Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Final Repirt ILT Hoshiarpur

Caricato da

Puneet BahriCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Final Repirt ILT Hoshiarpur

Caricato da

Puneet BahriCopyright:

Formati disponibili

1

SANT BABA BHAG SINGH INSTITUTE of ENGINEERING &

TECHNOLOGY

PADHIANA, DISTRICT-JALANDHAR (PUNJAB)

Submitted To:

Mr.Harish Arya

Submitted by:

Puneet Bahri

1168975 Mtech-2011

(Machine Design)

SANT BABA BHAG SINGH INSTITUTE of ENGINEERING &

PADHIANA, DISTRICT-JALANDHAR (PUNJAB)

Department of Mechanical Engineering

FORMAT & GUIDELINES FOR MIDTERM REPORT

TECHNOLOGY

(Size = 20, Times, Bold, Small Caps)

Contents of Midterm Report

(Size = 13, Times)

The midterm report must contain the elements given in the listing below:

1) Cover sheet

2) Title page

3) Abstract 4) Table Of Contents 5) Introduction 6) Title of the project/Assignment 7) Objectives 8)

Schedule of activities

9) Conclusions

10) Achievements till date.

11) Remaining Work.

12) Solution to problems (if any)

GUIDELINES FOR PREPARING MIDTERM REPORT:

1) Students may use descriptive, informative section and subsection titles for the body of midterm report. Use

the appropriate tense to describe the activity: "past work was done;" & "future work will be done."

2) The midterm will include several body sections that include continuing work, so each body section of the

midterm, should be divided into "Work Completed to Date", in which student will describe tasks, analyses,

results and their significance, and Future Work, in which student will describe what remains to be done, how

long they expect the tasks to take, and students plan to overcome anticipated obstacles.

PREFACE

God gives us life to decorate it with knowledge; life

without knowledge is like a river without water

Theoretical knowledge is only an overview whereas

practical knowledge is the actual implementation of the

theoretical knowledge. Practical knowledge is more precious than

theoretical knowledge.

An engineer without technical knowledge is like a soldier without

weapon.

As a part of study our institute (Sliet) introduced a new system of

training for internal students. We have to undergo training for 6 weeks in

a suitable industry. According to our trade to familiar with various

materials process products and applications.

The main purpose of industrial training is to provide the technical

knowledge and insight into various aspects of the industry atmosphere.

The knowledge of various working processes fabrication materials and

looking technology and the day to day trends in the industry.

For industrial training, i prefer Sonalika (ITL) Hoshiarpur because

this is the industry which is contributing in the field of development of

scientifically developed tract

Contents: -

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Introduction

Company profile

Heavy Machine Shop

Light Machine Shop

Gear Shop

Paint Shop

Engine Assembly Shop

Tractors Assembly shop

Quality Control Shop

Testing Shop

INTRODUCTION

Industrial Training is a most important part of study curriculum in Engg. education

field . I am being a student of B.E. in Mech. Engg. at (specialization in welding

technology). at SANT BABA BHAG SINGH INSTITUTION OF ENGINEERING, is

supposed to undergo industrial training for six month in the industry of my field of

interest.

So for the industrial training I have preferred Tractors Industries

because of its bright future. International Tractors Ltd. Vill. Chackgujran is one of

the best firm , which has got ISO 9001 certificate in just two years of its

establishment. The firm has acquired the state of the art technology from Renault

Agriculture Ltd. France with whom they have collaborated. The profits and growth

of company is amazingly superb. In just three years of establishment the company

is ranked in top positions. The Research & Development center of firm is completely

modern with latest technology. The work force of company is highly skilled at the

top level as well as at the floor level. At the same time the fresh graduatesbring in

the fresh ideas.And freshly it tie up with YANMAR COMPANY OF JAPAN makes

powerful tractors in small bodies.

The company is contributing its maximum to agricultural sector of

country in terms of tractor & its implements. The second

unit of company is engaged in making tractor implements which is again have

strong hold in market. And also having multiunit vehicle department is to good and

try to make god hold in the market. So I have preferred to join International

Tractors Ltd. for six month industrial training.

Established in 1969, Sonalika group from the very beginning has tried to

understand customer need so that they get better value for their money, hard earned.

Sonalika has state of manufacturing, spread in acres, located at Hoshiarpur and tax free

zone at AMB in Himachal Pradesh. Sonalika is the one of the top 3 tractor manufacturing

companies in India, other products include of, Multi utility vehicles, engines and various

farm equipments. Today the group stands tall with an approximate turnover of 3200 Core

INR. An average growth of 30% makes it one of the fastest growing corporate in India.

Its is also one of the few debt free companies. Group has strength of about 2000

employee & technocrats. History reveals that innovation is the key to continued progress

and when applied to technology that touches human life, it can unfold a whole new

economic phenomenon that has the power to change the world. With unique initiatives

like the Thought leadership Forum, Leadership Forum, group has been able to create a

unique platform for learning through success stories of industry leaders.

The industry has gradually transformed itself into a world-class player

involved in building state-of-the-art products, solutions and technologies. As an industry,

ITL is very conscious of our responsibility to society. Sonalika Foundation intends to

become a catalyst, encouraging our members to do more, capturing best practices for

quality and harnessing a greater range of resources, from the industry and beyond, to make

a major impact on the development. It has been its vision to cater to the needful agriculture

and auto industry with quality products through untiring dedication and activities. As it

steps in to its fifth decade of existence, we continue to lead the development. Tractor and

car plants work in 2 to 3 shifts depending upon volume of work for maximum production.

Sonalika continues to march ahead on road to success and glory driven by the force of

initiative and determination to have a leading position in the tractor industry in the days to

come. It has ventured in to automobile sector also with the launching of Rhino MUV- to

write another success story.

An Overview of The Group:The success saga of Sonalika Group a business conglomerate having prime interest in

agricultural & auto machinery goes back to nearly 5 decades.

The corporate philosophy embedded in trust, quality and commitment has helped the

group to carve out a niche for itself in the highly competitive world of Machinery.

Sonalika is the fastest growing tractor company registering growth over growth since its

inception has crossed 1.80 lac merely in 10 years & has attained one of the position in top

three in India

THE TOP MANAGEMENT :Chairman

Shri. L.D Mittal

Vice Chairman

Managing Director

Sh. L.D Mittal

Shri A.S Mittal

Shri D.K. Mittal

Sh. A.S Mittal

Sh. D.K Mittal

GROUP COMPANIES:International Tractors Ltd:International Tractors Limited was incorporate on October 17, 1995 for the manufacture

of Tractors and has since then built a distinct position for itself in the Tractor industry.

