Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Is.432.1.1982 For Mild and Tensile Steel For Concrete Reinforcement

Caricato da

Ankit SinglaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Is.432.1.1982 For Mild and Tensile Steel For Concrete Reinforcement

Caricato da

Ankit SinglaCopyright:

Formati disponibili

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

1 +, 1 +

01 ' 5

The Right to Information, The Right to Live

Step Out From the Old to the New

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS 432-1 (1982): Mild Steel and Medium Tensile Steel Bars

and Hard-Drawn Steel Wire for Concrete Reinforcement, Part

1: Mild Steel and Medium Tensile Steel Bars [CED 54:

Concrete Reinforcement]

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

IS : 432 ( Part I ) - 1 982

Indian Standard

SPECIFICATION FOR

MILD STEEL AND MEDIUM TENSILE STEEL

BARS AND HARD-DRAWN STEBLWIRE FOR

CONCRETE REINFORCEMENT

PART I MILD STEEL AND MEDIUM TENSILE STEEL BARS

( Third Revision )

Fifth Reprint DECEMBER 1992

UDC 669-14124-422+669-14018'295-422: 666-98224

(CJ Copyright 1982

BUREAU

OF INDIAN

STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

Gr 3

June 1982

IS : 432 ( Part I ) 1982

Indian Standard

SPECIFICATION FOR

MILD STEEL AND MEDIUM TENSILE .STEEL

BARS AND HARD-DRAWN STEEL WIRE FOR

CONCRETE REINFORCEMENT

PART I

MILD STEEL AND MEDIUM TENSILE STEEL BARS

( Third Revision)

Joint Sectional Committee for Concrete Reinforcement, BSMDC 8

Chairman

RepTeJenting

Central Public Works Department, New Delhi

SHRl G. S. RAO

Members

SUl'EttINTENDING ENGINEER ( CDO ) ( Alternate to

Shri G. S. Rao )

Da ]. L. AJMANI

The Tata Iron & Steel Co Ltd, Jamshedpur

SHRI A. N. MITRA ( Alternate)

.

SHRI S. BANERJEE

Steel Re-rolling Mills Association of India, Calcutta

SHRI S. N. CHANDA

Metallurgical and Engineering Consultants ( India )

Ltd, Ranchi

SHnI R. D. CnOUDIIARY ( Alternate)

CHIEF ENGINEER ( D & R)

Irrigation Department,Government of Punjab;

Chandigarh

DIRECTOR ( CD ) (Alternate )

DEPUTY DIR.ECTOR, STANDARDS Research, Designs & Standards Organization,

( B & S )-1

Lucknow

ASSISTANT D IRE C Ton,

STANDARDS ( B & S )-11 ( Alternate)

SaRI M. R. DOCTOR

Special Steels Ltd, Bombay

SHRI S. G. JOSHI ( Alternate)

SHRI V. GULATI

Heatly & Gresham ( India) Ltd, New Delhi

SURI P. K. GUl'TE

National Metallurgical Laboratory

( CSIR ),

Jamshedpur

SaRI N. C. JAIN

Stup Consultants Ltd, Bombay

. SHRI M. C. T ANDON ( Alternate)

SHRI M. P. JASUJA

Research & Development Centre for Iron & Steel

( Steel Authority of India Ltd ), Ranchi

SHRI A. JAYAGOPAL

Engineer-in-Chief's Branch, Army Headquarters,

New Delhi

MAJ R, CHANDRASEKHARAN ( Alternate)

( Continued on page 2 )

@ Copyright 1982

BUREAU OF INDIAN STANDARDS

This publication is protected under the Indian Cflpyllght Act ~ XIV of 1957) ud

reproduction in whole or in part by any means except with written permission of the

publisher shall be deemed to be an infringpment of copyright under the said Act

IS : 432 ( Part I ) - 1982

( Continued from page I )

Members

Representing

SURI S. Y. KHAN

Killick Nixon Ltd, Bombay

SHRI P. S. VENXAT ( Alternate)

SHRI K. K. KUANNA

National Buildings Organization, New Delhi

SURI K. S. SRINIVASAN ( Alternate)

