / 5.12 1.99.4p 8p 9.8

x

L

Mg

Tan1

YA

1/ 3

Pr oblem 1.27

A spher e of r adius 0.1 m and mass 8p kg is

attached to the lower end of a steel wir e of length

5.0 m and diamet er 103m. The wire is suspended

fr om 5.22 m high ceiling of a r oom. When the

spher e is made to swing as a simple pendulum, it

j ust gr azes the floor at its lowest point. Calculate

the velocity of the spher e at the lowest position.

Y for steel = 1.994 x 1011 N/m2.

5.22m

0.2m

mv2

CFF

r

mg

Sol : As the length of the wire is 5m and diameter

2 x 0.1 = 0.2 m and at lowest point it grazes the floor

which is at a distance 5.22 m from the roof, the

increase in length of the wire at lowest point

L 5.22 5 0.2

= 0.02 m

AKASH MULTIMEDIA

[as q 0 ]

But here r = 5 + 0.02 + 0.1 = 5.12 m

YAX 3

M 3

Lg

1/ 3

and as equation of circular motion of a mass m tied

to a string in a vertical plane is

mv 2 / r T mg

YAx 2

mg

2 L2

x 3 Mg

L3

YA

mv 2 / r T mg cos q

2T sin mg

2T mg

1.9941011 p 5104 0.02

YA

T

L

199.4p N

L

5

i.e., v 2 1215.12 / 8 77.44 , so v = 8.8 m/s.

1.12 Elongation of wir e due to its own weigt:

Consider a wire of length ' ' and cross sectional area A. If density of its material is d then

weight of the wire W A dg

dx

x

Let the wire is hanging from the rigid support.

The wire extends due to self weight

Let us consider an element of thickness dx at

a distance x from the free end.

The weight of the wire of length x is w1 = (Ax)dg

The extension of the element due to this weight is

w1 dx xAdg dx dg

de

x dx

AY

AY

Y

dg

The total extension e de Y x dx

0

0

dg

W

dg2

x

dx

= Y

, e

also e

2 AY

2Y

0

18

PHYSICS - I C

ELASTICITY

* Note 1.8 : The above formula can also derived by

considering total weight at center of mass and using

effective length / 2 .

F / 2

Ae

cm

/2

wt

F mg

2 AY

2 AY

A dg

2 AY

e dg

,

2Y

Note 1.9 : In the above case, if a force F is applied

at the lower end in addition to its weight then the

total elongation is

2dg F

e

2Y

AY

1.13 Ther mal Str ess:

a) Find the for ce with which the r ods acts on

each other at heigher temper atur e.

b) Find the lengths of the r ods at the higher

temperature.

Assume that there is no change in the crosssectional ar ea of the r ods and the r ods do not

bend. Ther e is no defor mation of walls.

1

a Y

aY

2

2 2

1 1

Sol : a) Due to heating the increases in length of the

composite rod will be

I 1a1t 2a2 t 1a1 2a2 t ... (1)

due to compressive force F from the walls,

due to elasticity, the decrease in length will be

F

F

F

D 1 2 1 2 .... (2)

AY1 AY2

A Y1 Y2

As the length of the composite rod remains

unchanged the increase in length due to heating must

be equal to decrease in length due to compression.

When a rod whose ends are rigidly fixed such that it

is prevented from expansion or contraction

undergoes a change in temperature, due to thermal

expansion or contraction a compressive or tensile

stress is developed init. Due to this thermal stress the

rod will exert a large force on the supports. If the

change in temperature of a rod of length ' ' is q o C .

Then

aq as a

Thermal strain =

Thermal stress = Y (thermal strain)

Thermal stress =

Y aq

Force F YAaq

Pr oblem 1.28

Two rodsof different metals, having the same

area of cross - section A, are placed end to end

between two massive walls as shown in fig. If the

temper atur e of both the r ods ar e now r aised by

t 0 C then

AKASH MULTIMEDIA

F

1a1 2a2 t 1 2

A Y1

b)

Y2

A 1a1 2 a2 t

1 2

Y1 Y2

As initially the length of one rod in L1 and due

to heating its length increases by 1 H a11t ,

while due to compression its length decreases by

1 C

F 1

AY1

so its final length

11 1 1 H 1 C

F 1

= 1 1a1t AY

1

19

PHYSICS - I C

ELASTICITY

1.14 Analogy of rod as a spr ing :

for the other rod

2 2 H 2 C

1

2

12 2 2a2t

We know Y

F2

AY2

Note 1.10: In the above problem length of composite

rod remains unchanged, i.e. 11 12 1 2 . but

that of individual rods changes i.e. 11 1 and

12 2 .

