Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

How Does A Drill Bit Work

Caricato da

rajasekharboDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

How Does A Drill Bit Work

Caricato da

rajasekharboCopyright:

Formati disponibili

How Does a Drill Bit Work?

A drill bit is what actually cuts into the rock when drilling an oil or gas well. Located at the tip of

the drillstring, below the drill collar and the drill pipe, the drill bit is a rotating apparatus that

usually consists of two or three cones made up of the hardest of materials (usually steel,

tungsten carbide, and/or synthetic or natural diamonds) and sharp teeth that cut into the rock

and sediment below.

Drill Bit

In contrast to percussion drilling, which consists of continuously dropping a heavy weight in the

wellbore to chip away at the rock, rotary drilling uses a rotating drill bit to grind, cut, scrape and

crush the rock at the bottom of the well. The most popular choice for drilling for oil and gas,

rotary drilling includes a drill bit, drill collar, drilling fluid, rotating equipment, hoisting apparatus

and prime mover.

The prime mover is the power source for the drilling, while the hoisting equipment handles lifting

the drill pipe to either insert it into the well or lift it out of the well. Rotating equipment is what

sets the whole system in motion. Before the early 1900s, drilling equipment was spun using

livestock and a wooden wheel, but now, the rotating equipment is put in motion by a rotary table,

which is connected to a square-shaped hollow stem, called a Kelly. Connected to the Kelly is

the drill collar, which puts pressure and weight on the drill bit to make it drill through the rock and

sediment. Capping off the drillstring is the drill bit, and encompassing the drilling process is

drilling fluid, which helps to provide buoyancy to the drill string, lubricate the drilling process and

remove cuttings from the wellbore.

Drill Bit

Types of Drill Bits

There are a number of different types of drill bits. Steel Tooth Rotary Bits are the most common

types of drill bits, while Insert Bits are steel tooth bit with tungsten carbide inserts.

Polycrystalline Diamond Compact Bits use synthetic diamonds attached to the carbide inserts.

Forty to 50 times stronger than steel bits, Diamond Bits have industrial diamonds implanted in

them to drill extremely hard surfaces. Additionally, hybrids of these types of drill bits exist to

tackle specific drilling challenges.

Various drilling designs are also employed for different results, including core bits, which gather

formation cores for well logging; mill bits, which help to remove cuttings from the well; and

fishtail bits, which enlarge the drill hole above the drill bit.

Different configurations work better on different formations; so a number of different drill bits

may be inserted and used on one well. Additionally, drill bits have to be changed due to wear

and tear. Drilling engineers choose the drill bits according to the type of formations encountered,

whether or not directional drilling is required, for specific temperatures, and if well logging is

being done.

When a drill bit has to be changed, the drill pipe (typically in 30-feet increments) is hoisted out of

the well, until the complete drill string has been removed from the well. Once the drill bit has

been changed, the complete drill string is again lowered into the well.

Potrebbero piacerti anche

- GemsDocumento80 pagineGemssaopaulo100% (1)

- DIAMOND 4csDocumento2 pagineDIAMOND 4csmakisglyka0% (1)

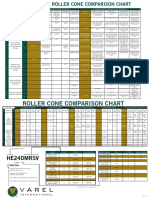

- VAREL RC Comparison Chart Final 2012Documento2 pagineVAREL RC Comparison Chart Final 2012Baitaw WanwarangNessuna valutazione finora

- Guide To Gem Cutting Styles ShapesDocumento13 pagineGuide To Gem Cutting Styles ShapesomarfarookkhanNessuna valutazione finora

- Drilling Bits: Dr. Gaurav Pandey Assistant Professor UpesDocumento78 pagineDrilling Bits: Dr. Gaurav Pandey Assistant Professor UpeshassanNessuna valutazione finora

- Lecture 5 Drill Bit Types and Their ApplicationsDocumento8 pagineLecture 5 Drill Bit Types and Their ApplicationsSaurav SenguptaNessuna valutazione finora

- Category and Selection of Roller BitDocumento23 pagineCategory and Selection of Roller BitEyanya MtilaNessuna valutazione finora

- Comparison - Jewellery CompaniesDocumento40 pagineComparison - Jewellery CompaniesKushagra VermaNessuna valutazione finora

- Drilling Bit DesignDocumento14 pagineDrilling Bit DesignMajedur Rahman100% (1)

- Black Max Downhole Motors PDFDocumento52 pagineBlack Max Downhole Motors PDFGeorge BoafoNessuna valutazione finora

- Rev 01-Dec-06Documento70 pagineRev 01-Dec-06zhujianglongNessuna valutazione finora

- Diamond GradingDocumento146 pagineDiamond GradingTudor Marcus100% (5)