Saar M. N. KUANNA

Bhilai Steel Plant, Bhilai

SHRI C. DASGUPU ( Alternate)

SHRI S. N. MANOHAR

Tata Consulting Engineers, Bombay

SRRI N. NAGARAJ ( Alternate)

SURI R. K. MATHUR

Public Works Department, Ludmow

SURI Y. K. MEHTA

The Concrete Association of India, Bombay

SURI E. T. ANTIA. ( Alternate)

DR P. K. MORANTY

Tor Steel Research Foundation in India, Calcutta

DR ING. P. K. BANERJEE ( Alternate) .

SURI A. D. NARAIN

Roads Wing, Ministry of Shipping and Transport

DR V. P. NARAYANASWAKY

Structural Engineering Research Centre (CSIR),

Roorkee

SHRI Z. GEORGE ( Alternate)

SURI S. N. PAL

M. N. Dastur & Co (P) Ltd, Calcutta

SHRI SALIL Roy ( Alternate)

SURI B. K. P ANTHAKY

Hindustan Construction Co Ltd, Bombay

SHRI P. V. NAIK ( Alternate)

DR G. P. SAH!I.

Gammon India Ltd, Bombay

SH,RIA. C. Roy ( Alternate)

SHRI T. SEN

IRe Steels Ltd, Calcutta

SURI SHIRISHH. SUAH

Tensile Steel Ltd, Bombay

SHRI M. S. PATHAK ( Alternate)

SHRI C. N. SRINIVASAN

C, R. Narayana Rao, Madras

SHRI C. N. RAGHAVENDRAN ( Alternate)

SHRI S. SUBRAMANIAN

Cement Research Institute of India, New Delhi

SHRI Asn, KUMAR ( Alternate)

SURI G. RAMAN,

Director General,BIS (&-ojfi&io Mnnlur)

Director ( Civ Engg )

SeCTdtlry

SHRi M. N. NEELAKANDHAN

Assistant Director ( Civ Engg) BIS

AMENDMENT NO. 1 DECEMBER 2004

TO

IS 432 (PART 1): 1982 SPECIFICATION FOR

MILD STEEL AND MEDIUM TENSILE STEEL BARS

AND HARD-DRAWN STEEL WIRE FOR CONCRETE

REINFORCEMENT

PART 1 MILD STEEL AND MEDIUM TENSILE STEEL BARS

( Third Revision)

( Page 4, clause 0.7 ) clause:

Insert the following new para at the end of the

The following test methods given in this Indian Standard are technically .

equivalent to those given in ISO Standards:

Sl No.

Title

IS No.

ISO No.

i)

Mechanical testing of

metals - Tensile testing

1608

6892

ii)

Method for bend test

1599

10065

NOTE - For assessing the conformity of the reinforcement to the requirements laid down

in this standard, this standard also permits the use of test methods covered by the above

ISO Standards.

(CED 54)

Reprography Unit, BIS, New Delhi. India

IS : 432 ( Part I ) - 1982

Indian Standard

SPECIFICATION FOR

MILD STEEL AND MEDIUM TENSILE STEEL

BARS AND HARD-DRAWN STEEL WIRE FOR

CONCRETE REINFORCEMENT

PART I

MILD STEEL AND MEDIUM TENSiLE STEEL BARS

( Third Revision)

o.

FOR E W 0 R D

0.1 This Indian Standard ( Part I ) ( Third Revision) was adopted by the

Indian Standards Institution on 31 March 1S-82, after the draft finalized

by the Joint Sectional Committee for Concrete Reinforcement had been

approved by the Civil Engineering Division Council and the Structural

and Metals Division Council.

0.2 This standard was first published in 1953 and subsequently revised

in 1960 and 1966. The present, revision has been taken up with a view

to modifying the earlier provisions in the light of the experience gained

during the use of this standard by both manufacturers and users.

0.3 This standard adopts SI units in specifying the various physical

requirements. Further, some of the provisions have been revised based

on the latest Indian Standards, such as IS: 226-1975*, IS: 961-l975t,

IS: l599-l974t, IS: l608-l972, IS: 1732-197111, IS: 1762 (Part 1)1974~ and IS : 1977-1975**.

