Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Autonext Study Material 1 (Engine) PDF

Caricato da

Abhishek JainDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Autonext Study Material 1 (Engine) PDF

Caricato da

Abhishek JainCopyright:

Formati disponibili

AutoNext

(A UNIT OF ENGINEERS HERITAGE TRUST)

STUDY MATERIAL

ENGINE

Study Material- 1 [Engine]

Page no. 2

STUDY MATERIAL -1

ENGINE

INDEX

CONTENT

PAGE NO

1.

INTRODUCTION

2.

ENGINE CLASSIFICATION

3.

4 STROKE & 2 STROKE ENGINE

11

4.

ENGINE PARTS & COMPONENTS

13

5.

DIESEL ENGINE

15

6.

PETROL ENGINE

18

7.

INTAKE SYSTEM

20

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 3

INTRODUCTION:

Engine is source of power for the car that makes

the car to move. Engine transforms the Chemical

Energy of fuel into thermal energy and uses this

energy to produce mechanical power. This power

is transmitted to the road wheels with the help of

transmission system

ENGINE SIZE

The displacement of all pistons (Area of piston x Stroke length x

Number of Cylinders) measured in cubic centimeters ( C.C).

C.C = D/4 x l x n Cm

Where D = Bore Diameter in centimeter

l = Stroke length in centimeter

n = Number of Cylinders.

BRAKE HORSE POWER (B.H.P)

Brake Horse Power is the unit of measuring power developed by an

engine. It is the actual power delivered at the flywheel of the engine.

B.H.P of the engine depends on it torque and engine speed (R.P.M).

Higher the B.H.P, more is the power of an engine.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 4

TORQUE

Torque = Force x Distance

In engine the torque is equal to force of which the piston moving

down multiplied by the distance from the center of the crank pin to

the centre of the crank shaft.

COMPRESSION RATIO

Compression Ratio compares the volume of air in the cylinder

before Compression with volume of air after compression.

Compression Ratio:

For Petrol Engines, generally, 8 to 10: 1

For Diesel Engines, generally, 17 to 24: 1

TOP DEAD CENTRE (T.D.C)

T.D.C means the piston is at its top most position in the cylinder

bore.

BOTTOM DEAD CENTRE (B.D.C)

B.D.C means the piston is at its bottom position in the cylinder

bore.

VOLUMETRIC EFFICIENCY

It is the volume of air and fuel mixture drawn into the cylinder at

normal atmospheric pressure and temperature to the piston

displacement.

Volumetric efficiency = Volume of Air and fuel Mixture at normal

atmospheric pressure and temperature / Piston Displacement (S.V)

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 5

CLASSIFICATION OF ENGINE

Engines May be Classified according to:

1. Engine Cycle

2. Number of strokes

3. Fuel Used

4. Type of Ignition

5. Number and Arrangement of Cylinders

6. Number and Arrangement of Cylinders

a) Engine Cycle

The two commonly used cycles on which the I.C. engines operate

are:

a) Otto Cycle

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 6

b)

Diesel Cycle

B) Number of strokes:

Automobile engines are classified as 2-Stroke engine or 4-Stroke

engine according to the number of strokes to complete a cycle.

In 2 stroke engine all the events of the cycle are completed in two

strokes of the piston.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 7

In 4 stroke engine all the events of the cycle are completed in four

strokes of the piston.

c) Fuel Used

a)Petrol or Gasoline

b)Diesel engine

c)Hybrid

engine

TYPE OF IGNITION:

a) SI Engine: In this type of engine, ignition takes place by means of an electric

spark provided by a spark plug. Petrol or Gasoline Vehicles are

sparking ignition engines.

b) Compression Ignition Engines: In this type of engines, ignition will take place with help of heat

generated by the compressed air in the cylinder. Diesel and Bio

Diesel vehicles are compression ignition engines.