Note 1.11 : In the above problem if the displacement

of junction point was asked,

This displacement is equal to change in length

of any one of the rod

F 1

1 1a1t

AY1 where

F 1a1 2a2 t

1 2

A

Y Y

1

2

a1Y1 a2Y2

If 1 2 then

Y Y t

1

2

* Pr oblem 1.29

A st eel wir e, 2mm in diameter, is j ust

st r et ched bet ween t wo f i xed poi nt s at a

temperatur e of 300C. Deter mineits tension when

the temper atur e falls to 200C. (Coefficient of

linear expansion of steel = 0.000011/0C; Young's

modulus for steel = 2.0 x 1011 Nm2)

F

Sol: Thermal stress = Yt

A

Tension in the wire YA t 2 t1 .

Here,

Y =2.0x1011 Nm2 ;

11106 / 0 C;

t2 = 300C; t1 = 200C; radius=1mm=1x103m;

A r 110 10 m

The tension in the wire

2

3 2

= 69.14N

AKASH MULTIMEDIA

AY

(or) F

AY

constant, depends on type of material

and geomentry of rod.

F k (or) (F = kx)

AY

Where k

is t he equivalent spring

constant.

Pr oblem 1.30

A mass mis attached with r od as shown in

figur e. This mass is slightly stretched and released

then find the time per iod. (Y isYoungs modulus

of rod, A is cross sectional area of rod, ' ' is its

length).

A

Y

T 2p

AY

m

m

T 2p

k

AY

1.15 Bulk modulus (K ) :

I t is defined as the r atio of the volume str ess

(nor mal str ess) to the volume str ain within the

elastic limit

volume stress

K

volume strain

F

2.0 1011 11106 106 30 20

stress

F

Y

strain

A

F

F

V V

F

F

20

PHYSICS - I C

ELASTICITY

when a solid (or) fluid is subjected to a change

in pressure, its volume changes but the shape remains

unchanged. The force per unit area, applied normally

and uniformaly to the surface of the body i.e pressure gives the stress and the change in volume per

unit volume gives the volume strain.

Thus if the volume 'V' of the body decreases

by an amount V when the pressure on its surface

is increased uniformaly by p , then in equilibrium.

volume stress = p

volume strain

Bulk modulus

P

V

The bulk modulus of a gas in adiabatic condition

is defined as adiabatic Bulk modulus of elasticity.

For adiabatic process PV = constant

differentiating both sides

P gV g 1dV V g dp 0

P gV g1dV V g dp

P gV gV 1dV V g dp

V

V

1.17 Adiabatic Bulk modulus of elasticity Ef :

1

dV dp

V

dp

dp

g p

gp

dV

dV E g p

f

V

V

gp

K V

P

V

The negative sign shows that with increase in

pressure, the volume decreses.

Note 1.12 : All the states of matter possess bulk

modulus

K solids K liquids K gases

Hence, adiabatic Bulk modulus of elasticity is

equal to g times pressure

Note 1.14 : Ratio of adiabatic to isothermal Bulk

modulus of elasticity

Note 1.13 : Gases have two bulk modulli, they are

Ef

1.16 I sother mal Bulk modulus of elasticity Eq :

Eq

The bulk modulus of a gas in isothermal condition is defined as isother mal Bulk modulus of

eleasticity. We know for isother mal process

PV = constant

Differentiating both sides

pdV + Vdp = 0

PdV = V dp

dp

dV

V

dp

Eq P

dV

Hence isot hermal elasticity is equal to

pressure.

AKASH MULTIMEDIA

gP

g

P

g > 1 E f Eq

adiabatic bulk modulus of elasticity is g times

to the isothermal bulk modulus of elasticity.

