Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Charging Set VGU Brochure 29072013

Caricato da

adyro12Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Charging Set VGU Brochure 29072013

Caricato da

adyro12Copyright:

Formati disponibili

Parker Worldwide

Charging Set / Vrificateur Gonfleur

VGU

Catalogue HY10-4016/UK

Connection

Europe, Middle East, Africa

DESCRIPTION

The VGU universal tester and pressurizer is an indispensable instrument for the verification, pressurization and nitrogen

bleeding of most of the hydraulic accumulators available on the market. To use this unit, it is screwed on the inflation valve of

the accumulator and connected via a high pressure hose to the nitrogen source, equipped with a pressure reducer. If only the

nitrogen pressure is to be controlled or reduced, this hose is not necessary.

The standard set is delivered in a storage case containing the following:

-

VGU universal tester and pressurizer (end M28x1.50).

-

Pressure gauge kit from 0 to 25 bar.

-

Pressure gauge kit from 0 to 250 bar.

-

Connection adaptors for inflation valves (7/8 5/8 8V1 - M28x1.50).

-

High pressure hose, 2.5 m long, for connecting to a nitrogen source.

-

Hexagon socket screw key 6mm.

-

Packets of replacement joints.

-

Operating instruction in English and French.

Note: On request, the following options are available:

-

Pressure gauge kits with different scale divisions: 63mm with glycerol bath back end G1/4 cyl. equipped with direct

gear for Minimess connection. Scale divisions 0-10, 0-60, 0-100, 0-400, with accuracy class 1.6%.

-

High pressure hose of different length with adaptors for nitrogen bottles from various countries (specify country), at

each end with a female swivel coupling G1/4 for connecting to the inflation port.

Maximum working pressure: limited by the maximum operating pressure of the installed pressure limited to 400 bar in

any case.

DESCRIPTION

Le vrificateur gonfleur universel, type VGU, est linstrument indispensable pour assurer la vrification, le gonflage et la purge

dazote de la plupart des accumulateurs hydropneumatiques existants sur le march. Pour utilisation, celui-ci sera viss sur la

valve de gonflage de laccumulateur et reli par un flexible haute pression la source dazote munie dun dtendeur. Sil sagit

uniquement de contrler ou rduire la pression dazote, ce flexible nest pas ncessaire.

Lensemble est livr en standard dans une mallette de rangement comprenant :

-

Vrificateur gonfleur universel VGU (sortie M28x1.50).

-

Kit manomtre de 0 25 bar.

-

Kit manomtre de 0 250 bar.

-

Adaptateurs pour raccordement sur valves de gonflage (7/8 5/8 8V1 - M28x1.50).

-

Flexible haute pression de longueur 2,5m permettant le raccordement une source dazote.

-

Cl mle 6 pans 6mm sur plats.

-

Pochettes de joints de rechange.

-

Notice dinstruction en anglais/franais.

Note : Sur demande il peut tre fourni avec :

-

Kit manomtres avec chelles de graduations diffrentes : 63mm bain de glycrine sortie arrire G1/4 cyl. quips

dun rapport direct pour connexion sur prise Minimess. Echelle de graduations de 0-10,0-60, 0-100,0-400, avec

classe de prcision 1.6%.

-

Flexible de longueur diffrente haute pression muni dadaptateurs pour bouteilles dazote de diffrents pays (spcifier

le pays) chaque extrmit un raccord tournant femelle G1/4 cyl. pour liaison lorifice de gonflage.

Pression dutilisation maximale : limite par la pression de service maximale du manomtre mont et limite 400 BAR de

toute faon.

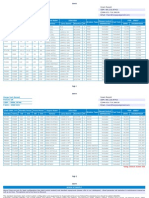

How to order a VGU Charging Set

Type

VGU/F

Pressure

Gauges

Connection

valve stem

High Pressure

Hose

Conditioning

25/250

TS2

Type of Charging Set / Type de vrificateur gonfleur

AE United Arab Emirates,

Dubai

Tel: +971 4 8127100

parker.me@parker.com

AT Austria, Wiener Neustadt

Tel: +43 (0)2622 23501-0

parker.austria@parker.com

AT Eastern Europe, Wiener

Neustadt

Tel: +43 (0)2622 23501 900

parker.easteurope@parker.com

8 : 7/8 - 14 UNF (short)

7/8 - 14 UNF (lenght)

5/8 - 18 UNF

HU Hungary, Budaoers

Tel: +36 23 885 470

parker.hungary@parker.com

IE Ireland, Dublin

Tel: +353 (0)1 466 6370

parker.ireland@parker.com

IT Italy, Corsico (MI)