By - AUTO-NEXT

Website: www.groupautonext.org

Page no. 8

Study Material- 1 [Engine]

d) Number and Arrangement of Cylinders:

a) Classification by Number of cylinders

i) Single cylinder engine

ii)Multi-cylinder engine

b) Classification by Arrangement of cylinders

i. INLINE ENGINE

ii. V-SHAPED ENGINE

iii. OPPOSED ENGINE

IV) RADIAL/ROTARY ENGINE

V-SHAPED

They are arranged in a v-shape

INLINE ENGINE

Arranged in a single line or a row

OPPOSED ENGINE

Are arranged in opposed position(180)

By - AUTO-NEXT

RADIAL ENGINE

Are arranged in radial direction

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 9

e) Valve arrangements:

i.

ii.

iii.

iv.

Over Head Valve (OHV) Engines

F Type (Side Valve) Engine

SOHC (Single Over Head Camshaft) engine

DOHC (Double Over Head Camshaft) engine

OVER HEAD VALVE (OHV)

Both inlet and exhaust valves

are arranged on cylinder

head and operated by a cam

shaft

F TYPE (SIDE VALVE) ENGINE

The inlet valves are arranged on the cylinder head.

The exhaust valves are arranged on the cylinder block.

By - AUTO-NEXT

Website: www.groupautonext.org

Page no. 10

Study Material- 1 [Engine]

SOHC (SINGLE OVER HEAD CAMSHAFT) ENGINE

Both inlet and exhaust

valves are arranged on

cylinder head and are

directly operated by a

single camshaft.

DOHC (DOUBLE OVER HEAD

CAMSHAFT) ENGINE

Both inlet and exhaust valves are

arranged on cylinder head and are

independently operated by

different camshafts.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 11

Working OF four Stroke & two stroke Engine:

4 Stroke Engine:

The four cycles refer to intake, compression, combustion (power), and

exhaust cycles that occur during two crankshaft rotations per power cycle

of the four-cycle engines.

1. INTAKE stroke: the piston descends from the top of the cylinder to the

bottom of the cylinder, reducing the pressure inside the cylinder. A

mixture of fuel and air, or just air in a diesel engine, is forced by

atmospheric (or greater) pressure into the cylinder through the intake

port. The intake valve(s) then close.

2. COMPRESSION stroke: With both intake and exhaust valves closed, the

piston returns to the top of the cylinder compressing the air, or fuel-air

mixture into the combustion chamber of the cylinder head.

3. POWER stroke: While the piston is close to Top Dead Center, the

compressed airfuel mixture in a gasoline engine is ignited, usually by a

By - AUTO-NEXT

Website: www.groupautonext.org

Page no. 12

Study Material- 1 [Engine]

spark plug, or fuel is injected into the diesel engine, which ignites due to

the heat generated in the air during the compression stroke. The

resulting massive pressure from the combustion of the compressed fuelair mixture forces the piston back down toward bottom dead centre.

4. EXHAUST stroke: The piston once again returns to top dead center

while the exhaust valve is open. This action evacuates the burnt products

of combustion from the cylinder by expelling the spent fuel-air mixture out

through the exhaust valve(s).

Two Stroke Engine:

The 2-cycle engine comprises of the two strokes. A two-stroke or 2-cycle

engine is a type of internal combustion engine which completes a power

cycle in only one crankshaft revolution and with two strokes, or up and

down movements, of the piston in comparison to a "four-stroke engine",

which uses four strokes to do so. This is accomplished by the end of the

combustion stroke and the beginning of the compression stroke happening

simultaneously and performing the intake and exhaust (or scavenging)

functions at the same time.

Two-stroke engines often provide high

power-to-weight ratio, usually in a

narrow range of rotational speeds

called the "power band", and,

compared to 4-stroke engines, have a

greatly reduced number of moving

parts.

By - AUTO-NEXT

Website: www.groupautonext.org

Page no. 13

Study Material- 1 [Engine]

Components of Engine:

1. Cylinder Head

2. Cylinder Head Gasket

3. Valve

4. Hydraulic Tappets

5. Camshaft

6. Cylinder Block

7. Piston

8. Piston Rings

9. Crankshaft

10. Connecting Rod

11. Main Bearing

12. Fly wheel

13. Oil Sump /Oil Pan

14. Oil Strainer

15. Oil Pump

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 14

FLYWHEEL

The flywheel is equipped to the transmission side of the crankshaft

to maintain the smooth rotation using inertia force and to reduce the

irregularity of the rotational force. The crankshaft is rotated twice per

one of the combustion. At the other strokes, the reversed directional

force shall be needed for the compression, the intake and exhaust. If

there is no flywheel, then the rotational force of the crankshaft shall

be reduced at these strokes. Therefore, when the intervals of the

each combustion stroke are long like in the idling state, the engine

may be stopped.

