Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Textile Industry in India PDF

Caricato da

arunDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Textile Industry in India PDF

Caricato da

arunCopyright:

Formati disponibili

A

BRIEF REPORT

ON

TEXTILE INDUSTRY IN INDIA

May, 2014

A brief report on Textile Industry in India

1. OVERVIEW OF INDIAN TEXTILE INDUSTRY

1.1

Background

India Textile Industry is one of the leading textile industries in the world. Though it was

predominantly unorganized industry even a few years back, but the scenario started changing after

the economic liberalization of Indian economy in 1991. The opening up of economy gave the muchneeded thrust to the Indian textile industry, which has now successfully become one of the largest in

the world.

India textile industry largely depends upon the textile manufacturing and export. It also plays a

major role in the economy of the country. India earns about 27% of its total foreign exchange

through textile exports. Further, the textile industry of India also contributes nearly 14% of the total

industrial production of the country. It also contributes around 3% to the GDP of the country.

India textile industry is also the largest in the country in terms of employment generation. It not only

generates jobs in its own industry, but also opens up scopes for the other ancillary sectors. India

textile industry currently generates employment to more than 35 million people.

Indian textile industry can be divided into several segments, some of which can be listed as below:

Cotton Textiles

Silk Textiles

Woolen Textiles

Readymade Garments

Hand-crafted Textiles

Jute and Coir

1.2

Current Scenario

The Indian Textiles Industry has an overwhelming presence in the economic life of the country.

Apart from providing one of the basic necessities of life, the textiles industry also plays a vital role

through its contribution to industrial output, employment generation, and the export earnings of the

country.

The sector contributes about 14 per cent to industrial production, 4 per cent to the gross domestic

product (GDP), and 17 per cent to the country's export earnings. It provides direct employment to

over 35 million people. The textiles sector is the second largest provider of employment after

agriculture. Thus, the growth and all round development of this industry has a direct bearing on the

improvement of the economy of the nation.

India has the potential to increase its textile and apparel share in the world trade from the current

level of 4.5 per cent to 8 per cent and reach US$ 80 billion by 2020.

1.3

Export Scenario

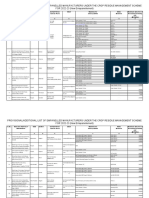

The targets for textiles exports for 2012-13 initially set at USD 38 billion have been revised upwards

to USD 39.60 billion, following the Foreign Trade Policy Annual Supplement in June, 2012. The

Private & Confidential

Page 2 of 13

A brief report on Textile Industry in India

details of exports targets fixed and achieved during the last three years and current year sector and

item-wise including apparel, man-made and cotton textiles are as under given in the Table below:-

Source: Foreign Trade Statistics of India (Principal Commodities & Countries).* as per latest figures available

1.4

Technical Textile Segment

The current market size of technical textile in India is estimated to be around USD 6.83 billion. The

overall technical textile industry in India is expected to grow at the rate of 11% year on year and

reach a market size of USD 11.36 billion by the year 2012-13. The current technical textile

consumption in India is estimated to be around USD 6.35 billion which is estimated to increase to

USD 10.69 billion by Market Size includes domestic consumption and exports the year 2012-13 The

Scheme for Growth and Development of Technical Textiles aims to promote indigenous

manufacture of technical textile to leverage global opportunities and cater to the domestic demand.

Further, the government is set to launch USD 44.21 million missions for promotion of technical

textiles, while the Finance Ministry has cleared setting up of four new research centers for the

industry, which include products like mosquito and fishing nets, shoe laces and medical gloves.

The global technical industry is estimated at USD 127 billion and its size in India is pegged at USD

11 billion.

Private & Confidential

Page 3 of 13

A brief report on Textile Industry in India

2. MAJOR PLAYERS IN TEXTILE INDUSTRY

2.1

Major Players in the industry

Company

2.2

Business areas

Welspun India Ltd

Vardhman Group

Alok Industries Ltd

Home textiles, bathrobes, terry towels

Yarn, fabric, sewing threads, acrylic fiber

Home textiles, woven and knitted apparel fabric,

garments and polyester yarn

Raymond Ltd

Worsted suiting, tailored clothing, denim, shirting,

woolen outerwear

Arvind Mills Ltd

Spinning, weaving, processing and garment

production (denims, shirting, khakis, knitwear)

Bombay Dyeing &

Manufacturing Company Ltd

Bed linen, towels, furnishings, fabric for suits, shirts,

dresses and saris in cotton and polyester blends

Garden Silk Mills Ltd

Mafatlal Industries Ltd

Aditya Birla Nuvo, a

diversified conglomerate of

the Aditya Birla Group,

comprising three divisions

Madura Garments, Jayashree

Textiles and Indian Rayon

ITC Lifestyle

Reliance Industries Ltd

Dyed and printed fabric

Shirting, poplins, bottom wear fabrics, voiles

Madura Garments lifestyle market (Louis

Philippe, Van Heusen, Allen Solly, The Collective)