0.4 The concrete reinforcement having an ultimate tensile strength of

not less than 540 Njmm 2 has been categorized as ' medium tensile steel

instead of' high tensile steel' (see IS: 96l-l975t) in this standard. In

concrete reinforcement, the term 'high tensile steel' is, as a general

*Specification for structural steel ( standard quality) (fifth revision ).

tSpecification for structural steel ( high tensile) ( second revision).

:j:Method for bend test for steel products other than sheet, strip, wire and lube (first

revision ).

Method for tensile testing of steel products (first revision).

IIDimensions for round and square steel bars for structural and general engineering

'

purposes (first revision).

~Code for designation of steel: Part I Based on letter symbols ( first revision).

*Specification for structural steel ( ordinary quality) ( second reois.ou ).

IS : 432 ( Part I ) 1982

practice, used to mean steel having tensile strengths in a still higher

range, say 1 000-2 20Q Njmm 2 which is generally used in prestressed

concrete.

0.5 Grade II mild steel bars are not recommended for use in structures

located in earthquake zones subjected to severe damage and for

structures subjected to dynamic loading (other than wind loading ),

such as railway and highway bridges (see IS: 1893-1975* and

IS: 1977-l97.5t).

0.6 \\"elding of reinforcement ban covered in this specification shall be

.done in accordance with the requirements orIS: 2751-1966t.

0.7 In the formulation of this standard, due weightage has been given to

international coordination among the standards and practices prevailing

in different countries in addition to relating it to the nractices in the field

in this country.

0.8 For the purpose of deciding whether a particular requirement of

this standard is complied with, the final value, observed or calculated,

expressing the result of a test or analysis, shall be rounded off in accordance with IS : 2-1960. 'Ehe number of significant places retained in the

rounded off value should be the same as that of the specified value in this

standard.

1. SCOPE

1.1 This standard ( Part I ) covers the requirements of mild steel and

medium tensile steel plain bars in round and square sections for use as

reinforcement in concrete.

2. TERMINOLOGY

2.0 For the purpose of this standard, the following definitions shall

apply.

2.1 Bar - A hot-rolled bar of steel of circular or square cross-section.

2.2 Bundle - Two or more 'coils' or a number of lengths properly

bound together,

2.3 Coil- One continuous bar as rolled in the form of a coil.

"Criteria for earthquake resistant design of structures (third revision ).

for structural steel ( ordinary quality) ( second rel'ision ).

tCode of practice for welding of mild steel ban used for reinforced concrete

.construction.

&Rules for rounding off numerical values ( rlllislfl).

tSpecifi~ation

IS : 432 ( Part I ) 1982

2.4 Elongation - Increase in length of a tensile test piece under .stress.

The elongation at fracture is conventionally expressed as a percentage of

the original gauge length of a standard test piece.

2.5 Nom.inal Size - The nominal size of a bar shall be the dimension

of the diameter of round bars and side of square bars.

2.6 Parcel - Any quantity of bars whether in coils or bundles, presented

for examination and test at anyone time.

2.7 Ultim.ate Tensile Stress -

The maximum load reached in a

tensile test divided by the original cross-sectional area of the gauge length

portion of the test piece.

2.8 Yield Stress - Stress (that is, load per unit cross-sectional area)

at which elongation first occurs in the test piece without increasing the

load during tensile test. In the case of steels with no such definite yield

point, the yield stress is the stress under the prescribed testing conditions

at which the: observed increase in the gauge length is 1/200 of the gauge

length when the rate at which the load applied is not more than 5

N/mm"/s when approaching the yield stress.

3. TYPES AND GRADES

3.1 Reinforcement supplied in accordance with this standard shall be

classified into the following types:

a) Mild steel bars, and

b) Medium tensile steel bars.

3.1.1 Mild steel bars shall be supplied in the following two grades:

a) Mild steel bars, Grade I; and

b) MiLl steel bars, Gracie II.