SPARK PLUG The spark plug ignites at the

compressed mixture to fire it

according to the spark arc by the

high voltage generated from the

ignition coil.

The spark plug contacts, at first,

with the mixture having the similar

temperature of outer atmosphere in

the intake stroke, After that, it

contacts with the exhaust gas over

2000.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 15

Diesel Engine:

Diesel engines are also known as compression ignition (CI) engines

as these engines do not need an ignition system unlike petrol

engines. The fuel is ignited by the compressed air temperature

developed due to higher compression ratio.

Working of 4 Stroke Diesel Engine:

Intake Stroke (Suction Stroke):

In Diesel engine, air alone is drawn into the cylinder during suction

stroke. During this stroke the piston from T.D.C to B.D.C and the

inlet valve opens and the air is sucked into the cylinder through inlet

valve.

Compression Stroke:

During this stroke the piston moves from B.D.C to T.D.C and the air

in the cylinder

gets compressed. Thus raises the air temperature

between 5000C to 8000C which is0 sufficient to ignite the diesel. The

flash point of the diesel fuel is 340 C.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 16

Power Stroke (Expansion Stroke):

At the end of compression stroke the diesel is sprayed into the

combustion chamber in fine atomized form. It causes explosion and

expansion of gases which in turn forces the piston to move from

T.D.C to B.D.C.

Exhaust Stroke:

During this stroke the piston from B.D.C to T.D.C and the exhaust

valve opens. Due to the upward movement of the piston the burnt

gases are pushed out.

Classification of Diesel Engines:

a)

b)

Direct Injection (D.I)

Indirect Injection (I.D.I)

Direct Injection (D.I)

In direct injection system the diesel

fuel is injected directly into the

combustion chamber which is

formed on the piston head.

The Advantages are

1. The efficiency is high.

2. The emissions are low.

The Dis-advantage is

The sound levels and vibrations

are higher.

By - AUTO-NEXT

Website: www.groupautonext.org

Page no. 17

Study Material- 1 [Engine]

In Direct Injection (IDI)

In this type of engine the Diesel is

injected into a pre-combustion chamber

which is connected to the main

combustion chamber by a narrow

opening. The initial combustion takes

place in this pre-combustion chamber

then spreads to the main combustion

chamber, thus slower the burning

process.

The Advantage is:

Sound levels and vibrations are reduced

The Dis-advantages are

1. Less Power

2. Less Efficiency

3. More Emissions

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 18

Petrol Engine:

Petrol engines are generally known as Spark Ignition (SI) engines as

these engines need an ignition system to provide a spark to ignite

the fuel and air mixture. The whole process is completed in four

stages.

Working of 4 Stroke petrol Engine

Intake Stroke (Suction Stroke):

The piston moves to B.D.C from T.D.C. causing the suction in side

the cylinder and sucks the air / fuel mixture in the cylinder via the

inlet tract. This stroke takes place during 0-1800.of crankshaft

rotation.

Compression Stroke:

The compression stroke is the second of the four strokes of the

cycle. The Piston Moves from B.D.C to T.D.C with both valves

closed. The air / fuel mixture is therefore compressed in the

combustion chamber as the piston moves up. The temperature and

pressure of the charge increases at the end of this stroke. This

stroke takes place during 1800 - 3600 of crank shaft rotation.

Power Stroke (Expansion Stroke ):

The intense heat and pressure generated by igniting the compressed

air/fuel mixture by spark plug in the cylinder causing pressure to increase

rapidly, this pressure forces the piston down towards the B.D.C with both

valves closed. This is the power stroke. This stroke takes place during

3600 - 5400 of crank shaft rotation.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 19

Exhaust Stroke:

The exhaust stroke is the last in the cycle. The piston starts moving from

B.D.C to T.D.C after the power stroke. The inlet valve remains closed

while the exhaust valve opens forces the burnt gases to go out through

the exhaust. This stroke takes place during 5400 7200 of crank shaft

rotation.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 20

INTAKE SYSTEM:

The intake system takes the air to mix with petrol and inhales the mixture

into the cylinder, in the case of petrol engines. In diesel engines air alone

is drawn in to the cylinder.