Jayashree Textiles domestic linen and worsted

yarn

Indian Rayon viscose filament yarn

Lifestyle market

Fabric, formal menswear

Profile of Major Players in India

2.2.1 Welspun India Ltd

Welspun India Limited (WIL) is the Flagship Company of Welspun Group with an enterprise value

of U.S. $ 3 billion. WIL is ISO 9001:2000, 14001 and SA 8000 certified company. WIL is a

composite textile mill producing Cotton Yarn, Terry Towels and Rugs for international market.

Welspun India Ltd. is one of the largest Home Textiles producers in Asia and amongst the top 4

producers of Terry Towels in the world. WIL is located at village Morai in Valsad district, Gujarat

State. WIL annual sales turnover for year 2009-2010 was Rs. 681.881 crores.

They have presence over 50 Countries, over 24,000 employees & 100,000+ shareholders, Welspun is

one of India's fastest growing conglomerates.

2.2.2 Vardhman Group

Vardhman Group was established in 1965 and is a leading textile conglomerate in India having a

turnover of $700 million. They have over 24 manufacturing facilities in five states across India; the

Private & Confidential

Page 4 of 13

A brief report on Textile Industry in India

Group business portfolio includes Yarn, Greige and Processed Fabric, Sewing Thread, Acrylic Fibre

and Alloy Steel.

Vardhman Group manufacturing facilities include over 8,00,000 spindles, 65 tons per day yarn and

fiber dyeing, 900 shuttle less looms, 90mn meters per annum processed fabric, 33 tons per day

sewing thread, 18000 metric tons per annum acrylic fiber and 100,000 tons per annum special and

alloy steel.

Products

Cotton Yarn

Special Blended Yarn

Organic Cotton

Yarn Core Spun Yarn

Fair Trade cotton

Yarn Melanges

Organic Fair Trade Cotton Yarn

Gassed Mercerized Yarn

Ellitwist Yarn

Modal Yarn

Vortex Yarn

Tencel Yarn

Slub Yarn

Viscose Yarn

Acrylic Yarn

Hand Knitting Yarn

Poly - Cotton Yarn

Specialty Yarn

Acrylic - Cotton Yarn

2.2.3 Alok Industries Ltd

Alok Industries Ltd. is an India-based textile manufacturing company and was established in 1986.

Alok Industries is a private textile manufacturing company and has manufacturing bases spread over

6 locations in Navi Mumbai in Vapi and Silvassa, situated in Maharashtra.

Its business domain involves weaving, knitting, processing, home textiles and ready-made garments

and its a diversified manufacturer of world-class home textiles, apparel fabrics, garments and

polyester yarns. Its buyers include manufacturers, exporters, importers, retailers, and branded

apparel manufacturers of the world. Further, it operates its embroidery business through its sister

concern, Grabal Alok Impex Ltd. Today, Alok Industries is one of the largest private exporters of

textiles in India. Its business operations are spread across all the continents. Moreover, the

manufacturing lab has been certified for ISO 9001:2000 quality standards.

Private & Confidential

Page 5 of 13

A brief report on Textile Industry in India

Alok Industries became a public limited company in 1993 and their shares are listed in Bombay

Stock Exchange and National Stock Exchange. The turnover increased by 39.33%.

Alok Industries product lines include Apparel Fabric (Woven)

Apparel Fabric (Knitted)

Garments

Home Textiles

Polyester Yarn

Embroidered Fabric

Retailing

2.2.4 Raymond Ltd

Raymond was incorporated in 1925 and has over 60% market share in worsted suiting in India The

company has a diverse product range of nearly 20,000 design and colors of suiting fabric. They

export their products to over 55 countries including USA, Canada, Europe, Japan and the Middle

East. The company has registered a turnover of USD 636.7 million for the FY 2011 as compared to

USD 364 million turnover in 2006.

Their suitings are available in India in over 400 towns through 3,000 retailers as well as over 500

exclusive retail shops.

Raymond is among the largest integrated manufacturers of worsted fabrics in the world. Raymond

Ltd. owns some of the most highly respected apparel brands in its portfolio like - Raymond,

Manzoni, Park Avenue, Color Plus, Parx, Park Avenue, Be:, Zapp and Notting Hill and GAS.

Raymond manufactures and markets brands like Kama Sutra condoms and even surgical gloves. The

Raymond Group also has an expansive retail presence. Raymond's wide range of products and

services are as follows:

Total textile solutions.

Fabrics (Worsted, Denim and Shirting).

Apparels (Tailored Clothing, Jeanswear and Dress Shirts).