ITL is manufacturing various Tractors of Sonalika brand between 30 H.P to 90 H.P, and

CLASS brand between 70 hp to 90hp. The tractors manufactured by company have

secured a reputation of performance, quality and reliability in the market because of their

maximum pulling power, minimum fuel consumption and low emission. All this makes

ITL one of the top five tractor selling companies in India. These tractors are also exported

to various countries including South Africa, Australia, Zimbabwe, Sri Lanka, Canada,

Bangladesh, Algeria, Zambia, Senegal, Ghana etc.

ITL has entered into strategic alliance with YANMAR of Japan for joint manufacturing

tractors in India. ITL has a marketing arrangement with TATA International for

development of selected South American and African market. The companys marketing

efforts are promoted by dealer network of 600, and 450 subdealers. Such a networking

has enabled the company to grow like a well-knit family whose roots lie in its customers,

who have providing constant feedback and support to allow the company to turn their

dreams into products.

ITL is also manufacturing tractors, meeting norms of Smoke & Mass Emission, Tested

and certified by ARAI, Pune. United States Environmental Norms Agency, Washington

DC has also certified our Engines. These certifications enabled SONALIKA Tractors to

enter into world Market. All the Models of Tractors and Combines Harvesters

manufactured by us are tested & approved by Central Farm Machinery and Tractors

Training & Testing Institute, Bundi (MP) India, (the Government of India Institute

authorized for issuing test reports).

Tractors from ITL offer the perfect combination of power and economy in the agriculture

utility segment. For fast efficient operation in the rows and a minimum width, which is

typical to small land holdings, the performance of ITL tractors is unparallel. Sonalika

tractors are easy to handle, with outstanding maneuverability, low center of gravity and a

tight turning radius, that combine to give fast and efficient operation in the field or yard.

10

Sonalika also manufacture tractors whose specifications are approved and tested

dimensionally and structurally, according to EEC and other international standard and

homologations. Some of our tractor models offer the most technically advanced features

available on the market today, including hydrostatic transmission, power steering,

differential lock and advanced safety devices.

11

12

Sonalika Group Introduction

Sonalika Group is contributing to green revolution in India Since 1969. Initially it started

with Farm Equipments and Machinery. Brand name of the group products is

"SONALIKA". Market share in Farm Equipments is 80 % in India. Group turnover is 220

Million USD (INR 1000 Crores). Sonalika Group is one of the top five tractor

manufacturers in India. Apart from tractors its product line includes multi utility vehicles,

three wheelers, engines , Hydraulic Systems , Casting , Forging , Brake System ,

Automotive components manufacturing and various farm equipments and implements.

Sonalika group since the inception has tried to understand customers need to be able to

facilitate them with its value for money products. The company has a state of art

manufacturing facilities, spread in acres, located in the pollution free suburbs of Punjab

andHimachalPradesh.

Sonalika is also an environmentally responsible corporate citizen and has developed inhouse, the vehicle engines that confirm to Bharat II Norms. It is now in the process of

developing the Bharat III engines for its advanced products. No wonder Sonalika

products have created a niche for themselves not only in India but also in foreign markets

including France, Zimbabwe and many of the South-Asian countries.

An average growth rate of 30% makes it one of the fastest growing corporate in India. It

also happens to be one of the very few debt free companies in the world. It employs about

2500 people including some of the renowned names in the industry. The company works

on the maxims of low production cost and clean and safe environment. Such efforts have

fetched the company the accreditations like ISO 9001:2000 and ISO 14001.

13

THE COMPANY BACKGROUND

Year

Tractors (Numbers)

1996-1997

396

1997-1998

2770

1998-1999

6211

1999-2000

8773

2000-2001

13496

2001-2002

17002

2002-2003

16464

2003-2004

20020

2004-2005

26082

Sonalika Group started its journey of success during 1976 when foundation of

small-scale unit to fabricate and assemble Wheat Harvesting Machines (Thrashers) was

laid. With the passage of time this small initiative was taken by Mittal brothers in 1976

turned into a great success due to the undulated efforts of its promoters and thousands of

employees who worked unaltered throughout. The great success provided further

motivation ultimately resulting in setting up a new plant in the name of International

14

Tractors Limited for the production of tractors, the demand and requirement of which was

steadily growing at that time. The plant which set up at Chak- Gujran (Hoshiarpur) is now

spread over an area of 65 acres (approx.) The Company's authorized Capital = Rs.56

million (As on 31/03/2001)

Issued, subscribed and Paid up Capital = Rs.50 Million (As on 31/03/2000)

Annual Turnover = Rs.2098 Million approx. (As on 31/03/2003)

Group Turnover The Group Turnover for the Current Fiscal Year is 1000 Crore INR

(Indian Rupees)

Tractors Productions Overview::

Agriculture Machinery Production Overview::

Year

Agriculture Machinery (Numbers)

1996-1997

5000

1997-1998

7500

1998-1999

12000

1999-2000

18000

2000-2001

24000

2001-2002

32000

2002-2003

17820

2003-2004

16090

2004-2005

18040

Group Units::

International Tractors LTD

Sonalika Agriculture Industries

Sonalika Capital Ltd.

Punjab Agriculture Industries

Casting Corporation of India

International Cars & Motors Ltd

International tractor Ltd. was established on 1996 - 1997. Now in JUNE2003,

the production rate of tractor is 60 per day. The total no of employees working in ITL is

15

1200.The total no of dealers of ITL in India & neighboring countries are 548. ITL have

introduced 15 models of tractors. There are 5 regional offices in India, which are at

DELHI, PATNA, AHMEDABAD, MANIPUR and BHOPAL. Turn over of ITL if

400/crore. Company got ISO 9001 Certificate in April 1999 BY ICL. Company is also

running its own agriculture equipment making industries, which is producing thrasher,

disk harrow, wheat harvester etc

MISSION:

International Tractors Ltd. offer quality product with distinctive features at

reasonable price .The company ensure better than the best after sale service for the

satisfaction of the customer .The firm is ranked as best in terms of its quality and

production front. Company is

exporting its tractors to different Asian as well as African

countries.

Following is the list of banks, ITL alliances with:

Canara Bank

ICICI Bank

State Bank of Patiala Andhra Bank

UTI Bank Ltd.

