Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Data on Ecosan Composting Toilets

Caricato da

EddiemtongaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Data on Ecosan Composting Toilets

Caricato da

EddiemtongaCopyright:

Formati disponibili

technical data sheets for ecosan components

ecosan program - Deutsche Gesellschaft fr Technische Zusammenarbeit (GTZ) GmbH

03 Composting Toilets

SOLID

BIOWASTE FAECES

General Description

Waterless toilet systems

Receive mainly faeces, but treatment of urine and

solid biowaste is possible as well

GREY

WATER

RAIN

WATER

COLLECTION

Dry organic bulking material should be added

Produce a valuable soil conditioner with low pathogen

content

Suitable for both industrial and developing countries

URINE

TREATMENT

UTILIZATION

General description

A

General Description

Detailed information on different

types of Composting Toilets

B.1

B.2

B.3

B.4

A.1

Single-vault composting toilets

Multiple-vault composting

toilets

Movable bucket / bin

composting toilets

Composting toilets with mixing

devices

conditions since their water content and

the nitrogen content are too high.

Therefore an additive or so-called

bulking agent is recommended to lower

the water content, to improve aeration

and to increase the carbon content of

the material. Wood, chips, bark chips,

sawdust, paper and other substances

are commonly used.

Manufacturers and commercially

available composting toilets

Basic principles

The basic principle of a composting

toilet

system

is

the

biological

degradation of excreta and toilet paper

in a specially designed container. Urine

is usually collected separately, or in

some types of composting toilets

collected and treated together with

faeces. Organic food waste can be

added too.

Box 1: Optimum conditions for

thermophilic composting, allowing

temperature to rise up to 5070C:

Good aeration

Moisture content 50-60%

C/N ratio 30-35

Note that optimum conditions are

rarely achieved in composting toilets.

The decomposition process is called

composting, which is the degradation

of organic matter by thermophilic

aerobic bacteria and other micro

organisms. These bacteria rely on a

good aeration of the material, on

optimal moisture content and a specific

carbon to nitrogen ratio.

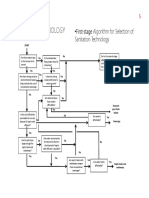

Figure 1: Schematic

of

continuous

composting toilet (Davison, 2001)

Since good aeration is very important,

the container is usually equipped with a

ventilation system that improves

aeration of the material and provides

odour control. Moreover, with bulking

agents, the pore spaces of the

composting pile can be increased;

hence it will be less compact, leading to

better aeration. However, too much air

flow can remove too much heat and

moisture, therefore the condition within

the composter should not be too cool or

dry.

Another benefit of adding bulking

materials is to increase C/N ratio in

order to attain the optimum composting

condition. Sometimes these bulking

materials also have an additional effect

on odour control by binding the

substances causing bad odours.

One main effect of the decomposition

process in a composting toilet is the

considerable volume reduction (10-30%

of the original mass), thus allowing the

prolonged storage of waste in the

container. The emptying frequency

depends on the size of the container,

the feeding rate and the composting

rate (volume reduction).

The decomposition process in a

composting toilet is rarely a real

thermophilic

composting

with

temperature rising above 50C, which

would guarantee complete pathogen

destruction and hygienization of the

waste. The pathogen content is reduced

considerably in a composting toilet.

However,

complete

pathogen

destruction can only be achieved if

good process conditions can be

guaranteed, e.g. by using an advanced

toilet design with insulation for

maintaining a high temperature within

the whole composting chamber.

The end product of a composting toilet

is an odourless stabilized material,

which is very valuable as soil

conditioner. It can be used directly for

non-food plants or for agriculture use.

Further treatment for hygienization such

as additional heap-composting or

prolonged storage (see box 2)

increases hygienic safety of agicultural

use.

A.2

Available technologies

Although there are many different

composting toilet designs that continue

to evolve, the basic concept of

composting remains the same.

Human excreta and food waste alone

do not provide those optimum

11/10/2006

version for discussion: please send your comments to ecosan@gtz.de

Page 1/3

technical data sheets for ecosan components

ecosan program - Deutsche Gesellschaft fr Technische Zusammenarbeit (GTZ) GmbH

A composting toilet has two basic

elements: a place to sit (or to squat) and

a composting chamber. Apart from

those basic elements, a ventilation

system is highly recommended in order

to stimulate aeration and prevent odour.