There are two different kinds of air-intake systems with the diesel engine

as well as with the gasoline-engine:

Naturally aspirated engine: The fresh charge is taken in, immediately

from the outside of the naturally aspirated engine and the exhaust fumes

are removed against the outside condition.

Turbocharging engine: The fresh charge is compressed before it is

taken in to intensify the quantity of charge and thus the power and the

torque.

In intake system, many modifications have taken place to increase the

volumetric efficiency. The volumetric efficiency is used for indicating the

intake ability of the mixture.

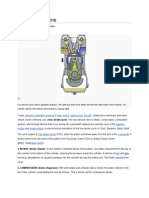

Turbo Charger

The purpose of Turbo charging is to achieve an increased performance

and torque of the combustion engine without increasing the size of the

Engine.

The exhaust driven turbine (exhaust turbine) is mounted on a

common shaft with the intake air compression turbine (intake turbine

or Compressor). So as the exhaust turbine rotates, the power is

transmitted through the shaft to the intake turbine which also

therefore rotates.

By - AUTO-NEXT

Website: www.groupautonext.org

Page no. 21

Study Material- 1 [Engine]

When the vehicle is being driven, exhaust gases are expelled from the

cylinders into a casing at great speed. The exhaust driven turbine is

positioned at the top of this casing to take advantage of this force and to

provide a very fast response time. This turbine can reach speeds of up to

230,000 rpm.

The rotation of the intake turbine draws in air and compresses it

between the vanes of an impeller. It is then thrown by centrifugal force

in to a casing which directs the air to the intercooler, from which it

enters the intake manifold.

By - AUTO-NEXT

Website: www.groupautonext.org

Page no. 22

Study Material- 1 [Engine]

WASTE GATE TURBOCHARGER:

This is a valve in the exhaust-gas tract in front of the turbine blade.

The compressor of the turbocharger is driven by exhaust gasses that

are directed through a turbine. To slow the compressor speed the

exhaust gasses are redirected from the turbine through a port in the

exhaust known as a waste gate.

The waste gate is controlled by a pressure activated piston. When

the intake reaches the desired pressure the piston opens the waste

gate and slows the compressor. This in turn lowers the intake

pressure. To raise turbo boost levels beyond the waste gates preset

level we need a way to not let the waste gate actuator see the actual

boost pressure. In the air supply line from the intake manifold to the

waste gate actuator a bleed valve is installed.

VARIABLE TURBINE GEOMETRY (VGT)

Variable Turbine Geometry technology is

commonly used in turbo diesel engines in

recent years. It is primarily used to reduce

turbo lag at low engine speed, but it is also

used to introduce EGR (Exhaust Gas

Recirulation) to reduce emission in diesel

engines. Here, we concentrate on the

former advantage.

By - AUTO-NEXT

Website: www.groupautonext.org

Study Material- 1 [Engine]

Page no. 23

Ordinary turbochargers cannot escape from turbo lag because at low

engine rpm the exhaust gas flow is not strong enough to push the

turbine quickly. This problem is especially serious to modern diesel

engines, because they tend to use big turbo to compensate for their

lack of efficiency.

A Variable Geometry Turbocharger is capable to alter the direction of

exhaust flow to optimize turbine response. It incorporates many

movable vanes in the turbine housing to guide the exhaust flow

towards the turbine. An actuator can adjust the angle of these vanes,

in turn vary the angle of exhaust flow.

At low rpm :

The vanes are partially closed, reducing the area hence accelerating

the exhaust gas towards the turbine. Moreover, the exhaust flow hits

the turbine blades at right angle. Both makes the turbine spins faster.