Punjab National Bank

(PNB)

Central Bank of India

Allahabad Bank

(CBI)

State Bank of

Corporation Bank

State Bank of

Union

Bikaner and Jaipur

Bank

of

Indore

India

(SBBJ)

Maharashtra

Oriental Bank of Bank of Punjab

Commerce (OBC) (BOP)

Bank

of

WORK CULTURE:

The I.T.L. Seeks to create a culture where each employee, vendor, and dealer

feels himself responsible and integral part of the enterprises. The work culture at I.T.L.

is open & participative.. Learning is encouraged in the company. Every member

respects 5 F formulas

16

1. Fast

2.

Focused

3. Fair

4.

Friendly.

5. Fun

This governs its approach to business and relationships within the organization.

It has designed its management structure in response to the needs of quick decisionmaking and operational flexibility even through hierarchies and designation does exit. It

is a highly informal organization where communication moves in all direction, decisionmaking is quick and to a large extent delegated.

FUTURE PLANS:

1. to provide superior quality tractors over all world with new technology at

reasonable rates, and to become no. 1 in automobile industry within five years.

2. Itl have plans to market 25,000 tractors during current financial year.

CAREER GROWTH

Sonalika group has grown 127% within a period of 3 years, If one shows good

performance in the assignments given to him there is nothing that can stop him from

developing new skills. The management also believes in imparting training on the job as

well as classroom training for improving / developing the employee in behavioral aspects

& functional /conceptual skills through training. The company believes in developing

human excellence.

ACHIEVEMENTS

17

o Company, which has shown about 127% increase in turnover within a period

of 3 years.

o Company has produced smoke free diesel engine.

o Company has increased its production of diesel engines up to 60 engines a

day.

o The company has obtained iso 9001 certification.

o Sonalika tractors have made rapid strides in indian tractor industry by having

sold 13496 tractors during 2000-2001 achieving over 50% growth vis--vis

industry drop to the tune of 10% as compared to preceding year.

o Itl has a network of around 514 dealers all over india.

OBJECTIVES OF COMPANY

The main objective of the company is to bring the latest technology of high

quality and cost advantage to its consumers. By having a strong r & d with help of its

technological partner renault agriculture, the fully computerization manufacturing facility

ensures a non-stop supply of quality tractors.

Apart from the general objective every departments have their own objectives.

Which are in tune with the main objective of the company? In that sense the main

objective of personnel department is maximum utilization and development of the human

resources available keeping all the aspect of human being in view?

The personnel department of itl, ensures the welfare of the employees at the

maximum level, and keeps morale of the company at high.

CORPORATE MISSION OF THE COMPANY

18

1. To achieve international standards of excellence in all aspects of agriculture and

diversified business with focus on customer delight through value of products and

services and cost reduction.

2. To maximize creation of wealthy value and satisfaction for the shareholders.

3. To attain leadership in developing, adopting and assimilating state of the art

technology for competitive advantage.

4. To provide technology and services through sustained research and development.

5. To faster a culture of participation and innovation for employees growth and

conditions.

6. To cultivate high standards of business ethics and total quality management for a

strong corporate identity and brand quality.

7. To help enrich the quality of life of the community and preserve ecological balance

and heritage through a strong environment conscience.

8. Hence the vision of the company can be described as providing latest technology

advanced tractors to the consumers. Maintaining standards of quality and customers.

Maintaining standards of quality and customers satisfaction. Constantly increasing

profits by achieving higher growth rate. The company had achieved an impressive

over 30% growth rate during last year when the entire industry was reeling under

economic recession.

At present the company has a strong nationwide network of 528 dealers. The distribution

in the various states is:

Andhra pradesh

26

Assam

Bangladesh

Bihar

37

Gujarat

31

19

Haryana

37

Himachal pradesh

Jammu &kashmir

Karnataka

18

Kerala

Madhya pradesh

68

Maharashtra

35

Mizoram

Nepal

Orissa

10

Punjab

48

Rajasthan

53

Tamil naidu

19

Uttar pradesh

131

West bengal

14

This distribution of dealer network has helped the company to provide sales and

services to its customers. The company is catering to the market not only throughout India but

also various other countries like Nepal and sri lanka.

20

Production Of Tractors

Sr. No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Financial year

1996-1997

1997-1998

1998-1999

1999-2000

2000-2001

2001-2002

2002-2003

2003-2004

2004-2005

2005-2006(Till

November)

Production (nos.)

396

2808

6375

6493

13502

16931

16627

19616

26855

16084

21

ORGANISATION CHART

Chairman

(Sh. L.D. Mittal)

Vice Chairman

(Sh. A.S. Mittal)

Managing Director

(Sh. D.K. Mittal)

Departments &

Divisions

TRACTOR R & D

HRD

HMS

EDP

LMS

GEAR SHOP

ENGINE R&D

SECURITY

22

ACCOUNTS

ENGINE ASSEMBLY

QUALITY CONTROL

PURCHASE

TRACTOR ASSEMBLY

MARKETING

STORE

23

INTRODUCTION: The Heavy Machine Shop is one of the most important shops

of the industry. It plays a very important role in the production of the tractor. As the

name suggests all the heavy components namely, the differential housing, the gear box

housing, the crankcase housing, the cage and trumpet are machine here. The shop is

called the backbone of the industry. The Heavy Machine Shop divided into five

sections.

1.

Differential housing line

2.

Gear box housing line

3.

Cage & trumpet line

4.

Crankcase housing line

5.

Tool room

All the sections are highly equipped with modern machinery

and equipment. Each section has a process layout i.e. the raw material is received at

one end and the finished component is dispatched from the other. The material

received is in form of casting. The machining process is carried out under strict quality

24

norms. There is inprocess inspection at each workstation. The component is made to

go through final inspection before it is dispatched for assembly.

The Material handling System in the H.M.S shop consists of

hydraulic lift trucks, power hoists, roller conveyors, overhead crane, fork lift trucks, bins

etc. the shop has well designed network of roller conveyors. The

castings from the truck are loaded onto these conveyors and the material travels to reach

the respective section.

At the end of each conveyor a section for inspection has been

made so as to make the component through the inspection process. Each workstation is

provided with a power hoist of 500Kg (load carrying capacity). These are used to pick

casting from conveyor and load them onto the machine and vice versa. There is also a

provision of a 2-ton carrying capacity overhead crane in each section.