1.18 Compr essibility :

The reciprocal of bulk modulus iscalled compressibility. i.e

1

Compressibility = Bulk mod ulus

1 V

V P

O.F = M1LT2

S.I unit of compressibility is N1 m2

Note 1.15 : A rigid body and an ideal liquid are incompressible i.e., compressibility is zero implies bulk

modulus is infinite

* 1.19 Density of compr essed liquid :

If a liquid of density ' r ', volume V and bulk

modulus 'K' is compressed, then its density increases

m

density r

V

21

PHYSICS - I C

ELASTICITY

1 r

V

-------- (1)

V

r

V

But by definition of bulk modulus

r

V P

V P

----------------(2)

V

V

K

r

from (1) and (2) r K

r1 r P

P

r1 r

r

r

K

K

P

r1 r 1

K

1

Also r r 1 CP where C is the com-

pressibility.

Sol : V 103 m3 ; V 106 m3 ; P 10 atm

= 1010 5 1106 Nm2

P

V

K =

V

1106

103 110 9 Nm2

V=

6

10

* Pr oblem 1.32

Deter mine the pr essur e r equir ed to r educe

the given volume of water by 1 % . Bulk modulus of water is 2 10 9 N m-2

V

1

, K= 2 10 9 N m-2 P = ?

V

100

P

V

K

V P K

V ,

V

9

= 210

4

V

R

V p R3 ,

3

3

V

R

Now by definition of bulk modulus

B V

* Pr oblem 1.31

A volume of 103 m 3 is subj ected to a

pressure of 10 atmospher e. The changein volume

is 10-6 m3. Find the bulk modulus of water.

(Atmospheric pressure= 1105 N m2 )

Sol :

Pr oblem 1.33

A solid sphere of r adius 'R' made of a mater ial of bulk modulus B is sur r ounded by a liquid

in a cylindr ical container. A massless piston of

ar ea 'A' floats on the sur face of the liquid. Find

the fr actional change in the r adius of the spher e

dR

, when a mass M is placed on the piston to

R

compr ess the liquid.

Sol : As for a spherical body

1

2 107 N m -2

100

AKASH MULTIMEDIA

P

V

P

Mg

i.e

V

V

B

AB

Mg

as P

dR 1 V

dR

Mg

R

3 V

R

3 AB

Pr oblem 1.34

A uniform pressure 'P' is exer ted on all sides

of a solid cube at temper atur e t 0C . By what

amount should the temper atur e of the cube be

r aised in or der to br ing its volume back to the

volume it had befor e the pr essur e was applied,

if the bulk modulus and coefficient of volume

expansion of the mater ial ar e B and g r espectively.

Sol : As by definition of bulk modulus

P

B V

V , with increase in pressure

decrease in volume of the cube will be given

by V

VP

, (as P P )

B

Now with rise in temperature due to thermal

expansion, volume increases so if ' q ' is the rise in

temperature then V V gq as g

V q

As the volume of the cube remains constant

VP

P

V gq q

B

gB

22

PHYSICS - I C

ELASTICITY

Pr oblem 1.35

When a r ubber ball of volumeV, bulk modulus 'K ' is taken to a depth 'h' in water, then decr ease in its volume is

P

m

K

Pa

V

v

V

phrg

PV

h

m

hr g V

K

v1

Pa p

hr g V

So decrease in volume of ball

K

1.20 M odulus of r igidity h (or ) shear modulus

Within elastic limit, the r atio of shear ing

str ess to the shear ing str ain is called modulus of

r igidity of the mater ial of the body.

shearing stress

h

shearing strain

A

cube to be slightly displaced or sheared relative to

one another, each line such as AB or CD in the cube

is rotated through an angle ' q ' by this shear..

The shearing strain is the angle q in radians

through which a line normal to a fixed surface has

turned. For small values of angle

AA1 x

AB

L

shear stress F / A

F

h

shear strain

q

Aq

shearing strain q

* In this case shape of a body changes but its volume remains unchanged.

* Only solids can exhibit a shearing as these have

definite shape.

* Pr oblem 1.36

A 5.0 cm cube of substance hasits upper face

displaced by 0.65 cm, by a tangential force of 0.25

N. Calculate the modulus of r igidity of t he

substance.

FL

FL

F

Sol : h =

, A = L2, h 2

A

L L

Here, L 5.0 102 m

0.65102 m ; F=0.25 N.

