Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NSH KBR Skop e 009 - Bus Duct Installation and Testing

Caricato da

Francisco Severino Gatoc Jr.Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

NSH KBR Skop e 009 - Bus Duct Installation and Testing

Caricato da

Francisco Severino Gatoc Jr.Copyright:

Formati disponibili

Nasser S.

Al-Hajri Corporation

Kingdom of Saudi Arabia

SK OLEFINS PLANT PROJECT

METHOD STATEMENT

FOR

BUS DUCT INSTALLATION AND TESTING

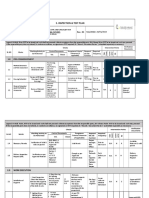

Document No.: NSH-KBR-SKOP-PRO-E-009

Job No.: 6484-GC-021-SC-008 &

Job No.:6484-AB-012-SC-009

A

B

C

D

Code

Approved

Approved W/Comments

Rejected

Cancelled

Status ()

Legend

KBR

Name

Comments:

Signature

Ready for Construction

Use for Construction. Re-Submission Required

Do Not Use for Construction

Not Required

Description

Saudi Kayan

Date

10-Jan-09

For Approval

S. Augustin

Ponraj

Rev.

Date

Reason for

Issue

Prepared By

Name

Signature

Manoj

Sign

Checked

By

Date

D. Harikumar

Sign

Approved

By

Sign

Doc. No.: NSH-KBR-SKOP-PRO-E-009

Rev.: 0, Date : 10thJanuary 2009

SK OLEFINS PLANT PROJECT

METHOD STATEMENT FOR

BUS DUCT INSTALLATION AND TESTING

Page 2 of 7

TABLE OF CONTENTS

1. SCOPE

2. PURPOSE

3. REFERENCE

4. DEFINITION

5. RESPONSIBILITIES

6. TOOLS AND EQUIPMENTS

7. MATERIAL STORAGE, HANDLING & INSPECTION

8. INSTALLATION

9. TESTING

10. SAFETY

11. ATTACHMENT

Doc. No.: NSH-KBR-SKOP-PRO-E-009

Rev.: 0, Date : 10thJanuary 2009

SK OLEFINS PLANT PROJECT

METHOD STATEMENT FOR

BUS DUCT INSTALLATION AND TESTING

Page 3 of 7

1. SCOPE

This construction procedure covers requirements for the Bus duct installation and

testing in Saudi Kayan Olefins Project. This procedure describes installation

techniques and different requirements to be adhere during execution of bus duct

installation and testing work. It intents to co-relate and control all the tasks needed to

be done in order to get a satisfactory results.

2. PURPOSE

The purpose of this procedure is to ensure all the installation and testing shall be

carried out in a neat, efficient and workmanlike manner, assuring satisfactory /

proper operation. The work shall be in accordance with the requirements of the

project specifications, and shall fulfill their true intent and meaning.

3. REFERENCE

IEC

International Electro technical Commission

IEEE

Institute of Electrical and Electronics Engineering

NACE

National Association of Corrosion Engineering

NEMA

National Electrical Manufacturers Association

NEC

National Electrical Code

000-65S-0001

Criteria for electrical system design

000-65S-0002

Electrical codes and standards

000-65S-0057

Specification for site inspection and testing for acceptance of

Electrical Equipment and materials.

SES-E25-S01

Bus Bars and Bus Ducts

SES-Q01-G02

General surface preparation and external painting of equipment

and piping.

4. DEFINITION

SKOP

KBR

NSH

Saudi Kayan Olefins plant

Kellogg Brown & Root Saudi Ltd

Nasser S. Al Hajri Corp.

Doc. No.: NSH-KBR-SKOP-PRO-E-009

Rev.: 0, Date : 10thJanuary 2009

SK OLEFINS PLANT PROJECT

METHOD STATEMENT FOR

BUS DUCT INSTALLATION AND TESTING

Page 4 of 7

5. RESPONSIBILITIES

5.1

Project Manager / Construction Manager

The Project Manager / Construction Manager is responsible for the proper

implementation of this procedure.

5.2

QA/QC Manager

QA/QC Manager is responsible for the implementation of all required quality

control activities and inspection for this particular job.

5.3

QA/QC Engineer

QA/QC Engineer is responsible for the proper carrying out of the inspection

respective to this procedure.

5.4

Electrical Manager

Electrical Manager will be coordinating with concerned personnel at site, plan

the daily work schedule, allocate the job to concerned supervisors, and

controlling the installation works in all the areas.