25

MACHINES IN HMS

DIFFERENTIAL HOUSINING LINE

Following are the machines in differential line:

Vertical Milling Centre (VMC 1200) I

Vertical Milling Centre (VMC 1200) - II

Duplex Milling Machine - I

Duplex Milling Machine II

Rough Boring machine

Fine Boring Machine - I

Fine boring machine II

Multiple spindle drilling machine - I

Multiple spindle drilling machine - II

26

Multiple spindle drilling machine III

GEARBOX HOUSING LINE

Following are the machines in the gearbox housing line:

Rough boring Machine

Fine boring m/c (Special purpose machine)

Heavy duty Lathe

CAGE HOUSING LINE

Following are the machines in cage housing line:

Lathe (4 jaw chuck) - Qty. 3

Lathe (Qty. 2)

Grinding Machine

Boring m/c.

27

28

INTRODUCTION: L.M.S. is shop for manufacturing small components of the tractor in Sonalika.

International tractors limited. This is a small shop where light components operations

are performed on the light components of tractors. There are about different types of

machines where different operations are performed on different components for

production work. Main operations performed in L.M.S. are as follows: DRIILING

FACING

TAPPING

TURNING

REAMING

BORING

MILLING

GRINDING

Etc.

Components made in L.M.S. shop are as follows: 1. Response valve housing

2. Relief valve

3. Release valve

4. Piston for relief & release valve

5. Gear shifter lever

6. High Low leaver

29

30

INTRODUCTION:Gear shop is also main shop of International Tractor Ltd. In

gear shop the external as well as internal gears are cut on the components. gears

are cut with hob cutter process, gear shaping with broaching process and

finishing with shaving process. Gears are commanly used to transmit power from

one shaft to another shaft with some reduction or acceleration. Gears are having

great advanantages as compared to belts in terms space and power transmission.

In tractor a power of about 25 to 60 H.P is transmitted with minimum noise and

in a very limted space by gears. The gear shop of S.I.T Ltd. has high precision

instruements to check the gear profile ,lead , run out, and pitch.

Following are the main shafts and gears on which teeth

and and splines are cut in gear shop of sonalika international tractor ltd.

1) B.P left shaft

2) B.P right shaft

31

3) Input shaft

4) Intermediate shaft

5) Lay out shaft

6) Output shaft

7) Gear z-18

8) Gear z-23

9) Gear z-25

10) Gear z-26

11) Gear z-32

12) Gear z-33

13) Gear z-34

14) Gear z-35

15) Gear z-36

16) Gear z-37

17) Gear z-39

18) Gear z-35 (sliding)

19) C.M gear z-47

20) C.M gear z-43 (duel)

21) C.M gear z-45

32

22) Ideal clutch gear

23) Coupling sleeve

24) Sleeve

33

INTRODUCTION: -

Engine can be called as heart of automobile. Engines are used for different purpose The

engine used in INTERNATIONAL TRACTORS is of these types. The engine fitted in

740 DI is made by SYMPSONS, which are exported.The engine in 50 & 60 H.P. are of

two types one is standard model and its design is taken from ZETOR of Check-osolavia

and other is fuel efficient model in which crank case and head design is taken from AVL

(Auto Vehicle Ltd.0 of Austria. Due to better performance of F.E. model engines the

production of standard engines is stopped now.

The engine shop of INTERNATIONAL TRACTOR LTD. Is well furnished

with latest fitting and checking instruments. . The workers in this shop are of high

skill level and have lot of experience. The production of shop is about 80-85 engines

per day and can be increased if required. All the component of engines except

crankcase is brought from outsides. The shop is having latest engine testing shop and

having latest equipment. In testing shop engine is checked for efficiency, specific fuel

consumption power, torque, leakage, rpm and other faults like below from crankcase

The finally tested are sent to the assembly.

34

The assembly of engine is done in stage that is described as below:

STAGE: -1

1. Loading of crankcase and air blowing.

2. CYLINDER LINER FITTING: The liners available in I.T.L.. are of three grades i.e. A, B & C grades. The A

grade liner has dimension of +12 microns, B grade has dimension of +24 microns

and C grade has dimension of +36 microns. The cylinder lining has 2 seats one is for

oil and other is for water. The grade sign of liner should be kept toward camshaft.

3.CRANK SHAFT FITTING: First of all bush type liner are inserted into the bearing holes. The linear is

provided with recess to store a minimum amount of oil, which wets the crankshaft

during starting of engine. The bearing cup is opened and crankshaft assembly is placed

into it. The bearing cup is tightened again with 10-12-kgm torques and crankshaft is

checked, that it is revolving easily.

STAGE: -2

1. TIMING GEAR FITTING: The idler gear shaft is pushed into the crankcase and roller type bearing with

lock is inserted into the shaft. The idler timing gear is then pressed into the bearing.

The timing gear is punched at two places and punched sign has to be matched with the

punched mark on crankshaft.

2. PISTON ASSEMBLY FITTING: The piston assembly is fitted into the linear and big end is tightened to the

crankshaft with 8-10 kgm torque. The pistons are also grade as A, B, C has same that

35

A-grade line is fitted with A-grade piston assembly. the grade mark should be towards

camshaft. The piston ring cuts should be so adjusted that there should not be in same

line.

STAGE: -3

1. LUBRICATING OIL PUMP MOUNTING: The lubrication oil pumps connected to crank shaft gear by an idler gear of 2-3

degree. The crankshaft gear and pump gear are of 22 teeths each. The pump is

provided with a relief valve that opens at 4 kgf forces. In case there is over loading or

some thing injected in main oil gallery then pressure is released from this valve.

2. REAR COVER AND FRONT COVER MOUNTING: The rear cover and front cover are cleaned properly with air and then fitted to

engine with seals in between.

STAGE: -4

1 CAM SHAFT FITTING: The camshaft is inserted into the camshaft hole with be-baring and bolt ends are

locked by circlip. The crankshaft is forged from alloy steel or cast from hardened cast

iron and is case hardened. The tap-pet used on cams is of spherical base and are

slightly wear pattern preve-nting edge loading which is major cause of failure. The one

end of camshaft is provided with gear, which is linked with idler gear Z-50. for exact-ct

timing the camshaft gear mark is matched with mark on ideal gear. Another gear is

attached with idler gear, which serve the purpose of driving the fuel injection pump.