4. MANUFACTURE AND CHEMICAL COMPOSITION

4.1 Steel for mild steel reinforcement bars, Gracie I shall be manufactured

and have the chemical composition in accordance with the requirements

of Steel Designation Fe 41O-S ofJS : 226-1975*.

4.2 Steel for mild steel reinforcement bars, Grade II shall be manufactured and have the chemical composition in accordance with the

requirements of Steel Designation Fe 410-0 ofIS : 1977-1 975t.

Specification for structural steel ( standard quality) (fifth revision ).

tSpecification for structural steel ( ordinary quality) ( second revision).

IS : 432 ( Part I ) 1982

4.3 Medium tensile steel bars shall be manufactured and have the

chemical composition in accordance with the requirements of Steel

Designation Fe 540 W-HT ofIS : 961-1975*

5. FREEDOM FROM DEFECTS

5.1 All finished bars shall be well and cleanly rolled to the dimensions

and weights specified. They shall be free from cracks, surface flaws,

laminations and rough, jagged and imperfect edges and all other harmful

derec~.

.

6. NOMINAL SIZES AND MASS

6.1 Sizes - Mild steel and medium tensile steel bars shall be supplied in

the following nominal sizes:

5, 6, 8, 10, 12, 16, 20, 22, 25, 28.

32, 36, 40, 45 and 50 mm

Diameter ofround bars or side

of square bars

6.2 Mass 1971t.

The mass of bars shall be in accordance with IS: 1732-

7. TOLERANCES

7.1 The rolling and cutting tolerances shall be in accordance with IS :

1852-1973t.

8. PHYSICAL REQ.UIREMENTS

8.1 The ultimate tensile stress, yield stress and percentage elongation

when determined in accordance with 9.2 shall be as given in Table I;

8.2 The bars shall also withstand the bend test specified in 9.3.

9. TESTS

9.1 Selection and Preparation of Test Samples.- Unless otherwise specified in this standard, the requirements ofIS : 226-1S75 shall

apply.

9.1.1 All test pieces of bars shall be selected by the purchaser or his

authorized representative, either:

a) from the cutting of bars; or

*Specification for structural steel ( high tensile ) ( second revision ).

tDimensions for round and square steel bars for structural and general engineering

purposes (first mi.Hon ).

tSpecification for rolling and cutting tolerances for hot-rolled steel products ( secotut

revision ).

'

Specification for structural steel ( standard quality) (fifth Tension ).

IS : 432 ( Part I ) 1982

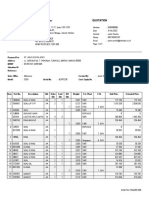

TABLE 1 MECHANICAL PROPERTIES OF BARS

( Claus, 8.1 )

SL

No.

TypE AND NOJ(f1(AL SIZE

OF BAR

ULTIKATE

YIELD STRES!)

TENSILE

ELONGATIONPERCENT,

STRE88,

Min

I.

Min

Min

410

250

23

.10

2-40

23

370

225

23

370

215

25

540

350

20

540

340

20

510

330

20

Jfild Steel Grad, I

For bars up to and including

20mm

For bars over 20 mm, up to

and including 50 mm

2. Mild Steel Grade II

For bars up to and including

20mm

For bars over 20 mm, up to

and including 50 mm

3. M,dium Tensile Steel

For bars up to and including

16mm

For bars over 16 mm, up to

and including 32 mm

For bars over 32 mm, up to

and Including 50 mm

-Elongation on a gauge length 565 V So where So is the cross-sectional area of the

teat piece.

b) if he so desires, from any bar or the coil, after it has been cut to

the required or specified length and the test piece taken from any

part of it.

9.1.1.1 In neither case, the test piece shall be detached from the bar

or the coil, except in the presence of the purchaser or his authorized

representative.

9.1.1.2 Before test pieces are selected, the manufacturer or supplier

shall furnish the purchaser or his authorized representative with copies

of the mill records giving the number of bars in each cast with sizes as

well as the identification marks whereby the bars from their cast or each

coil can be identified.