Brands (Raymonds, Manzoni, Park Avenue, Color Plus, Parx,Be: Zapp!, Notting Hill and

The Raymond Shop).

Woolen Outerwear.

Furnishings.

Retail (The Raymond Shop and Brand Store).

Engineering (Files, Cutting Wools, Hand Tools and Agri tools and Auto Components).

Personal Care (Park Avenue and Kamasutra).

Prophylactic (Kamasutra and Surgical Gloves).

International Business.

Corporate Wear

Private & Confidential

Page 6 of 13

A brief report on Textile Industry in India

2.2.5 Bombay Dyeing

Bombay Dyeing is one of the leading companies in the textile business. In fact, India has made a

position in the world textile sector holding the hands of Bombay Dyeing. The textile products of the

company are exported to different nations all across the world like the United States, European

Union Countries, Australia and New Zealand.

2.3

Products of Bombay Dyeing:

Bombay Dyeing by using advanced technology has brought about a change in the textile business.

The entire production is divided into two broad streams, weaving and spinning and winding. The

production level on a daily basis is over 300,000 meters of fabrics. Some of the important products

of the company that have already become significant in both, domestic and export markets are:

Cotton Sheeting

Polyester Cotton Sheeting

Poly Cotton Drills

Shoe Lining and Duck Fabrics

Satin Furnishings

Yarn dyed fabrics

Flannel Sheeting

Dobby and Fine Count made-ups

Down proof Shells and Comforters

Towels, Table Tops and Napkins

Bombay Dyeing at present is the largest exporter of sophisticated made-up items and also of

products made of cotton and poly cotton. Bombay Dyeing has created a sizable market in the

production of a wide range of fabrics and ready-mades. This includes both formal and casual wear.

The ready-made collection of the Bombay Dyeing has been changing its production pattern with the

evolving fashion trends. The consumer section of Bombay Dyeing comprise of bed linen, towels,

furnishings, suiting and shirting fabrics, and cotton and polyester blended dresses and saris.

Technology used in Bombay Dyeing:

The technology applied in the production process in Bombay Dyeing is of international standards.

Regarding the weaving facilities, the technology used is from one of the most technologically

advanced company of the world, Sulzer. The automations used in weaving, spinning and winding by

Bombay Dyeing are like Sulzer Projectile Machines, Sulzer Airjet Machines, Schlafhorst Autocore

Rotors, Auto Corner Winding Spindles and Schweiter CA - 11 Spindles.

Private & Confidential

Page 7 of 13

A brief report on Textile Industry in India

3. GOVERNMENT INITIATIVES AND REGULATORY

FRAMEWORK

3.1

Government Initiatives

The Government of India has promoted a number of export promotion policies for the Textile

sector in the Union Budget 2011-12 and the Foreign Trade Policy 2009-14. This also includes the

various incentives under Focus Market Scheme and Focus Product Scheme; broad basing the

coverage of Market Linked Focus Product Scheme for textile products and extension of Market

Linked Focus Product Scheme etc. to increase the Indian shares in the global trade of textiles and

clothing. The various schemes and promotions by the Government of India are as follows It has allowed 100 per cent Foreign Direct Investment (FDI) in textiles under the automatic route.

3.1.1 Welfare Schemes: The Government has offered health insurance coverage and life insurance coverage

to 161.10 million weavers and ancillary workers under the Handloom Weavers' Comprehensive

Welfare Scheme, while 733,000 artisans were provided health coverage under the Rajiv Gandhi

Shilpi Swasthya Bima Yojna.

3.1.2 E-Marketing: The Central Cottage Industries Corporation of India (CCIC), and the Handicrafts and

Handlooms Export Corporation of India (HHEC) have developed a number of e-marketing

platforms to simplify marketing issues. Also, a number of marketing initiatives have been taken up

to promote niche handloom and handicraft products with the help of 600 events all over the

country.

3.1.3 Skill Development: As per the 12th Five Year Plan, the Integrated Skill Development Scheme aims to

train over 2,675,000 people within the next 5 years (this would cover over 270,000 people during the

first two years and the rest during the remaining three years). This scheme would cover all sub

sectors of the textile sector such as Textiles and Apparel; Handicrafts; Handlooms; Jute; and

Sericulture.

3.1.4 Credit Linkages: As per the Credit Guarantee program, over 25,000 Artisan Credit Cards have been

supplied to artisans, and 16.50 million additional applications for issuing up credit cards have been

forwarded to banks for further consideration with regards to the Credit Linkage scheme.

3.1.5 Financial package for waiver of overdues: The Government of India has announced a package of US$

604.56 million to waive of overdue loans in the handloom sector. This also includes the waiver of

overdue loans and interest till 31st March, 2010, for loans disbursed to handloom sector. This is

expected to benefit at least 300,000 handloom weavers of the industry and 15,000 cooperative

societies.

