Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ijri Me 02 0011

Caricato da

ijripublishersTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ijri Me 02 0011

Caricato da

ijripublishersCopyright:

Formati disponibili

International Journal of Research and Innovation (IJRI)

International Journal of Research and Innovation (IJRI)

1401-1402

MULTI CAVITY DIE PREPARATION, ANALYSIS AND MANUFACTURING

PROCESS OF DIESEL ENGINE PISTON

Kola Nagarjuna1, Koyilakonda-Sumanth2, Godi Subba Rao3,

1 Research Scholar, Department of Mechanical Engineering, Hyderabad Institute of Technology and Management, Hyderabad, India

2 Assistant professor,Department of Mechanical Engineering, HyderabadInstitute of Technology and Management, Hyderabad, India

3 professor , Department of Mechanical Engineering, HyderabadInstituteOf Technology And Management,Hyderabad,India

Abstract

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders,

among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by

piston rings. The piston transforms the energy of the expanding gasses into mechanical energy. The piston rides in the

cylinder liner or sleeve. Pistons are commonly made of aluminum or cast iron alloys.

In our project a piston for 1300cc diesel engine car will be designed using empirical formulas for the material Cast

Iron. A 2D drawing is created from the calculations. The piston is modeled from 2D drawing using CREO parametric

(Pro/Engineer) software.

Validation of die will be done using structural and dynamic analysis done in Ansys.

Generally manufacturing process for pistons is casting. So we have to design a die tool for the piston manufacturing. Designing of casting tool die for four cavities will be done. Core and Cavity will be extracted and total die will be

designed as per the standards. CNC program will be generated for both core and cavity.

Modeling, core cavity extraction, die design and CNC program generation is done in CREO parametric (Pro/Engineer)

software.

*Corresponding Author:

Kola Nagarjuna

Research Scholar, Department of Mechanical Engineering,

Hyderabad Institute of Technology and Management,

Hyderabad,India

Published: July 22, 2014

Review Type: peer reviewed

Volume: II, Issue : IV

Citation: Kola Nagarjuna, Research Scholar (2015) MULTI

CAVITY DIE PREPARATION, ANALYSIS AND MANUFACTURING PROCESS OF DIESEL ENGINE PISTON

INTRODUCTION TO PISTON

In every engine, piston plays an important role in working

and producing results. Piston forms a guide and bearing

for the small end of connecting rod and also transmits

the force of explosion in the cylinder, to the crank shaft

through connecting rod.

The piston is the single, most active and very critical component of the automotive engine. The Piston is one of the

most crucial, but very much behind-the-stage parts of

the engine which does the critical work of passing on the

energy derived from the combustion within the combustion chamber to the crankshaft. Simply said, it carries

the force of explosion of the combustion process to the

crankshaft.

Apart from the critical job that it does above, there are

certain other functions that a piston invariably does -- It

forms a sort of a seal between the combustion chambers

formed within the cylinders and the crankcase. The pistons do not let the high pressure mixture from the com-

bustion chambers over to the crankcase.

PISTON DESCRIPTION

Pistons move up and down in the cylinders which exerts

a force on a fluid inside the cylinder. Pistons have rings

which serve to keep the oil out of the combustion chamber

and the fuel and air out of the oil. Most pistons fitted in a

cylinder have piston rings. Usually there are two springcompression rings that act as a seal between the piston

and the cylinder wall, and one or more oil control ring s

below the compression rings. The head of the piston can

be flat, bulged or otherwise shaped. Pistons can be forged

or cast. The shape of the piston is normally rounded but

can be different. A special type of cast piston is the hypereutectic piston. The piston is an important component of

a piston engine and of hydraulic pneumatic systems. Piston heads form one wall of an expansion chamber inside

the cylinder. The opposite wall, called the cylinder head,

contains inlet and exhaust valves for gases. As the piston

moves inside the cylinder, it transforms the energy from

the expansion of a burning gas usually a mixture of petrol

or diesel and air into mechanical power in the form of a

reciprocating linear motion. From there the power is conveyed through a connecting rod to a crankshaft, which

transforms it into a rotary motion, which usually

164

International Journal of Research and Innovation (IJRI)

Drives a gearbox through a clutch. Components of a typical, four stroke cycle, DOHC piston engine. (E) Exhaust

camshaft, (I) Intake camshaft, (S) Spark plug, (V) Valves,

(P) Piston, (R) Connecting rod, (C) Crankshaft, (W) Water

jacket for coolant flow.