0.25

0.2510 4

=

5.0102 0.65102

3.25

2

= 769.2 N m

fixed

A1

x

L q

C1

q

Fixed

consider a cube of material fixed at its lower

face and acted upon by a tangential force 'F' at its

upper surface having area A as shown in the figure.

F// el F

A

A

As shown in above figure, the shearing force

'F' causes the consecutive horizontal layers of the

Shearing stress

AKASH MULTIMEDIA

* Pr oblem 1.37

A tangential for ce of 2100 N is applied on a

sur face of ar ea 3106 m 2 which is 0.1 m fr om

a fixed face. The for ce pr oduces a shift of 7mm

of upper sur f ace wi t h r espect t o bot t om.

Calculate the modulus of rigidity of the material.

Sol:

F = 2100 N ; A = 3106 m2 ;

L =0.1m; 7103 m.

h

FL

2100 0.1

=1x1010 Nm2

A 3106 7103

23

PHYSICS - I C

ELASTICITY

* Pr oblem 1.38

A steel plate of face ar ea 2 cm2 and the

thickness 1.0cm is fixed r igidly at the lower face.

A tangential force of 10 N is applied on the upper

sur face . Find the later al displacement of the

upper sur face with r espect to the lower sur face.

Rigidity modulus of steel = 8.41010 Nm -2

Sol : A 2cm2 2 104 m2 ;

L=1.0 cm= 1102 m;

F=10 N. h 8.41010 N m-2 ; ?

FL

h

A

The lateral displacement of the upper face with

respect to the lower face is

FL

Ah

101102

2104 8.41010

1

107 m = 5.952109 m.

=

16.8

Pr oblem 1.39

Calculate the for ce F needed to punch a

1.46 cm diameter hole in a steel plate1.27 cm thick

(as shown in fig). The ultimate shear str ength of

steel is 345 M N/m2

=

Type of

stress

Stress

Sol : As in punching, shear elasticity is involved, the

hole will be punched it

F11

ultimate shear stress

A

F11 > (shear stress) X Area

F11 min = (3.45 X 108) 2prL A 2prL

8

2

2

= 3.4510 23.140.7310 1.2710 200KN

1.21 Some impor tant points on modulus of

elasticity

1) Young's modulus (Y) and rigidity modulus

( h ) exist only for solids but not for liquids. This is

because liquids and gases cannot be deformed along

one dimension only and also cannot sustain ( shear

strain). Bulk modulus (K) exists for all states of mater

(solids, liquids and gases)

2) Gases being most compressible are least elastic while solids are most elastic.

Esolid Eliquid E gas

Strain

Elongation or

Two equal and

compression

opposite forces

Tensile

parallel to force

perpendicular

or

direction

to opposite

compressive

faces

L / L

(longitudinal strain)

s F / A

Two equal and

opposite forces

parallel to opposite

surfaces [forces

Shearing in each case such

Pure shear, q

that total force and

total torque on the

body vanishes]

Bulk

Forces perpendicular

everywhere to the Volume change

surface, force per (compression or

elongation)

unit area (pressure)

same everywhere

V / V

AKASH MULTIMEDIA

Change in

Elastic Name of State of

shape volume modulus modulus Matter

No

Yes

Yes

No

No

Yes

F L

AL

Young's

modulus

Solid

F q

Shear

modulus

Solid

p

B

V / V

Solid,

Bulk

liquid

modulus and gas

24

PHYSICS - I C

3) For a perfectly rigid body as L, V or

f 0 , So Y, K or h will be ' a ' i.e elasticity of a

rigid body is infinite.

4) Greater the value of modulli of elasticity, more

elastic is the material.

1

1

1

, Ka

But as Y a

and h a

for a

f

L

V

constant stress, smaller change of shape or size for a

given stress corresponds to greater elasticity.

ex :(1) For same load, more elongation is produced

in rubber wire than in steel wire of same cross-section hence steel is more elastic than r ubber.

ex : (2) Water is more elastic than air as volume

change in water is less for same applied pressure

5) The value of moduli of elasticity is independent of the magnitude of the stress and strain. It depends on the nature of the material of the body.

6) For a given material there can be different

moduli of elasticity depending on the type of stress

applied and the strain produced.

7) In a suspension br idge as there is a stretch

in the ropes by the load of the bridge, the elasticity

involved is linear or tensile.