Available systems can be distinguished

is as follows:

Toilet seat and composting container

in the same unit, or separate

Some composting toilet systems have

the seat and the composting container

spatially separate, e.g. the toilet seat is

in the ground floor and the container is

situated below in the basement,

connected by a vertical tube. Other

systems have the toilet seat in the same

unit with the container. In that case,

containers are usually smaller and have

to be emtied more often.

Urine diversion or not

The toilet can be designed either with

or without urine diversion.

Detailed information on urine diversion

can be found in the GTZ technical data

sheet for urine diversion (01) on

http://www.gtz.de/en/themen/umweltinfrastruktur/wasser/9397.htm

It should be noted that without urine

diversion, more bulking agent needs to

be added in order to significantly lower

moisture level and increase C:N ratio to

attain the optimum treatment conditions.

Urine adds more water than is

necessary and it has a very high

nitrogen content. The moisture content

of faeces without urine (66-80%), plus

the addition of toilet paper and bulking

material are sufficient for good

processing.

Many composting toilets also have a

drainage system to allow evacuation of

liquids. These liquids are called

leachate

and

have

very

high

concentrations of nutrients, organics

and also contain pathogens. Leachate

needs to be collected, treated and

reused if possible. Urine diversion

usually allows to avoid or to

considerably

reduce

leachate

production.

Self-constructed

procured

or

commercially

There are many designs and models

offered by manufacturers all over the

world with a large range of prices.

However composting toilets can also be

self-constructed. Manufactured toilets

are often more expensive than selfconstructed systems.

11/10/2006

Box 2:

Suggested alternative recommendations for primary treatment of dry faeces

before use at household level. No addition of new material. (Schnning and

Stenstrm, 2004)

Treatment

Storage (only

treatment) at ambient

temperature 2-20C

Criteria

1,5-2 years

Storage (only

treatment) at 20-35C

Storage and alkaline

treatment

>1 year

pH >9 during

> 6 months

Low-tech or high-tech

The systems range from low-tech

(simple, non-electric, but more care is

required) to high-tech (complex, electric,

very low labour work, but higher cost)

systems. Low-tech composters are

simple reactors in which all is collected

and allowed to decompose in at

ambient temperature. They require the

user to take a more active role in the

day-to-day maintenance of the unit.

High-tech units can be equipped with

electric fans, automatic mixers and

thermostatically controlled heaters and

require very low level of user

intervention.

Single-vault (continuous) or multiplevault (batch)

Either multiple chambers batch composting, e.g. EcoTech Carousel, or single chamber continuous composting

process shown in figure 1, e.g. Clivus

multrum, Clivus minimus, BioLet, etc.

are feasible to use.

On-site or off-site composting

Most composting toilets process the

material on-site in a composting chamber that is located directly under in the

toilet seat or in the basement of the

building. Other systems however use

movable collection bins or containers

that are emptied frequently and where

the material is then transported to an

external site for treatment.

A.3

Applicability

Comment

Will eliminate most bacterial pathogens,

substantially reduce viruses, protozoa

and parasites, some soil-b ova may

persist

As above

Temperature <35, moisture content

>25 or lower pH will prolong the time

for absolute elimination

With proper management the toilet is

easy to use and to maintain, and the

final product is a high-quality compost

soil

conditioner

for

garden

or

agriculture.

Compared to dehydration toilets,

composting toilets require higher costs

in term of excreta management. The

most important difference between this

technology and that of dehydration is

the moisture content of faeces within

the vault (around 50% comparing to

25% in dehydration toilet). Composting

toilets need organic bulking materials to

increase carbon content whereas

dehydration toilet can use also other dry

absorbents as ash or dry soil to lower

the moisture content. The nutrients in

products from composting toilet are

more readily available to plants than

those from dehydration toilet.

Compared

to

VIP/pit

latrines,

composting toilets can be built above

ground level as permanent structure.

There is no need for digging deep pit

and periodical replacement of the facility

when pits are full.