Tel: +39 02 45 19 21

parker.italy@parker.com

KZ Kazakhstan, Almaty

Tel: +7 7273 561 000

parker.easteurope@parker.com

AZ Azerbaijan, Baku

Tel: +994 50 22 33 458

parker.azerbaijan@parker.com

NL The Netherlands, Oldenzaal

Tel: +31 (0)541 585 000

parker.nl@parker.com

BE/LU Belgium, Nivelles

Tel: +32 (0)67 280 900

parker.belgium@parker.com

NO Norway, Asker

Tel: +47 66 75 34 00

parker.norway@parker.com

BG Bulgaria, Sofia

Tel: +359 2 980 1344

parker.bulgaria@parker.com

PL Poland, Warsaw

Tel: +48 (0)22 573 24 00

parker.poland@parker.com

BY Belarus, Minsk

Tel: +375 17 209 9399

parker.belarus@parker.com

PT Portugal, Leca da Palmeira

Tel: +351 22 999 7360

parker.portugal@parker.com

CH Switzerland, Etoy

Tel: +41 (0)21 821 87 00

parker.switzerland@parker.com

RO Romania, Bucharest

Tel: +40 21 252 1382

parker.romania@parker.com

CZ Czech Republic, Klecany

Tel: +420 284 083 111

parker.czechrepublic@parker.com

RU Russia, Moscow

Tel: +7 495 645-2156

parker.russia@parker.com

DE Germany, Kaarst

Tel: +49 (0)2131 4016 0

parker.germany@parker.com

SE Sweden, Spnga

Tel: +46 (0)8 59 79 50 00

parker.sweden@parker.com

DK Denmark, Ballerup

Tel: +45 43 56 04 00

parker.denmark@parker.com

SK Slovakia, Bansk Bystrica

Tel: +421 484 162 252

parker.slovakia@parker.com

ES Spain, Madrid

Tel: +34 902 330 001

parker.spain@parker.com

SL Slovenia, Novo Mesto

Tel: +386 7 337 6650

parker.slovenia@parker.com

FI Finland, Vantaa

Tel: +358 (0)20 753 2500

parker.finland@parker.com

TR Turkey, Istanbul

Tel: +90 216 4997081

parker.turkey@parker.com

FR France, Contamine s/Arve

Tel: +33 (0)4 50 25 80 25

parker.france@parker.com

UA Ukraine, Kiev

Tel +380 44 494 2731

parker.ukraine@parker.com

GR Greece, Athens

Tel: +30 210 933 6450

parker.greece@parker.com

UK United Kingdom, Warwick

Tel: +44 (0)1926 317 878

parker.uk@parker.com

North America

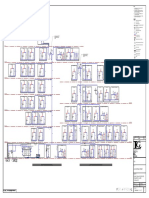

P0 (t2) = P0 (t0) x

US USA, Cleveland

(industrial)

Tel: +1 216 896 3000

whereby:

AU Australia, Castle Hill

Tel: +61 (0)2-9634 7777

CN China, Shanghai

Tel: +86 21 2899 5000

P0 (t2)

P0 (t0)

t2

t0

= inflation pressure at control temperature in bar (absolute value)

= nitrogen pressure P0 at 20C in bar (absolute value)

= control of gas inflation temperature

= reference temperature at 20C

P0 (t2)

P0 (t0)

t2

t0

= pression de gonflage la temprature de contrle en bar (valeur absolue)

= pression dazote P0 20C en bar (valeur absolue)

= temprature de contrle ou de gonflage du gaz

= temprature de rfrence 20C

CORRECTION OF THE NITROGEN INFLATION PRESSURE P0 ACCORDING TO THE OPERATING TEMPERATURE

CORRECTION DE LA PRESSION DE GONFLAGE AZOTE P0 EN FONCTION DE LA TEMPERATURE DE FONCTIONNEMENT

HK Hong Kong

Tel: +852 2428 8008

Inflation pressure P0 at operating temperature t2 in bar (absolute value)

Pression de gonflage P0 temprature de fonctionnement t2 en bar (valeur absolue)

IN India, Mumbai

Tel: +91 22 6513 7081-85

JP Japan, Fujisawa

Tel: +81 (0)4 6635 3050

KR South Korea, Seoul

Tel: +82 2 559 0400

MY Malaysia, Shah Alam

Tel: +60 3 7849 0800

NZ New Zealand, Mt Wellington

Tel: +64 9 574 1744

SG Singapore

Tel: +65 6887 6300

TH Thailand, Bangkok

Tel: +662 717 8140

TW Taiwan, Taipei

Tel: +886 2 2298 8987

South America

AR Argentina, Buenos Aires

Tel: +54 3327 44 4129

BR Brazil, Cachoeirinha RS

Tel: +55 51 3470 9144

MX Mexico, Apodaca

Tel: +52 81 8156 6000

dans laquelle:

Asia Pacific

CL Chile, Santiago

Tel: +56 2 623 1216

t2 + 273

t0 + 273

US USA, Elk Grove Village

(mobile)

Tel: +1 847 258 6200

VGU

Charging Set

Vrificateur Gonfleur

8V1

G 1/4 gas cyl.