- Lab Grown Diamond at SuratDocumento17 pagineLab Grown Diamond at SuratSanjay Thakkar100% (1)

- Gas Lift ProductsDocumento86 pagineGas Lift ProductshaudvNessuna valutazione finora

- Roller Cone Bit DesignDocumento17 pagineRoller Cone Bit Designknn52unnNessuna valutazione finora

- Spring 2017 Gems Gemology v2 PDFDocumento145 pagineSpring 2017 Gems Gemology v2 PDFJORGE LUIS HERNANDEZ DUARTENessuna valutazione finora

- RDT Heavy Weight Drill Pipe PDFDocumento2 pagineRDT Heavy Weight Drill Pipe PDFLizandro Quispe GomezNessuna valutazione finora

- Summer 2018 Gems Gemology PDFDocumento150 pagineSummer 2018 Gems Gemology PDFArmando Michel Gabriel Cury FilhoNessuna valutazione finora

- Drilling Bit Introduction and Bit Selection (Part 2)Documento32 pagineDrilling Bit Introduction and Bit Selection (Part 2)Ali AlakariNessuna valutazione finora

- Drilling Bit SelectionDocumento22 pagineDrilling Bit SelectionRFV100% (1)

- Kymera Mach 4 Hybrid Drill Bit FlyerDocumento2 pagineKymera Mach 4 Hybrid Drill Bit FlyerReginaMendozaNessuna valutazione finora

- 2006-2007 Varel FixedCutterBitsCatalogDocumento24 pagine2006-2007 Varel FixedCutterBitsCatalogAndrzej KonopkaNessuna valutazione finora

- Air and Gas Drilling NewDocumento19 pagineAir and Gas Drilling Newabdul wahabNessuna valutazione finora

- Wellbore Cleanup Magnets BrochureDocumento12 pagineWellbore Cleanup Magnets Brochurefreebookie88100% (1)

- Daihatsu PartDocumento1 paginaDaihatsu PartLeonard Capriant100% (1)

- PDC - Terminology and MechanicsDocumento17 paginePDC - Terminology and MechanicsKaleem UllahNessuna valutazione finora

- Varel Mining CatalogDocumento24 pagineVarel Mining CatalogEmerson Phocco Yauli100% (1)

- Drilling Engineering: PETE 203Documento48 pagineDrilling Engineering: PETE 203AbdullahNessuna valutazione finora

- Fishing Tools - Internal Catch Taper Taps: Product Line ProductDocumento2 pagineFishing Tools - Internal Catch Taper Taps: Product Line ProductrezaNessuna valutazione finora

- 8 5-Mme65rDocumento1 pagina8 5-Mme65rWHWENNessuna valutazione finora

- How Do Mooring Systems WorkDocumento4 pagineHow Do Mooring Systems WorkrajasekharboNessuna valutazione finora

- Stinger BrochureDocumento22 pagineStinger BrochurediegoilNessuna valutazione finora

- PDC Make-Up TorqueDocumento1 paginaPDC Make-Up TorqueSug E QalanderNessuna valutazione finora

- Drilling Bits SPE Series-ADIDocumento62 pagineDrilling Bits SPE Series-ADIAlfredo TintayaNessuna valutazione finora

- Geothermal Well Design PDFDocumento7 pagineGeothermal Well Design PDFLaurencius YanuarNessuna valutazione finora

- FA94Documento81 pagineFA94saopauloNessuna valutazione finora

- Type BitsDocumento3 pagineType BitsHuda BasimNessuna valutazione finora

- Drilling BitsDocumento9 pagineDrilling BitsAli AbdelrahemNessuna valutazione finora

- How Does Pipeline Pigging WorkDocumento3 pagineHow Does Pipeline Pigging WorkrajasekharboNessuna valutazione finora

- Smith BitDocumento4 pagineSmith BitRio RizkiNessuna valutazione finora

- H03729Documento4 pagineH03729AQUILES CARRERANessuna valutazione finora

- Rock BitsDocumento17 pagineRock Bitssuresh_501Nessuna valutazione finora

- 2016 - D - Good Sampling Practice (MNT)Documento14 pagine2016 - D - Good Sampling Practice (MNT)Mário de Freitas100% (1)

- How Is Nitrogen Used in Oil and Gas FieldsDocumento4 pagineHow Is Nitrogen Used in Oil and Gas FieldsrajasekharboNessuna valutazione finora

- Mainan DewasaDocumento153 pagineMainan DewasaHeris SitompulNessuna valutazione finora

- GT Drilling Bits 6aug FinalDocumento46 pagineGT Drilling Bits 6aug FinalRanjith Premadasan100% (1)