8) In an automobile tyr e as air is compressed

the elasticity involved is volume, i.e., bulk.

9) In transmitting power an automobile shaft

is sheared as it rotates, so the elasticity involved is

shear, i.e., rigidity.

10) When a coiled spr ing is stretched, the deformation of the wire of the spring is in the form of a

twisting strain so the elasticity involved is shear, i.e.,

rigidity.

11) In a water lift pump as the water is compressed, the elasticity involved is volume, i.e., bulk

12) The shape of r ubber heels changes under

stress, the elasticity involved is shear, or rigidity.

1.22 Poisson's r atio :

When a wire is stretched by a force along its

length, then its length increases and the radius (or)

diameter decreases as shown in the figure.

AKASH MULTIMEDIA

ELASTICITY

The r atio of change in r adius (or ) diameter

to the or iginal r adius (or ) diameter is called later al strain

L

r

(D)

r r

D D

D

Lateral strain

D (or)

r

r

The ratio of change in length to the original

length is called longitudinal strain

Longitudinal strain

Lateral strain is directly proportional to the longitudinal strain

lateral strain a (longitudinal strain)

Lateral strain = s (longitudinal strain)

Where ' s ' is poisson's ratio. It depends on the

nature of the material.

Poisson's ratio ( s ) is defined as the ratio of lateral

strain to longitudinal strain.

Lateral strain

poisson ' s ratio s

Longitudinal strain

D

D

s

negative sign indicates that the radius or diameter of the wire decreases when it is stretched.

Poissons's ratio has no units and dimensions as

it is ratio of two strains.

The theroetical limits of poisson's ratio are from

1 to + 0.5. But its practical limits are from 0 to 0.5

and generally between 0.2 and 0.4.

1.23 Relation among volume strain, Lateral strain

and poisson's r atio :

Consider a wire of length ' ' and radius 'r', then

its volume V p r 2 (1)

V

r

2

V

r

25

PHYSICS - I C

ELASTICITY

r

r

s

But we know

r

s

r

V

2s

12s

V

V

0,

Note 1.16 : If a material has s 0.5 then

V

V 0 , there in no change in the volume of

the body and the material is said to be incompressible.

The fractional increase in volume,

V

0.01(12x0.30)=0.01x0.40=0.004.

V

1.24 BEHAVI OUR OF A M ETAL WI RE

UNDER I NCREASI NG L OAD

Consider a metal wire having its upper end fixed

to a rigid support and loaded at the lower end by

attaching a weight hanger. Let the load be increased

gradually. To study the behaviour of the metal wire

under increasing load, a graph is plotted between

the stress on the Y axis and the strain on the X

axis. In general, the curve shown in figure is obtained

for ductile materials that can be drawn into wires.

* Pr oblem 1.40

A 3 cm long copper wir e is str etched to incr ease its length by 0.3 cm. find the later al strain

in the wire, if the Poissons r atio for copper is

0.26.

Sol : L = 3cm ; L 0.3cm; s 0.26.

Longitudinal strain

L 0.3

0.1

L

3

LateralStrain

LongitudinalStrain

The Lateral Strain = s LongitudinalStrain

= 0.260.1

= 0.026.

* Pr oblem 1.41

Find the fr actional incr ease in volume of a

wir e of cir cular cr oss section if its longitudinal

str ain is 1% . s 0.30

Sol: we know that

dV dL

1 2s

V

L

Here,

dL

1

1%

0.01; s 0.30.

L

100

AKASH MULTIMEDIA

1. From O to P the graph is a straight line showing that stress is proportional to strain i.e., the wire

obeys Hooke's law upto the point P. So, P is called

the proportionality limit of the wire.

2. From P to E as the graph is slightly curved, the

stress is not proportional to strain. If the load is

removed at any point between O and E it will regain

its natural length. The point E is called the elastic

limit. In case of some materials, the wire may obey

Hooke's law upto E coinciding E with P i.e., P will

be the elastic limit for such materials.

3. On increasing the load beyond elastic limit, the

graph is more curved upto the point Y called yield

point. From E to Y, the wire does not obey Hooke's

law indicating that for a small increase in load there

is greater increase in length. If the load applied on

the wire is removed between E and Y, the wire does

not regain its natural length completely. It will have

a permanent increase in length. This behaviour of

26

PHYSICS - I C

ELASTICITY

the wire is shown by the dashed line which is a

straight line that cuts the xaxis not at O but at O1.