IS : 432 ( Part I ) 1982

9.2 Tensile Test - The ultimate tensile stress, yield stress anti elongation of bars shall be determined in accordance with the requirements of

IS : 1608-1972* read in conjunction with IS: 226-1975t. The' test

pieces shall be cut from the finished material and straightened where

necessary. They shall not be annealed or otherwise subjected to heat

treatment. Any slight straightening which may be required shall be done

cold.

9.2.1 In case of bars, the size of which is nbtuniform throughout the

length of test piece, limits shall be applied according to the actual maximum thickness of the piece selected for testing.

9.2.2 Should a tensile test piece break ontside the middle half of its

gauge length and the percentage elongation obtained is less than that

specified, the test may be discarded at the manufacturer's option, and

another test mace from the same bar.

9.3B,end Test - The bend test-shall be performed in accordance with

the requirements of IS : 1599-19i4~ read in conjunction with 1S : 2261975t.

9.4 Retest - Should anyone of the test pieces first selected fail to pass

any of the tests specified in this standard, two further samples shall be

selected for testing in respect of each failure. Should the test pieces from

both these additional samples pass, the material represented by the test

samples shall be deemed to comply with the requirements of that particular test. Should the test piece from either of these additional samples

fail, the material represented by the test: samples shall be considered as

not having complied with this standard.

9.5 Sampling - Sampling for tensile and bend tests shall be in accord..

ance with IS: 226-1975t.

10. DEUVERY, INSPECTION AND TESTING FACILITIES

10.1 'Unless otherwise specified,general requirements relating to the

supply of material, inspection and testing: shall conform to IS :.13871967.

10.2 No. material shall be despatched from the manufacturer's or

suppliers' premises prior to its being certified by the purchaser or his

authorized representative as having fulfilled the tests and requirements

laid down in this standard except where the bundle or coil containing

the bars is marked with the lSI Certification Mark.

*Method for tensile testing of steel products (first rezision).

tSpecification for structural steel ( standard quality ) (fifth re;;isitm).

tMethod for bend test for steel products other than sheet" strip, wire ..and tube

(first rezisiiJn ).

General requirements for the~ply of metallurgical materials (first m.nerl ).

IS : 432 ( Part I ) - 1982

10.3 The- purchaser or his authorized representative shall be at liberty

to inspect :and verify the steel maker's certificate of cast analysis at the

premises of the manufacturer or supplier; when the purchaser requires

an actual analysis of finished material, this shall be made at a place

agreed to between the purchaser and the manufacturer or supplier.

10.4 Manufacturer's Certificate - In the case of bars which have

not been inspected at the manufacturer's works, the manufacturer or

supplier, as the case may be, shall supply the purchaser or his authorized

representative with. the certificate stating the process of manufaCture

and also the test sheet signed by the manufacturer giving the result of

each mechanical test applicable to the material purchased, and the

chemical composition, if required. Each test sheet shall indicate the

number or identification mark of the cast to which it applies, corresponding to the number or identification mark to be found on the

material.

11. IDENTIFICATION AND MARKING

11.1 The manufacturer or supplier shall have ingots, billets and bars or

bundles of bars marked in such a way that all finished bars can be traced

to the cast from which they were made. Every facility shall be given to

the purchaser or his authorized representative for tracing the bars to the

cast from which they were made.

11.2 The medium tensile steel bars shall be suitably marked to identify

them from mild steel bars. Mild steel bars Grade I and II shall have

distinctive identification tags.

11.3 Each bundle or coil containing the bars may also be suitably

marked with the Standard Mark, in which case the concerned test certificate shall also bear the Standard Mark.

NOTE - The use of the Standard Mark is governed by the provisions of the

Bureau of Indian Standards Act, 1986and the Rules and Regulations made thereunder. The Standard Mark on products covered by an Indian Standard conveys

the assurance that they have been produced to comply with the requirements of that

standard under a well defined system of inspection, testing and quality control

which is devised and supervised by BIS and operated by the producer .. Standard

marked products are also continuously checked by BIS for conformity to that

'standard as a further safeguard. Details of conditions under which a licence for

the use of the Standard Mark may be granted to manufacturers or producers may

be obtained from the Bureau of Indian Standards.