- Analisis Penggunaan Bit For ChevronDocumento15 pagineAnalisis Penggunaan Bit For Chevronfaishal hafizhNessuna valutazione finora

- DrillingDocumento61 pagineDrillingAjay RanaNessuna valutazione finora

- Rollercone Bit DesignDocumento15 pagineRollercone Bit Designvano0Nessuna valutazione finora

- Confined Compressive Strength Model of Rock For Drilling OptimizationDocumento7 pagineConfined Compressive Strength Model of Rock For Drilling Optimizationodex100% (2)

- Defining BitsDocumento2 pagineDefining BitsahmedNessuna valutazione finora

- A Presentation ON Drill Bits: Submitted To: Er. Akash Rana (HOD) Petroleum DepttDocumento26 pagineA Presentation ON Drill Bits: Submitted To: Er. Akash Rana (HOD) Petroleum DepttJohar marwatNessuna valutazione finora

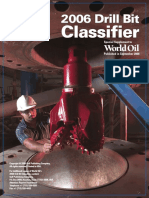

- Drill Bit Classifier 2006Documento17 pagineDrill Bit Classifier 2006amin peyvandNessuna valutazione finora

- Chap EDocumento44 pagineChap ERANJITH K PNessuna valutazione finora

- Deliver The Well: Rodney Howard Halliburton, AberdeenDocumento100 pagineDeliver The Well: Rodney Howard Halliburton, AberdeenЮрий УсковNessuna valutazione finora

- 12 BT 0123 Stinger North Dakota CsDocumento2 pagine12 BT 0123 Stinger North Dakota CsdiegoilNessuna valutazione finora

- Core Drilling and Coring Tools: F Conventional Coring F Wireline (WL) - Coring F New Coring TechniqueDocumento10 pagineCore Drilling and Coring Tools: F Conventional Coring F Wireline (WL) - Coring F New Coring TechniqueMarcos SobreiroNessuna valutazione finora

- Drill Bit Classifier 2007Documento17 pagineDrill Bit Classifier 2007amin peyvandNessuna valutazione finora

- Bit ClassifierDocumento104 pagineBit Classifiersaeed65Nessuna valutazione finora

- Drill String ComponentsDocumento17 pagineDrill String ComponentsMUHAMMED FUADNessuna valutazione finora

- A. Introduction Lesson1Documento34 pagineA. Introduction Lesson1SeptianNessuna valutazione finora

- Reference Photo:: 6 In. (152.4mm) ATJ-4Documento1 paginaReference Photo:: 6 In. (152.4mm) ATJ-411tkt11Nessuna valutazione finora

- Bico Handbk 11-11Documento88 pagineBico Handbk 11-11faishal hafizhNessuna valutazione finora

- Underreamer - WikipediaDocumento2 pagineUnderreamer - WikipediaHistory MatchingNessuna valutazione finora

- 8-P-80 Mud Pump BrochureDocumento2 pagine8-P-80 Mud Pump Brochuredavorp1402Nessuna valutazione finora

- 65500e Hydro-Form CentralizersDocumento2 pagine65500e Hydro-Form CentralizersNavin KumarNessuna valutazione finora

- Sharoshechnye DolotaDocumento79 pagineSharoshechnye DolotaperstasNessuna valutazione finora

- Fixed Cutter Bit, DAD ClassDocumento18 pagineFixed Cutter Bit, DAD ClassAboZaidNessuna valutazione finora

- 06 TESME DrillingDocumento7 pagine06 TESME Drillingsoftminestudio100% (1)

- Well Completion and Its TypesDocumento14 pagineWell Completion and Its TypesJagdish annayaNessuna valutazione finora

- How Does A Drill Bit WorkDocumento2 pagineHow Does A Drill Bit WorkCris TinaNessuna valutazione finora

- Drilling Technology - PE 348Documento14 pagineDrilling Technology - PE 348HamaamNessuna valutazione finora

- Drilling Engineering Pe 311 An Introduction To Drilling Drill BitsDocumento14 pagineDrilling Engineering Pe 311 An Introduction To Drilling Drill BitsHamaamNessuna valutazione finora

- Where Is Heavy Oil FoundDocumento1 paginaWhere Is Heavy Oil FoundrajasekharboNessuna valutazione finora

- How Is Heavy Oil ProducedDocumento2 pagineHow Is Heavy Oil ProducedrajasekharboNessuna valutazione finora

- How Does Core Analysis WorkDocumento4 pagineHow Does Core Analysis WorkrajasekharboNessuna valutazione finora

- How Does Gas Injection WorkDocumento3 pagineHow Does Gas Injection WorkrajasekharboNessuna valutazione finora

- What Is EOR, and How Does It Work?: Thermal RecoveryDocumento4 pagineWhat Is EOR, and How Does It Work?: Thermal RecoveryrajasekharboNessuna valutazione finora