OO1 is the permanent set.

|

Strain OO

|

Permanent increase in length OO

4. When the wire crosses the point Y strain

increases rapidly without any increase in the load.

So, yield point is defined as the point beyond which

strain increases rapidly without any increase in load.

Beyond the point Y as the wire becomes thin and

the stress for the same load becomes larger and larger

increasing the strain further and further. If the load

is not removed the strain increases continuously till

the wire reaches a point T. The stress corresponding

to T is called the tensile strength of the given material.

The tensile strength is ratio of maximum load to

which the wire may be subjected by slowly

increasing the load to the original area of crosssection of the wire.

5. Beyond the point T, the thinning of the wire is

no longer uniform and the wire shows necks.

Immediately, as this occurs, the stress decreases

automatically and the part TB is obtained. At B the

wire ultimately breaks. B is called breaking point.

6. If large deformation occurs between the elastic

limit and the breaking point, the material is ductile.

Ex : copper, silver, gold etc.,

7. If the deformation between the elastic limit and

the breaking point is very small or if the wire breaks

immediately after crossing the elastic limit, the

material is brittle. Ex : glass, ceramic etc.

1.25 BREAK I NG STRESS :

i) The breaking stress of a wire is the maximum

stress at which the wire breaks.

ii)

Breaking stress =

BreakingForce

initialareaofcrosssection

iii) Breaking force = Breaking stress x area of cross

section.

iv) Breaking stress a) depends only on the nature

of material of the wire b) is independent of the length

and area of cross-section of the wire.

v) Breaking force a) is independent of length of

the wire b) depends on the area of cross-section and

nature of material of the wire.

AKASH MULTIMEDIA

vi) Breaking force is proportional to area of crosssection.

vii) If we cut a cable that can support a maximum load of

W into two equal parts, then each part can support a

maximum load of W.

viii) A very long wire suspended vertically may

break due to its own weight

The maximum length of a wire that can hung

without breaking under its own weight is

mg Ag

g

breaking stress =

A

A

Breaking Stress

rg

Note 1.17 : A metal rope of density b has breaking

stress (B:S). This rope is used to measure the depth

of the sea. Then the depth of the sea that can be

measured without breaking is

r

r

mg1 Arb g1

rb

rb

B. S. =

grb r

A

A

B.stress

grb r

(Whoe PL is the density of sea water)

* Pr oblem 1.42

Find the greatest length of the wir e made of

mater ial of br eaking str ess 8x108Nm 2 and

density 8x103kgm3 that can be suspended from

a rigid support without breaking. (g = 10 ms2)

Sol:

Greatest length of the wire without breaking.

Braking Stress

rg

Here, breaking stress = 8 x 108 Nm2;

r = 8 x 103 kg m3; g = 10 ms2.

8108

1104 m 10km

3

810 10

27

PHYSICS - I C

ELASTICITY

* Pr oblem 1.43

A block of mass 1 kg is fastended to one end

of a copper wir e of cr oss- sectional ar ea 1 mm2

and is r otated in a ver tical cir cle of r adius 20 cm.

I f the br eaking str ess of copper is 5 x 108 Nm2,

find the maximum number of r evolutions the

block make in the minute without the str ing

breaking.

Sol : Maximum tension on the string = Breaking

stress x Area of cross - section

= 5x108 x1x10 6= 500 N.

When a body revolves in a horizontal circle,

Tension on the string = Centripetal force

500 = mr w 2

Where m = 1 kg, r = 0.20m, w = ?

500 = 1 x 0.2 x w 2

500

w2

2500

0.2

Maximum angular speed, w 50 rad s1 .

t= 60 s,n= ?

2p n

2p n

w

50

,

t

60

The maximum number of revolut ions ,

n

50 60 1500

477.4rpm.

2p

p

1.26 Elastic Fatigue : When a body is subjected to

a repeated stress, even within the elastic limit, it

becomes weak since it loses its elastic property to

some extent temporarily. If greater stress is applied

on the body without knowing present state, cracks

develop within the body and it breaks. This occurs

even for a stress lesser than that of breaking stress.