2. PUMP AND FLYWHEEL MOUNTING: -

36

The flywheel is mounted the crankshaft and bolts are tightened with 11-12 kgm

force. The F.I. pump is connected to the F.I.P. gear through the F.I.P. drive shaft. The

F.I.P. drive shaft is special desig-ned to advance the timing of injection. The both ends

of F.I.P. drive shaft is provided with spline on one side a key is provide which is locked

to timing gear and recess on other side is pushed into the the F.I.pump slots. The angle

between the key and recess is of 18 degree. Thus the fuel injection is advanced by 18

degree

STAGE: -5

CYLINDER HEAD MOUNTING: The cylinder head assembly is placed on the piston and studs are passed through

its. If the height of piston at T.D.C. from the surface is more than 0.1mm than the

gaskets of given thickness are used. If it is 0.1mm to 0.5mm than 1.2mm thick gasket

is used If it is 0.5mm to 0.8mm than 1.5mm thick gasket is used. cylinder head nuts are

tightened by 17-18 kgm forces.

STAGE: -6

1 WATER BODY AND PULLEY MOUNTING: 1 .The water body is mounted with thermostat control valve. The valves open at 70

Celsius. Thus engine is kept at correct temperature. The pulley is mounted on

crankshaft.

2 Water return line exhaust flange and inlet manifold mounting.

STAGE: -7

37

To complete the engine removes it from the trolley. Before removing the engine from

trolley the base plate, filters and other accessories are properly tightened. Then the

engine is removed to roller stand.

STAGE: -8

1 Keep the engine on stationary frame.

2 Rocker arm fitting : The rocker arms with spherical followers are inserted into galleries and connected to

the rockers arm. To compensate for thermal expansion the gap between inlet rocker

arm and valve is adjusted to 0.2mm. The gap between exhaust valve and exhaust

rocker arm is 0.25mm.

3 Self-started and dynamo mounting.

4 Fuel injection pump mounting and set fuel injection pump.

The gear of F.I.P. is first of all meshed with the F.I.P. drive shaft (with recess)

and is loosely tightened. To set the timing of gear first of all pointer is tighten on the

crankcase and flywheel is rotated which is mashed for (6, 18, 20 & 24) angles. The

pointer is set at 18 degree of flywheel and then the pump is rotated clockwise till the

oil from first nozzles stop out flowing. At this position a cut mark is made on both the

pump and crankcase for future settings. The pump is tigh-tened properly and pipes are

tightened over nozzles and injectors.Head of engine is covered with covers and

complete engine is send to engine testing shop.

38

ENGINE SPECIFICATION

TYPE

4 CYLINDERS, 4 STROKES

COMBUSTION

DIRECT INJECTION

BORE

100 mm

STROKE

110 mm

CYLINDER DISPLACEMENT

3456 cc

COMPRESSION RATIO

17:1

FIRING ORDER

1-3-4-2

ATOMISING SETTING PRESSURE 205 5 kgf/cm

INJECTING TIMING

25 + 1 B.T.D.C

FUEL INJECTION PUMP

INLINE

GOVERNOR & FLANGE MOUNTED.

INLET VALVE OPENS

TYPE

10 A.T.D.C

TOTAL INLET OPEN PERIOD

TOTAL OUTLET PERIOD

AIR CLEANER

MECHANICAL

26 B.T.D.C

EXHAUST VALVE OPEN

LUB OIL PRESSURE

WITH

236

236

2-5 kgf/cm (2200 RPM AT 80 CELSIUS)

TWO STAGE WITH OIL FILLING

COOLING WATER COOLED WITH THERMOSTAT CONTROL

CAPACITY OF FUEL

FILLING OF OIL SUMP

73 LIT

12 LIT

39

FILLING OF F.I.P.

0.6 LIT (MICO SYSTEM)

CLUTCH DRY, DOUBLE CLUTCH PLATE, ACTUATION, THROUGH

HEAVY DUTY SPRING ENSURING LONGER CLUTCH LIFE AT CONSTANT

OPERATING PRESSURE.

ALTERNATOR

12 V/44 amp

STARTER

12 V/4 H.P.

40

INTRODUCTION: Q.C. shop firstly we are talk about what is the quality control? It

is Systematic control of those variables encountered in a manufacturing process, which

affect the excellence of the product. Such variable result from the Application of material,

men, machine and manufacture-ring conditions only when these variables are regulated to

the extent that they do not detract unit is main shop of sonalika international tractor ltd .In

necessarily from the excellent of the ring-ring process as reflected in the quality of the

finished product, can the control of quality be said to exist. Generally, inspection, which

is the process of sorting good from bad, is the process of sorting good from bad, is

considered as a form of quality control. But quality control and inspect-ion are different.

Conceptually, a Q.C. aim of prevention of defects at the very source relies on effective

held back system and corrective action procedure. Acceptance of material after subjecting

them to in section at inward goods store is inspection concept. Q.C.concept is to take

early step to ensure that the material to be supplied is going to be manufactured to the

plant's requirements. So as to ultimately eliminate the in ward goods inspection.

41

Discovering that the components produced are not as per required dimensional

specifications due to wrong tool or improper settling after the production is over is

inspection concept. To prevent the issue of a wrong tool and to have a set up approval

procedure prior to starting continuous production and keeping a simple check during

production, are Q.C. concepts.

Q.C.uses inspection as a valuable tool. In quality control programmed inspection data are

effectively used to take prompt corrective actions to arrest the incidence of defects in the

job on hand to plan the prevention of occurrence of the same or similar defects in future.

OBJECTIVE OF Q.C.

The main objective of a quality control programmed in sonalika international LTD.

(1)

Evaluation of quality standards of incoming material, product in actual

manufacture, and have out going product.

(2)

Judging the complicity of the process to the established standard and taking

suitable action when deviations are noted.

(3)

Evaluation of optimum quality obtainable under given conditions.

(4)

To improve quality and productivity by process control and experimentation.

42

(5)

Developing procedures for good vender vendee relations.

(6)

Developing quality consciousness both within and outside the organization.

QUALITY CHARACTERISTICS

Following are main quality characteristics for components used

in sonalika international tractor ltd.

(1)

A dimension is a characteristic.

(2)

A chemical properties is a characteristic.

(3)

A sensory properties is a characteristic.

All these characteristics contribute towards the quality of the

product. So we can say that appearance of product is a quality characteristic ices of the

43

product. Similarly performance, length of life, dependability, reliability, durability,

maintainability, fed, sound, etc. are all characteristics is like a building block that goes

in to the construction of say, an arch, which may be considered to be quality.

44

INTRODUCTION:Tractor assembly shop is main shop of sonalika international

tractor Ltd. In this shop the different machining parts, housing and other components

which are finished or machined in other departments of the industry and other

components which are purchased from outside are assembled here. Then assembled

components like differential housing, gearboxes, rear covers, Trumpet housing and other

housing are send to main line for Tractor assembly. In main Tractor assembly line tractors

are send to paint shop through overhead endless chain rotating conveyor. It is supported

from ceiling and has a fixed path to travel which saves valuable floor space. The

arrangement is such that lifting mechanisum (with help of hook) lowers down for loading

and unloading of tractors. Following are main phase of assembly: (1) Differential housing assembly.