By - AUTO-NEXT

Website: www.groupautonext.org

Potrebbero piacerti anche

- Honda GX 390 Tech Manual PDF - 8667353 PDFDocumento7 pagineHonda GX 390 Tech Manual PDF - 8667353 PDFnefrain mucho50% (2)

- Internal Combustion EnginesDocumento14 pagineInternal Combustion EnginesAnonymous 1zFjCuBxNessuna valutazione finora

- Yanmar 6AYM WET DatasheetDocumento2 pagineYanmar 6AYM WET Datasheetafandybaharuddin100% (4)

- Four-Stroke Diesel EngineDocumento12 pagineFour-Stroke Diesel EnginedarioNessuna valutazione finora

- 11.9TDI PD BKC InjectorDocumento2 pagine11.9TDI PD BKC Injectorcork_ie100% (1)

- Daewoo Lanos - Engine ControlDocumento768 pagineDaewoo Lanos - Engine ControlParilla1392% (25)

- Applied Thermal Engineering: Prof. K. K.SHARMADocumento69 pagineApplied Thermal Engineering: Prof. K. K.SHARMAKaran100% (1)

- 4 Petrol EngineDocumento7 pagine4 Petrol Engineayesha amjadNessuna valutazione finora

- 1 - Internal Combustion EngineDocumento6 pagine1 - Internal Combustion EngineCamia Empleo100% (1)

- Internal Combustion Engines Chapter 1. IntroductionDocumento8 pagineInternal Combustion Engines Chapter 1. IntroductionJerry B CruzNessuna valutazione finora

- Applied ThermodynamicsDocumento83 pagineApplied ThermodynamicsKaranNessuna valutazione finora

- IC Engines Unit 4 - TDDocumento43 pagineIC Engines Unit 4 - TDchincha chuNessuna valutazione finora

- Unit-I: TO Ic EnginesDocumento43 pagineUnit-I: TO Ic EnginesLeo Dev WinsNessuna valutazione finora

- Le2 Basic Components and Working PrinciplesDocumento46 pagineLe2 Basic Components and Working Principlessaichandrasekhar_dNessuna valutazione finora

- Applied Thermal EngineeringDocumento83 pagineApplied Thermal Engineeringommech2020Nessuna valutazione finora

- At6311 Ac Lab ManualDocumento78 pagineAt6311 Ac Lab Manualvivek kumarNessuna valutazione finora

- Introduction IC EnginesDocumento8 pagineIntroduction IC EnginesSarmad Altaf Hafiz Altaf HussainNessuna valutazione finora

- Prepared By: Nimesh Gajjar: Construction and Working of I.C. EngineDocumento68 paginePrepared By: Nimesh Gajjar: Construction and Working of I.C. EngineTanpaNamaNessuna valutazione finora

- I C EngineDocumento73 pagineI C EngineHarshit AgarwalNessuna valutazione finora

- 4 Stroke Petrol EngineDocumento11 pagine4 Stroke Petrol EngineAnkit Joshi50% (4)

- IC Engines PPT Lecture No 1Documento33 pagineIC Engines PPT Lecture No 1VishweshRaviShrimali100% (1)

- Thermo Ex.4Documento5 pagineThermo Ex.4Hafeez AliNessuna valutazione finora

- Ic Engine NotesDocumento60 pagineIc Engine Notessamarth motka100% (1)

- EME Notes Unit 1Documento11 pagineEME Notes Unit 1SumanranuNessuna valutazione finora

- Engine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyDocumento61 pagineEngine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyZain Ul AbideenNessuna valutazione finora

- Automative Electronics and Hybrid VehicleDocumento34 pagineAutomative Electronics and Hybrid VehicleNIKHIL ASNessuna valutazione finora

- Unit I (IC Engines)Documento13 pagineUnit I (IC Engines)prasanthiNessuna valutazione finora

- Experiment No: 3: Esme7109/Basic Mechanical Engineering Lab/Btech 1 YearDocumento5 pagineExperiment No: 3: Esme7109/Basic Mechanical Engineering Lab/Btech 1 YearM ChandanNessuna valutazione finora

- 4.internal Combustion EnginesDocumento20 pagine4.internal Combustion Enginesstrategy onesmusNessuna valutazione finora

- Demonstration of Compression and Expansion Process in Engine! Introduction To Internal Combustion Engines!Documento49 pagineDemonstration of Compression and Expansion Process in Engine! Introduction To Internal Combustion Engines!SHANTHARAMAN P PNessuna valutazione finora

- Unit 1 Construction and Operation: External Combustion EngineDocumento14 pagineUnit 1 Construction and Operation: External Combustion Enginekrishna samNessuna valutazione finora