Ex : When a metal wire is bent once, it may not

break. But, it breaks when it is bent repeatedly at the

same point. This weakness or the state of temporary

loss of elastic nature of the body when subjected to

repeated stress is called elastic fatigue.

If the material is given some rest, i.e., kept in

unstrained state for some time, it regains its original

elastic nature.

AKASH MULTIMEDIA

1.27 EL ASTI C AFTER EFFECT:

When stress is removed the strain does not

reduce to zero at once. It takes some time for the

strain to become zero after the removal of stress, the

delay in recovering back to the original condition on

removal of deforming force is called elastic aftereffect. This effect is very much dominant in glass

while it is totally absent in quartz, phosphor bronze,

silver and gold.

1.28 Str ain energy : When a wire has natural length,

the potential energy corresponding to the atomic and

molecular forces is minimum. When the wire is

deformed, internal forces called restoring forces are

set up and work is to be done against these forces to

produce the deformation. This work done is stored

in the wire as potential energy which is called strain

energy.

Str ain Ener gy is the ener gy stor ed in a body due

to its defor mation :

1.29 Expr ession for str ain ener gy or wor k done

in str etching a wir e : Consider a metal wire of

length L and crosssectional area A fixed at one end

and is stretched by an external force applied at the

other end. The force is so adjusted that the wire is

only slowly stretched. This ensures that at any time

during the extension the external force is equal to

the tension in the wire. When the extension is e, the

wire is under a longitudinal stress F/A, where F is

the tension at that instant of time. The strain is x/L.

Let the force acting on a wire suspended from a

rigid support be F. The work done in increasing its

length by de is

dW = Fde

The total work done in increasing the length of

wire by e is obtained by integrating the above

expression between the limits 0 and e.

e

W dW Fde

e

=

0

YAe

de

L

Y FL

Ae

YA e 2 YAe e 1

Fe

L 2

L 2 2

28

PHYSICS - I C

This is stored as strain energy in the wire.

1

Strain energy in the wire = Fe

2

Strain energy per unit volume of the wire

1 Fe

1 F e

.

2 AL 2 A

1

Stress Strain

2

2

1 Stress

strain Stress

=

Y

2

Y

1

2

= strain Y

2

When the external force is withdrawn, the stress

disappears and the strain energy appears as heat. The

above relation holds good for longitudinal, volume

and shearing strains.

Note 1.18:

i) Work done in stretching a wire,

w=

1

2

ii) w = 12

x stretching force x extension.

1 F 2 1 F2

1 YAe 2

Fe =

=

2 AY

2 pr 2 y

2 l

iii) w = 12 x stress x strain x volume of the wire

iv) Area under F-e graph gives the work done

or the strain energy sto red in t he wire.

Area =

1

2

F.e = W

* Pr oblem 1.44

I f Youngs modulus of the mater ial of a wire

is 1.2 1011 N m2, calculate the wor k done in

str etching the wir e of length 3 m and cr oss- sectional ar ea 4 mm2 when it is suspended ver tically

and a load of 8 kg is attached to its lower end.

Sol : Y = 1.21011 Nm -2 : L =3 m; A = 4mm2

= 4106 m2 ; M= 8 kg.

1

work done = stretching force increase in

2

length.

FL

But increase in length, e

AY

AKASH MULTIMEDIA

ELASTICITY

1 F 2 L 1 Mg L

The work done =

2 AY 2

AY

2

8 9.8 3

1

2 4106 1.21011

= 0.0192 J

2

Pr oblem 1.45

A metal wire of length and cross-sectional

area A has mass m. I t is stretched by an amount

eby a load of mass M . I f the wir e br eaks at the

point of suspension due to the load then find the

r ise in temper atur e of the wir e ?

1

1

Strain energy = F.e Mg e

2

2

As the wire breaks strain energy stored in the

wire appears in the form of heat.

1

Mg e mst [s = specific heat of wire]

2

Mg e

2 ms

Pr oblem 1.46

A stone of mass m is pr oj ected fr om a

r ubber catpult of length and cr oss-sectional

area A stretched by an amount e. I f Y be the

youngs modulus of r ubber then find the velocity

of pr oj ection of stone ?