3.1.6 Textiles Parks: The Indian Government has given approval to 40 new Textiles Parks to be set up and

this would be executed over a period of 36 months. The new Textiles Parks would leverage

employment to 400,000 textiles workers. The product mix in these parks would include apparels and

garments parks, hosiery parks, silk parks, processing parks, technical textiles including medical

textiles, carpet and power loom parks.

Private & Confidential

Page 8 of 13

A brief report on Textile Industry in India

3.2

Recent Developments

Along with the increasing export figures in the Indian Apparel sector in the country,

Bangladesh is planning to set up two Special Economic Zones (SEZ) for attracting Indian

companies, and duty free trade between the two countries. The two SEZs are intended to

come up on 100-acre plots of land in Kishore ganj and Chattak, in Bangladesh.

Italian luxury major Canali has entered into a 51:49 Joint Venture with Genesis Luxury

Fashion, which currently has distribution rights of Canali-branded products in India. The

company will now sell Canali branded products in India exclusively.

Name of SEZ

and status

Mahindra City

SEZ

(Functional)

Tamil Nadu

Area

(hectares)

607.1

Sector

Apparel and

fashion

accessories

Developer/P

romoter

Mahindra

Group and

Tamil Nadu

Industrial

Development

Corporation

(TIDCO)

Surat Apparel

Park

(Functional)

Gujarat

56

Textiles

Gujarat

Industrial

Development

Corporation

(GIDC)

Brandix India

Apparel City

(BIAC)

(Functional)

Andhra

Pradesh

404.7

Textiles

Brandix India

Apparel City

PvtLtd

Karnataka

Industrial

Areas

Development

Board

Karnataka

Textiles

Karnataka

Industrial

Areas

Development

Board

Private & Confidential

State

Details

Mahindra City is Indias

first integrated business

city, divided into business

and lifestyle zones. The

business zone provides

plug-n-play

working

spaces.

This

zone

comprises

an

SEZ

(primarily for exporters)

and domestic tariff area

(DTA) for companies

targeting the domestic

market. The lifestyle zone

offers residential units,

schools, medical centres,

malls, business hotels and

recreation facilities.

Key

industrial

units

include Safari Exports,

Venus

Garments,

Benchmark Clothings, P.

K. International, Formal

Prints, J.R. Fashion and

Ganga Export.

Integrated apparel supply

chain city plans to house

world-class apparel chain

partners. 60 million litres

of water per day is

available. Has one of the

most advanced effluent

treatment systems in the

region. BIAC has a

dedicated 200 MW power

sub-station.

Page 9 of 13

A brief report on Textile Industry in India

(KIADB)

(Functional)

(KIADB)

In addition to the four functional SEZs, there are 13 in-principle approved, 19 formally approved

and 12 notified SEZs in India

From

January 2000 to June 2011, 482 Mergers and Acquisitions (M&A) deals have taken place.

The top five M&A deals* are listed below

M&A scenario details

Period : 1 January 2000 to 1 May 2013

Acquirer Name

Target Name

Top 5

deals

1

2

3

4

Grashim Industry

Madura Garments

Himachal Fibers

B R Machine Tools Pvt. Ltd

Terrace Bay Pulp

Pantaloon Retail

Balmukhi Textiles Pvt Ltd

Bombay Rayon Fashions Ltd

Largest deal

(USD million)

360.0

333.3

NA

721.1

5

6

Group of Investors

M C Spinners Pvt. Ltd

Provogue (India) Ltd

Maxwell Industries

526.9

8.47

Other government initiatives Scheme for Integrated Textile Parks, 2005

The scheme was introduced to neutralize the weakness of fragmentation in the various subsegments of the textiles value chain and the unavailability of quality infrastructure.

In the 12th Five Year Plan (201217), the government plans to spend US$ 9.1 billion on textiles as

against US$ 4 billion in the 11th Plan.

3.3

Policy and regulatory framework

The Ministry of Textiles is responsible for policy formulation, planning, development, export

promotions and trade regulation in the textile sector. This includes all natural and manmade

cellulosic fiber used to make textiles, clothing, and handicrafts. National Textile Policy, 2000 -the

policy was introduced for the overall development of the textiles industry. The key areas of focus

include

Technological upgrades

Enhancement of productivity

Quality consciousness

Strengthening of raw material base

Product diversification

Private & Confidential

Page 10 of 13

A brief report on Textile Industry in India

Increase in exports and innovative marketing strategies

Financing arrangements

Increasing employment opportunities

Integrated human resource development

3.3.1 Technology Mission on Cotton (TMC), 2000the scheme was introduced to address concerns around

cotton production and processing sectors and to place the cotton economy on a sound footing. It

was initially to be phased out at the end of the Tenth Five Year Plan (200207). However, the

schemes Mini Mission was extended into the Eleventh Plan for two years to accomplish targets.

