Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mixing Time Jet Mixer

Caricato da

LTE002Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mixing Time Jet Mixer

Caricato da

LTE002Copyright:

Formati disponibili

VOL. 2, NO.

5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

MIXING TIME ESTIMATION AND ANALYSIS IN A JET MIXER

P. Kalaichelvi1, Y. Swarnalatha1 and T. Raja1

Department of Chemical Engineering, National Institute of Technology, Trichirapalli, Tamil Nadu, India

E-mail: kalai@nitt.edu

ABSTRACT

Mixing of reactants, catalysts, etc. in a chemical reactor may be achieved using jets which offer the advantage of

having no moving parts inside the reactor. While there have been many experimental studies and thumb rules for the

design of jets, the details of mixing process is not properly understood. An experiment was carried out to study the effects

of various parameters such as nozzle diameter, angle of inclination, jet position and jet velocity on mixing time. Results

show that, for a given geometric arrangement, the angle of the jet injection is significantly more important in determining

the time required for 95% mixing than the length of the jet. The optimum angle was found to be an injection angle of 30

for jet located either at two-third of the volume of the tank or top and bottom of the tank, which gave the shortest mixing

time. The optimum angle is not universal and varies with the location of the jet inlet. An increase in the nozzle diameter

was found to reduce the mixing time at a given level of power consumption and in turn the energy efficiency can be

improved.

Keywords: jet mixer; mixing time; jet velocity.

INTRODUCTION

Mixing is an important unit operation in many

chemical engineering applications. Mixing is usually

carried out in order to produce a uniform mixture and it

can be achieved using mechanical mixers, fluid jet mixers,

static mixer or pipelines with tees. It can be used for a

variety of purposes. e.g, homogenization of physical

properties and composition prevention of stratification (or)

deposition of suspended particles, for and improved rates

of heat, mass transfer and chemical reactions1. Examples

of mixing operations include dissolution, leaching, gas

absorption, crystallization and liquid-liquid extraction.

Depending on the specific application and process mixing

may be done in batch wise (or) in continuous mode and

the content may be stirred either by rotating turbines and

propellers (or) by jets of liquid. Jet mixers are one of the

simplest devices to achieve mixing. In fact, side entry

mixers (or) jet mixers are commonly used to achieve

mixing in storage tank. In jet mixing, a part of the liquid in

the tank is drawn through a pump and returned as a highvelocity jet through a nozzle into the tank. This jet entrains

some of the surrounding liquid and creates a circulation

pattern within the vessel thus leading to mixing of the

content. In jet mixers, a fast moving jet stream of liquid is

injected into a slow moving (or) stationary bulk liquid.

The relative velocity between the jet and the bulk liquid

creates a turbulent mixing layer at the jet flow, entraining

and mixing the jet liquid with the bulk liquid. Based on

this concept, it has been assumed that longer jet lengths

results in better mixing. The jet length, referred to as the

maximum distance a jet travels before it impinges on the

opposite wall. This means that for a jet injected at the

bottom of a tank, an injection along the diagonal of the

liquid mass inside the tank results in the longest jet.

Accordingly, for an aspect ratio (tank diameter/liquid

height) of 1, an angle of injection of 45 results in the

longest jet length. Jet mixers are easy to install; there is no

requirement for any structural reinforcement of the tank

and they are normally cheaper compared with

conventional mixing devices. In large storage tanks the

conventional top entry mixer may not be suitable. Usually,

small side entry mixers are used, but they require

mechanical seals and contain rotating equipment inside the

tank. In such situations, mixing induced by a jet of liquid

can be advantageous2. Jet mixers can be used for sludge

suspension processes where the particles are of fairly

small size. The issues that need to be addressed are: (i) the

effect of nozzle angle over a wide range. (ii) the effect of

nozzle diameter and (iii) the effect of nozzle position on

mixing time. From a process point of view the various

nozzle configurations need to be compared on the basis of

equal power input. The various factors that influence the

energy efficiency have to be studied. Systematic studies

of jet mixing are of fairly recent origin. The early work in

this area was done by Prosser (1949)3 and Fossett (1951)4

who reported performance figures of free jets for mixing

fluids in large circular tanks.

MATERIALS AND METHODS

Experimental setup

The experimental set up used in the present study

is shown schematically in Figure-1. It consists of a

metallic tank of diameter 28cm and height 45cm. The

liquid level in all the experiments was kept constant at

28cm from the bottom. The outlet of the tank was located

at 4cm from bottom. A centrifugal pump of 0.5hp was

used to recycle part of the liquid from the tank and return

it to the tank with a high velocity through a nozzle.

Nozzles of different diameters and angles were tested.

These are listed in Table-1.

The tank was provided with two positions at

which the conductivity probe could be located. Initial trials

were done to identify the locations, where minimum

mixing were possible and based on which the location of

the conductivity probes were decided. These positions are

shown in Figure-1. The conductivity probe was connected

to a conductivity meter. Tap water was used as the

35

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

working fluid and a small amount of sodium chloride

solution is added as the tracer pulse at the centre of the

vessel at the top liquid surface. The jet could be oriented at

various angles (15, 30, 45 and 60 degrees) to the

horizontal with the help of specially fabricated nozzles.

Mixing time was considered as the time required attaining

95% of the fully mixed concentration. Each mixing time

experiment was repeated at least three times (initial runs

were repeated more times) and average mixing times were

taken.

Figure-1. Experimental setup.

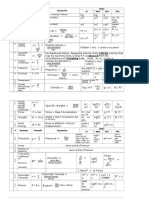

Table-1. Dimensional details of the nozzles.