Solution :

1

Strain energy = F.e

2

1 YAe

1 YAe2

e

=

2

2

As the stone is released, the strain energy in the

catpult appears in the form of kinetic energy of the

stone.

1 YAe 2 1 2

mv

2

2

2

YAe

YAe2

v2

, v

m

m

29

PHYSICS - I C

ELASTICITY

1.30 Exper imental deter mination of Youngs

modulus (Y) Sear les appar atus

Youngs modulus of the material of a wire can

be experimentally determined by Searles method.

Extension

Descr iption : Two wires of the same material,

length and area of cross section, suspended from a

rigid support carry at their lower ends, two

rectangular metal frames as shown in figure. One of

the wires is called experimental wire and the other

wire is called reference wire. The frame attached to

the reference wire carries a constant weight to keep

the wire stretched without any kinks. The frame

attached to the experimental wire carriers a hanger,

over which slotted weights can be slipped as required.

A spirit level is hinged with one end to the frame

attached to the reference wire and rests horizontally

on the tip of a micrometer screw which can be

worked in the frame attached to the experimental wire

along a vertical scale marked in millimeter.

relative to the other frame and the air bubble shifts to

one side. The micrometer screw is now adjusted to

take back the air bubble to the centre and the

micrometer screw reading is noted.

4) The experiment is repeated at least five times

every time increasing the load by half a kilogram

weight. Readings of the micrometer screw are noted

while increasing and decreasing the load and mean

reading is found.

5) The difference between the first and second

readings gives the increase in length or extension

produced in the experimental wire when the load is

increased by half a kilogram weight. The difference

between the first and third readings gives the

extension for a load of one kilogram weight.

1

Similarly, the extensions for 1 , 2, .... kg wt are

2

found.

6) A graph is plotted between the load and

extension. The graph is a straight line and gives the

elongation e for a load Mg.

Load

7) The radius, r, of the experimental wire is

found by using a screw gauge and measuring the

diameter at 6 or 7 places of the wire. The length, L,

of the experimental wire is measured with the help

of a meter scale.

8) Substituting the values of r, L and

Mg

in

e

the formula of Young modulus.

Wor king :

1) A suitable load is kept on the hanger so that

the experimental wire is straight without kinks.

2) The micrometer screw is adjusted so that the

air bubble in the spirit level comes in the centre. The

reading of the micrometer screw is noted.

3) Half a kilogram weight is then slipped into

the hanger. This elongates the experimental wire. The

frame attached to the experimental wire moves down

AKASH MULTIMEDIA

F L

Mg L

=

( F = Mg and A = pr 2 )

Ae

pr e

the Youngs modulus of the material is

calculated.

Sour ces of er r or and their minimisation : There

are two sources of error in the experiment.

i) The support may yield when the load is attached

at the lower end of the experimental wire and the

30

PHYSICS - I C

measured value of increase in length may not be

correct. ii) While the experiment is carried out,

temperature may change which causes some increase

in length. The measured value of increase in length

becomes incorrect.

Both the errors are minimized by using the

reference wire. The yield of support or the change

of temperature affects both the experimental and

reference wires. The relative increase of the

experimental wire with respect to the reference wire

will give correct increase in length.

L ong Answer Questions

1.

Shor t Answer Questions

2.

3.

Ver y Shor t Answer Questions

1.

2.

3.

4.

5.

6.

7.

Define Hooke's law of elasticity. Descr ibe

Sear les method to deter mine the Young's

modulus of the mater ial of a wir e.

1.

ELASTICITY

8.

9.

10.

Def i ne H ook e' s l aw of el ast i ci t y,

pr opor tionality limit, per manent set and

Br eaking str ess.

Define modulus of elasticity, stress, strain the

Poission's ratio.

11.

Define defor mation and defor ming for ce.

M ention the differ ence between elastic and

plastic bodies.

14.

4.

Descr ibe the behaviour of a wir e under

gr adually incr easing load.

5.

DefineYoung's modulus, Bulk modulus and

Rigidity modulus.

6.

Define str ess and explain the types of str ess.

7.

Define str ain and explain the types of strain.

8.

Define strain energy and derive the equation

for the same.

9.

Steel exhibits mor e elastic natur e than

r ubber Explain.

10. I f a wire is bent continuously at a par ticular