Composting toilets are sealed systems

that exclude

any

infiltration of

contaminated

liquids

into

the

groundwater or other harmful emissions

into the environment.

Composting toilets can close the

nutrient cycle, turning a dangerous

waste product into safe compost,

without smell, hassle, or fly problems.

Composting toilets eliminate the need

for flushing water. No water supply (no

expensive installation for infrastructure

like water supply line and sewerage) is

necessary. Furthermore, it allows for the

recycling of valuable plant nutrients via

compost products.

They are usually less expensive than

conventional septic systems or sewered

systems (if costs for sewerage and

wastewater treatment are considered)

treatment and they will reduce

household total water consumption by

at least 25%.

This technology is suitable for both

industrialized and developing countries,

especially in arid regions and regions

without piped water or sewers. It works

without

water

and

wastewater

connection.

In several projects composting toilets

have

also

been

successfully

implemented in houses with several

floors.

In term of operation and maintenance,

composting toilets are most suitable

version for discussion: please send your comments to ecosan@gtz.de

Page 2/3

technical data sheets for ecosan components

ecosan program - Deutsche Gesellschaft fr Technische Zusammenarbeit (GTZ) GmbH

when users are committed to operate

the system carefully. Composting toilets

need more care than dehydration toilets

in the case of low-tech systems.

A.4

Further reading

Esrey, St. A., et. al., 1998, Ecological

sanitation. Department for Natural

Resources and the Environment, Sida,

Stockholm, Sweden.: Well-illustrated

book concerning different types of

composting

toilet

as

well

as

performance and health issues.

sources and the Environment, Sida,

Stockholm, Sweden.

Montgomery, T., 1990, On-Site wastewater treatment systems, Technical Bulletin No. 6, The New Alchemy Institute.

Peasey, A., 2000, Health aspects of dry

sanitation with waste reuse. Task No.

324, WELL.

Reed, B. and Shaw, R. Using human

waste, technical brief no. 63, WELL.

Del Porto, D. and Steinfeld, C., 2000,

The composting toilet system book. The

Center for Ecological Pollution Prevenst

tion (CEPP), 1 ed. with additions.: information on several types of composting toilet system, including practical application and maintenance.

Jenkins, Joseph, 2005, The Humanure

handbook a guide to composting human manure, Joseph Jenkins Inc,

Grove City, USA.

lain, Christophe, 2005, Un petit coin

pour soulage la plante Toilettes sches et histoires deau, ditions Goutte

de Sable, Athe, France.

A.5

References

Crennan, L., waterless toilets, Home,

Technical Manual: design for lifestyle

and the future, www.greenhouse.gov.au

Davison, L. and Schwizer, B., 2001,

Waterless composting toilets, septic

safe, Environment & Health Protection

Guidelines: On-site Sewage Management for Single Households.

Esrey, St. A., et. al., 1998, Ecological

sanitation. Department for Natural Re-

2006, GTZ

technical data sheets for ecosan

components

authors: GTZ ecosan team (Christine

Werner, Nathasith Chiarawatchai,

Florian Klingel, Patrick Bracken)

Deutsche Gesellschaft fr Technische

Zusammenarbeit (GTZ) GmbH

ecosan program

Dag-Hammarskjld-Weg 1-5

65760 Eschborn, Germany

T +49 6196 79-4220

F +49 6196 79-7458

E ecosan@gtz.de

I www.gtz.de/ecosan

11/10/2006

version for discussion: please send your comments to ecosan@gtz.de

Page 3/3

Potrebbero piacerti anche

- Home Bin CompostingDocumento9 pagineHome Bin CompostingqfarmsNessuna valutazione finora

- Solid Waste BiotechnologyDocumento7 pagineSolid Waste Biotechnologyani putkaradzeNessuna valutazione finora

- Compost Toilet Guidelines 30 June 2010Documento33 pagineCompost Toilet Guidelines 30 June 2010andrewb2005Nessuna valutazione finora

- Dranco Technology Digest Organic WasteDocumento7 pagineDranco Technology Digest Organic Wastemime840% (1)

- Composting Process GuideDocumento37 pagineComposting Process GuideHeruogut SianiparNessuna valutazione finora