Diameter

of nozzle

(mm)

Angle of nozzle

(Degrees)

15

30

45

60

10

15

30

45

60

15

15

30

45

60

RESULTS AND DISCUSSION

Experiments results on mixing time obtained for

various nozzle sizes (5 mm, 10 mm and 15 mm), nozzle

locations (top, 2/3rd and bottom positions) and nozzle

angles (15, 30, 45 and 60 degrees of inclination) have been

analyzed and discussed under different and suitable

heading.

Effect of nozzle position on mixing time

The jet was placed at three different position i.e.

at the top (28cm from the top), two-third (18.6 from the

top) and at the bottom (3cm from the bottom of the tank).

When the jet was placed at the top position, the flow field

formed was not good, hence it resulted in larger mixing

time. When the jet was placed at two- third position, the

flow field was good, but there were some irregularities in

the flow, which leads to improper mixing. Jet placed at the

bottom gave shortest mixing time compared to others. The

flow field formation was regular and uniform. Hence it

was found that when the jet placed at the bottom position

gave optimum mixing time for this geometry of the tank.

However this optimum position is not universal and varies

with the geometry of the tank.

Effect of nozzle angle on mixing time

The effect of nozzle angle was studied by

measuring the mixing time with the nozzles having angle

of 15, 30, 45and 60 by keeping the nozzles at all the

three locations (top, 2/3rd and bottom position) and this

was repeated for all three nozzle diameters (5mm, 10mm

36

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Nozzle at top position

50

40

30

20

30 DEG

10

0

60 DEG

45 DEG

15 DEG

30

30 DEG

20

45 DEG

10

60 DEG

0

0

10

12

JET VELOCITY(m/s)

(2.a) Effect of jet velocity on mixing time (5mm)

JET VELOCITY Vs MIXING TIME

50

40

30

20

10

0

40

15 DEG

30

30 DEG

20

45 DEG

10

60 DEG

15 DEG

30 DEG

45 DEG

60 DEG

10

MIXING TIME (sec)

15 DEG

15 DEG

30

20

30 DEG

45 DEG

10

0

60 DEG

10

10

15

JET VELOCITY (m/s)

45 DEG

60 DEG

12

40

30 DEG

10

JET VELOCITY Vs MIXING TIME

50

40

30

20

10

0

4

Nozzle at Bottom Position

JET VELOCITY Vs MIXING TIME

(2.f) Effect of jet velocity on mixing time (15mm)

12

(2.b) Effect of jet velocity on mixing time (10mm)

JET VELOCITY (m/s)

0

2

JET VELOCITY (m/s)

MIXING TIME (sec)

15

(2.e)Effect of jet velocity on mixing time (10mm)

50

(2.g) Effect of jet velocity on mixing time (5mm)

12

JET VELOCITY Vs MIXING TIME

(2.c)Effect of jet velocity on mixing time (15mm)

rd

Nozzle at 2/3 position

JET VELOCITY Vs MIXING TIME

MIXING TIME (sec)

JET VELOCITY ( m/s)

40

15 DEG

30

30 DEG

20

45 DEG

10

60 DEG

0

0

M IX IN G TIM E (sec)

10

JET VELOCITY (m/s)

JET VELOCITY Vs MIXING TIME

0

MIXING TIME ( sec )

40

15 DEG

MIXING TIME (sec)

MIXING TIME (sec)

JET VELOCITY Vs MIXING TIME

JET VELOCITY Vs MIXING TIME

MIXING TIME (sec)

and 15mm). Data was collected, analysed and compared

(Figure-2).

60

10

12

JET VELOCITY (m/s)

15 DEG

40

30 DEG

45 DEG

20

60 DEG

0

0

10

(2.h) Effect of jet velocity on mixing time (10mm)

Figure-2. Effect of jet velocity on mixing time using

different nozzle angles and positions.

12

JET VELOCITY (m/s)

(2.d) Effect of jet velocity on mixing time (5mm)

In all cases it was observed that mixing time for the nozzle

angle 300 were found to be minimum. At a nozzle angle of

450, the jet length is the longest, as it directly hits the

opposite corner of the tank before getting diverted by its

impact on the wall as shown in Figure-3. However the

mixing time is not very low as expected as the jet velocity

following impact seems to be very weak and the jet have

dispersed significantly especially after impacting

somewhere near the angle near opposite to the injection

point. When the angle of nozzle was lowered from 450,

more of the fluid volume comes within the upper more

agitated zone. The re-circulated jet is much stronger than

before. As a result, the mixing time is a strong function of

37

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

the volume fraction under strong agitation, goes on

decreasing progressively with the decrease in nozzle

angle, until an optimum is observed for an angle of 30.

The observation has been well explained with flow fields

produced at different configuration (Figure-3). When the

jet is further lowered below this nozzle angle say at 15,

the wall effects due to the base of the tank come into

effect, which reduces the effectiveness of the jet as a

mixer. For nozzle angle more than 45, that is 60 there is

a rollover of the jet after it hits the top of the tank. After

rollover, a liquid motion driven by the jet flow moves the

fluid along the tank wall and agitates the bulk fluid4.

Figure-3. Schematic representation of the flow field

produced by nozzles of different angles.

From the Figure-3, it is observed that when the nozzle

angle was horizontal, the jet was horizontal and mainly

confined to the bottom of the tank. The tracer pulse was

introduced at the top liquid surface was found to mix very

slowly with the liquid near the bottom and hence resulting

in poor mixing. When the nozzle angle was higher say 30

the jet was free from wall. It also had large path length; as

a result, it entrained the surrounding liquid to a large

extent, which resulted in better mixing (lower mixing

time). In addition, the tracer pulse was put at the top;

poorly mixed liquid at the tank bottom was circulated

through the pump and the nozzle and reached the top due

to the inclination of the nozzle. Thus, making the nozzle

inclined at 300 had a two-fold effect. It enables the jet to

spread and entrain more of the surrounding liquids. The

liquid from the poorly mixed bottom region was circulated

through the pump and the nozzle to the top. As the results

of both of these, the mixing time is better. These results

are in accordance with the general recommendation made

by Jayanthi (2001)5 that the jet should be oriented so that

its path length is largest and recycling of liquid should be

from the region, which is not well mixed. From the same

set of graphs shown in Figure-2, it is observed that

increase in jet velocity has decreased the mixing time in

all the cases, due to the higher turbulence created at higher

jet velocity.