TS2 : connection for French bottle/Bouteiille Franaise

TS3 : connection for German bottle/Bouteille Allemande

TS8 : connection for Italian bottle/Bouteille Italienne

equation used / Formule a Appliquer

CA Canada, Milton, Ontario

Tel: +1 905 693 3000

ZA South Africa, Kempton Park

Tel: +27 (0)11 961 0700

parker.southafrica@parker.com

25/250

25/400

Charging Set / Vrificateur Gonfleur

VGU

Catalogue HY10-4016/UK

173

164

155

147

138

130

121

112

104

95

91

86

82

78

73

69

65

60

56

52

48

43

39

35

30

26

22

17

13

8.6

4.3

-20

183

171

162

153

144

135

126

117

108

99

94

90

85

81

76

72

67

63

58

54

49

45

40

36

31

27

22

18

14

9

4.5

-10

186

177

168

158

149

140

130

121

112

103

98

93

89

84

79

75

70

65

61

56

51

47

42

37

33

28

23

19

14

9.3

4.7

0

193

184

174

164

155

145

135

126

116

106

101

97

92

87

82

77

72

68

63

58

53

48

43

39

34

29

24

19

15

9.7

4.8

10

200

190

180

170

160

150

140

130

120

110

105

100

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

20

207

197

186

176

166

155

145

134

124

114

109

103

98

93

88

83

78

72

67

62

57

52

47

41

36

31

26

21

16

10

5.2

30

214

203

192

182

171

160

150

139

128

118

112

107

102

96

91

86

80

75

69

64

59

53

48

43

37

32

27

21

16

11

5.3

40

Operating temperature t in C

Temprature de fonctionnement t en C

221

210

198

187

176

165

154

143

132

121

116

110

105

99

94

88

83

77

72

66

61

55

50

44

39

33

28

22

17

11

5.5

50

227

216

205

193

182

171

159

148

136

125

119

114

108

102

97

91

85

80

74

68

63

57

51

45

40

34

28

23

17

11

5.7

60

234

222

211

199

187

176

164

152

141

129

123

117

111

105

100

94

88

82

76

70

64

59

53

47

41

35

29

23

18

12

5.9

70

241

229

217

205

193

181

169

157

145

133

127

120

115

108

102

96

90

84

78

72

66

60

54

48

42

36

30

24

18

12

6

80

248

235

223

211

198

186

173

161

149

136

130

124

118

112

105

99

93

87

81

74

68

62

56

50

43

37

31

25

19

12

6.2

90

255

242

229

216

204

191

178

166

153

140

134

127

121

115

108

102

96

89

83

76

70

64

57

51

45

38

32

26

19

13

6.4

100

261

248

235

222

209

196

183

170

157

144

137

131

124

118

111

105

98

92

85

78

72

65

59

52

46

39

33

26

20

13

6.5

110

268

255

241

228

215

201

188

174

161

148

141

134

127

121

114

107

101

94

87

81

74

67

60

54

47

40

34

27

20

13

6.7

120

200

190

180

170

160

150

140

130

120

110

105

100

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

Nitrogen inflation pressure P0 at 20C in bar (absolute value)

Pression de gonflage azote P0 20C en bar (valeur absolue)

Example: Inflation pressure = 80 bar at 20C, operating temperature t2 = 50C, the pressure reading value should be P0 at 50C = 88 bar

Exemple : Pression de gonflage = 80 bar 20C, pression de fonctionnement t2 = 50C, la lecture de la pression doit tre P0 50C = 88 bar

NOTE:

It is imperative to wait for the thermal exchange caused by pressure shifts to stabilize in order to check or adjust the pre-filling pressure. As a

safety measure, isolate the nitrogen source during the stabilization period.

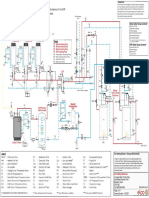

TS9 : connection for Netherlands bottle/Bouteille Hollandaise

For other connections : consult Parker Olaer

Pour autres raccordements : consulter Parker Olaer

3: Plastic Box / Coffret plastique

Parker Hannifin

Accumulator and Cooler Division Europe

Colombes, France

2013 Parker Hannifin Corporation. All rights reserved.

Catalogue HY10-4016/UK, ZZ-1M, 07/2013

EMEA Product Information Centre

Free phone: 00 800 27 27 5374

(from AT, BE, CH, CZ, DE, DK, EE, ES, FI, FR, IE, IL,

IS, IT, LU, MT, NL, NO, PL, PT, RU, SE, SK, UK, ZA)

US Product Information Centre

Toll-free number: 1-800-27 27 537

www.parker.com

Your local authorized Parker distributor

NOTA:

Il est impratif dattendre que lchange thermique provoqu par le mouvement des pressions soit stabilis pour vrifier ou ajuster la prcharge.

Par scurit, pendant la priode de stabilisation, isoler la source dazote.

Parker Hannifin

Accumulator and Cooler Division Europe

Colombes, France

Catalogue HY10-4016/UK

Description (GB)

Charging Set / Vrificateur Gonfleur

VGU

SAFETY INSTRUCTIONS AND RECOMMENDATIONS:

1.

2.

3.

4.

5.

6.

Before any use of the VGU tool, carefully read the directions and safety instructions in this guide.

In any case observe the pressure limits indicated on the various appliances. If necessary, refer to the applicable operating instructions.

Before any nitrogen pressurization measurement the accumulator of the hydraulic circuit under pressure has to be isolated and discharged on the

hydraulic side. If required, immobilize it and define a safety zone.

Only use the nitrogen purity 99,8% (N2) to pressurize the accumulators.

The installation of a pressure reducer between the nitrogen bottle and the tester and pressurizer is mandatory.

The VGU tester and pressurizer is an inspection tool. After using and before restarting the accumulator, it has to be removed from the accumulator.

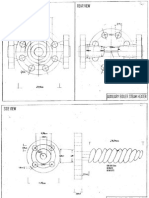

VERIFYING THE INFLATION PRESSURE:

1.

2.

3.

Recommendations:

Before proceeding to any operation concerning the initial pressurization of an accumulator, consult the applicable

operating instructions.

Pressurization limits: According to models, refer to the accumulator manual. The nitrogen pressure varies as a function of the gas temperature.

After each inflation and deflation of nitrogen, wait for the temperature to stabilize before checking the pressure. This may last several minutes

or several tens of minutes depending on the accumulator size. Never exceed the maximum permissible pressure PS or the maximum inflation

pressure P0 Max indicated on the accumulator or in the instructions accompanying the appliance.

Taking into account the temperature influence on the precharge pressure: In order to observe the working pressures of the accumulator, it is

advised to adjust the inflation pressure P0 according to the operating or control temperature (see table giving inflation pressure corrections).

Bladder accumulator:

Remove the plugs on the inflation valve side of the accumulator.

Select the adaptor set according to the inflation valve (Pos. 1 or 2) or (2+3) or 5

Unscrew the screw (Pos. 4) of the selected adaptor by means of the 6 mm hexagon key delivered with the case.

Manually remove the adaptor on the inflation valve.

Take the VGU from the case, install the pressure gauge compatible with the pressure to be verified and make sure the purge valve (Pos. C) is

safely closed.

Manually tighten the knurled ring (Pos. B) of the VGU to the adaptor, positioning the device in such a way that the pressure gauge values can be

easily read.

Arrange for the opening of the inflation valve by TIGHTENING the lobe wheel (Pos. A) until the inflation pressure is indicated on the

pressure gauge.

Membrane or piston accumulator:

When using a membrane or piston accumulator with inflation valve equipped with a CHC screw loosen the latter by a quarter turn with the help of the 6

mm hexagon key supplied with the case before installing the VGU. Take the VGU from the case, install the pressure gauge compatible with the pressure

to be verified and make sure the purge valve (Pos. C) is safely closed.

The VGU is directly mounted on the installation valve without adaptor.

- Arrange for the opening of the inflation valve by UNSCREWING the lobe wheel (Pos.A) until the inflation pressure is indicated on the pressure gauge.