- BIOLOGICAL TREATMENT AND COMPOSTING newDocumento9 pagineBIOLOGICAL TREATMENT AND COMPOSTING newKiruthika KiruthiNessuna valutazione finora

- Waterless Composting Toilets Regulations and RecommendationsDocumento2 pagineWaterless Composting Toilets Regulations and RecommendationsAdewale Adefemi JonathanNessuna valutazione finora

- BioCycle Magazine Article OpenRoad CompostingDocumento6 pagineBioCycle Magazine Article OpenRoad CompostingPaula Hewitt AmramNessuna valutazione finora

- Construction Manual LUPO Digester Ethiopia GTZ 2002Documento30 pagineConstruction Manual LUPO Digester Ethiopia GTZ 2002Micah Allen100% (4)

- Sewage Treatment PlantDocumento9 pagineSewage Treatment PlantAldricCyrQuiambaoPeruchoNessuna valutazione finora

- Sludge Treatment, Reuse and Disposal: 5.1 StabilisationDocumento2 pagineSludge Treatment, Reuse and Disposal: 5.1 StabilisationArgie AdduruNessuna valutazione finora

- Bio Digesters: Biodigester Basic Information - Facts & Questions - Docx Page 1 / 4Documento4 pagineBio Digesters: Biodigester Basic Information - Facts & Questions - Docx Page 1 / 4Richard Mwatujobe100% (1)

- Presentation: Submitted To: Sir Aleem Ahmed Created By: Syeda Sana Ayesha (b0901100)Documento24 paginePresentation: Submitted To: Sir Aleem Ahmed Created By: Syeda Sana Ayesha (b0901100)Aleem AhmedNessuna valutazione finora

- Aerobic CompostingDocumento4 pagineAerobic CompostingChris MohankumarNessuna valutazione finora

- Physical, Chemical & Biological: Design of Facilities For Treatment of Waste WaterDocumento118 paginePhysical, Chemical & Biological: Design of Facilities For Treatment of Waste WaterAseem Vivek Masih100% (1)

- Waste - Solid W Mangemt L-3Documento18 pagineWaste - Solid W Mangemt L-3Thivi KuttyNessuna valutazione finora

- 1992 National Waste Processing Conference 05Documento9 pagine1992 National Waste Processing Conference 05aymmon8950Nessuna valutazione finora

- Composting From A To ZDocumento14 pagineComposting From A To ZMarco GiallonardiNessuna valutazione finora

- Commercial Composting GuideDocumento4 pagineCommercial Composting GuideShiva ChiramshiNessuna valutazione finora

- Solid-Waste Treatment and Disposal: IncinerationDocumento7 pagineSolid-Waste Treatment and Disposal: IncinerationCourage ChigerweNessuna valutazione finora

- Report Home CompostingDocumento15 pagineReport Home CompostingneerajNessuna valutazione finora

- Aerobic Digestion: ProcessDocumento5 pagineAerobic Digestion: Processshabeer ahmadNessuna valutazione finora

- Onsite Wastewater Treatment Systems1Documento10 pagineOnsite Wastewater Treatment Systems1Nour BakhoumNessuna valutazione finora

- Overview of Activated Sludge ProcessDocumento32 pagineOverview of Activated Sludge ProcesssoorajTVMNessuna valutazione finora

- WWTP ProcessDocumento14 pagineWWTP ProcessShimmer WongNessuna valutazione finora

- Capstone Composting PaperDocumento3 pagineCapstone Composting Paperapi-270165707Nessuna valutazione finora

- 43 4 Biological ProcessesDocumento12 pagine43 4 Biological ProcessesrobbyrokenNessuna valutazione finora

- Anaerobic Digestion For Environmental ProcessesDocumento5 pagineAnaerobic Digestion For Environmental ProcessesWONG TSNessuna valutazione finora

- AnswersDocumento5 pagineAnswersDivyam ShreevatsalNessuna valutazione finora

- Biogas Plant Site Selection Criteria-UpdateDocumento6 pagineBiogas Plant Site Selection Criteria-UpdateAbduletif HeboNessuna valutazione finora