5.5

Electrical Supervisor

Electrical supervisor is responsible to monitor all day to day field activities,

assuring that implementation is as per this procedure and relevant referenced

standards and as per HSE policy manual.

5.6

Safety Manager / Supervisor

Safety Manager / Supervisor will make sure that all the safety requirements

are fulfilled prior to start of the job. Job Safety Analysis / Safety Task

Assignments will be strictly implemented.

6. TOOLS AND EQUIPMENTS

The following necessary construction equipment / instrument, tools & tackles shall

be used to carry out the installation works.

Fitter Tool box

Drilling Machine

Megger

Multi Meter

Doc. No.: NSH-KBR-SKOP-PRO-E-009

Rev.: 0, Date : 10thJanuary 2009

SK OLEFINS PLANT PROJECT

METHOD STATEMENT FOR

BUS DUCT INSTALLATION AND TESTING

Page 5 of 7

7. MATERIAL STORAGE, HANDLING & INSPECTION

7.1

Upon receipt of the material, it shall be checked with respect to project

specification, approved construction drawings, manufacturer catalogue and

delivery note.

7.2

Visual inspection shall be carried out to check condition and physical damage

of bus ducts.

7.3

Check condition of shipping bracing and crating.

7.4

Check equipment number against single line diagram.

7.5

Check the name plate against online diagram.

7.6

Using supplier drawings, check the entire assembly, including auxiliary

equipment for missing parts.

7.7

Damaged material shall be recorded and reported.

7.8

Availability of all materials and their conformance to standards, specification &

inspection reports shall be checked.

7.9

To ensure that the bus ducts and accessories are stored as per the

manufacturers recommendations.

7.10

When outdoor storage is necessary, elevate well above ground and enclose

with durable, waterproof wrapping.

8. INSTALLATION

8.1

Erect horizontal and vertical supports at the required locations as per lay out

drawings and manufacturers instructions.

8.2

The bus duct is to be erected and routed as per the erection drawings.

8.3

Before installation, elevation of connecting flanges at transformer and

switchgear end shall be checked with respect to bus duct drawings, proper

opening in S/S for bus duct entry shall be done.

8.4

Assembling of all the parts and connections of bus duct shall be made at site.

8.5

Confirm that the bus duct is aligned properly.

8.6

Outdoor enclosures shall have a sloped top that prevents collection of water.

Doc. No.: NSH-KBR-SKOP-PRO-E-009

Rev.: 0, Date : 10thJanuary 2009

SK OLEFINS PLANT PROJECT

METHOD STATEMENT FOR

BUS DUCT INSTALLATION AND TESTING

Page 6 of 7

8.7

The insulators in bus ducts shall be inspected for any possible damage.

8.8

The insulators shall be cleaned with carbon tetrachloride.

8.9

Contact surface of bus bars, bus bar bolts and nuts shall be thoroughly

cleaned and wiped.

8.10

Petroleum jelly shall be applied and bolted connection made.

8.11

Confirm the complete bolting for all bus duct and conductors and also confirm

gasketing and check for the water leakage between the ducts.

8.12

Bolted bus bar connections shall be made with the bolts passing through the

bus bars in a way that they can be properly torqued and locked. Ensure that

the connections are torqued as per the manufacturers instructions.

8.13

Termination at correct point at both ends and proper earthing of bus duct to

be checked.

8.14

The bus duct shall be properly supported between switchgear and

transformer.

8.15

Expansion joints flexible connections etc. of bus duct shall be properly

connected.

8.16

Minimum clearance between phases and neutral / earth to be checked &

ensured.

8.17

Ensure for proper clearance, where visible, between bus bars, and between

bus bars and the enclosure.

8.18

Color coding shall be ensured where applicable.

8.19

Ensure that drain holes are unplugged.

8.20

Before the final box-up it shall be ensured IR value shall be checked.

8.21

The bus duct should be cleaned and ensure that it is free of any foreign

materials inside and then close the bus duct.

8.22

The opening in the wall where the bus duct enters the switchgear room shall

be completely sealed to avoid rainwater entry.

Doc. No.: NSH-KBR-SKOP-PRO-E-009

Rev.: 0, Date : 10thJanuary 2009

SK OLEFINS PLANT PROJECT

METHOD STATEMENT FOR

BUS DUCT INSTALLATION AND TESTING

Page 7 of 7

9. TESTING

9.1

The following tests are to be carried out on the bus duct with in the presence

of vendor representative,

IR Test

HV Test

10. SAFETY

10.1

All safety precautions will be taken care as required as per HSE Plan.