THREE CASES ARE POSSIBLE

The displayed nitrogen pressure P0 is correct

-

Manually unscrew (in case of bladder accumulators) or tighten (in case of membrane or piston accumulators with

CHC screw) the lobe wheel (Pos. A) to allow reclosing of the inflation valve.

-

Loosen the purge valve (Pos. C) to purge the VGU.

-

Remove the VGU assembly from the adaptor or the inflation valve.

-

Unscrew the adaptor equipped with an appropriate screw (if used).

Important: When using membrane or piston accumulators with a CHC screw do not forget to retighten the CHC screw by means of the 6 mm

hexagon key delivered with the case.

The displayed nitrogen pressure P0 is too high

-

Loosen the purge valve (Pos. C) to reduce the nitrogen pressure of the accumulator until the required P0 pressure after stabilization is

reached (the nitrogen escapes to the ambient air).

-

Retighten the purge valve (Pos. C).

-

Remove the VGU following the procedure P0 read correctly.

The displayed nitrogen pressure P0 is too low

-

Remove the knurled plug (Pos. D).

-

Connect the end of the high pressure hose G1/4 cyl. (cone at 60) to the valve (Pos. E).

-

Connect the other end of the high pressure hose to the nitrogen source equipped with a pressure reducer via the supplied adaptor.

-

Slightly open the valve of the nitrogen source, especially if the accumulator has a small capacity and low operating pressure.

-

Loosen or tighten the lobe wheel (Pos. A) according to the accumulator type to allow pressure build up.

-

As soon as the P0 pressure is reached and stabilized, close the valve of the nitrogen source.

-

Loosen or tighten the lobe wheel (Pos. A) to release the screw (Pos. 4) of the inflation valve.

-

Loosen the purge valve (Pos. C) to purge the VGU.

-

Carefully take off the high pressure hose to purge it.

-

Reinstall the knurled plug (Pos. D) to the valve (Pos. E)

-

Remove the VGU assembly from the adaptor or the inflation valve.

-

Unscrew the adaptor equipped with an appropriate screw (if used).

After removing the VGU, make sure the inflation valve is tight. Retighten the plug(s) on the inflation valve side.

MAINTENANCE OF THE VGU TESTER AND PRESSURIZER:

It is recommended to check the various joints at regular intervals (cleanliness, detection of possible defects, thread wear) as well as the sealing parts.

For questions of all kinds or additional information please contact Olaer or an authorized agent. Spare part kits are available from Parker Olaer (contact

Parker Olaer).

Catalogue HY10-4016/UK

Description (FR)

Charging Set / Vrificateur Gonfleur

VGU

CONSIGNES DE SECURITE ET RECOMMANDATIONS:

1.

2.

3.

4.

5.

6.

Avant toute utilisation de loutillage VGU, lire attentivement les instructions et consignes de scurit figurant dans cette notice.

Respecter imprativement les limites de pression indiques sur les diffrents quipements. Si ncessaire recourir aux notices

dinstruction applicables.

Avant toute mesure de gonflage en azote, il est impratif disoler laccumulateur du circuit hydraulique sous pression et de procder sa dcharge

ct hydraulique. Procder son immobilisation si ncessaire et dlimiter une zone de scurit

Nutiliser que de lazote (N2) de puret 99,8% pour le gonflage des accumulateurs.

Il est impratif de monter un dtendeur entre la bouteille dazote et le vrificateur gonfleur.

Le vrificateur gonfleur VGU est un outillage de contrle. Aprs utilisation et avant remise en fonctionnement de laccumulateur, il est impratif de

le dmonter de laccumulateur.

Charging Set / Vrificateur Gonfleur

VGU

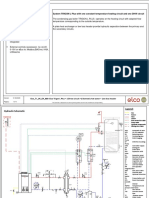

Catalogue HY10-4016/UK

Connections

6 flats/Pans 32 SP

Charging Set / Vrificateur Gonfleur

VGU

Catalogue HY10-4016/UK

Option: According countries

Option: Selon pays

Direct connection pressure gauge coupling

Raccord direct de manomtre

6 flats/Pans 28 SP

6 flats/Pans 27 SP

6 flats/Pans 32 SP

VERIFICATION DE LA PRESSION DE GONFLAGE:

1.

2.

3.

Recommandations:

Avant de procder toute opration portant sur le pr gonflage dun accumulateur, consulter la notice

dutilisation applicable.

Limites de gonflage: Suivant modles consulter imprativement la notice de laccumulateur. La pression dazote varie avec la temprature du gaz.

Aprs chaque gonflage ou dgonflage dazote, attendre la stabilisation de la temprature avant de contrler la pression. Cette dure peut atteindre

plusieurs minutes ou plusieurs dizaines de minutes en fonction de la taille de laccumulateur. Ne jamais dpasser la pression maximale admissible

PS ou la pression de gonflage maximale P0 Max, le cas chant indique sur laccumulateur ou sur la notice fournie avec lappareil.

Prise en compte de linfluence de la temprature sur la pression de pr gonflage: Afin de respecter les pressions dutilisation de laccumulateur, il

est conseill doptimiser la pression de gonflage P0 la temprature de travail ou de contrle (voir tableau de correction de la pression

de gonflage).

GB/AUSTRALIA

GB/AUSTRALIE

USA

ITALY/ITALIE

G 5/8 male

24,51 x 1/14 male

21,8 x 1/14 male

Accumulateur vessie :

Dvisser le/les bouchons ct valve de gonflage de laccumulateur.

Slectionner le jeu dadaptateurs selon la valve de gonflage (Rep. 1 ou 2) ou (2+3) ou 5.

Dvisser compltement la vis (Rep.4) de ladaptateur choisi laide de la cl 6 pans de 6mm fournie dans la mallette.

Visser manuellement ladaptateur sur la valve de gonflage.