(2) Rear cover assembly.

(3) Gear box assembly.

(4) Main line assembly phase.

45

(5) Paint phase.

(6) Assembly of accessories and inspection.

Procedure for Differential Assembly

1. Punch the serial no on differential housing like (EZESY121130/3)

and attach

ball bearing in TP bore and circlip (lock) in PTO bore in differential housing.

2. Load the differential housing on trolley.

3. Fix the PTO shaft in PTO bore and thrust bearing cone 2 nos in BP shaft bore.

4. Fix the left BP shaft with cage assembly and fit it in differential housing. Then fit

right BP shaft with needle bearing in cage assembly and also casting

simultaneously.

5. Fit the TP in TP bore.

6. Take housing hole and fit it in seal carrier then fixes this assembly with shim on BP

shaft and tight it temporary.

7. Then pre loading is done to check the no of shim and bearing setting. Back lash is

also check by applying yellow paint on gear teeth and also check setting of the gear

teeth.

8. Then fix the stud at the holes near the trumpet bore. Then insert gasket and fit the

trumpet assembly then fit the bull gear with lock plate.

9. Tight all the stud and nuts & bolt.

10.Attach PTO shaft and fix front cover on it.

11.Attach brake liner liner 2 nos.

12.Fix Break drum on left and right side with BP shaft. At the same time fit the filter

pipe.

13.Fix the sleeve on PTO shaft and then fix PTO shifter and tight its nut.

14.Attach section pipe and also attach a small pipe on break drum.

15.Dispatch it to next section.

46

Procedure for assemble the Gear box

1. Clean the gear box housing and load it on the working trolley.

2. Fit the bearing and circlip in the casting.

3. Fix the idler cluster with the idler cluster shaft.

4. Fit the input shaft to the gear box housing and lock it with circle.

5. Fix the lay shaft and lock it with check nut and torque it.

6. Fit the intermediate shaft.

7. Fit the shifter rod and shifter fork.

8. Attach the internal gear to the GB housing.

9. Fit the planet carrier assembly to the gear box and insert the output shaft in it

10.Attach the high low shifter fork to the hi low.

11.Fit the inner bush CA guide, CA shaft and CA fork.

12.Mounting hydraulic pump.

13.Suction and delivery plate and tube to the pump.

14.ZF steering assembly to the ZF mounting bracket.

15.Attach gear shifter housing to the gear box.

16.Check all the gear engagement.

17.Final inspection.

47

Rear Cover Assembly Procedure

1. Cleaning and loading the rear cover on the working trolley.

2. Fit the sensor bush to the sensor hole.

3. Fit the stud on the rear end.

4. Fix the breather bolt and cap it with breather cap.

5. Turn the rear cover downward.

6. Place the gasket on the position draft sector on assembly section.

7. Bolt the coupler connection bush with rear cover.

8. Place the ram arm on ram cover housing.

9. Place the rock shaft in the ram arm assembly by light hammering.

10.Place the spacers one by one with mandrel.

11.Fit the lift arm to the rock shaft and bolt at with a retainer plate.

12.Place the connecting shaft ram arm inside the ram cylinder assembly.

13.Bolt the ram cylinder assembly with rear cover.

14.Couple the fork on coupler assembly to control valve and bolt the RV housing.

15.Gauge the position of draft assembly with gauge of 53.5mm.

16.Lock the coupler with lock nut.

17.Turn the rear cover upward and attach the RV housing assembly.

18.Fix the sensor tube on the stud and bolt it.

19.lift the rear cover and place on the testing machine.

20.Check for proper working and maximum lift capacity of the lift.

21.Couple the rear cover with chassis.

48

Tractor assembly procedure

1. Differential housing loading on line.

2. Trumpet assembly mounting.

3. Gear box assembly mounting.

4. Rear cover assembly mounting.

5. Engine assembly mounting.

6. Front axle assembly mounting.

7. Chassis pre-cleaning.

8. Chassis washing.

9. Dry up zone.

10.Primer zone.

11.Final coating.

12.Flash off zone.

13.Paint touch up in flash off zone.

14.Chassis baking.

15.Cooling zone.

16.Fuel tank manufacturing and fuel supply system.

17.Radiator mounting and fan fitment.

18.Electric fitment.

19.Fender mounts.

20.Drive seat fitting.

21.All type of accessories.

22.Rear and front wheel fitting.

23.Bonnet mounting.

24.Diesel and transmission oil filling.

25.Precleaner fitting.

26.Air cleaner mounting.

27.line inspection.

28.Tractor unloading from line.

29.Roller testing.

30.Road testing.

31.Major and minor reworking.

32.Transmission oil filtering.

33.Pre-delivery inspection (PDI).

49

34.Storage shed.

35.Tractor washing and final inspection.

36.Ready for dispatch.

37.Dispatch ramp.

38.Loading on truck or by road dispatch.

39.Out from gate.

50

51

INTRODUCTION:The paint shop is the one of the most modernized shop of

International Tractors Ltd. The out looking and surface finish is of world class

quality. Paint give protection to tractor from corrosion for enhancing the

appearance for a longer period and at the same time it protects the body from

rust. The paint consits of Linseed oil , Pigment (as per requirement of master piece)

and turpentine oil or some other solvent to thin the mixture. Magnesium silicate

is also added to

impart improved resistance to cracking of the paint film. The

drying time hardness and elasticity of paint film depend principaly on the drying

oil, temperature of oven, and the time for which it is kept in the oven. The

present paint shop is giving an excellent

componentsof tractors parts.

coating , production and finishing of

52

PROCEDURE FOR PAINT QUALITY:-

(1)

Even covering of paint should be there on the components. The surface

should be smooth and there should be no unevenness.

(2)

The minimum required thickness of painted surface should be

65 microns.

(3)

The minimum gloss level required is 95%.

(4)

The components should be free from dust particles.

(5)

Minimum allowable dust is 5%of the total painted area.

(6)

The components should be free from dents and other superfical

marks.

(7)

Minimum allowable dents are 1% and these should not be on the face

surface

(8) The painted surface must pass cross batch test 100/100.

(9) The shade should be matching with the master shade (this test will bbe

performed at the time of receiving of paints ,however in doubt the master panel

should be consulted.)

53

54

PROCEDURE FOR TESTING A TRACTOR

S.