BUREAU

OF

INDIAN

STANDARDS

Headquarters:

.Manak Bhavan, 9 Bahadur Shah Zalar Marg, NEW DELHI 110002

Teiephones : 331 01 31

Telegrams: Manaksansth8

.3311375

(Common to all Offices)

Region(ll Offices:

Ietephane

Central

: Manak Bhavan, 9, Bahadur Shah Zatar Marg.

S331 01 31

NEW DELH I 110002

?331.1375

37 86..~62

: 1/14 C.I.T. Scheme VII M,

Eastern

Y.J.P. Road, Maniktola, CALCUTTA 700054

.

, 21843

: SCO 445-446, Sector 35-C, CHANDIGARH 16bo36

Northern

Southern

: C.I.T. Campus, IV Cross Road, MADRAS 600113

41 29 16

t Western

: ManakalaYil, E9 MlDC, Marol. Andheri (East).

6329295

BOMBAY 400093

Branch Offices:

'Pushpak'. NurmohamectShaikh Marg, Khanpur, AHMADABAD 380001

t Peenya Industrial Area, 1st Stage, Bangalore- Tumkur Road,

BANGALORE 560058.

Gangotri Complex, 5thFloor. Bhadbhada Road. T.T. Nagar.

BHOPAL 462003

Plot No. 82/83, Lewis Road, BHUBANESHWAR 751002

Kalai Kathir Building, 6/48-A Avanasi Road, COIMBATORE 641037

Quality Marking Centre, N.H IV, N.I.T" FARIDABAD 121001

Savitri Complex, 116 G, T. Road, GHAZIABAD 201001

53/5 Ward No. 29, R.G. Barua Road. 5th By-lane.

GUWAHATI 781003

5-8-56C L. N. Gupta Marg, ( Nampally Station Road)

HYDERABAD 500001

R14 Yudhister Marg, C Scheme. JAIPUR 302005

117/418 B Sarvodaya Nagar, KANPUR 208005

';t No. A-9, House No. 561/63, Sindhu Nagar. Kanpur Road.

LUCKNOW 226005

Patliputra Industria Estate. PATNA 800013

District Industries Centre Complex. Bagh-e-Ali Maidan

SR/NAGAR 190011

T. C. No. 14/1421, University P.O.. Palavarn.

THIRUVANANTHAPURAM 695034

Inspection Offices (With Sale Point) :

Pushpanjali. First Floor, 205-A West High Court Road

Shankar Nagar Square, NAGPUR 440010

Institution of Engineers (India) Building. 1332 Shivaji Nagar.

PUNE 411005

Safes Office Calcutta is at 5 Chowringhee Approach.

P. O. Princep Street, CALCUTTA

t Sales Office is at Novelty Chambers, Grant Road, BOMBAY

:I: Sates Office is at Unity Building, Narasimharaja Square.

B.ANGALORE

26348

394955

'>It

554021

53627

26705

8-71 19 96

33177

231083

63471

21 6876

55507

62305

621 04

5251 71

52435

276800

Printed at Dee Kay Printers, New Delhi. India

Potrebbero piacerti anche

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Type Design ofDocumento8 pagineType Design ofAnkit SinglaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Design of RCC Wing WallDocumento6 pagineDesign of RCC Wing WallAnkit Singla100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- CalsiDocumento2 pagineCalsiAnkit SinglaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Head Loss of SyphonDocumento6 pagineHead Loss of SyphonAnkit SinglaNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Cleanouts HandoutDocumento2 pagineCleanouts HandoutGIANNA MARIE BALIBAGNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- D1 PlansDocumento14 pagineD1 PlansansonchongNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Valvula ASCO Falcon SB2500Documento2 pagineValvula ASCO Falcon SB2500Elmer HuashuayoNessuna valutazione finora