- Septic TankDocumento18 pagineSeptic Tankhanslo123Nessuna valutazione finora

- Ijciet 08 09 044 PDFDocumento7 pagineIjciet 08 09 044 PDFnivedhithaNessuna valutazione finora

- BIOFILTRATION FOR CONTROL OF AIR POLLUTIONDocumento23 pagineBIOFILTRATION FOR CONTROL OF AIR POLLUTIONKarthikeyanNessuna valutazione finora

- MBBR Technology Process DescriptionDocumento4 pagineMBBR Technology Process DescriptionPuspalata JenaNessuna valutazione finora

- Basics of Composting June 2009 PDFDocumento3 pagineBasics of Composting June 2009 PDFMuntazir BeegunNessuna valutazione finora

- Environmental and Sanitary EngineeringDocumento22 pagineEnvironmental and Sanitary EngineeringAhmed Ali Akbar PhambraNessuna valutazione finora

- Waste Water Treatment in 40 CharactersDocumento6 pagineWaste Water Treatment in 40 Charactersstylish eagle100% (1)

- Composting and Waste StabilizationDocumento5 pagineComposting and Waste StabilizationKhushbakht KhushiNessuna valutazione finora

- Portable Toilet For Disaster Relief KinstedtDocumento3 paginePortable Toilet For Disaster Relief KinstedtMustafa HyaliNessuna valutazione finora

- Operation & Maintenance Guideline For Bio-Digesters: 6 Economics 11Documento13 pagineOperation & Maintenance Guideline For Bio-Digesters: 6 Economics 11myco samNessuna valutazione finora

- Bio Energy LabDocumento8 pagineBio Energy LabdjpundirNessuna valutazione finora

- WastewaterDocumento12 pagineWastewaterJerome JavierNessuna valutazione finora

- Bio Gas Plant PDFDocumento7 pagineBio Gas Plant PDFrajasekaran2323Nessuna valutazione finora

- BiogasDocumento5 pagineBiogasjyoti singhNessuna valutazione finora

- DISPOSALDocumento9 pagineDISPOSALCourage ChigerweNessuna valutazione finora

- Waste-To-Energy & Material Recovery: Chapter 5: Aerobic CompostingDocumento32 pagineWaste-To-Energy & Material Recovery: Chapter 5: Aerobic CompostingMryam 'Nessuna valutazione finora

- Secondary Treatment System: Trickling FilterDocumento5 pagineSecondary Treatment System: Trickling FilterMaryrose GalapNessuna valutazione finora

- Triclikg FilterDocumento7 pagineTriclikg FilterPriya SinghNessuna valutazione finora

- Effluent TreatmentDocumento21 pagineEffluent TreatmentRadhika AnandkumarNessuna valutazione finora

- EVALUATING COMPOSTING TECHNOLOGIESDocumento15 pagineEVALUATING COMPOSTING TECHNOLOGIESAnu ThomasNessuna valutazione finora

- Activated Sludge Calculations Excel CourseDocumento22 pagineActivated Sludge Calculations Excel CoursesahatNessuna valutazione finora

- Tissue Culture Lab PDFDocumento13 pagineTissue Culture Lab PDFTimothy Dalingay Jr.100% (2)

- Bio ProjectDocumento21 pagineBio ProjectlaughingsweetyNessuna valutazione finora

- TechnologiesDocumento12 pagineTechnologiesHamed MehriNessuna valutazione finora

- Biogas Generator Construction and Operation GuideDocumento9 pagineBiogas Generator Construction and Operation GuideSKNessuna valutazione finora

- Biogas Generator Construction and Operation GuideDocumento9 pagineBiogas Generator Construction and Operation GuideSKNessuna valutazione finora

- Microsoft Powerpoint - Technical Presentation On Bio-TowersDocumento19 pagineMicrosoft Powerpoint - Technical Presentation On Bio-TowersbathalapalliNessuna valutazione finora

- Nayer FinalDocumento4 pagineNayer Finaltalha riazNessuna valutazione finora

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationDa EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationValutazione: 3 su 5 stelle3/5 (1)

- Composting Process: Organic Manures through Eco-Friendly Waste Management PracticesDa EverandComposting Process: Organic Manures through Eco-Friendly Waste Management PracticesNessuna valutazione finora