Prendre le VGU dans la mallette, monter le manomtre compatible avec la pression vrifier, sassurer que le robinet de purge (Rep.C) est

bien ferm.

Visser manuellement la bague molete (Rep.B) du VGU sur ladaptateur en positionnant lappareil de faon permettre une lecture facile

du manomtre.

Commander louverture de la valve de gonflage en VISSANT le volant lobes (Rep. A) jusqu la lecture de la pression de gonflage sur

le manomtre.

Accumulateur membrane ou piston :

En prsence daccumulateur membrane ou piston, avec valve de gonflage quipe dune vis CHC, dbloquer celle-ci dun quart de tour laide de

la cl 6 pans de 6 mm fournie dans la mallette avant de monter le VGU. Prendre le VGU dans la mallette, monter le manomtre compatible avec la

pression vrifier, sassurer que le robinet de purge (Rep.C) est bien ferm.

Le VGU se monte directement sans adaptateur sur la valve de gonflage.

- Commander louverture de la valve de gonflage en DEVISSANT le volant lobes (Rep.A) jusqu la lecture de la pression de gonflage sur

le manomtre.

TROIS CAS PEUVENT SE PRESENTER

La pression dazote P0 lue est correcte

-

Dvisser (cas des accumulateurs vessie) ou visser (cas des accumulateurs membrane ou piston quips dune vis CHC) manuellement

le volant lobes (Rep.A) pour permettre la valve de gonflage de se refermer.

-

Desserrer le robinet de purge (Rep.C) pour purger le VGU

-

Dvisser lensemble VGU de ladaptateur ou de la valve de gonflage

-

Dvisser ladaptateur quip de sa vis approprie (si utilise)

Important : Dans le cas des accumulateurs membrane ou piston quips dune vis CHC, ne pas oublier de rebloquer la vis CHC avec la

cl six pans de 6mm fournie dans la mallette.

La pression dazote P0 lue est excessive

-

Desserrer le robinet de purge (Rep.C) pour baisser la pression dazote de laccumulateur jusqu obtenir la pression P0 dsire aprs

stabilisation (lazote schappe lair libre).

-

Resserrer le robinet de purge (Rep.C).

-

Dmonter le VGU en respectant la procdure P0 lue correcte .

La pression dazote P0 lue est insuffisante

-

Enlever le bouchon molet (Rep.D).

-

Raccorder lextrmit du flexible haute pression G1/4 cyl. (cne 60) la valve (Rep. E).

-

Raccorder lautre extrmit du flexible haute pression la source dazote munie dun dtendeur par lintermdiaire de ladaptateur fourni.

-

Ouvrir trs modrment le robinet de la source dazote, surtout si laccumulateur est de petite capacit et de basse pression de service.

-

Dvisser ou visser le volant lobes (Rep A) selon le type daccumulateur pour admettre la pression.

-

Lorsque la pression P0 est atteinte et stabilise, fermer le robinet de la source dazote.

-

Dvisser ou visser le volant lobes (Rep.A) pour librer la vis (Rep.4) de la valve de gonflage.

-

Desserrer le robinet de purge (Rep.C) pour purger le VGU.

-

Dmonter le flexible haute pression doucement pour le purger.

-

Remonter le bouchon molet (Rep.D) sur la valve (Rep.E).

-

Dvisser lensemble VGU de ladaptateur ou de la valve de gonflage.

-

Dvisser ladaptateur quip de sa vis approprie (si utilise).

Aprs dmontage du VGU, sassurer de ltanchit de la valve de gonflage. Revisser le/les bouchon(s) ct valve de gonflage.

Pressure gauge

Manomtre

High Pressure Hose

Flexible haute pression

VGU

6 flats/Pans 32 SP

6 flats/Pans 32 SP

Direct connection to

M28 dia x 1.50 accumulator

valve with 6 mm A/F

Hexagonal socket head screw

6 flats/Pans 27 SP

Raccordement direct sur

valve accumulateur M28 x

1.50 avec vis 6 pans

creux 6S/p.

Long adaptor

Adaptateur long

7/8 - 14 UNF

FRANCE/ BELGIUM/ SPAIN

JAPAN/JAPON

JAPAN/JAPON

BRASIL/BRESIL

FRANCE/BELGIQUE/ESPAGNE

22 x 1/14 female

W 23 x 1/14 male

G 1/2 female

21,7 x 1/14 female

Set of adapters

Jeu dadaptateurs

6 flats/Pans 32 SP

6 flats/Pans 27 SP

6 flats/Pans 32 SP

Connection to nitrogen source

Raccordement sur source dazote

Short adaptor

Adaptateur court

7/8 - 14 UNF

Adaptor / adaptateur

5/8 - 18 UNF

Adaptor / adaptateur

5/8 - 18 UNF

6 flats/Pans 32 SP

Coupling / Raccord

8 V1 - VG 8

GERMANY/ BELGIUM/ HOLLAND/ SWEDEN/ NORWAY/ SWISS

ALLEMAGNE/BELGIQUE/HOLLANDE/SUIDE/Norvge/SUISSE

CHINA/CHINE

24,32 x 1/14 female

M 22 x 1,5 female

CHINA/CHINE

G 5/8 female

S:

T:

U:

V:

MAINTENANCE DU VERIFICATEUR GONFLEUR VGU:

Threaded or slick / Filet ou lisse

Threaded / Filet

Slick / Lisse

Valve / Valve

W:

X:

Y:

Z:

Valve stem + valve core / Corps de valve + obus de valve

Valve stem + valve / Corps de valve + valve

Valve stem + integrated valve / Corps de valve + valve intgre

Valve + integrated valve / Valve + valve intgre

Il est recommand de vrifier intervalles rguliers les diffrentes pices de raccordement (propret, dtections ventuelles danomalies, usure des

filetages) ainsi que les pices dtanchit (joints). Pour toute question ou demande dinformation complmentaire, contacter Olaer ou un agent agr.