10.2

NSH Safety Supervisor shall carry out the safety site inspections to ensure

that safety requirements laid out in the safe work plan are followed during and

after the installation work. NSH Safety Manager / Supervisor shall review

Safety Action Plan and secure Work Permit if necessary prior to start of any

activities shall be strictly followed as per JSA.

10.3

Equipment, tools and materials inspection for installation works shall be

inspected by NSH Safety Manager / Supervisor prior to forwarding to KBR

Safety Department inspection prior to use at site to ensure their safe

worthiness at work. The inspection Reports shall be kept for record.

11. ATTACHMENT

JSA

******EEnndd******

Potrebbero piacerti anche

- QA/QC Checklist - Installation of MDB Panel BoardsDocumento6 pagineQA/QC Checklist - Installation of MDB Panel Boardsehtesham100% (1)

- Inspection and Test Plan For Switchgear: Before ManufacturingDocumento5 pagineInspection and Test Plan For Switchgear: Before ManufacturingELE FutureWillNessuna valutazione finora

- QC EngineerDocumento4 pagineQC EngineerSajjad AfzalNessuna valutazione finora

- C - Electrical Quality Control Plan - March 2013Documento36 pagineC - Electrical Quality Control Plan - March 2013mkrasanNessuna valutazione finora

- Cable Testing Procedure ElectDocumento5 pagineCable Testing Procedure ElectMohd Hanim Abas100% (1)

- Electrical Method Statement GN 8Documento5 pagineElectrical Method Statement GN 8Chandree BoonzaaierNessuna valutazione finora

- Inspection and Test Plan: Project NameDocumento2 pagineInspection and Test Plan: Project NameehteshamNessuna valutazione finora

- CT Secondary InjectionDocumento2 pagineCT Secondary InjectionHumayun AhsanNessuna valutazione finora

- Itp Electrical CableDocumento2 pagineItp Electrical CablekamlNessuna valutazione finora

- Inspection and Test Plan For Battery Charger PDFDocumento5 pagineInspection and Test Plan For Battery Charger PDFkrit_kasemNessuna valutazione finora

- Cathodic Protection System MMO Grid of Tank Quality Control and Inspection Report FormDocumento5 pagineCathodic Protection System MMO Grid of Tank Quality Control and Inspection Report Formjamal2877Nessuna valutazione finora

- DB ChecklistDocumento4 pagineDB ChecklistJabinNessuna valutazione finora

- Site Acceptance Test Report For MV Panel - J04: MV Switchgear Functional TestsDocumento2 pagineSite Acceptance Test Report For MV Panel - J04: MV Switchgear Functional TestsGajendran SriramNessuna valutazione finora

- Attachment E - UPS Checklist PDFDocumento1 paginaAttachment E - UPS Checklist PDFnandaanujNessuna valutazione finora

- Paint Certificate 80A45-1Documento1 paginaPaint Certificate 80A45-1Shyam_Nair_9667Nessuna valutazione finora

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocumento12 pagine00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNessuna valutazione finora

- Bus Duct Unloading, Shifting, Installing MS 01Documento25 pagineBus Duct Unloading, Shifting, Installing MS 01Sufiyan KhedekarNessuna valutazione finora

- Portacabin Inspection ChecklistDocumento2 paginePortacabin Inspection ChecklistApm FoumilNessuna valutazione finora

- Ooredoo: Method Statement For Fiber Optic Cable WorkDocumento5 pagineOoredoo: Method Statement For Fiber Optic Cable WorkYousaf RichuNessuna valutazione finora

- QCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)Documento15 pagineQCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)arockiyathassNessuna valutazione finora

- Bus DuctDocumento4 pagineBus Ductsardarmkhan100% (1)

- Bus Duct Installation - Method of StatementDocumento13 pagineBus Duct Installation - Method of StatementTalha Altaf100% (1)

- Xyz Company: PurposeDocumento5 pagineXyz Company: PurposeAnonymous 3eHGEDbxNessuna valutazione finora

- 014 - G.I Duct, Accessories and FittingsDocumento14 pagine014 - G.I Duct, Accessories and FittingsJomy JohnyNessuna valutazione finora

- Iwp Cable Tray Installation Checklist: Appendix - 9Documento3 pagineIwp Cable Tray Installation Checklist: Appendix - 9dennykvg0% (1)