- Ethical Consent For NursesDocumento17 pagineEthical Consent For NursesEddiemtongaNessuna valutazione finora

- Course Outline - WRMDocumento4 pagineCourse Outline - WRMEddiemtongaNessuna valutazione finora

- Sustainability of Sanitary Facilities in The Construction Environment in Mzuzu CityDocumento11 pagineSustainability of Sanitary Facilities in The Construction Environment in Mzuzu CityEddiemtongaNessuna valutazione finora

- Unlocking tourism potential through SA's heritageDocumento8 pagineUnlocking tourism potential through SA's heritageEddiemtongaNessuna valutazione finora

- Water International Volume 36 Issue 4 2011 (Doi 10.1080/02508060.2011.594983) Murray, Ashley Cofie, Olufunke Drechsel, Pay - Efficiency Indicators For Waste-Based Business Models - Fostering PrivaDocumento18 pagineWater International Volume 36 Issue 4 2011 (Doi 10.1080/02508060.2011.594983) Murray, Ashley Cofie, Olufunke Drechsel, Pay - Efficiency Indicators For Waste-Based Business Models - Fostering PrivaEddiemtongaNessuna valutazione finora

- Factors Influencing The Performance of Faecal Sludge Management in ThylandDocumento16 pagineFactors Influencing The Performance of Faecal Sludge Management in ThylandEddiemtongaNessuna valutazione finora

- Employment GuaranteeDocumento29 pagineEmployment GuaranteeEddiemtongaNessuna valutazione finora

- The Socio-spatial Construction of (In)accessible Public ToiletsDocumento13 pagineThe Socio-spatial Construction of (In)accessible Public ToiletsEddiemtongaNessuna valutazione finora

- N. Cukjati; G.D. ZupanДЌiДЌ; M. RoЕЎ; V. Grilc - Composting of Anaerobic Sludge- An Economically FeasDocumento8 pagineN. Cukjati; G.D. ZupanДЌiДЌ; M. RoЕЎ; V. Grilc - Composting of Anaerobic Sludge- An Economically FeasEddiemtongaNessuna valutazione finora

- Day 1.1-Sipho MkhwanaziDocumento21 pagineDay 1.1-Sipho MkhwanaziEddiemtongaNessuna valutazione finora

- Day 2.1-Perry MoodleyDocumento53 pagineDay 2.1-Perry MoodleyEddiemtongaNessuna valutazione finora

- Water Science and Technology Volume 36 Issue 11 1997 (Doi 10.1016/s0273-1223 (97) 00684-7) Svend-Erik Jepsen Michael Krause Henrik Grüttner - Reduction of Fecal Streptococcus and Salmonella byDocumento8 pagineWater Science and Technology Volume 36 Issue 11 1997 (Doi 10.1016/s0273-1223 (97) 00684-7) Svend-Erik Jepsen Michael Krause Henrik Grüttner - Reduction of Fecal Streptococcus and Salmonella byEddiemtongaNessuna valutazione finora

- Day 1.2-Phillip SitholeDocumento16 pagineDay 1.2-Phillip SitholeEddiemtongaNessuna valutazione finora

- Journal of Purchasing & Supply Management: Florence Crespin-Mazet, Emmanuelle DontenwillDocumento11 pagineJournal of Purchasing & Supply Management: Florence Crespin-Mazet, Emmanuelle DontenwillEddiemtongaNessuna valutazione finora

- Cecil Lue-Hing; Peter Matthews; Juraj NГ Mer; Nagaharu Okuno; Lu - Sludge Management in Highly UrbanizedDocumento8 pagineCecil Lue-Hing; Peter Matthews; Juraj NГ Mer; Nagaharu Okuno; Lu - Sludge Management in Highly UrbanizedEddiemtongaNessuna valutazione finora

- Solar Drying in Sludge Management in TurkeyDocumento15 pagineSolar Drying in Sludge Management in TurkeyEddiemtongaNessuna valutazione finora