Effect of nozzle diameter on mixing time

In order to analysis the effect of nozzle diameter

on mixing time, the same data set was plotted (Figure-4)

for the nozzles positioned at bottom and top positions

whereas the plots corresponding to the nozzles positioned

at other locations are also available elsewhere6. Analysis

the graphs (in Figure-4) drawn between jet velocity versus

mixing time for different nozzle diameters show that, for

any angle, an increase in the nozzle diameter leads to

reduction in the mixing time at the same level of power

consumption. For example, graph corresponding to 30

nozzle and 5mm of diameter, at the bottom position

(Figure-4), shows that the mixing time would be about 10

seconds, and the mixing time for 10mm nozzle would be

about 6 seconds. Thus, an increase in the nozzle diameter

leads to better mixing at the same level of power

consumption. When the diameter was increased, the flow

rate through the nozzle increases for the same level of

velocity. This would mean that for a given power, the

liquid is circulated faster through the bigger nozzle, which

leads to reduction in the mixing time.

But when 15mm diameter was used the mixing

time was found to be to more than 10mm and less that

5mm nozzle diameter. The reason for this is the flow field

was not uniform in 15mm diameter and the flow was

disturbed by the walls of the tank. The diameter of 10mm

was found to be optimum for this geometry of the tank and

this optimum diameter is not universal and varies with the

geometry of the tank.

When two nozzle of different diameter (d1 and d2)

are operated at velocities Uj1 and Uj2, respectively, in such

a way that the power input by both is the same, the ratio of

the velocity through the two nozzles would have to be in

the following manner:

Uj2/Uj1 = (d2/d1)2/3... (1)

As a result, the ratio of flow rates (Q = /4*d 2*Uj)4

through the nozzle having different diameter being

operated at equal power consumption would be:

Q2/Q1 = (d2/d1) .(2)

This equation indicates that, as the nozzle diameter

increases, the flow rate through the nozzle increases for

the same level of velocity. This would mean that for a

given power, the liquid is circulated faster through the

bigger nozzle, which leads to reduction in the mixing time.

The ratio of the momentum flux entering the tank (J = /

4dj 2 Uj 2) through the nozzles having different diameter

being operated at equal power consumption is:

J2/J1= (d2/d1)2/3. (3)

The above equation also shows that, as the nozzle

diameter increases, the momentum flux entering the tank

through the nozzle increases for the same level of power

consumption. An increase in the momentum flux implies

that the mixing is more vigorous with a large diameter

nozzle at the same level of power consumption4. The

increase in the momentum flux and the flow rate thus

explains the reduction in the mixing time with an increase

in the diameter. Thus larger diameter nozzle is more

energy efficient than the smaller diameter Nozzles as

hypothesized by Fox and Gex (1956)7.

38

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

Nozzle at top position

Nozzle at bottom position

JET VELOCITY Vs MIXING TIME

JET VELOCITY Vs MIXING TIME

50

40

30

20

10

0

5mm DIA

10mm DIA

15mm DIA

10

40

30

20

10

0

M IX IN G T IM E

(se c )

M IX IN G T IM E (s e c )

www.arpnjournals.com

5mm DIA

10mm DIA

15mm DIA

12

JET VELOCITY (m/s)

10

15

JET VELOCITY (m/s)

(4.e) Effect of jet velocity on mixing time (15 deg)

JET VELOCITY Vs MIXING TIME

JET VELOCITY Vs MIXING TIME

M IX IN G T IM E ( s e c )

50

40

5mm DIA

30

10mm DIA

20

15mm DIA

10

0

0

10

M IX IN G T IM E (se c )

(4.a) Effect of jet velocity on mixing time (15deg)

40

30

20

10

0

5mm DIA

10mm DIA

15mm DIA

12

10

15

JET VELOCITY (m/s)

JET VELOCITY (m/s)

(4.f) Effect of jet velocity on mixing time (30 deg)

JET VELOCITY Vs MIXING TIME

JET VELOCITY Vs MIXING TIME

M IX IN G T IM E (s e c )

50

M IX IN G T IM E

(se c )

(4.b)Effect of jet velocity on mixing time (30deg)

40

40

5mm DIA

30

10mm DIA

20

15mm DIA

10

5mm DIA

20

10mm DIA

15mm DIA

0

0

0

0

10

12

10

15

JET VELOCITY (m/s)

JET VELOCITY (m/s)

(4.g) Effect of jet velocity on mixing time (45 deg)

JET VELOCITY Vs MIXING TIME

JET VELOCITY Vs MIXING TIME

M I X I N G T I M E ( se c )

50

40

5mm DIA

30

10mm DIA

20

15mm DIA

10

0

0

10

12

JET VELOCITY (m/s)

(4.d)Effect of jet velocity on mixing time (60 deg)

M IX IN G T IM E

(se c )

(4.c)Effect of jet velocity on mixing time (45deg)

40

30

20

10

0

5mm DIA

10mm DIA

15mm DIA

10

15

JET VELOCITY (m/s)

(4.h) Effect of jet velocity on mixing time (60 deg)

Figure-4. Effect of nozzle diameter on mixing time.