- Maharashtra State Board of Technical Education Certificate: Mechanical Engineering of Marathwada Mitra Mandal'sDocumento16 pagineMaharashtra State Board of Technical Education Certificate: Mechanical Engineering of Marathwada Mitra Mandal's190 208 Rahul DhaneshwarNessuna valutazione finora

- Petrol Engine: Working CyclesDocumento7 paginePetrol Engine: Working CyclesBrijesh Patel100% (1)

- Eme Module IiiDocumento35 pagineEme Module IiiPrashanth JNessuna valutazione finora

- Chap 3Documento57 pagineChap 3jatadharaNessuna valutazione finora

- Module - 3 Internal Combustion Engines and Refrigeration and Air ConditioningDocumento18 pagineModule - 3 Internal Combustion Engines and Refrigeration and Air Conditioninghimanshu malik100% (1)

- Yy Y Yy" Y! Y YyyDocumento14 pagineYy Y Yy" Y! Y YyyVenkatachalam AnnamalaiNessuna valutazione finora

- Engine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyDocumento61 pagineEngine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyMuhammad BilalNessuna valutazione finora

- I C - Engines-NotesDocumento15 pagineI C - Engines-Notessuhas_SCEMNessuna valutazione finora

- Chapter 1 - ICEDocumento51 pagineChapter 1 - ICEsubNessuna valutazione finora

- Diesel EngineDocumento14 pagineDiesel EngineAyşenur ÇetinNessuna valutazione finora

- Basics of EnginesDocumento7 pagineBasics of EnginesMian AsimNessuna valutazione finora

- Unit 3Documento16 pagineUnit 3Shivanand BurliNessuna valutazione finora

- Lecture Notes ON Internal Combustion Engine: Course Code: Me 4101Documento10 pagineLecture Notes ON Internal Combustion Engine: Course Code: Me 4101MahiNessuna valutazione finora

- I C Engine TerminologyDocumento47 pagineI C Engine TerminologyShubham SharmaNessuna valutazione finora

- Hand Made CarDocumento33 pagineHand Made CarSahil DhirNessuna valutazione finora

- Unit 1Documento32 pagineUnit 1Rakeshkumarceg100% (1)

- Mini Project PresentationDocumento24 pagineMini Project PresentationHarshit SharmaNessuna valutazione finora

- Vehicle Design and Characteristics (Sathybama)Documento95 pagineVehicle Design and Characteristics (Sathybama)shaziya mehrinNessuna valutazione finora

- Chapter 02 - Internal Combustion EngineDocumento47 pagineChapter 02 - Internal Combustion EngineYsmael Alongan B. MangorsiNessuna valutazione finora

- Thermal Engineering Laboratory IDocumento44 pagineThermal Engineering Laboratory Iselvakumar3738sNessuna valutazione finora

- IC Engine PPT ch-1Documento73 pagineIC Engine PPT ch-1ashenafi tesfaye100% (1)

- IC Engines GeneralDocumento46 pagineIC Engines Generalirfan khanNessuna valutazione finora

- Ic EnginesDocumento46 pagineIc Enginesranjith kumarNessuna valutazione finora

- I.C. Engines: (I) According To The Type of Fuel UsedDocumento15 pagineI.C. Engines: (I) According To The Type of Fuel UsedSreejith VaneryNessuna valutazione finora

- Four Stroke EngineDocumento8 pagineFour Stroke EngineVamsidhar ReddyNessuna valutazione finora

- Thermodynamics Lab ReportDocumento49 pagineThermodynamics Lab Reportjawad60% (5)

- Otto CycleDocumento16 pagineOtto CycleSwati MadanNessuna valutazione finora

- Assembly Engine DepartmentDocumento6 pagineAssembly Engine Departmentslick shadowNessuna valutazione finora

- Ic EngineDocumento23 pagineIc EngineGanesh kumar100% (1)

- Thermo NotesDocumento18 pagineThermo NotesPavan SharmaNessuna valutazione finora

- Indivual Report ME372Documento10 pagineIndivual Report ME372محمد MqNessuna valutazione finora

- Engine Principles: Topics Covered in ThisDocumento11 pagineEngine Principles: Topics Covered in ThisBogdan PuiaNessuna valutazione finora