- Water Science and Technology Volume 39 Issue 5 1999 (Doi 10.1016/s0273-1223 (99) 00097-9) Ralf Otterpohl Andrea Albold Martin Oldenburg - Source Control in Urban Sanitation and Waste ManagementDocumento8 pagineWater Science and Technology Volume 39 Issue 5 1999 (Doi 10.1016/s0273-1223 (99) 00097-9) Ralf Otterpohl Andrea Albold Martin Oldenburg - Source Control in Urban Sanitation and Waste ManagementEddiemtongaNessuna valutazione finora

- Journal of Water Sanitation and Hygiene For Development Volume Issue 2017 (Doi 10.2166/washdev.2017.073) Balasubramanya, Soumya Evans, Barbara Ahmed, Rizwan Habib, Ah - Take It Away - The Need FoDocumento8 pagineJournal of Water Sanitation and Hygiene For Development Volume Issue 2017 (Doi 10.2166/washdev.2017.073) Balasubramanya, Soumya Evans, Barbara Ahmed, Rizwan Habib, Ah - Take It Away - The Need FoEddiemtongaNessuna valutazione finora

- Willy Chipeta Final Thesis 15-09-2016Documento101 pagineWilly Chipeta Final Thesis 15-09-2016EddiemtongaNessuna valutazione finora

- FSM Paper 2 Comp An Rev 2014 05 14 FINALDocumento19 pagineFSM Paper 2 Comp An Rev 2014 05 14 FINALEddiemtongaNessuna valutazione finora

- Durban Peer Exchange 2011 Learning NoteDocumento16 pagineDurban Peer Exchange 2011 Learning NoteEddiemtongaNessuna valutazione finora

- Durban Waste Management 2Documento18 pagineDurban Waste Management 2EddiemtongaNessuna valutazione finora

- Kennedy-Walker, Ruth Holderness, Tomas Barr, Stuart Alderson, - Network Modelling For Road-Based FDocumento10 pagineKennedy-Walker, Ruth Holderness, Tomas Barr, Stuart Alderson, - Network Modelling For Road-Based FEddiemtongaNessuna valutazione finora

- Experiments With Ecological Sanitation and Pit Emptying in Maputaland South AfricaDocumento15 pagineExperiments With Ecological Sanitation and Pit Emptying in Maputaland South AfricaEddiemtongaNessuna valutazione finora

- Employment GuaranteeDocumento29 pagineEmployment GuaranteeEddiemtongaNessuna valutazione finora

- Environmental Modelling & Software Volume 24 Issue 3 2009 (Doi 10.1016/j.envsoft.2008.08.003) F. Devesa J. Comas C. Turon A. Freixó F. Carrasco M. Poch - Scenario Analysis For The Role of SaniDocumento10 pagineEnvironmental Modelling & Software Volume 24 Issue 3 2009 (Doi 10.1016/j.envsoft.2008.08.003) F. Devesa J. Comas C. Turon A. Freixó F. Carrasco M. Poch - Scenario Analysis For The Role of SaniEddiemtongaNessuna valutazione finora

- Network Modelling For Road-Based Faecal Sludge ManagementDocumento9 pagineNetwork Modelling For Road-Based Faecal Sludge ManagementEddiemtongaNessuna valutazione finora

- Namibia Formalisation of Informal SettlementsDocumento23 pagineNamibia Formalisation of Informal SettlementsEddiemtongaNessuna valutazione finora

- Solids Sep and Pond TreatmDocumento88 pagineSolids Sep and Pond TreatmEddiemtongaNessuna valutazione finora

- Mirela - Alexandra ENACHE, Norbert KAZAMER, Radu Stepanescu University "Politehnica" of Timișoara, Timișoara, RomaniaDocumento9 pagineMirela - Alexandra ENACHE, Norbert KAZAMER, Radu Stepanescu University "Politehnica" of Timișoara, Timișoara, RomaniaStephanie BergNessuna valutazione finora

- Australian/New Zealand Standard: On-Site Domestic Wastewater Treatment Units Part 2: Waterless Composting ToiletsDocumento7 pagineAustralian/New Zealand Standard: On-Site Domestic Wastewater Treatment Units Part 2: Waterless Composting ToiletsCrab Crab0% (3)

- Sep Tank DesignDocumento36 pagineSep Tank Designsrinivasakannan23Nessuna valutazione finora