Suzuki GS 150 R specifications

Engine type : air cooled 4-stroke SOHC

Bore stroke(mm)=5758.6

Displacement =149.5CC

Maximum power = 13.8bhp @8500rpm

Maximum torque = 13.4Nm @ 6000 rpm

Compression ratio =9.35/1

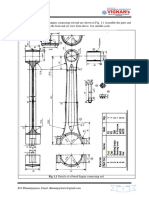

3D MODEL PREPARATION

SKETCHER

REVELOVED MODEL

SLOT CUTTING

INTRODUCTION TO CASTING

Casting is one of the oldest procedures done on metals.

Many products are formed using this method. Here is an

attempt to share the knowledge of casting.

Casting is one of four types: sand casting, permanent

mold casting, plaster casting and Die casting. All these

types of castings have their own advantages and disadvantages. Depending on the properties of the product requited, one of the casting is selected.

Sand Casting: Sand casting is the oldest casting of the

above. This method of casting is in use since 1950.The

texture of the product depends on the sand used for casting. The end product is given smooth finishing at the end.

Usually iron, steel, bronze, brass, aluminium, magnesium alloys which often include lead, tin, and zinc are used.

DIE CASTING

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a

mold cavity, which is machined into two hardened tool

steel dies. Most die castings are made from non-ferrous

metals, specifically zinc, copper, aluminium, magnesium,

lead, pewter and tin based alloys. Depending on the type

of metal being cast, a hot- or cold-chamber machine is

used.

Volume of the component

;(v) =83406.96

Projected area

;(a)=3569.66

A1 (side wall)

=1275.88

Density of material

;26e-6+

Mass No Of Cavities

x=4

Total projected area

=a*x

=3569.66*4

A=14278.64

Projected area of over flows and feed system

Af=A *c/100

C=10% of A

=142.78

Over all projected area:=A+a1+Af

=14278.64+142.78+1275.88

=15697.3mm2

Specific injection pressure of aluminum for

pressure DIA casting =8kgf/mm2

Total force acting on die plates

F=projected area *injection pressure

=15697.3*8

=125578.4kg

=125.57 Tons

Considering factor of safety of *1.2

125.5784*1.2=150.69=151 Tons

Required clamping force >150 tons

160 tons machine specifications

Clamping force

=160 tons

Die stroke

=380mm

Die - height

=200-550mm

Plate size

=675*680

Injection stroke (L)=340

Plunger die

=50,60,65mm

Shot wt

=1.3,1.8,2.1

FILL TIME :- 0.092(582-516+(0.3*4.8))8.93/(516-100)

=0.092(66+(1.44))8.923/416

=0.092*67.44*8.93/416

=55.40/416

=0.133sec

=133 kg sec

MANUFACTURING (MOLD EXTRACTION)

A die is usually made in two halves and when closed

it forms a cavity similar to the casting desired. One half of

the die that remains stationary is known as cover die and

the other movable half is called ejector die.

165

International Journal of Research and Innovation (IJRI)

Molds separate into at least two halves (called the core

and the cavity) to permit the part to be extracted. In general the shape of a part must not cause it to be locked into

the mold. For example, sides of objects typically cannot be

parallel with the direction of draw (the direction in which

the core and cavity separate from each other). They are

angled slightly (draft), and examination of most plastic

household objects will reveal this. Parts that are "bucketlike" tend to shrink onto the core while cooling, and after

the cavity is pulled away. Pins are the most popular method of removal from the core, but air ejection, and stripper plates can also be used depending on the application.