Parker Olaer met votre disposition des kits de pices de rechange (consulter Parker Olaer).

Parker Hannifin

Accumulator and Cooler Division Europe

Colombes, France

Parker Hannifin

Accumulator and Cooler Division Europe

Colombes, France

Parker Hannifin

Accumulator and Cooler Division Europe

Colombes, France

Parker Hannifin

Accumulator and Cooler Division Europe

Colombes, France

Potrebbero piacerti anche

- MeditationDocumento130 pagineMeditationadyro12100% (2)

- 9500 ManualDocumento37 pagine9500 Manualanjana0% (1)

- Analysis of Rates For Water Supply and SanitationDocumento186 pagineAnalysis of Rates For Water Supply and Sanitationhlaung100% (8)

- Fire Sprinkler System ReportDocumento26 pagineFire Sprinkler System ReportFrederick Bibong Alayon0% (3)

- 24 Ford EE New HollandDocumento239 pagine24 Ford EE New HollandJohn Mendoza PachecoNessuna valutazione finora

- API RP-576 Inspection of Pressure-Relieving DevicesDocumento67 pagineAPI RP-576 Inspection of Pressure-Relieving DevicesIbrahim Eldesoky100% (9)

- lt3 00032 2 A p24 p30sDocumento67 paginelt3 00032 2 A p24 p30sBruno SamaeianNessuna valutazione finora

- Install and Operate ECO-DRAIN 32 Condensate DrainDocumento36 pagineInstall and Operate ECO-DRAIN 32 Condensate Drainadyro1275% (4)

- Murphy Controls and Instrumentation Catalogue PDFDocumento74 pagineMurphy Controls and Instrumentation Catalogue PDFEnergoCentr67% (3)

- Flange Leakage Check Calculation - Updated On 27-09-2009Documento24 pagineFlange Leakage Check Calculation - Updated On 27-09-2009SamNessuna valutazione finora

- AutoimmuneSolution FINALDocumento24 pagineAutoimmuneSolution FINALadyro12100% (1)

- B10 Steam-Distribution SpiraxSarcoDocumento56 pagineB10 Steam-Distribution SpiraxSarcomello_dubNessuna valutazione finora

- Pukor 11-049e Priced Gsec Pdvsa Gas-Mega-Project 11058a-In-12 (P)Documento43 paginePukor 11-049e Priced Gsec Pdvsa Gas-Mega-Project 11058a-In-12 (P)avaisharmaNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Z Parts List Air Hire PricesDocumento15 pagineZ Parts List Air Hire PricesUbanAirlanggaNessuna valutazione finora

- Letter To WASA Chairman Requesting Waiver For Plumbing LicenseDocumento7 pagineLetter To WASA Chairman Requesting Waiver For Plumbing LicenseJeffrey JamesNessuna valutazione finora

- Vanzetti Cryogenic Pumps & Technology GuideDocumento0 pagineVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiNessuna valutazione finora

- Hydrostatic System - Test and AdjustDocumento23 pagineHydrostatic System - Test and AdjustSanchez Gamarra AndyNessuna valutazione finora

- 23.bladder AccumlatorDocumento12 pagine23.bladder AccumlatorM S GokulNessuna valutazione finora

- Barjatya Ji 1185Documento3 pagineBarjatya Ji 1185Adinath InfrastructureNessuna valutazione finora

- PSV Sizing Tool - API BasedDocumento11 paginePSV Sizing Tool - API BasedJoseph Paul Ilagan0% (1)

- Dse PN MetricDocumento29 pagineDse PN MetricSuman DeyNessuna valutazione finora

- Hagglunds Viking MK 64 163000 Bo LN 0100Documento26 pagineHagglunds Viking MK 64 163000 Bo LN 0100thijssilderhuis100% (1)

- VDO Marine CatalogDocumento24 pagineVDO Marine CatalogssinokrotNessuna valutazione finora

- Ads 000014 02 en PDFDocumento40 pagineAds 000014 02 en PDFalexsandr0% (1)

- T7a Iso Uk Parkersales eDocumento6 pagineT7a Iso Uk Parkersales eJose FernandezNessuna valutazione finora

- m3814 OmegaDocumento8 paginem3814 OmegaNelson GodoyNessuna valutazione finora

- Bomba de Lubricação Automatca de MarteloDocumento53 pagineBomba de Lubricação Automatca de MarteloDaniel F BarrosNessuna valutazione finora

- SDMO Subsidiaries and Power Products Around the WorldDocumento8 pagineSDMO Subsidiaries and Power Products Around the Worldecytrangulo5526Nessuna valutazione finora

- Pompe Hori InoxDocumento22 paginePompe Hori InoxNour Nour El IslamNessuna valutazione finora

- Surge Tank Maint Bulletin PDFDocumento2 pagineSurge Tank Maint Bulletin PDFihllhmNessuna valutazione finora

- Harga Jual Genset Deutz GermanyDocumento2 pagineHarga Jual Genset Deutz GermanyAgung SetiawanNessuna valutazione finora

- Optimex Prei RangeDocumento12 pagineOptimex Prei RangeThomas DamonNessuna valutazione finora

- Universal Charging Unit for Bladder, Piston & Diaphragm AccumulatorsDocumento10 pagineUniversal Charging Unit for Bladder, Piston & Diaphragm AccumulatorsFernando Borges ChachaNessuna valutazione finora

- Style 07 Zero-Flex Rigid Coupling: Product DescriptionDocumento0 pagineStyle 07 Zero-Flex Rigid Coupling: Product Descriptionpca97Nessuna valutazione finora

- Advance Valve - ProfileDocumento2 pagineAdvance Valve - ProfileRajat AgrawalNessuna valutazione finora

- User's Guide: FMG-1000-SKDocumento8 pagineUser's Guide: FMG-1000-SKeng_seng_lim3436Nessuna valutazione finora

- Johnson Controls Hvac Equipments Controls Katalog 2010Documento52 pagineJohnson Controls Hvac Equipments Controls Katalog 2010niti860Nessuna valutazione finora