3.3.2 Jute Technology Mission (JTM), 2006, The objectives of this programme include

Improving the yield and quality of jute fiber

Strengthening existing infrastructure for the development and supply of quality seeds

Improving the quality of fiber through better methods of retting and extraction technologies

Increasing the supply of quality raw material to the jute industry at reasonable prices and

developing efficient market linkages for raw jute.

Modernizing, upgrading technology, improving productivity, diversifying and developing

human resource for the jute industry

Developing and commercializing innovative technology for the diversified use of jute and

allied fiber

3.3.3 Development of mega cluster schemes

Comprehensive Power looms Cluster Development Scheme (CPCDS)

To assist entrepreneurs to set up world-class units with modern infrastructure, latest

technology and adequate training and human resource development (HRD) inputs along

with appropriate market linkages.

Comprehensive Handloom Cluster Development Scheme (CHCDS)

Formulated to address the challenges faced by weavers within the cooperative sector and

outside, due to poor infrastructure in some clusters.

Comprehensive Handicrafts Cluster Development Scheme (CHCDS)

The textile industry segments eligible to avail concessional loans for technology upgrade

requirements include

Spinning, cotton ginning and pressing

Silk reeling and twisting

Wool scouring and combing

Synthetic filament yarn texturising, crimping and twisting

Manufacturing of viscose filament yarn (VFY) or viscose staple fiber (VSF)

Weaving or knitting including non-wovens and technical textiles

Garments, made-up manufacturing

Processing of fiber, yarn, fabric, garments and made-ups

Jute

Private & Confidential

Page 11 of 13

A brief report on Textile Industry in India

4. INVESTMENTS AND OPPORTUNTIES

4.1

Investment

The textiles sector has witnessed a spurt in investment during the last five years. The industry

(including dyed and printed) attracted foreign direct investments (FDI) worth US$ 1.22 billion

during April 2000 to February 2013.

Some of the major investments in Indian Textile Industry are:

4.2

British clothing brand Super dry plans to open 20 stores in India over the next five years, as

per Mr. James Holder, Founder, Super dry

The Export Promotion Council for Handicrafts (EPCH) is setting up an international lace

trade centre at Narsapuram in Andhra Pradesh (AP) with an outlay of Rs 15.33 crore (US$

2.82 million)

The Aditya Birla Group has signed an in-principle agreement to buy the assets of Ontariobased Terrace Bay Pulp Mill for Rs 605 crore (US$ 111.62 million). The acquisition would be

carried out through AV Terrace Bay (Canada), a special purpose vehicle (SPV) in which two

group companies, Grasim Industries and Thailand-based Thai Rayon Public, would hold

stake

American apparel-maker, Tommy Hilfiger plans to add 500 stores in India over the next five

years as part of their expansion spree. Currently, Tommy Hilfiger operates 58 franchisee

outlets and over 60 shop-in-shops in other department stores

Italian luxury apparel maker, CancliniTessile is tying up with Tirupur-based Emperor

Textiles to stitch its shirts in India. The equal joint venture (JV) with Emperor Textiles will

set up a separate manufacturing unit in Tirupur to manufacture Italian fabric for domestic

consumption

Opportunities

The potential size of the Indian textiles industry is expected to reach US$ 220 billion by 2020.

4.2.1 Private sector participation in silk production

The Central Silk Board has set a target of 23,000 tonnes in 2012-13 to 33,000 metric tonnes per

annum before the end of the current Five Year Plan period. It has also proposed to enlarge the area

under mulberry silkworm food plants to 0.25 million hectares, which is expected to produce an

additional 6,400 MT of mulberry raw silk and increase employment. To achieve these targets,

alliances with the private sector, especially major agro-based industries in both pre-cocoon and postcocoon segments, is being encouraged.

4.2.2 Technical textiles

The textiles industry complements the growth of several industries and institutions such as the

defence forces, railways and government hospitals, which are the key institutional buyers of technical

textiles. The market is likely to grow to USD31 billion by 2020, implying a CAGR of 10 per cent.

Private & Confidential

Page 12 of 13

A brief report on Textile Industry in India

This industry includes the production of flexible packaging material for industrial, agricultural and

consumer goods. Among the other segments, protech, oekotech, sportech and geo-tech have

significant growth potential. Indias technical textile industry is mainly dominated by unorganized

players. However, it is an emerging area for investment with good growth opportunities.

4.2.3 Retail sector

With consumerism and disposable income on the incline, the retail sector has witnessed rapid

growth in the past decade. Several international retailers are also focusing on India due to its

emergence as a potential sourcing destination.