Most ejection plates are found on the moving half of the

tool, but they can be placed on the fixed half.

Core: The core which is the male portion of the mold forms

the internal shape of the molding.

Cavity: The cavity which is the female portion of the mold,

gives the molding its external form.

Shrinkage allowance considered as 1.3% for aluminum

and the mould draft considered as 1.

CASTING TOOL DESIGN FOR MULTY CAVITY PISTON

EXPLODED VIEW

CORE & CAVITY PREPARATION OF MODEL

PARTING SURFACE

STRUCTURAL ANALYSIS ON MULTI CAVITY PISTON

DIE

CAVITY

The above image shows imported model

CORE

The above image shows meshed model

166

International Journal of Research and Innovation (IJRI)

tools. Industrial production lines involve changing the

shape, form and/or composition of the initial products

known as raw materials into products fit for final use

known as finished products.

PROCEDURE OF MANUFACTURING

CAVITY ROUGHING

The above image shows load applied

CUTTING TOOL

The above image shows total deformation

VERICUT

ROUGHING PROGRAM

The above image shows stress

INTRODUCTION TO MANUFACTURING

The manufacturing of various products is done at different scales ranging from humble domestic production of

say candlesticks to the manufacturing of huge machines

including ships, aeroplanes and so forth. The word manufacturing technology is mainly used for the latter range of

the spectrum of manufacturing, and refers to the commercial industrial production of goods for sale and consumption with the help of gadgets and advanced machine

%

G71

O0001

(D:\nsr\roughing.ncl.1)

N0010T1M06

S5000M03

G00X5.Y-5.

G43Z0.H01

G01Z-5.F200.

X201.177

Y-9.914

X5.

Y-14.828

X201.177

167

International Journal of Research and Innovation (IJRI)

Y-19.742

X5.

Y-24.656

X201.177

Y-29.57

X5.

Y-34.484

X201.177

Y-39.398

X5.

Y-44.313

Results table

STRUCTURAL ANALYSIS

Existing Model

Modified Model

Total deformation

0.010822

0.0090683

Stress

37.317

31.116

Strain

0.00034214

0.00028758

FATIGUE ANALYSIS

Existing Model

Modified Model

LIFE

1e6

1e6

Damage

1000

1000

Safety factor

2.3099

2.7703

Biaxiality indication

0.98181

0.99333

Alternating stress

37.317

31.116

graphs

Conclusion:

This project work deals with Multy cavity die preparation

and manufacturing process of diesel engine piston".

In the first step data collection and inputs are collected

for the design of piston for diesel engine.

In the next step design calculations are done using mathematical formulaes from the calculations piston dimensions are required.

A 3d model was generated using above calculations.

Tool design calculations are done to prepare the die assembly.

Core and cavity inserts are prepared using manufacturing model in pro- engineer.

Mould tool parts are prepared and assembled withdrew

set.

Structural and Fatigue Analysis is conducted on mold to

find structural and Fatigue behavior to, modifications

done for core & cavity models to increase strength by adding stress relief holes.

CNC program was generated for both core and cavity inserts.

168

International Journal of Research and Innovation (IJRI)

By observing above information it concludes that using

above process piston manufacturing can be done with

multy cavities so it increases the production rate which

in terms effects on reduction of cost of part production.

author

REFERENCES

1.Thermal analysis and optimization of i.C. Engine piston

using finite element method

2.Design and analysis of i.C. Engine piston and pistonring using catia and ansys software