Effect of power on mixing time

This section deals with energy efficiency of jet

mixer. Previous researchers4 have shown that the jet

mixers are less energy efficient as compared with the top

entry agitators, but are economically attractive (lower

capital cost as compared with top entry mixers). Grenville

and Tilton (1966)8 investigated the mixing process by

giving a pulse of tracer (electrolyte) through the jet nozzle

and by monitoring the conductivity at three locations

within the tank. They have proposed that the mixing

process was controlled by the turbulent kinetic energy

dissipation rate in the region far away from the jet

entrance. They have taken the energy dissipation rates in

the region far way from the nozzle to be proportional to jet

velocity and the jet diameter at the location.

The power consumed in mixing process (the power input

through the nozzle) was calculated using the kinetic

energy of the jet as follows:

Pj= (/8)*(*dj2*Uj 3) . (4)

Various correlations available in literature (Fossett and

Prosser, 19493; Okita and Oyama, 19639; Grenville and

Tilton, 19968, 199710) used to predict the mixing time,

show that the mixing time is inversely proportional to the

39

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

jet velocity and the nozzle diameter. The correlation

reported by Grenville and Tilton (19968, 199710) are valid

over a very wide range of the tank diameters and therefore

can be considered to be dependable for scale-up. Thus, the

mixing time can be considered to be inversely proportional

to the product of jet velocity and diameter. That is,

Tm (1/ Uj*dj) or in other words:

(Tm2/Tm1) = (Uj1*dj1)/ (Uj2*dj2).... (5)

At equal power, the jet velocity and diameter are related

through equation (1). Substituting for Uj2 /Uj1 from

equation (1) in equation (5) gives

Tm2/Tm1 = (dj1/dj2) 1/3 or in other words:

Tm *dj1/3 = constant..... (6)

The above equation also shows that the product

of mixing time and nozzle diameter raised to the power

1/3 would be constant (and independent of the diameter)

for a given level of power consumption8. To test this

hypothesis, the data for different nozzle diameter were replotted (figures available elsewhere6). From the figure it

can be seen that, for a particular nozzle angle, the data for

various nozzle diameters (from 5 to 10mm 3 folds

variation) fall along a single straight line. Thus for a given

level of power consumption, an increase in the nozzle

diameter would reduce the mixing time. This result is very

important for scale-up or for retrofitting jet mixers to

improve the mixing efficiency.

Optimum conditions for tank geometry

The optimum angle was also confirmed by

plotting graphs between the angle and power with constant

mixing time. The mixing time was taken as 20, 25 and 30

seconds. From all the graphs (Figure-5 a-h), it was

observed that an angle of 30 was optimum, irrespective of

position of nozzle and nozzle diameter. The power

consumption was less for 30 degree nozzle with 5mm

diameter. The bottom position again gave a better result.

The power consumption was found to be shortest

for a mixing time of 30 seconds in all the cases. From the

Figure-5g, the power consumption for 10mm diameter at

bottom position for 30 degree nozzle angle for 20 second

of mixing time is 10 watts, while for 25 seconds it is 6.2

watts and for 30 seconds it is 2 watts, whereas from the

Figure-5b, the power consumption for 10mm diameter at

top position for 30 degree nozzle angle for 20 second of

mixing time is 18 watts, while for 25 seconds it is 7 watts

and for 30 seconds it is 4 watts. The optimum angle for

this geometry with minimum power consumption was

found to be 30 degrees. The optimum diameter for less

power consumption is 5mm, but 10mm diameter gives

shortest mixing time compared to 5mm. This optimum

diameter, angle and position are not universal and vary

with the geometry of the tank.

Optimum geometry ratio

The optimum nozzle position, angle and diameter

with respective to the geometry of the tank used in the

study was determined by plotting the ratio of diameter of

nozzle to the diameter of the tank with the mixing time for

all position and angle with constant diameter and these

graphs are shown in Figure-6. It was found form the

graphical analysis that the optimum angle was 30 degrees

at bottom position for all diameters of the nozzle as

visualized and detailed in earlier sections. The optimum

diameter with respective to the geometry and mixing time

was 10mm.

40

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Nozzle at top position

ANGLE Vs POWER

ANGLE Vs POWER

P O W E R (W atts)

10

8

POWER (FOR 20 SEC)

POWER (FOR 25 SEC)

POWER(FOR 30SEC)

P O W E R ( W atts)

12

0

0

10

20

30

40

50

60

35

30

25

20

15

10

5

0

POWER (FOR 20 SEC)

POWER (FOR 25 SEC)

POWER(FOR 30SEC)

70

10

20

30

40

50

60

70

ANGLE (DEG)

ANGLE (DEG)

(5.e) Effect of nozzle angle on power requirement

(for 10mm)

Nozzle at bottom position

ANGLE Vs POWER

ANGLE Vs POWER

P O W E R (W atts)

40

30

POWER (FOR 20 SEC)

20

POWER (FOR 25 SEC)

POWER(FOR 30SEC)

10

PO W ER (W atts)

(5.a) Effect of nozzle angle on power requirement

(for 5mm)

15

POWER (FOR 20 SEC)

10

POWER (FOR 25 SEC)

POWER(FOR 30SEC)

0

0

10 20 30 40 50 60 70

0

0

10

20

30

40

50

60

ANGLE (DEG)

70

ANGLE (DEG)

(5.b) Effect of nozzle angle on power requirement

(for 10mm)

(5.f) Effect of nozzle angle on power requirement

(for 5mm)

100

80

60

40

20

0

ANGLE Vs POWER

POWER (FOR 20 SEC)

POWER (FOR 25 SEC)

POWER(FOR 30SEC)

PO W ER(W atts)

P O W E R (W atts)

ANGLE Vs POWER

30

POWER (FOR 20 SEC)