- GP1850WF GP1850WDF Installation Manual Va1Documento74 pagineGP1850WF GP1850WDF Installation Manual Va1Jose Maria MadrigalNessuna valutazione finora

- Aire y Frenos Especificaciones 140HDocumento18 pagineAire y Frenos Especificaciones 140Hlark_Nessuna valutazione finora

- Manual VT+660Documento21 pagineManual VT+660alejjavierdelgadoNessuna valutazione finora

- Welding Consumables-Stainless SteelDocumento27 pagineWelding Consumables-Stainless SteelibicengNessuna valutazione finora

- 855 (1400)Documento6 pagine855 (1400)Harman Singh NagpalNessuna valutazione finora

- Ss 6358Documento70 pagineSs 6358davidninrioNessuna valutazione finora

- Eerpac P39Documento2 pagineEerpac P39Erwin Castro100% (1)

- Flowmeter FTB-1300 Series CatalogoDocumento16 pagineFlowmeter FTB-1300 Series CatalogoAlbert AlmeidaNessuna valutazione finora

- Actuator BARDocumento16 pagineActuator BARRohit GadekarNessuna valutazione finora

- Mofh318 Inch EnusDocumento6 pagineMofh318 Inch EnusSelvedin GudicNessuna valutazione finora

- GD Qf450sb FeDocumento11 pagineGD Qf450sb FeCesar MoraNessuna valutazione finora

- Harga Jual Genset PerkinsDocumento3 pagineHarga Jual Genset PerkinsAgung SetiawanNessuna valutazione finora

- 0-9V 1A Transformer SpecificationDocumento4 pagine0-9V 1A Transformer SpecificationChristine Jam Pangan AlmogueraNessuna valutazione finora

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocumento8 pagineRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaNessuna valutazione finora

- Turbo Jet Manual English Current-1Documento21 pagineTurbo Jet Manual English Current-1irrygNessuna valutazione finora

- Hydrostatic TestDocumento22 pagineHydrostatic TestGuido Emanuel SteinbachNessuna valutazione finora

- Manual de Mantenimiento BS2640.180Documento28 pagineManual de Mantenimiento BS2640.180Roberto Daniel Sanchez MelgarejoNessuna valutazione finora

- Medaes Agss CatalogDocumento3 pagineMedaes Agss CatalogzampacaanasNessuna valutazione finora

- Epsilon 4 Stage E13D - E1AD - E1BB - E1EA O&MDocumento45 pagineEpsilon 4 Stage E13D - E1AD - E1BB - E1EA O&Mambrose entemangNessuna valutazione finora

- JCI Cataloge 2014Documento60 pagineJCI Cataloge 2014KAZIMALI25Nessuna valutazione finora

- Equipmentwise InstrumentsDocumento32 pagineEquipmentwise InstrumentsValipireddy NagarjunNessuna valutazione finora

- IEEE Database From Design of Reliable Industrial and Commercial Power SystemsDocumento33 pagineIEEE Database From Design of Reliable Industrial and Commercial Power SystemsLuis Eduardo VielmaNessuna valutazione finora

- Groenveld Twin Parts BookDocumento8 pagineGroenveld Twin Parts BookRobin KeenlysideNessuna valutazione finora

- Virgo Top Entry Valve BrochureDocumento8 pagineVirgo Top Entry Valve BrochureUday Gokhale0% (1)

- Grundfos - CR 64 3 2 A F A E HQQE PDFDocumento11 pagineGrundfos - CR 64 3 2 A F A E HQQE PDFNgô LinhNessuna valutazione finora

- Volvo Diesel Generator p150v Tad720geDocumento4 pagineVolvo Diesel Generator p150v Tad720geEvany Ziñho QNessuna valutazione finora

- Transmission Pressures - Test and Adjust: Cerrar SISDocumento6 pagineTransmission Pressures - Test and Adjust: Cerrar SISGiménez CristianNessuna valutazione finora

- CFW 701 Hvac Brochure enDocumento4 pagineCFW 701 Hvac Brochure enAG0525Nessuna valutazione finora

- New Burner RG 2Documento17 pagineNew Burner RG 2winkyaw333Nessuna valutazione finora

- TB Mag ManualDocumento60 pagineTB Mag Manualyanina25Nessuna valutazione finora

- SatrocatDocumento255 pagineSatrocatLiszy ViktóriaNessuna valutazione finora

- Ready and Easy To Be Installed: Single Phase Complete Solution With All Integrated ProtectionsDocumento2 pagineReady and Easy To Be Installed: Single Phase Complete Solution With All Integrated ProtectionsErnesto CasaretoNessuna valutazione finora

- Gear ActuactorsDocumento8 pagineGear Actuactorsmetasoniko2014Nessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- 2 TRIGON XXL 1 CHP 2 Buffers PHE 1 VT Heating Circuit and 1 DHW Calorifier 1Documento1 pagina2 TRIGON XXL 1 CHP 2 Buffers PHE 1 VT Heating Circuit and 1 DHW Calorifier 1adyro12Nessuna valutazione finora

- 1 X TRIGON L Plus Boiler LLH 1CT Heating Circuit 1 DHW Circuit With A CalorifierDocumento4 pagine1 X TRIGON L Plus Boiler LLH 1CT Heating Circuit 1 DHW Circuit With A Calorifieradyro12Nessuna valutazione finora

- 1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating CircuitsDocumento5 pagine1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating Circuitsadyro12Nessuna valutazione finora

- Delta Ia-Plc DVPPCC01 I Tse 20160503Documento2 pagineDelta Ia-Plc DVPPCC01 I Tse 20160503adyro12Nessuna valutazione finora

- Mon2 Mon2 Mon2 Mon2 Mon2: Izvorne Upute Za RadDocumento1 paginaMon2 Mon2 Mon2 Mon2 Mon2: Izvorne Upute Za Radadyro12Nessuna valutazione finora