- Planning and Design of Sanitation System On Low Income PeopleDocumento10 paginePlanning and Design of Sanitation System On Low Income PeopleMd. Habibur Rahman Bejoy Khan ,155408Nessuna valutazione finora

- Composting Toilet Construction ManualDocumento23 pagineComposting Toilet Construction ManualalinupNessuna valutazione finora

- NCM 104 Handout On EhsDocumento5 pagineNCM 104 Handout On EhsJerah Aceron SatorreNessuna valutazione finora

- Dometic Envirolet VF CatalogDocumento20 pagineDometic Envirolet VF CatalogunyimNessuna valutazione finora

- Contemporary Toilet DesignsDocumento48 pagineContemporary Toilet DesignsUmeshSanghviNessuna valutazione finora

- PPG 4 Treatment and Disposal of Sewage Where No Foul Sewer Is Available PDFDocumento12 paginePPG 4 Treatment and Disposal of Sewage Where No Foul Sewer Is Available PDFjoseNessuna valutazione finora

- Clivusmultrum Composting Toilets BookletDocumento16 pagineClivusmultrum Composting Toilets BookletGreen Action Sustainable Technology GroupNessuna valutazione finora

- Sanitation Selection AlgorithmDocumento3 pagineSanitation Selection AlgorithmClarita BangunNessuna valutazione finora

- What Is A Composting Toilet & Does It Work - Angi (Angie's List)Documento18 pagineWhat Is A Composting Toilet & Does It Work - Angi (Angie's List)Ilie TicaNessuna valutazione finora

- Household SanitationDocumento10 pagineHousehold SanitationHelder MbidiNessuna valutazione finora

- Recode Case Studies For Ecological SanitationDocumento20 pagineRecode Case Studies For Ecological SanitationMolly DanielssonNessuna valutazione finora

- A New, User-Friendly, Urine-Diverting, Waterless, Composting Eco-ToiletDocumento11 pagineA New, User-Friendly, Urine-Diverting, Waterless, Composting Eco-ToiletNishkarsh AgarwalNessuna valutazione finora

- Brochure BioletDocumento16 pagineBrochure BioletValmik SoniNessuna valutazione finora

- Source BookDocumento330 pagineSource Bookcdarrellg2430Nessuna valutazione finora

- Guidelines For Waterless-Double-Chamber Composting Toilets V.1 - HPPB (2018)Documento24 pagineGuidelines For Waterless-Double-Chamber Composting Toilets V.1 - HPPB (2018)HPPBNessuna valutazione finora

- Guide to Building Pit ToiletsDocumento4 pagineGuide to Building Pit ToiletsKiran BasuNessuna valutazione finora

- Alternative Onsite Sewage Disposal Technology: A ReviewDocumento38 pagineAlternative Onsite Sewage Disposal Technology: A ReviewWashington State Institute for Public PolicyNessuna valutazione finora

- Easy CellarDocumento88 pagineEasy Cellar9pbdqm8zq2Nessuna valutazione finora

- 15472012asnzs 6151Documento10 pagine15472012asnzs 6151Alan Cherem ZorkotNessuna valutazione finora

- Initial Data Base For Family Nursing PracticeDocumento9 pagineInitial Data Base For Family Nursing PracticeAlyanna Crisologo100% (1)

- Composting Toilet Report ADocumento4 pagineComposting Toilet Report Aapi-234699482Nessuna valutazione finora

- Pit Latrine Design-GodDocumento11 paginePit Latrine Design-GodGerald MagingaNessuna valutazione finora

- Composting ToiletsDocumento3 pagineComposting Toiletsapi-3704111100% (1)

- Lahore College Water Conservation AssignmentDocumento18 pagineLahore College Water Conservation AssignmentKhiZra ShahZad100% (2)

- Compost Toilet InstuctionsDocumento2 pagineCompost Toilet Instuctionsfgaspar4uNessuna valutazione finora

- At For Water Supply and Sanitation 3, Health Aspects of Excreta and Sullage ManagmentDocumento319 pagineAt For Water Supply and Sanitation 3, Health Aspects of Excreta and Sullage ManagmentjimborenoNessuna valutazione finora