20

POWER (FOR 25 SEC)

10

POWER(FOR 30SEC)

0

0

10 20 30 40 50 60 70

10

20

(5.c) Effect of nozzle angle on power requirement

(for 15mm)

Nozzle at 2/3rd position

POWER (FOR 20 SEC)

POWER (FOR 25 SEC)

POWER(FOR 30SEC)

0

0 10 20 30 40 50 60 70

ANGLE (DEG)

(5.d) Effect of nozzle angle on power requirement

(for 5mm)

P O W E R (W a tts)

P O W E R (W a tts)

50

60

70

ANGLE Vs POWER

15

40

(5.g) Effect of nozzle angle on power requirement

(for 10mm)

ANGLE Vs POWER

10

30

ANGLE (DEG)

ANGLE (DEG)

80

60

POWER (FOR 20 SEC)

40

POWER (FOR 25 SEC)

20

POWER(FOR 30SEC)

0

0

20

40

60

80

ANGLE (DEG)

(5.h) Effect of nozzle angle on power requirement

(for 15mm)

Figure-5. Effect of nozzle angle on power required for mixing nozzle at top position.

41

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Nd/Nt Vs MIXING TIME

MIXINGTIME (sec)

60

50

15 Deg of B

30 deg of B

40

45 deg of B

30

60 deg of B

20

3o deg of T

15mm deg of T

45deg of T

10

60 deg of T

15 deg of 2/3rd

45 deg of 2/3rd

0.1

0.125

0.15

0.175

0.2

0.225

0.25

60 deg of 2/3rd

Nd/Nt (NO UNITS)

(6.a) Nd/Nt Vs Mixing time (for 5mm diameter)

MIXING TIME (sec)

Nd/Nt Vs MIXING TIME

45

40

35

30

25

20

15

10

5

0

15 Deg of B

30 deg of B

45 deg of b

60 deg of B

15mm deg of T

3o deg of T

45deg of T

60 deg of T

15 deg of 2/3rd

30 deg of 2/3rd

0.2

0.25

0.3

0.35

0.4

0.45

45 deg of 2/3rd

60 deg of 2/3rd

Nd/Nt ( NO UNITS)

(6.b) Nd/Nt Vs Mixing time (for10mm diameter)

Nd/Nt Vs MIXING TIME

MIXING TIME (sec)

50

15 Deg of B

40

30 deg of B

30

60 deg of B

20

45deg of T

15mm deg of T

60 deg of T

10

15 deg of 2/3rd

30 deg of 2/3rd

45 deg of 2/3rd

0.4

0.45

0.5

0.55

0.6

0.65

0.7

60 deg of 2/3rd

Nd/Nt ( no units)

(6.c) Nd/Nt Vs Mixing time (for 15mm diameter)

Figure-6. Optimum nozzle position and configuration for the tank geometry.

CONCLUSIONS

Experiments were conducted by varying

parameters like jet diameter, jet position and jet inclination

to find their effects on mixing time. The optimum angle is

found to be an injection angle of 30 for jet located either

at two-third of the volume of the tank or top and bottom of

the tank, which gives the shortest mixing time. This

optimum angle is not universal and varies with the

location of the jet inlet. In this study, an increase in the

nozzle diameter was found to reduce the mixing time at a

given level of power consumption and in turn the energy

efficiency can be improved. It was found that a diameter

of l0 mm gives a shortest mixing time, but diameter of

5mm has a less power consumption compared to 10mm

diameter, so the optimum diameter could be between 5 to

10mm for this geometry. In the present work, it was found

that jet introduced from a 10mm nozzle at the bottom of

the tank at an angle of inclination of 300 gave an optimum

mixing time for the preferred geometry.

42

VOL. 2, NO. 5, OCTOBER 2007

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2007 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

NOMENCLATURE

dj

H

Pj

T

Uj

Diameter of the jet/nozzle, m

Liquid height, m

J

Momentum of jet, Kg m /s 2

Nd

Diamter of the Nozzle, m

Diamter of the tank, m

Nd

Power (input through nozzle), Watts

Qj

Liquid jet flow rate, m3/s

t

Time, s

Diameter of tank, m

Mixing time, s

Tm

Velocity of jet, m/s

[3] Fossett H. and Prosser L.E. 1949. Journal of

Institute of Mechanical Engineers. Vol. 160, p. 224.

[4] Fossett, H. 1951. Trans. Instn. Chem. Engrs. Vol.

29, p. 164.

[5] Jayanthi. 2001. Chemical Engineering Science. Vol.

56, p. 193.

[6] Swarnalatha Y. 2005. Studies on jet mixing. M.

Tech. Thesis. National Institute of Technology,

Thiruchirappalli.

GREEK SYMBOLS

[7] Fox E. A. and Gex V. E. 1956. AIChE journal. Vol.

2, p. 539.

Density of the fluid, kg/m3

Jet angle in degrees.

Pi

[8] Grenville R. K. and Tilton J. N. 1996. Transactions

of the Institution of Chemical Engineers. Vol. 74A,

p. 390.

REFERENCES

[1] Patwardhan A. W. 2002. Chemical Engineering

Science. Vol. 57, p. 1307.

[2] Zughbi H. D. and Rakib M. A. 2004. Chemical

Engineering Science. Vol. 59, p. 829.

[9] Okita N. and Oyama Y. 1963. Japanese Journal of

Chemical Engineers. 31(9): 101.

[10] Grenville R. K. and Tilton J. N. 1997. Proceedings

of the 9th European conference on mixing. p. 67.