- Comparison of Diesel and Petrol EnginesDa EverandComparison of Diesel and Petrol EnginesValutazione: 2.5 su 5 stelle2.5/5 (3)

- Obd 2Documento113 pagineObd 2jorge Angel LopeNessuna valutazione finora

- Engine Ct3-44Tv Spare Parts ManualDocumento57 pagineEngine Ct3-44Tv Spare Parts ManualCircle ChanNessuna valutazione finora

- 1995 KLX650 CarburetorDocumento3 pagine1995 KLX650 CarburetorPedro VegaNessuna valutazione finora

- Massey Ferguson 7465 TRACTOR (TIER 3 Perkins Engine) Service Parts Catalogue Manual (Part Number 3906141)Documento19 pagineMassey Ferguson 7465 TRACTOR (TIER 3 Perkins Engine) Service Parts Catalogue Manual (Part Number 3906141)bvk2980022Nessuna valutazione finora

- Exhaust System: Service and RepairDocumento20 pagineExhaust System: Service and RepairrodolfodiazNessuna valutazione finora

- Combustion in Si and Ci Engines: Lecture NotesDocumento7 pagineCombustion in Si and Ci Engines: Lecture NotesZEDI gamingNessuna valutazione finora

- LRL0096ENG - Land Rover Warranty Code Manual (1997)Documento26 pagineLRL0096ENG - Land Rover Warranty Code Manual (1997)Master XeotoNessuna valutazione finora

- Eco 100 +Documento66 pagineEco 100 +Leidy Viviana Ramírez SánchezNessuna valutazione finora

- 307 2.0 Diesel BoschDocumento3 pagine307 2.0 Diesel BoschStar MotorsNessuna valutazione finora

- Gaso, 1550, Duplex, Piston Pump (Mud Pump) : SpecsDocumento3 pagineGaso, 1550, Duplex, Piston Pump (Mud Pump) : SpecsÆmanuel J SilvaNessuna valutazione finora

- Engine: Service and Repair Removal and InstallationDocumento12 pagineEngine: Service and Repair Removal and InstallationVinnie IngallsNessuna valutazione finora

- Q150 WML 202Documento46 pagineQ150 WML 202manualNessuna valutazione finora

- Datashhet 4012-46tag2aDocumento5 pagineDatashhet 4012-46tag2aacrotech100% (1)

- Catalogo Motor KubotaDocumento16 pagineCatalogo Motor KubotaLilly Novillo100% (1)

- A Carter Thermo-Quad Guide: Contents..Documento31 pagineA Carter Thermo-Quad Guide: Contents..Chris EvrardNessuna valutazione finora

- Chapter (1) Automotive Systems (9 Pages)Documento9 pagineChapter (1) Automotive Systems (9 Pages)Nyi Nay MinNessuna valutazione finora

- Chapter 13 - Camshaft DriveDocumento10 pagineChapter 13 - Camshaft Drivenikolasthermosolutions100% (1)

- Merc 700 Parts CatalogDocumento92 pagineMerc 700 Parts Catalogcolo1evanNessuna valutazione finora

- 3) 20 Interactive Questions On Engine CyclesDocumento72 pagine3) 20 Interactive Questions On Engine CyclesRowan WilsonNessuna valutazione finora

- Spare Parts For Boom Lift/Scissor Lift: Jace Lim 9792 1721Documento11 pagineSpare Parts For Boom Lift/Scissor Lift: Jace Lim 9792 1721Renzo De PisisNessuna valutazione finora

- T25 2013 Catalogue 75dpi PDFDocumento68 pagineT25 2013 Catalogue 75dpi PDFsinyoprimaNessuna valutazione finora

- MiHHT 2655 Heckenschere HomeliteDocumento5 pagineMiHHT 2655 Heckenschere Homelitetihomir maricNessuna valutazione finora

- SAMPLE PROBLEM of Otto CycleDocumento19 pagineSAMPLE PROBLEM of Otto CycleBenedict ReductoNessuna valutazione finora

- 2 CMHDocumento121 pagine2 CMHنهمياسباريراNessuna valutazione finora

- D 0836 RadilicaDocumento12 pagineD 0836 Radilicadzadza2Nessuna valutazione finora