No.

1

2

Description

Check the water level

Check the level of water in:

i. Differential

ii.

Air cleaner

iii.

iv.

Steering gear box

Engine sump

v.

3

4

5

6

7

8

9

10

FIP

Wheel alignment

Clutch paddle freely play adjustment

Break paddle freely play adjustment

Check working of all gauges

(Temperature, oil pressure, RPM, Amp

gauge)

Check all electricity system like (Horn,

Battery & Light etc.)

Hydraulic testing:

i.

Lift capacity

ii.

Proper up & down movement

of lift with draft and position

control lever

Leakage for all possible point

a) Gear box check for proper

engagement:

H-1

L-1

R-1

H-2

L-2

R-2

H-3

L-3

H-4

L-4

Observation

Fully filled

Filled between max. and min. on dip

stick

Filled upto marked level

Fully filled

Filled between max. and min. on dip

stick

Fully filled

Toe should be 2.5mm

Should keep 1.75 to 1.00

Should keep 1.75 to 2.00

All are in working condition

All are in working condition

12 Quintals

Very slow

No leakage

Properly working

55

11

12

13

14

b) Check for any abnormal noise in No abnormal noise should be there

each gear

Engine

a) Oil pressure

i. At 725-750rpm (min)

Should >0.5Kg/cm2

ii. At 2150-2200rpm (max)

b) Temperature of water in working

condition

Clutch:

Check for clutch vibration at

725750 rpm

Clutch working (For double

clutch)

i. Half pressing of clutch pedal

ii.

Fully pressing of clutch

pedal

Differential:

a) Check for abnormal noise in

forward running.

i

At engine rpm 1800-2000

ii At engine rpm 725-1000

b) Check for abnormal noise from

the spider kit while left and

right.

c) PTO working

i Live PTO

(For single

clutch)

ii Group PTO (For double

clutch)

Check for belt tension

Should >0.5<4.5Kg/cm2

70-80oC

On pressing the clutch the

transmission drive can be engage and

disengaged.

Transmission and PTO drive stop

(Only in double clutch)

No abnormal noise should be there

Properly working

10mm

56

WORKING INSTRUMENT FOR TRACTOR ROOLING

TESTING SHOP

1. Place the tractor on the roller.

2. Tie up the tractor from rear with hook provide for it.

3. Remove one end of the draw bar and insert the end of the chain weight in it.

4. Remove one end of the draw bar and insert the other end of the chain weight in it.

5. Run tractor for idle rpm for5-7 min.

6. Gradually increases rpm of full throttle for 15min.

7. After this check all the joint and any leakage from hydraulic system.

8. Check shifting of all gears and run them at least 1-2min.

9. Check hydraulic lift working by lift the weight.

10.During running at the idle rpm & full throttle check all electrical equipments

weather they are working properly or not.

11.Unlock all the chain and hook from rear.

12.Hang the weight chains back on their place.

13.Remove the tractor from the rollers and check LH and RH brakes separately on

rear.

Sequence of operation in chassis painting

1. Pre treatment of chassis

a. Degreasing of chassis with chemical solution to remove oil and grease.

b. Misting spry.

c. Water rinse.

2. Water drying

a. The chassis dries in oven at 90oc temp for 10min (During travel.).

3. Primary inspection and surface preparation.

4. Spray booth

a. Primary application.

b. Flash off for 2-3min.

c. Top coat application.

5. flash off zone

a. Flash off for 10min (During travel).

6. Baking

a. Baking of chassis in baking oven at 120oc for 30min during travel.

7. Chassis ready for assembly.

57

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Color Forecasting For FashionDocumento193 pagineColor Forecasting For Fashiongravata_df100% (18)

- Starbucks Case StudyDocumento13 pagineStarbucks Case StudySuchita SuryanarayananNessuna valutazione finora

- 80 REAL TIME SELENIUM Interview Questions and Answers List of Top Selenium Interview Questions and Answers For Freshers Beginners and Experienced PDFDocumento45 pagine80 REAL TIME SELENIUM Interview Questions and Answers List of Top Selenium Interview Questions and Answers For Freshers Beginners and Experienced PDFPuneet Bahri83% (29)

- LS-DYNA Material TableDocumento15 pagineLS-DYNA Material TablePuneet BahriNessuna valutazione finora

- STP Analysis of L'oreal.: Presented By: Shreya Gupta Roll No: 59 Course: MBA Sem 1Documento11 pagineSTP Analysis of L'oreal.: Presented By: Shreya Gupta Roll No: 59 Course: MBA Sem 1shreyaNessuna valutazione finora

- Hot Shoppes Company HIstoryDocumento8 pagineHot Shoppes Company HIstoryStefan Setiadi Tanuwidjaja100% (1)

- AMWAYDocumento21 pagineAMWAYneenu860% (5)

- Qsys Pro: A10 Nios II Hello WorldDocumento28 pagineQsys Pro: A10 Nios II Hello WorldPuneet BahriNessuna valutazione finora

- Serv - Chula.ac - TH Pphongsa Teaching Vibration Ch3Documento95 pagineServ - Chula.ac - TH Pphongsa Teaching Vibration Ch3Puneet BahriNessuna valutazione finora

- Mechanical Vibrations For Engineers AbDocumento219 pagineMechanical Vibrations For Engineers Abshyamsundarsr100% (2)

- Akron 1354739399Documento152 pagineAkron 1354739399Puneet BahriNessuna valutazione finora

- The Numerical Simulation of Foam - An Example of Inter-Industrial SynergyDocumento17 pagineThe Numerical Simulation of Foam - An Example of Inter-Industrial SynergyPuneet BahriNessuna valutazione finora

- Agile1 AnswerDocumento5 pagineAgile1 AnswerPuneet BahriNessuna valutazione finora

- Class - IX (English) The Road Not Taken (Multiple Choice Questions)Documento16 pagineClass - IX (English) The Road Not Taken (Multiple Choice Questions)Puneet BahriNessuna valutazione finora

- Erke Wang-Ansys ContactDocumento42 pagineErke Wang-Ansys ContactanilmaviNessuna valutazione finora

- Design Parameters of Driver Seat in An AutomobileDocumento5 pagineDesign Parameters of Driver Seat in An AutomobilePuneet BahriNessuna valutazione finora

- How Seat Belts Work All About Seat Belts TAKATA All Around You TAKATADocumento3 pagineHow Seat Belts Work All About Seat Belts TAKATA All Around You TAKATAPuneet BahriNessuna valutazione finora