43

Potrebbero piacerti anche

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- Calculation For Jet MixerDocumento3 pagineCalculation For Jet MixerrohitkushNessuna valutazione finora

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesDa EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNessuna valutazione finora

- Schulkes - Slug Frequencies Revisited PDFDocumento15 pagineSchulkes - Slug Frequencies Revisited PDFneverwolfNessuna valutazione finora

- The Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemDa EverandThe Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemNessuna valutazione finora

- Joukowsky EquationDocumento1 paginaJoukowsky Equationvijay_jvNessuna valutazione finora

- Prediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent CorrelationDocumento18 paginePrediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent Correlationcamilo_ortiz_6Nessuna valutazione finora

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- Steam-Water Two-Phase Flow in Large Diameter Vertical PipingDocumento11 pagineSteam-Water Two-Phase Flow in Large Diameter Vertical Pipingfujiman35Nessuna valutazione finora

- Jet Mixing CalculationDocumento3 pagineJet Mixing CalculationRachel FloresNessuna valutazione finora

- NU - Lecture 12 (WATER HAMMER)Documento1 paginaNU - Lecture 12 (WATER HAMMER)Mr. Mark B.100% (1)

- Impeller Design For Mixing of SuspensionsDocumento16 pagineImpeller Design For Mixing of SuspensionsFaycel OuerdienNessuna valutazione finora

- Two Phase Flow Modeling - PE 571: Chapter 3: Slug Flow Modeling Dukler and Hubbard - Horizontal PipesDocumento29 pagineTwo Phase Flow Modeling - PE 571: Chapter 3: Slug Flow Modeling Dukler and Hubbard - Horizontal PipesAnonymous QSfDsVxjZNessuna valutazione finora

- 1Documento7 pagine1sri9987Nessuna valutazione finora

- Fluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of PumpsDocumento17 pagineFluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of Pumps12Nessuna valutazione finora

- Tank EductorDocumento3 pagineTank Eductorkonainglincho001Nessuna valutazione finora

- Water Hammer ArticleDocumento14 pagineWater Hammer ArticleayoungaNessuna valutazione finora

- 06+shell+and+tube+hx SDocumento65 pagine06+shell+and+tube+hx SMuhammad HaidiNessuna valutazione finora

- NU - Lecture 12 (WATER HAMMER) PDFDocumento1 paginaNU - Lecture 12 (WATER HAMMER) PDFMr. Mark B.Nessuna valutazione finora

- Lab 4-Friction Losses and Minor LossesDocumento7 pagineLab 4-Friction Losses and Minor LossesJJ Sean CruzNessuna valutazione finora

- Water Hammer: Values For CalculationDocumento3 pagineWater Hammer: Values For CalculationEng-CalculationsNessuna valutazione finora

- Me 2204 Fluid Mechanics and Machinery LiDocumento8 pagineMe 2204 Fluid Mechanics and Machinery LiSheryll de GuzmanNessuna valutazione finora

- Two Phase FlowDocumento4 pagineTwo Phase FlowsindalvaleriNessuna valutazione finora

- Mixing Nozzles For Brewery TanksDocumento8 pagineMixing Nozzles For Brewery TanksVikk SuriyaNessuna valutazione finora

- Support Arrangement Natural FrequencyDocumento3 pagineSupport Arrangement Natural FrequencyrajeevfaNessuna valutazione finora

- Specific Heat Capacity, Thermal Conductivity and Thermal Diffusivity of Ammonium Nitrate in The Temperature Interval 293 - 433 K20Documento4 pagineSpecific Heat Capacity, Thermal Conductivity and Thermal Diffusivity of Ammonium Nitrate in The Temperature Interval 293 - 433 K20sj_scribdNessuna valutazione finora

- Lid Driven CavityDocumento24 pagineLid Driven CavityShashank MishraNessuna valutazione finora

- Water Hammer in Pumped Sewer MainsDocumento45 pagineWater Hammer in Pumped Sewer MainsManikandanNessuna valutazione finora

- Reverse WaterhammerDocumento10 pagineReverse WaterhammerjygomezNessuna valutazione finora

- Modeling Spring Cans With FrictionDocumento1 paginaModeling Spring Cans With FrictionKirana SbNessuna valutazione finora

- Brill Beggs ZDocumento3 pagineBrill Beggs ZtechbhaskarNessuna valutazione finora

- Pressure Drop in PipelineDocumento13 paginePressure Drop in PipelineNilambar BarihaNessuna valutazione finora

- 2013 Lect6 FORCES ON PIPE BENDSDocumento39 pagine2013 Lect6 FORCES ON PIPE BENDSBagus PrakasaNessuna valutazione finora

- A Fundamental Equation For The Calculation of The Thermodynamic Properties of EthanolDocumento17 pagineA Fundamental Equation For The Calculation of The Thermodynamic Properties of EthanolVlaicu AlexNessuna valutazione finora

- Finned Tube Heat ExchangerDocumento3 pagineFinned Tube Heat ExchangerShreya Sahajpal KaushalNessuna valutazione finora

- Packed Bed AbsorptionDocumento4 paginePacked Bed AbsorptionSenthilNathanNessuna valutazione finora

- Chen 3009 - Tutorial 2-2021 RevisedDocumento43 pagineChen 3009 - Tutorial 2-2021 RevisedRosario QFNessuna valutazione finora

- Orifice CalculationDocumento3 pagineOrifice Calculationchandramohan muruganNessuna valutazione finora

- LAB14 MARCET BOILER (Abstract, Intro, Aim, Theory)Documento3 pagineLAB14 MARCET BOILER (Abstract, Intro, Aim, Theory)Nurwani HussinNessuna valutazione finora

- PSV Reaction Force CalculationDocumento2 paginePSV Reaction Force CalculationSuthanNessuna valutazione finora

- AgitatorDocumento2 pagineAgitatorThiruvilan Arakkonam Mohan100% (1)