- Commissioning Observation and Testing Report: 1. General Project InformationDocumento1 paginaCommissioning Observation and Testing Report: 1. General Project InformationHumaid ShaikhNessuna valutazione finora

- ITP For MV Power Cables & Accessories InstallationDocumento1 paginaITP For MV Power Cables & Accessories InstallationAdil HasanovNessuna valutazione finora

- Instrumentation FormsDocumento7 pagineInstrumentation FormsMark TrussellNessuna valutazione finora

- E14-B LV Switchboard and MCCDocumento3 pagineE14-B LV Switchboard and MCCAmyNessuna valutazione finora

- Itp - Electrical Second FixDocumento4 pagineItp - Electrical Second Fixirfan vpNessuna valutazione finora

- Cable Tray Inst in The Concrete-EnDocumento15 pagineCable Tray Inst in The Concrete-EngkutNessuna valutazione finora

- DTS - DTA Control Sheet 19.01.2017Documento618 pagineDTS - DTA Control Sheet 19.01.2017Shabbir HasanNessuna valutazione finora

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Documento1 paginaKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNessuna valutazione finora

- Example Recommended Spare Parts - DRAFTDocumento5 pagineExample Recommended Spare Parts - DRAFTvoNessuna valutazione finora

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocumento4 paginePurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxNessuna valutazione finora

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Documento4 pagineMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Pump ChlorineDocumento44 paginePump ChlorineAlexandreCaironiNessuna valutazione finora

- QA/QC Responsibilities: InspectionsDocumento1 paginaQA/QC Responsibilities: InspectionsVenkata Suresh MandavaNessuna valutazione finora

- Itr Ew 01a - EngDocumento2 pagineItr Ew 01a - Engwassim nasriNessuna valutazione finora

- TFR CommissioningDocumento24 pagineTFR CommissioningKrishna DNessuna valutazione finora

- Acdb FQPDocumento9 pagineAcdb FQPAnonymous vcadX45TD7Nessuna valutazione finora

- WMS Electrical Working On or Near Exposed Energised Electrical EquipmentDocumento7 pagineWMS Electrical Working On or Near Exposed Energised Electrical EquipmentFresly PatriaNessuna valutazione finora

- Is 818 Code of Practice For Safety and Health For Welding and Gas CuttingDocumento50 pagineIs 818 Code of Practice For Safety and Health For Welding and Gas CuttingPULSEMURALI100% (3)

- FAT ProcedureDocumento1 paginaFAT ProcedureGoyal SanjaiNessuna valutazione finora

- Installation and Operating Manual For Pneumatic Control ValvesDocumento1 paginaInstallation and Operating Manual For Pneumatic Control ValvesFairos ZakariahNessuna valutazione finora

- Method Statement - Polarity TestDocumento5 pagineMethod Statement - Polarity TestKhaled Badawy100% (1)

- Q A P (Qap) - DCCC: Uality Ssurance LANDocumento4 pagineQ A P (Qap) - DCCC: Uality Ssurance LANsasikumarNessuna valutazione finora

- Method Statement For Grounding and Lighting Protection.Documento11 pagineMethod Statement For Grounding and Lighting Protection.Praveen KumarNessuna valutazione finora

- Table of Contents Test RunDocumento52 pagineTable of Contents Test RunTEMIDAYONessuna valutazione finora

- ITP InstrumentationDocumento9 pagineITP InstrumentationzhangyiliNessuna valutazione finora

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocumento3 pagineFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005Nessuna valutazione finora

- KP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksDocumento3 pagineKP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksUtku Can KılıçNessuna valutazione finora

- 12.es-10 Capcitor BankDocumento5 pagine12.es-10 Capcitor BankDEADMANNessuna valutazione finora

- CL-NG-6460-002-020 Checklist For Surge Arrester Rev00Documento2 pagineCL-NG-6460-002-020 Checklist For Surge Arrester Rev00WajahatNessuna valutazione finora

- Insulation Resistance Test FormDocumento1 paginaInsulation Resistance Test FormJohny AdvientoNessuna valutazione finora

- Method Statement For Testing & Commissioning of Central Battery SystemDocumento6 pagineMethod Statement For Testing & Commissioning of Central Battery SystemBabuNessuna valutazione finora

- Electrical Work ProcedureDocumento18 pagineElectrical Work ProcedureWilliam Berrospi Garcia100% (3)