- General guidance on a hydraulic scheme for a CHP systemDocumento1 paginaGeneral guidance on a hydraulic scheme for a CHP systemadyro12Nessuna valutazione finora

- Cuptor ElectricDocumento6 pagineCuptor Electricadyro12Nessuna valutazione finora

- Wgo Carlin Burner Manual 1Documento29 pagineWgo Carlin Burner Manual 1adyro12Nessuna valutazione finora

- (Ebook - PDF) Lost Books of The Bible - Gospel of Thomas, Scholars' Translation PDFDocumento13 pagine(Ebook - PDF) Lost Books of The Bible - Gospel of Thomas, Scholars' Translation PDFadyro12Nessuna valutazione finora

- SIOV Leaded StandarD-1317152Documento48 pagineSIOV Leaded StandarD-1317152adyro12Nessuna valutazione finora

- Navicat enDocumento195 pagineNavicat enadyro12Nessuna valutazione finora

- Aragaz Nelu Parts1Documento10 pagineAragaz Nelu Parts1adyro12Nessuna valutazione finora

- Servomotoare HoneywellDocumento2 pagineServomotoare Honeywelladyro12Nessuna valutazione finora

- Aragaz Nelu - Parts1 PDFDocumento22 pagineAragaz Nelu - Parts1 PDFadyro12Nessuna valutazione finora

- Alev SensörüDocumento10 pagineAlev Sensörüadana123Nessuna valutazione finora

- Vgu VG3Documento3 pagineVgu VG3adyro12Nessuna valutazione finora

- 6th Gen Intel Core-Intel Xeon FactsheetDocumento13 pagine6th Gen Intel Core-Intel Xeon FactsheetTracy WilliamsNessuna valutazione finora

- RCDocumento7 pagineRCadyro12Nessuna valutazione finora

- Dsa842000 181Documento1 paginaDsa842000 181adyro12Nessuna valutazione finora

- OILTECH PISTON ACCUMULATORS 250 BAR SELECTION GUIDEDocumento2 pagineOILTECH PISTON ACCUMULATORS 250 BAR SELECTION GUIDEadyro12Nessuna valutazione finora

- ME ProgramDocumento21 pagineME Programadyro12Nessuna valutazione finora

- File 1358196026Documento18 pagineFile 1358196026adyro12Nessuna valutazione finora

- File 1358194781Documento1 paginaFile 1358194781adyro12Nessuna valutazione finora

- A.B Steam HeaterDocumento2 pagineA.B Steam Heateradyro12Nessuna valutazione finora

- EsabwDocumento114 pagineEsabwadyro12Nessuna valutazione finora

- Olaer VguDocumento2 pagineOlaer Vguadyro12Nessuna valutazione finora

- Experiment No. 1-To Study Cochran and Babcock and Wilcox BoilersDocumento8 pagineExperiment No. 1-To Study Cochran and Babcock and Wilcox BoilersShahedNessuna valutazione finora

- Stick Hydraulic SystemDocumento9 pagineStick Hydraulic SystemWaridi RidiNessuna valutazione finora

- American Electrical HeycoAgro Cross ReferenceDocumento2 pagineAmerican Electrical HeycoAgro Cross ReferenceSreegith ChelattNessuna valutazione finora

- Flange IdentifierDocumento2 pagineFlange IdentifierBabi Lakhdari100% (1)

- Pipe Schedule DimensionsDocumento50 paginePipe Schedule DimensionsTIPAZONessuna valutazione finora

- Angeles - Momentum TransferDocumento16 pagineAngeles - Momentum TransferJaden BrownNessuna valutazione finora

- Flange Data Chart: Mactech Portable Machining SolutionsDocumento2 pagineFlange Data Chart: Mactech Portable Machining SolutionsOktayKulNessuna valutazione finora

- W023 - R01 Water TanksDocumento21 pagineW023 - R01 Water TanksZaw Moe AungNessuna valutazione finora

- Steam Trap Data SheetDocumento10 pagineSteam Trap Data SheetfkhajehNessuna valutazione finora

- Fundamentals of Fluid PressureDocumento11 pagineFundamentals of Fluid PressureMarvin BermidoNessuna valutazione finora

- PipeXtra Size ChartsDocumento6 paginePipeXtra Size ChartsKuldeep28883Nessuna valutazione finora

- 60ws e LGL DR XX 8090 Rev 1Documento1 pagina60ws e LGL DR XX 8090 Rev 1Mihai Aurel IoanaNessuna valutazione finora

- Group 2 Main Control Valve: 1. StructureDocumento26 pagineGroup 2 Main Control Valve: 1. StructurePower MobileNessuna valutazione finora

- SAIC-S-4002 Rev 7Documento6 pagineSAIC-S-4002 Rev 7Muhammad TariqNessuna valutazione finora

- Programmable Macro Language (Basic) FunDocumento46 pagineProgrammable Macro Language (Basic) FunVinit DhandeNessuna valutazione finora

- m1011 Jamban Cubluk Berventilasi Dan Leher AngsaDocumento14 paginem1011 Jamban Cubluk Berventilasi Dan Leher AngsaNafisa MeisaNessuna valutazione finora

- ASK PP18 1BZ0-Oct2023 (A)Documento32 pagineASK PP18 1BZ0-Oct2023 (A)Vijayagan ChinnappanNessuna valutazione finora

- Phase 1 Pre-Pour Inspection ReportDocumento8 paginePhase 1 Pre-Pour Inspection Reportdefe123Nessuna valutazione finora

- Alamos: Conduct of Engineering Formal Clarification or Interpretation RequestDocumento6 pagineAlamos: Conduct of Engineering Formal Clarification or Interpretation RequestmohdfirdausNessuna valutazione finora

- Item 1 - GA10010207 PN 400819Documento1 paginaItem 1 - GA10010207 PN 400819Pablo GarcíaNessuna valutazione finora