4.2.4 Centres of Excellence (CoE) for research and technical training

The Government of India has proposed the establishment of several CoEs for training the

workforce in the textiles sector. Four CoEs have been identified for four thrust segments of

technical textiles geotech, meditech, protech and agrotech. These CoEs, with national and

international accreditation, are aimed at creating facilities for testing and evaluation and developing

resource centres and facilities for training.

Private & Confidential

Page 13 of 13

Potrebbero piacerti anche

- Textile Industry in IndiaDocumento0 pagineTextile Industry in IndiashanujssNessuna valutazione finora

- Our Delighted Customers: Milestones ReachedDocumento5 pagineOur Delighted Customers: Milestones ReachedAbhijitNessuna valutazione finora

- Resumes ViralDocumento2 pagineResumes ViralViral PathakNessuna valutazione finora

- Nidhish Raju Resume New UpdateDocumento3 pagineNidhish Raju Resume New UpdateCma Nidhish RajuNessuna valutazione finora

- Parag Sarode Resume (MTECH)Documento4 pagineParag Sarode Resume (MTECH)Sarode RamNessuna valutazione finora

- HR Professional with 3 Years ExperienceDocumento5 pagineHR Professional with 3 Years Experiencenavatha25Nessuna valutazione finora

- PDF List of Sugar Mills in Tamilnadu - CompressDocumento3 paginePDF List of Sugar Mills in Tamilnadu - CompressrakeshNessuna valutazione finora

- Amal RajDocumento6 pagineAmal Rajdr_shaikhfaisalNessuna valutazione finora

- List of Textile Industries in Ap: Name of The Industry DistrictDocumento10 pagineList of Textile Industries in Ap: Name of The Industry DistrictDnyaneshwar PatilNessuna valutazione finora

- Himanshu Lohia: Curriculum VitaeDocumento4 pagineHimanshu Lohia: Curriculum Vitaehimanshulohia85Nessuna valutazione finora

- Introduction LetterDocumento1 paginaIntroduction LetterBashirNessuna valutazione finora

- Privatised Water Project Fails IndustriesDocumento34 paginePrivatised Water Project Fails IndustriesDrVarghese Plavila JohnNessuna valutazione finora

- Curriculum Vitae: Dhasho85@yahoo - inDocumento4 pagineCurriculum Vitae: Dhasho85@yahoo - indhasho85100% (1)

- Muralidharan (Resume Old)Documento2 pagineMuralidharan (Resume Old)Igs Assessment Kerala Branch100% (1)

- Sugar Company (1) (14 Files Merged)Documento14 pagineSugar Company (1) (14 Files Merged)Akun SatuNessuna valutazione finora

- Indian Paper Industry Size, Growth & Future OutlookDocumento34 pagineIndian Paper Industry Size, Growth & Future OutlookNizar AlifNessuna valutazione finora

- Krishna Kanth Kammaganti: Key QualificationsDocumento3 pagineKrishna Kanth Kammaganti: Key Qualificationsనాని కమ్మగంటిNessuna valutazione finora

- Patiala 16Documento15 paginePatiala 16Harpreet KaurNessuna valutazione finora

- Shree Cement Annual Report 2019 PDFDocumento283 pagineShree Cement Annual Report 2019 PDFRajan KumarNessuna valutazione finora

- Amol Magar. - M.tech-PDEDocumento2 pagineAmol Magar. - M.tech-PDEAmol MagarNessuna valutazione finora

- The Gujarat Volume 1 January 2017 EditionDocumento60 pagineThe Gujarat Volume 1 January 2017 EditionABCDNessuna valutazione finora

- CV Vijay M - SAP ABAP DeveloperDocumento3 pagineCV Vijay M - SAP ABAP DeveloperRamakrishnan AlagarsamyNessuna valutazione finora

- Rohit - Resume Jan 12Documento4 pagineRohit - Resume Jan 12Rohit ShindeNessuna valutazione finora

- 0 Hardeepsinh Solanki OriginalDocumento2 pagine0 Hardeepsinh Solanki OriginalHdh SolankiNessuna valutazione finora

- Manojkumar Ashwin ShedgeDocumento3 pagineManojkumar Ashwin ShedgePRADEEP MOHITENessuna valutazione finora

- Raja C 1Documento4 pagineRaja C 1Sree BNessuna valutazione finora

- Pidilite Competitor AnalysisDocumento4 paginePidilite Competitor AnalysisAashna DuggalNessuna valutazione finora

- Hydro ProjectsDocumento24 pagineHydro Projectsホセ 死ぬNessuna valutazione finora

- Anzirresume - Dip ChemDocumento6 pagineAnzirresume - Dip ChemMuthuKumar ArunachalamNessuna valutazione finora