- A4-P 13.0 enDocumento13 pagineA4-P 13.0 enAtiq Ur RehmanNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Notice of Violation (NOV) - 04.30.20 - 2861-2865 San Bruno AveDocumento42 pagineNotice of Violation (NOV) - 04.30.20 - 2861-2865 San Bruno AveJoe EskenaziNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Financial Mismanagement: A Leading Cause of Time and Cost Overrun in Mega Construction Projects in PakistanDocumento4 pagineFinancial Mismanagement: A Leading Cause of Time and Cost Overrun in Mega Construction Projects in Pakistanscriptd_ozd3nNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Gear Box Cat 12HDocumento28 pagineGear Box Cat 12HBetty CuperNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- ETABS 2016 16.2.1-Report ViewerDocumento22 pagineETABS 2016 16.2.1-Report ViewerdannaluciaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Road Work - Uddipa - Final Offer-Green ViewDocumento1 paginaRoad Work - Uddipa - Final Offer-Green ViewDebkumar ChowdhuryNessuna valutazione finora

- Business Name: Solanki Plastic Business Address: 72/2, Khatipura, Near ElectronicDocumento3 pagineBusiness Name: Solanki Plastic Business Address: 72/2, Khatipura, Near ElectronicShelendraSinghNessuna valutazione finora

- Bond Dek™ BrochureDocumento10 pagineBond Dek™ BrochureEbrahim FlorisNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Sigma Catalogue 2014Documento60 pagineSigma Catalogue 2014Chien Nguyen Dang100% (2)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- CPWD Par 2020Documento45 pagineCPWD Par 2020Jitendra Meena93% (14)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- PT Trakindo Utama: QuotationDocumento5 paginePT Trakindo Utama: Quotationabdul KadirNessuna valutazione finora

- UNDP - Procurement User Guide Jan 2006 PDFDocumento86 pagineUNDP - Procurement User Guide Jan 2006 PDFPres Asociatie3k100% (1)

- Approach Cross Country PipelinesDocumento3 pagineApproach Cross Country PipelinesrutujaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Design - Sagainc.: Wall Elevation 4 Wall Elevation 5Documento1 paginaDesign - Sagainc.: Wall Elevation 4 Wall Elevation 5Rachelle AbingNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- Australian Termite Standard 3660Documento9 pagineAustralian Termite Standard 3660Yash Alvares0% (1)

- Concrete Making MaterialsDocumento55 pagineConcrete Making Materialsjaffna100% (1)

- Historical Development of Iron Screw Pile FoundationsDocumento21 pagineHistorical Development of Iron Screw Pile FoundationsLaurentiu irimiaNessuna valutazione finora

- 湖边小筑,瑞士 / Atelier Scheidegger Keller: (http://www.scheideggerkeller.ch) for providing the following descriptionDocumento23 pagine湖边小筑,瑞士 / Atelier Scheidegger Keller: (http://www.scheideggerkeller.ch) for providing the following descriptionLu DitianNessuna valutazione finora

- Fan Coil UnitDocumento4 pagineFan Coil UnitZuberYousufNessuna valutazione finora

- BS 6073-2Documento14 pagineBS 6073-2TAMRAIZNessuna valutazione finora

- Estimation and Analysis of Cooling Load For IndianDocumento9 pagineEstimation and Analysis of Cooling Load For IndianFaquruddinNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Analisa Struktur DG Metode Cross PDFDocumento167 pagineAnalisa Struktur DG Metode Cross PDFImam MumtazNessuna valutazione finora

- Kawayan ToroganDocumento2 pagineKawayan ToroganFaith CenaNessuna valutazione finora

- Assessment of The Strength of Conventionally Produced Sandcrete Blocks and Burnt BricksDocumento8 pagineAssessment of The Strength of Conventionally Produced Sandcrete Blocks and Burnt BricksKalsoom MansoorNessuna valutazione finora

- CP13 - 1999 MV and AC in BuildingDocumento56 pagineCP13 - 1999 MV and AC in Buildingbozow bozowlNessuna valutazione finora

- Technical Data - CABLE 2P X 1 SQMMDocumento1 paginaTechnical Data - CABLE 2P X 1 SQMMManoj AgarwalNessuna valutazione finora

- ASTM StandardsDocumento4 pagineASTM StandardsBalaji Lubricants & ChemicalsNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)