- Inputs Required For FIV & AIV StudyDocumento1 paginaInputs Required For FIV & AIV StudyRonak MotaNessuna valutazione finora

- Tank DesignDocumento2 pagineTank DesignkamleshyadavmoneyNessuna valutazione finora

- Liquid Jet Mixers: Circulate LiquidsDocumento2 pagineLiquid Jet Mixers: Circulate LiquidsaravindNessuna valutazione finora

- CHE 503 Power Consumption in AgitatorDocumento16 pagineCHE 503 Power Consumption in AgitatorNurtasha AtikahNessuna valutazione finora

- Performance Thermo CompressorsDocumento8 paginePerformance Thermo CompressorsclintoncNessuna valutazione finora

- Design of AgitatorDocumento3 pagineDesign of AgitatorManish PatelNessuna valutazione finora

- Water HammerDocumento1 paginaWater HammerrosinniNessuna valutazione finora

- Fluid Mech - Chap 8Documento57 pagineFluid Mech - Chap 8hananNessuna valutazione finora

- FRP Flange DesignDocumento29 pagineFRP Flange DesignSubhadip RoyNessuna valutazione finora

- 6.1 Agitation Power Number and Scale Up 2020Documento26 pagine6.1 Agitation Power Number and Scale Up 2020Neybil100% (1)

- Two-Phase Flow Gas-Liquid Gas-Solid Liquid-Liquid Liquid-SolidDocumento9 pagineTwo-Phase Flow Gas-Liquid Gas-Solid Liquid-Liquid Liquid-SolidKarina MandasariNessuna valutazione finora

- Agitated Vessel Report - ASDocumento9 pagineAgitated Vessel Report - ASAbhijeet SinghNessuna valutazione finora

- Design of AgitatorDocumento3 pagineDesign of Agitatorkaps12Nessuna valutazione finora

- Shell and Tube Heat Exchanger Design Using CFD ToolsDocumento4 pagineShell and Tube Heat Exchanger Design Using CFD ToolsChockalingam AthilingamNessuna valutazione finora

- Closed Conduit Flow ExptDocumento99 pagineClosed Conduit Flow ExptStephanie Anne FortinNessuna valutazione finora

- Ijest NG Vol.1 No.1 pp.245 253Documento9 pagineIjest NG Vol.1 No.1 pp.245 253prabhjot singh1Nessuna valutazione finora

- MultiphaseflowDocumento15 pagineMultiphaseflowAndres VallebellaNessuna valutazione finora

- 海洋钻井平台散料处理系统固相输运的预测模型 PDFDocumento15 pagine海洋钻井平台散料处理系统固相输运的预测模型 PDFbruce lianNessuna valutazione finora

- Soil WashingDocumento19 pagineSoil WashingLTE002Nessuna valutazione finora

- ZH - 2005 RCDocumento99 pagineZH - 2005 RCLTE002Nessuna valutazione finora

- High PerformanceDocumento3 pagineHigh PerformanceLTE002Nessuna valutazione finora

- Cal Methodology - Energy Saving - Electrical - HouseholdDocumento15 pagineCal Methodology - Energy Saving - Electrical - HouseholdLTE002Nessuna valutazione finora

- Biomass To Ethanol ProcessDocumento132 pagineBiomass To Ethanol ProcessLTE002Nessuna valutazione finora

- Simulation of High-Speed FillingDocumento13 pagineSimulation of High-Speed FillingLTE002Nessuna valutazione finora

- Trigger Sprayer Dynamic Systems ModelDocumento5 pagineTrigger Sprayer Dynamic Systems ModelLTE002Nessuna valutazione finora

- Paper - 84 Magnetic FormingDocumento8 paginePaper - 84 Magnetic FormingLTE002Nessuna valutazione finora

- 49 Structure Porosity of Flocculated ADDocumento8 pagine49 Structure Porosity of Flocculated ADLTE002Nessuna valutazione finora

- Paper - 5 Noise MinimizationDocumento5 paginePaper - 5 Noise MinimizationLTE002Nessuna valutazione finora

- Descriptive Essay MeaningDocumento13 pagineDescriptive Essay MeaningMeatan Labocse100% (1)

- Act 151Documento1 paginaAct 151api-361980058Nessuna valutazione finora

- The Urantia Book (Public Domain)Documento1.806 pagineThe Urantia Book (Public Domain)Lenny100% (13)

- RPH Midterm ExamDocumento6 pagineRPH Midterm ExamNicole LaderasNessuna valutazione finora

- In The Midst of HardshipDocumento14 pagineIn The Midst of HardshipJules GajesNessuna valutazione finora

- Backgrounder 4 (Ahmad & Tank 2021) - Sharia Law and Women's RightsDocumento6 pagineBackgrounder 4 (Ahmad & Tank 2021) - Sharia Law and Women's RightsaminNessuna valutazione finora

- The Kartilya Was About Lessons That Would Serve As A Guide For Me in Living A Moral and Ethical LifeDocumento1 paginaThe Kartilya Was About Lessons That Would Serve As A Guide For Me in Living A Moral and Ethical LifeCleo TrinidadNessuna valutazione finora

- Personal Development: Quarter 2 - Module 19: Becoming Responsible in Personal RelationshipsDocumento27 paginePersonal Development: Quarter 2 - Module 19: Becoming Responsible in Personal RelationshipsSamantha Beatriz B ChuaNessuna valutazione finora

- Topic One - Nature and Functions of LawDocumento7 pagineTopic One - Nature and Functions of LawAdetutu AnnieNessuna valutazione finora

- Prato 1999Documento3 paginePrato 1999Paola LoloNessuna valutazione finora

- The Impact of Culture On The Quality of Internal Audit An Empirical Study.Documento22 pagineThe Impact of Culture On The Quality of Internal Audit An Empirical Study.Vaisal AmirNessuna valutazione finora