- Mechanical VibrationsDocumento262 pagineMechanical VibrationsPuneet BahriNessuna valutazione finora

- Seat Belts & Child RestraintsDocumento228 pagineSeat Belts & Child RestraintsautocontactNessuna valutazione finora

- MRev High Deck Bus Rollover PDFDocumento54 pagineMRev High Deck Bus Rollover PDFPuneet BahriNessuna valutazione finora

- Erke Wang-Ansys ContactDocumento42 pagineErke Wang-Ansys ContactanilmaviNessuna valutazione finora

- U.S. Department of Transportation: National Highway Traffic Safety AdministrationDocumento31 pagineU.S. Department of Transportation: National Highway Traffic Safety AdministrationPuneet BahriNessuna valutazione finora

- ComputingTechnology 017Documento9 pagineComputingTechnology 017Puneet BahriNessuna valutazione finora

- Guru Nanak Dev Engg College LudhianaDocumento7 pagineGuru Nanak Dev Engg College LudhianaPuneet BahriNessuna valutazione finora

- Simple Vibration Problems With MATLAB (And Some Help From MAPLE)Documento170 pagineSimple Vibration Problems With MATLAB (And Some Help From MAPLE)megustalazorraNessuna valutazione finora

- Guru Nanak Dev Engg College LudhianaDocumento7 pagineGuru Nanak Dev Engg College LudhianaPuneet BahriNessuna valutazione finora

- Result Result Result: True Public Void Throws IfDocumento1 paginaResult Result Result: True Public Void Throws IfPuneet BahriNessuna valutazione finora

- SdofDocumento160 pagineSdofddanielwork2060Nessuna valutazione finora

- Fea of Seat As Per AIS 023 Test RequirementsDocumento8 pagineFea of Seat As Per AIS 023 Test RequirementsPuneet BahriNessuna valutazione finora

- Frequently Asked Questions - Formatting and Publishing An SAE Technical PaperDocumento3 pagineFrequently Asked Questions - Formatting and Publishing An SAE Technical PaperPuneet BahriNessuna valutazione finora

- 03 Borrvall DYNAmoreNordic PDocumento22 pagine03 Borrvall DYNAmoreNordic PPuneet BahriNessuna valutazione finora

- Seatbelt 2 D GuidelineDocumento6 pagineSeatbelt 2 D GuidelinePuneet BahriNessuna valutazione finora

- Haptik Assistant Handbook V1.0Documento7 pagineHaptik Assistant Handbook V1.0Puneet BahriNessuna valutazione finora

- 03 Borrvall DYNAmoreNordic PDocumento22 pagine03 Borrvall DYNAmoreNordic PPuneet BahriNessuna valutazione finora

- Altair PresentationDocumento22 pagineAltair PresentationPuneet BahriNessuna valutazione finora

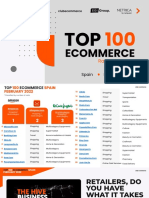

- TOP 100 - February 2022Documento14 pagineTOP 100 - February 2022DavidNessuna valutazione finora

- Emami ReportDocumento43 pagineEmami ReportABHISHEK VERMANessuna valutazione finora

- Sales Order - Training GuideDocumento292 pagineSales Order - Training GuideRamesh BalajiNessuna valutazione finora

- BIR Sample NewsletterDocumento24 pagineBIR Sample NewsletterIzyan NurbaitiNessuna valutazione finora

- Franchising 1Documento49 pagineFranchising 1kyla euniceNessuna valutazione finora

- Ready Made GarmentDocumento5 pagineReady Made GarmentRajeev AttriNessuna valutazione finora

- ObjectivesDocumento3 pagineObjectivesKaneki KenNessuna valutazione finora

- Design For Recyclability Scorecard - MorrisonsDocumento7 pagineDesign For Recyclability Scorecard - MorrisonsMerys BerrioNessuna valutazione finora

- Anna Sui Fashion DesignerDocumento4 pagineAnna Sui Fashion DesignerHarrys Mursid WibowoNessuna valutazione finora

- MT Chains Evolution - AUG'23Documento16 pagineMT Chains Evolution - AUG'23DatThienTuNessuna valutazione finora

- Introduction To KFCDocumento2 pagineIntroduction To KFCJaspreet Tanda100% (2)

- The Food Systems Diagram-1Documento1 paginaThe Food Systems Diagram-1Edlyn ArmeñaNessuna valutazione finora

- E-Commerce and Handicrafts in Bangladesh and India 2018 Final ReportDocumento184 pagineE-Commerce and Handicrafts in Bangladesh and India 2018 Final ReportMukul Bishwas100% (1)

- CCD VS BaristaDocumento11 pagineCCD VS BaristaShibnathRoyNessuna valutazione finora

- Questions and Answers About Lead in Ceramic Tableware: Contra Costa Health Services / Lead Poisoning Prevention ProjectDocumento4 pagineQuestions and Answers About Lead in Ceramic Tableware: Contra Costa Health Services / Lead Poisoning Prevention Projectzorro21072107Nessuna valutazione finora

- Reebok - I Am What I Am. Topic Case Study Presented To Sir LiaquatDocumento25 pagineReebok - I Am What I Am. Topic Case Study Presented To Sir LiaquatQaisar Sardar Khokher89% (9)

- Marketing Project STPDocumento16 pagineMarketing Project STPAniket UpadhyayNessuna valutazione finora

- Food AggregatorsDocumento3 pagineFood AggregatorsAnany UpadhyayNessuna valutazione finora

- 1563470470430iGymZrii86pAaf8p PDFDocumento2 pagine1563470470430iGymZrii86pAaf8p PDFPreeti SinghNessuna valutazione finora

- Marketing Plan of New Product DevelopmentDocumento24 pagineMarketing Plan of New Product DevelopmentShovon BasakNessuna valutazione finora

- 21789497Documento4 pagine21789497Raj ChhedaNessuna valutazione finora

- Santorini Condotel and CondominiumDocumento1 paginaSantorini Condotel and CondominiumDPS1911Nessuna valutazione finora

- Cod1410 3110Documento11 pagineCod1410 3110Tj TalhaNessuna valutazione finora

- Bank Job: AchieDocumento19 pagineBank Job: Achiereza786Nessuna valutazione finora

- Retail Franchising: The Word "Franchise" Is of Anglo-French Derivation - From Franc, Meaning FreeDocumento17 pagineRetail Franchising: The Word "Franchise" Is of Anglo-French Derivation - From Franc, Meaning Freeprabhatrc4235Nessuna valutazione finora