- NSH KBR Skop e 007 - Junction Boxes InstallationDocumento6 pagineNSH KBR Skop e 007 - Junction Boxes InstallationFrancisco Severino Gatoc Jr.Nessuna valutazione finora

- Method Statement TrayDocumento38 pagineMethod Statement Traywaseem kausar100% (1)

- Job Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006Documento11 pagineJob Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006mahesh naikNessuna valutazione finora

- Chapter03 - How To Retrieve Data From A Single TableDocumento35 pagineChapter03 - How To Retrieve Data From A Single TableGML KillNessuna valutazione finora

- Review Questions Financial Accounting and Reporting PART 1Documento3 pagineReview Questions Financial Accounting and Reporting PART 1Claire BarbaNessuna valutazione finora

- Mentorship ICT at A GlanceDocumento5 pagineMentorship ICT at A GlanceTeachers Without Borders0% (1)

- Mutual Fund Insight Nov 2022Documento214 pagineMutual Fund Insight Nov 2022Sonic LabelsNessuna valutazione finora

- ADS Chapter 303 Grants and Cooperative Agreements Non USDocumento81 pagineADS Chapter 303 Grants and Cooperative Agreements Non USMartin JcNessuna valutazione finora

- Singapore Electricity MarketDocumento25 pagineSingapore Electricity MarketTonia GlennNessuna valutazione finora

- Reverse Osmosis ProcessDocumento10 pagineReverse Osmosis ProcessHeshamNessuna valutazione finora

- 11 TR DSU - CarrierDocumento1 pagina11 TR DSU - Carriercalvin.bloodaxe4478100% (1)

- Effective Communication LeaderDocumento4 pagineEffective Communication LeaderAnggun PraditaNessuna valutazione finora

- DevelopmentPermission Handbook T&CPDocumento43 pagineDevelopmentPermission Handbook T&CPShanmukha KattaNessuna valutazione finora

- Marshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianDocumento3 pagineMarshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianValenVidelaNessuna valutazione finora

- Perhitungan Manual Metode Correlated Naïve Bayes Classifier: December 2020Documento6 paginePerhitungan Manual Metode Correlated Naïve Bayes Classifier: December 2020andreas evanNessuna valutazione finora

- LISTA Nascar 2014Documento42 pagineLISTA Nascar 2014osmarxsNessuna valutazione finora

- Brother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDocumento123 pagineBrother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDuplessisNessuna valutazione finora

- Standard Cost EstimatesDocumento12 pagineStandard Cost EstimatesMasroon ẨśầŕNessuna valutazione finora

- Marketing Management - Pgpmi - Class 12Documento44 pagineMarketing Management - Pgpmi - Class 12Sivapriya KrishnanNessuna valutazione finora

- Nasoya FoodsDocumento2 pagineNasoya Foodsanamta100% (1)

- Pharmaceutical Microbiology NewsletterDocumento12 paginePharmaceutical Microbiology NewsletterTim SandleNessuna valutazione finora

- Faida WTP - Control PhilosophyDocumento19 pagineFaida WTP - Control PhilosophyDelshad DuhokiNessuna valutazione finora

- Double Inlet Airfoil Fans - AtzafDocumento52 pagineDouble Inlet Airfoil Fans - AtzafDaniel AlonsoNessuna valutazione finora

- SDM Case AssignmentDocumento15 pagineSDM Case Assignmentcharith sai t 122013601002Nessuna valutazione finora

- Minas-A6 Manu e PDFDocumento560 pagineMinas-A6 Manu e PDFJecson OliveiraNessuna valutazione finora

- Indirect Teaching Strategy??: Name: Topic: Under SupervisionDocumento9 pagineIndirect Teaching Strategy??: Name: Topic: Under SupervisionSeham FouadNessuna valutazione finora

- Enumerator ResumeDocumento1 paginaEnumerator Resumesaid mohamudNessuna valutazione finora

- Midterm Exam StatconDocumento4 pagineMidterm Exam Statconlhemnaval100% (4)

- Oddball NichesDocumento43 pagineOddball NichesRey Fuego100% (1)

- Computer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingDocumento228 pagineComputer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingWilfredo MolinaNessuna valutazione finora

- Appleyard ResúmenDocumento3 pagineAppleyard ResúmenTomás J DCNessuna valutazione finora

- AdvertisingDocumento2 pagineAdvertisingJelena ŽužaNessuna valutazione finora

- Press Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFDocumento6 paginePress Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFJay ShahNessuna valutazione finora