- Epekto NG Paninigarilyo Sa Kabataan ThesisDocumento5 pagineEpekto NG Paninigarilyo Sa Kabataan ThesisWriteMyPaperCollegeWichitaFalls100% (1)

- Applying The Rossiter-Percy Grid To Online Advertising Planning - The Role of Product - Brand Type in Previsit IntentionsDocumento9 pagineApplying The Rossiter-Percy Grid To Online Advertising Planning - The Role of Product - Brand Type in Previsit Intentionsa861108Nessuna valutazione finora

- Application of Aging Theories To NursingDocumento3 pagineApplication of Aging Theories To NursingArvin LabradaNessuna valutazione finora

- EcoStruxure Power Advisor - TrainingDocumento12 pagineEcoStruxure Power Advisor - TrainingFred Javier Melendez GarcíaNessuna valutazione finora

- Special Power of AttorneyDocumento1 paginaSpecial Power of Attorneyraine121992Nessuna valutazione finora

- Nguyễn Thành Tín SPA-K42B Robinson Crusoe 1. Tell briefly of Enlightenment and Daniel Defoe. - The Age of EnlightenmentDocumento4 pagineNguyễn Thành Tín SPA-K42B Robinson Crusoe 1. Tell briefly of Enlightenment and Daniel Defoe. - The Age of EnlightenmentnguyenthanhtinNessuna valutazione finora

- 5 Minute Spotlight - Vacuum Extraction and Forceps DeliveryDocumento2 pagine5 Minute Spotlight - Vacuum Extraction and Forceps DeliveryMikeNessuna valutazione finora

- Artificial Intelligence: (Unit 2: Agents)Documento5 pagineArtificial Intelligence: (Unit 2: Agents)Lucky sahNessuna valutazione finora

- Forging A Field: The Golden Age of Iron Biology: ASH 50th Anniversary ReviewDocumento13 pagineForging A Field: The Golden Age of Iron Biology: ASH 50th Anniversary ReviewAlex DragutNessuna valutazione finora

- ACS ChartDocumento1 paginaACS ChartJoey TingNessuna valutazione finora

- Project Rahul (Internal Resistance)Documento13 pagineProject Rahul (Internal Resistance)Ricky Kumar72% (18)

- Full Download Introduction To Operations and Supply Chain Management 3rd Edition Bozarth Test BankDocumento36 pagineFull Download Introduction To Operations and Supply Chain Management 3rd Edition Bozarth Test Bankcoraleementgen1858100% (42)

- Joan of Arc Inspiring Example Barbara BeckwithDocumento4 pagineJoan of Arc Inspiring Example Barbara BeckwithraikibaNessuna valutazione finora

- Creative Writing Rubric - Vocaroo RecordingDocumento2 pagineCreative Writing Rubric - Vocaroo RecordingSherwin MacalintalNessuna valutazione finora

- 323 1251 090Documento40 pagine323 1251 090primaryrateNessuna valutazione finora

- Chapter 8 Accounts Receivable and Further Record-Keeping: Discussion QuestionsDocumento3 pagineChapter 8 Accounts Receivable and Further Record-Keeping: Discussion Questionskiet100% (1)

- Moy Ya Lim Yao vs. Commissioner of ImmigrationG.R. No. L-21289 SCRA 292 DigestDocumento2 pagineMoy Ya Lim Yao vs. Commissioner of ImmigrationG.R. No. L-21289 SCRA 292 DigestKhen Tamdang100% (1)

- In Search of The Temples of YHWH of SamaDocumento20 pagineIn Search of The Temples of YHWH of Samalgrozea2451Nessuna valutazione finora

- Example: 3: 6314 Square and Cube Numbers Page 1Documento4 pagineExample: 3: 6314 Square and Cube Numbers Page 1Anonymous OlT7WTNessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningDa EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningValutazione: 5 su 5 stelle5/5 (4)

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDa EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNessuna valutazione finora

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Solar Energy: Survive Easily on Solar Power Off the GridDa EverandSolar Energy: Survive Easily on Solar Power Off the GridNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Formulas and Calculations for Drilling OperationsDa EverandFormulas and Calculations for Drilling OperationsNessuna valutazione finora

- Electric Motor Control: DC, AC, and BLDC MotorsDa EverandElectric Motor Control: DC, AC, and BLDC MotorsValutazione: 4.5 su 5 stelle4.5/5 (19)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Renewable Energy Finance: Theory and PracticeDa EverandRenewable Energy Finance: Theory and PracticeValutazione: 4 su 5 stelle4/5 (1)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDa EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNessuna valutazione finora

- Natural Gas Processing: Technology and Engineering DesignDa EverandNatural Gas Processing: Technology and Engineering DesignValutazione: 5 su 5 stelle5/5 (8)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureDa EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureValutazione: 3.5 su 5 stelle3.5/5 (48)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Oil companies and the energy transitionDa EverandOil companies and the energy transitionNessuna valutazione finora

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Handbook of Offshore Oil and Gas OperationsDa EverandHandbook of Offshore Oil and Gas OperationsValutazione: 4.5 su 5 stelle4.5/5 (4)

- Oil: An Overview of the Petroleum IndustryDa EverandOil: An Overview of the Petroleum IndustryValutazione: 4.5 su 5 stelle4.5/5 (3)

- Green Hydrogen Supply: A Guide to Policy MakingDa EverandGreen Hydrogen Supply: A Guide to Policy MakingValutazione: 5 su 5 stelle5/5 (1)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- The Homeowner's DIY Guide to Electrical WiringDa EverandThe Homeowner's DIY Guide to Electrical WiringValutazione: 5 su 5 stelle5/5 (2)