- State Wise Industry OpportunitiesDocumento16 pagineState Wise Industry OpportunitiesGogol SarinNessuna valutazione finora

- Deepak JainDocumento5 pagineDeepak Jaindr_shaikhfaisalNessuna valutazione finora

- Welspun ReporteDocumento16 pagineWelspun Reportesachin patilNessuna valutazione finora

- Ultra TechDocumento35 pagineUltra TechAnsh SharmaNessuna valutazione finora

- List of Companies Sap NewDocumento30 pagineList of Companies Sap NewDasi Rakesh KumarNessuna valutazione finora

- WTE Client ListDocumento99 pagineWTE Client ListPooja MasalNessuna valutazione finora

- Zeitlin & Company Preferred Vendor List, 2009Documento17 pagineZeitlin & Company Preferred Vendor List, 2009api-26011493Nessuna valutazione finora

- AN-P-20220217-01 Rotating Equipment Monitoring Vibration Polymers PDFDocumento2 pagineAN-P-20220217-01 Rotating Equipment Monitoring Vibration Polymers PDFHimanshu Sharma100% (1)

- DpkresumeDocumento2 pagineDpkresumearyan77777Nessuna valutazione finora

- List of Industries Booking Effluent Under 20 MLD in Ankleshwar and PanoliDocumento2 pagineList of Industries Booking Effluent Under 20 MLD in Ankleshwar and PanoliSupriyaNessuna valutazione finora

- Pre Feasibility Report For Welspun Iron & Steel Pvt. LimitedDocumento25 paginePre Feasibility Report For Welspun Iron & Steel Pvt. LimitedkalaiNessuna valutazione finora

- Consolidated List of EPC Member Units Yet To Submit Returns OnlineDocumento68 pagineConsolidated List of EPC Member Units Yet To Submit Returns OnlineSanjay BoseNessuna valutazione finora

- Top Bangladeshi companies by categoryDocumento2 pagineTop Bangladeshi companies by categoryTitas KhanNessuna valutazione finora

- 2.mold Tek Packaging Initial (ICICI)Documento14 pagine2.mold Tek Packaging Initial (ICICI)beza manojNessuna valutazione finora

- Crop Residue Management Scheme 2022-23 Empanelled ManufacturersDocumento26 pagineCrop Residue Management Scheme 2022-23 Empanelled ManufacturersAlok Singh DangiNessuna valutazione finora

- Technical Textiles: The Future of TextilesDocumento49 pagineTechnical Textiles: The Future of TextilesGunjan KumarNessuna valutazione finora

- Company Reference List - 2013 PDFDocumento13 pagineCompany Reference List - 2013 PDFMuhamad FajriNessuna valutazione finora

- Nashik District Hazardous Waste Generators DetailsDocumento224 pagineNashik District Hazardous Waste Generators Detailsraj RajputNessuna valutazione finora

- Every Pharmaceutical Company 2008 IndiaDocumento331 pagineEvery Pharmaceutical Company 2008 IndiaDanaNessuna valutazione finora

- Catagory Ame Data PDF FreeDocumento224 pagineCatagory Ame Data PDF FreeRICL Sales ISONessuna valutazione finora

- Ddecor Home Fabrics PVT LTDDocumento14 pagineDdecor Home Fabrics PVT LTDsanthosh0% (1)

- Municipal Solid Waste Management in India With Special Reference To Tirupati Town in Andhra PradeshDocumento4 pagineMunicipal Solid Waste Management in India With Special Reference To Tirupati Town in Andhra PradeshInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Spice BoardDocumento84 pagineSpice BoardsrinivasNessuna valutazione finora

- GIDC Saykha Industrial Estate: Engineering ChemicalsDocumento17 pagineGIDC Saykha Industrial Estate: Engineering ChemicalsjitendraNessuna valutazione finora

- Archean Chemical Industries LTD - Initiating Coverage - 19122023 - FinalDocumento30 pagineArchean Chemical Industries LTD - Initiating Coverage - 19122023 - FinalaccountsNessuna valutazione finora

- CompReg 19NOVEMBER2021Documento2.568 pagineCompReg 19NOVEMBER2021a NaniNessuna valutazione finora

- ClientsDocumento2 pagineClientsK RaushanNessuna valutazione finora

- Ambala CityDocumento48 pagineAmbala Citysandeep DwivediNessuna valutazione finora

- List of Approved Vendors - Wagon Dte ItemsDocumento3 pagineList of Approved Vendors - Wagon Dte ItemsPramodNessuna valutazione finora

- Textile Industry in IndiaDocumento15 pagineTextile Industry in IndiaKannan Krishnamurthy50% (2)

- Cotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingDa EverandCotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingHua WangNessuna valutazione finora

- Fabric Types and CareDocumento58 pagineFabric Types and CareAnissa Manlangit100% (1)