- How Do US Natural Gas Pipelines Move Gas To MarketsDocumento3 pagineHow Do US Natural Gas Pipelines Move Gas To MarketsrajasekharboNessuna valutazione finora

- How Do Subsea Trees WorkDocumento2 pagineHow Do Subsea Trees WorkrajasekharboNessuna valutazione finora

- How Does Subsea Processing WorkDocumento4 pagineHow Does Subsea Processing WorkrajasekharboNessuna valutazione finora

- How Do Umbilicals WorkDocumento2 pagineHow Do Umbilicals WorkrajasekharboNessuna valutazione finora

- How Does Directional Drilling WorkDocumento2 pagineHow Does Directional Drilling WorkrajasekharboNessuna valutazione finora

- How Does Blowout Control WorkDocumento3 pagineHow Does Blowout Control WorkrajasekharboNessuna valutazione finora

- How Does A Top Drive Work?: Top Drivesource: Aker SolutionsDocumento2 pagineHow Does A Top Drive Work?: Top Drivesource: Aker SolutionsrajasekharboNessuna valutazione finora

- How Does Well Control WorkDocumento3 pagineHow Does Well Control WorkrajasekharboNessuna valutazione finora

- How Are HP/HT Reservoirs Developed?Documento3 pagineHow Are HP/HT Reservoirs Developed?rajasekharboNessuna valutazione finora

- How Does A Drillship WorkDocumento2 pagineHow Does A Drillship WorkrajasekharboNessuna valutazione finora

- AIDICO ECO-STONE Sustainable System Implementation For Natural Stone Production and Use PDFDocumento81 pagineAIDICO ECO-STONE Sustainable System Implementation For Natural Stone Production and Use PDFDaniNessuna valutazione finora

- Gems Jewellery Industry in ChinaDocumento103 pagineGems Jewellery Industry in ChinaPrachur Singhal100% (1)

- Examen Icfes Ingles Grado 10Documento16 pagineExamen Icfes Ingles Grado 10freddy possu vasquezNessuna valutazione finora

- The Big BreachDocumento243 pagineThe Big BreachMara MeliNessuna valutazione finora

- Technology of Machine Tools: Diamond, Ceramic, and Cermet Cutting ToolsDocumento44 pagineTechnology of Machine Tools: Diamond, Ceramic, and Cermet Cutting ToolsAnibal DazaNessuna valutazione finora

- Standards For Expanded Metal: EMMA 557Documento18 pagineStandards For Expanded Metal: EMMA 557vangoetheNessuna valutazione finora

- NPD10-DA90 SmallfileDocumento6 pagineNPD10-DA90 SmallfileWernerNessuna valutazione finora

- Problem 1:: SolutionDocumento5 pagineProblem 1:: SolutionAkash SalgarNessuna valutazione finora

- Sarah Gets A DiamondDocumento13 pagineSarah Gets A DiamondDhanunjai IitbNessuna valutazione finora

- PAWN and DIAMOND Rates For Workshops 08.13.2020-1Documento3 paginePAWN and DIAMOND Rates For Workshops 08.13.2020-1Laksmi ValdezNessuna valutazione finora

- 2018 in The Realm of The Diamond King M PDFDocumento16 pagine2018 in The Realm of The Diamond King M PDFIlich_Garc_a_9133Nessuna valutazione finora

- De Beers and NestleDocumento4 pagineDe Beers and NestlegagafikNessuna valutazione finora

- Internship Report Scope of Indian Gems and Jwellery Market in International MarketDocumento56 pagineInternship Report Scope of Indian Gems and Jwellery Market in International MarketNIKHILPATNI50% (2)

- De Beers Insight Report 2014 PDFDocumento90 pagineDe Beers Insight Report 2014 PDFAntonia Maria100% (1)

- Precision ManufacturingDocumento18 paginePrecision ManufacturingUrgie KuNessuna valutazione finora

- ToolingBox Solid CBN Inserts Brochure-2022Documento24 pagineToolingBox Solid CBN Inserts Brochure-2022ToolingBoxNessuna valutazione finora

- IdexOnline 280Documento144 pagineIdexOnline 280hbraga_sruivalNessuna valutazione finora

- S. Jogani Exports Private LimitedDocumento6 pagineS. Jogani Exports Private Limitedarc14consultantNessuna valutazione finora

- Economic Activities in SuratDocumento6 pagineEconomic Activities in SuratsidharthNessuna valutazione finora

- Quick Guide To Using Electric Nail Files and ToolsDocumento21 pagineQuick Guide To Using Electric Nail Files and ToolsAndjelko BrajkovicNessuna valutazione finora