Kola Nagarjuna

Research Scholar,

Department of Mechanical Engineering,

Hyderabad Institute of Technology and Management,

Hyderabad,India

3.Design analysis and optimization of piston using catia

and ansys

4.Simulation of thermal-mechanical strength for marine

engine piston using fea

5.Thermal analysis and optimization of i.C. Engine piston

using finite element method

Koyilakonda-Sumanth

Assistant professor

Department of Mechanical Engineering,

Hyderabad Institute of Technology and Management,

Hyderabad,India

6.Modeling and analysis of diesel engine piston

7.Modeling, analysis and optimization of diesel engine

piston

8.Thermal analysis of diesel engine piston

9.Finite element analysis and optimization of i.C. Engine

piston using radioss and optistruct

Godi Subba Rao

professor

Department of Mechanical Engineering,

Hyderabad Institute of Technology and Management,

Hyderabad,India

169

Potrebbero piacerti anche

- Structural and Modal Analysis of An Engine Block by Varying MaterialsDocumento4 pagineStructural and Modal Analysis of An Engine Block by Varying MaterialsijripublishersNessuna valutazione finora

- Modeling and Thermal Analysis of Air-Conditioner EvaporatorDocumento6 pagineModeling and Thermal Analysis of Air-Conditioner EvaporatorijripublishersNessuna valutazione finora

- CFD Analysis On Pulsating Heat Pipe To Improve Heat TransferDocumento5 pagineCFD Analysis On Pulsating Heat Pipe To Improve Heat TransferijripublishersNessuna valutazione finora

- Ijri Cce 01 008Documento16 pagineIjri Cce 01 008ijripublishersNessuna valutazione finora

- CFD Analysis On Ejector Cooling System With Variable Throat GeometryDocumento6 pagineCFD Analysis On Ejector Cooling System With Variable Throat GeometryijripublishersNessuna valutazione finora

- Ijri Cce 01 010Documento22 pagineIjri Cce 01 010ijripublishersNessuna valutazione finora

- Ijri Cce 02 004Documento7 pagineIjri Cce 02 004ijripublishersNessuna valutazione finora

- Ijri Cce 02 006Documento9 pagineIjri Cce 02 006ijripublishersNessuna valutazione finora

- Ijri Cce 01 006Documento13 pagineIjri Cce 01 006ijripublishersNessuna valutazione finora

- International Journal of Research and Innovation : Model On Carpooling Technique To Reduce Congestion 1401-1402Documento7 pagineInternational Journal of Research and Innovation : Model On Carpooling Technique To Reduce Congestion 1401-1402ijripublishersNessuna valutazione finora

- Ijri Cce 01 012Documento9 pagineIjri Cce 01 012ijripublishersNessuna valutazione finora

- International Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402Documento13 pagineInternational Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402ijripublishersNessuna valutazione finora

- Ijri Cce 01 011Documento6 pagineIjri Cce 01 011ijripublishersNessuna valutazione finora

- Ijri Cce 02 008Documento8 pagineIjri Cce 02 008ijripublishersNessuna valutazione finora

- Ijri Cce 01 005Documento4 pagineIjri Cce 01 005ijripublishersNessuna valutazione finora

- Ijri Cce 02 007Documento8 pagineIjri Cce 02 007ijripublishersNessuna valutazione finora

- Ijri Cce 02 005Documento7 pagineIjri Cce 02 005ijripublishersNessuna valutazione finora

- Ijri Cce 01 009Documento9 pagineIjri Cce 01 009ijripublishersNessuna valutazione finora

- Ijri Cce 01 002Documento7 pagineIjri Cce 01 002ijripublishersNessuna valutazione finora

- Ijri Cce 01 003Documento12 pagineIjri Cce 01 003ijripublishersNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Jhon Deere 4045Documento606 pagineJhon Deere 4045ubaldo caraballo100% (4)

- DETROIT - 6-71 - (Maintenance)Documento204 pagineDETROIT - 6-71 - (Maintenance)Farlen Bulsoni100% (2)

- CK Geely 00001Documento115 pagineCK Geely 00001Miguel Angel PanequeNessuna valutazione finora

- Foton Faw Shacman Sinotuck Howo Truck Spare Parts From Cinaautoparts GroupDocumento284 pagineFoton Faw Shacman Sinotuck Howo Truck Spare Parts From Cinaautoparts GroupCINA auto partsNessuna valutazione finora

- CVT and Shift Indicator, Engine ControlDocumento20 pagineCVT and Shift Indicator, Engine ControlZM OhnNessuna valutazione finora