- Biodegradable Textiles, Recycling, and Sustainability AchievementDocumento38 pagineBiodegradable Textiles, Recycling, and Sustainability AchievementSherin ShakerNessuna valutazione finora

- Criteria For Selecting LinenDocumento44 pagineCriteria For Selecting LinenSathiya SarangapaniNessuna valutazione finora

- Ancient Egypt - Flax and LinenDocumento8 pagineAncient Egypt - Flax and LinenMax BergerNessuna valutazione finora

- TextileOutlookInternational Issue 151 PDFDocumento0 pagineTextileOutlookInternational Issue 151 PDFaagrawal3Nessuna valutazione finora

- Womens Set of Viking Winter Clothes BaseDocumento18 pagineWomens Set of Viking Winter Clothes BasePablo Martinez100% (2)

- Grade 9Documento84 pagineGrade 9Noel Angelo BacaniNessuna valutazione finora

- Grade 11 and 12 TVL TOS Second QuarterDocumento2 pagineGrade 11 and 12 TVL TOS Second Quarterᜃᜓᜊᜒᜈ ᜄ᜔ᜈᜀᜌᜀᜐNessuna valutazione finora

- Scientific Details of The Linen Frequency StudyDocumento5 pagineScientific Details of The Linen Frequency Studysmart544689% (9)

- Tecoya Trend 11 January 2021Documento4 pagineTecoya Trend 11 January 2021pankaj1508Nessuna valutazione finora

- TEXPROCIL Member Profiles - VTG 2017 - ENGDocumento10 pagineTEXPROCIL Member Profiles - VTG 2017 - ENGAnkit KaushikNessuna valutazione finora

- Laundry InggrisDocumento18 pagineLaundry InggrisSUMARTANessuna valutazione finora

- Fabric World: (This Definition Was Kindly Provided by Karen At)Documento106 pagineFabric World: (This Definition Was Kindly Provided by Karen At)Vikas SoodNessuna valutazione finora

- Laundry Services Contract FORM NO: - : India International CentreDocumento7 pagineLaundry Services Contract FORM NO: - : India International CentreDebju DasNessuna valutazione finora

- Introduction To TEXTILES - Fibres, Classification, Properties and IdentificationDocumento66 pagineIntroduction To TEXTILES - Fibres, Classification, Properties and IdentificationP. Lakshmanakanth100% (11)

- Indiana Nurse Aide Curriculum Appendix A Procedures 51-72Documento36 pagineIndiana Nurse Aide Curriculum Appendix A Procedures 51-72Tanu BhatiaNessuna valutazione finora

- Fabric Formation ProcessesDocumento14 pagineFabric Formation ProcessesYOghi PRatamadseecxerzNessuna valutazione finora

- Lecture Three Natural Bast FiberDocumento46 pagineLecture Three Natural Bast FiberGemeda GebinoNessuna valutazione finora

- PR Kit Cat 2015 PDFDocumento31 paginePR Kit Cat 2015 PDFDanny DoanNessuna valutazione finora

- San Pedro-Villa Concepcion Elementary SchoolDocumento6 pagineSan Pedro-Villa Concepcion Elementary SchoolDonna Lornne CabutajeNessuna valutazione finora

- Clothing Guide Men Latest Lowres PDFDocumento35 pagineClothing Guide Men Latest Lowres PDFEncarniVergaraNessuna valutazione finora

- Towel Buyers & Importers in UAEDocumento5 pagineTowel Buyers & Importers in UAEmubashir rehmanNessuna valutazione finora

- Grade9 3rd and 4th Quarter PDFDocumento116 pagineGrade9 3rd and 4th Quarter PDFdiana tolopiaNessuna valutazione finora

- As 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksDocumento9 pagineAs 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksSAI Global - APACNessuna valutazione finora

- Procedure in Making An Occupied BedDocumento7 pagineProcedure in Making An Occupied Bedcrrfrnc77% (13)

- Bedmaking and Hospital House KeepingDocumento37 pagineBedmaking and Hospital House KeepingKristine QuindozaNessuna valutazione finora

- Report on Internship Training at S.G GroupDocumento59 pagineReport on Internship Training at S.G GroupNaresh KumarNessuna valutazione finora

- Laundry and Linen Management PracticesDocumento8 pagineLaundry and Linen Management Practicesniraj_sdNessuna valutazione finora

- Prevent Linen MisuseDocumento10 paginePrevent Linen MisuseNishant Kumar100% (1)

- TLE Home Economics: Quarter 1 - Module 4: Project Plan, Materials and Tools For Household LinensDocumento32 pagineTLE Home Economics: Quarter 1 - Module 4: Project Plan, Materials and Tools For Household LinensYna FordNessuna valutazione finora