- Yamaha Ft60dehd Ft60deht Ft60det 2012Documento71 pagineYamaha Ft60dehd Ft60deht Ft60det 2012Eduardo CortezNessuna valutazione finora

- EngineDocumento41 pagineEngineMadhanmohan ChandrasekaranNessuna valutazione finora

- GP040-070VX Brochure 2.15Documento16 pagineGP040-070VX Brochure 2.15Neil DesaiNessuna valutazione finora

- SM F4GE-IVECO Backhoe EN PDFDocumento117 pagineSM F4GE-IVECO Backhoe EN PDFjulianmata71% (7)

- 1400 Kva MitsubishiDocumento4 pagine1400 Kva MitsubishiAbid LakhaniNessuna valutazione finora

- Auxiliary Engine InterlocksDocumento38 pagineAuxiliary Engine InterlocksSidwalkNessuna valutazione finora

- 4BT33 G3 PDFDocumento2 pagine4BT33 G3 PDFacere18Nessuna valutazione finora

- OMC SterndriveDocumento59 pagineOMC Sterndrivesalvatore dalessandro100% (1)

- Detroit Diesel S40 - Operators ManualDocumento156 pagineDetroit Diesel S40 - Operators ManualFktrctqNessuna valutazione finora

- Common-Rail EFI DieselDocumento36 pagineCommon-Rail EFI DieselMak uniangNessuna valutazione finora

- RAIDER R150 High (FU150SCDX2L5-P31)Documento70 pagineRAIDER R150 High (FU150SCDX2L5-P31)GAYLE GONessuna valutazione finora

- The Audi 1.8L and 2.0L Third Generation Ea888 Engines: Eself-Study Program 920243Documento72 pagineThe Audi 1.8L and 2.0L Third Generation Ea888 Engines: Eself-Study Program 920243sergio ulises santi huashuaNessuna valutazione finora

- QSK 78 Cam FollowerDocumento5 pagineQSK 78 Cam Followershamim imthiyas0% (1)

- Detroit Diesel Catalog 2009Documento72 pagineDetroit Diesel Catalog 2009rcervantes1883100% (2)

- TVS Max 4R/ST Parts CatalogueDocumento59 pagineTVS Max 4R/ST Parts CatalogueLorenzo Jill83% (6)

- NC250 Engine ManualDocumento60 pagineNC250 Engine ManualTallerSoldaduraAluminioInoxidable67% (3)

- Waukesha Gas Engines: Control SystemsDocumento15 pagineWaukesha Gas Engines: Control SystemsKilienNessuna valutazione finora

- Buhler Versatile 2375 Tractor Workshop Repair Service ManualDocumento2.809 pagineBuhler Versatile 2375 Tractor Workshop Repair Service ManualAndreyNessuna valutazione finora

- Ford EDIS IgnitionDocumento11 pagineFord EDIS IgnitionSalvador PinedaNessuna valutazione finora

- Assembly DrawingsDocumento15 pagineAssembly DrawingsN Dhanunjaya Rao BorraNessuna valutazione finora

- Cost Reduction of A Diesel Engine Using The DFMA MethodDocumento23 pagineCost Reduction of A Diesel Engine Using The DFMA Methodalice000Nessuna valutazione finora

- Enviando MOTOR MAZDA Hyster-897477-02-01-Srm0496 PDFDocumento38 pagineEnviando MOTOR MAZDA Hyster-897477-02-01-Srm0496 PDFPedro Carvalho100% (2)

- Ley Power LP D G SetDocumento4 pagineLey Power LP D G SetSaranya DeviNessuna valutazione finora

- 3516B Generator Set Engine - Fuel Injector Adjustment - SIS - CATERPILLARDocumento5 pagine3516B Generator Set Engine - Fuel Injector Adjustment - SIS - CATERPILLARpevare78% (9)

- Seminar On Governor: Rahul Kumar 7 SEMDocumento21 pagineSeminar On Governor: Rahul Kumar 7 SEMVijay SainiNessuna valutazione finora