Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Curriculum of Bachelor in Industrial Engineering

Caricato da

Pratikshya DevkotaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Curriculum of Bachelor in Industrial Engineering

Caricato da

Pratikshya DevkotaCopyright:

Formati disponibili

Tribhuvan University, Institute of Engineering, Thapathali campus

Tribhuvan University

Institute of Engineering

Bachelor Degree

in

Industrial Engineering

Four Year Syllabus

Tribhuvan University, Institute of Engineering, Thapathali campus

Table Of Content

S. No.

i

ii

iii

Iv

v

1)

2)

Course Title

Table of Content

First Year I & II Part Specification.

Second Year I & II Part Specification

Third Year I & II Part Specification.

Fourth Year I & II Part Specification.

1.1

First Year First Part

1.1.1

Engineering Mathematics I

1.1.2

Computer Programming

1.1.3

Engineering Drawing I

1.1.4

Engineering Physics

1.1.5

Applied Mechanics

1.1.6

Basic Electrical Engineering

1.2

First Year Second Part Specification

1.2.1

Engineering Mathematics II

1.2.2

Engineering Drawing II

1.2.3

Basic Electronics Engineering

1.2.4

Engineering Chemistry

1.2.5

Fundamental of Thermodynamics And Heat

Transfer

1.2.6

Workshop Technology

2.1

Second Year First Part Specification

2.1.1

Engineering Mathematics III

2.1.2

Fluid Mechanic and Machines

2.1.3

Material Science and metallurgy

2.1.4

Work Study and Ergonomics

2.1.5

Economics

2.1.6

Manufacturing Technology

2.1.7

Computer Aided Drawing

2.1.8

Group Work and Presentation I

2.2

Second Year Second Part Specification

Pages

4

5

6

7

3)

8

9

11

14

16

18

20

22

24

26

29

31

34

35

37

39

41

42

44

46

4)

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.2.8

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.1.7

3.1.8

3.1.9

3.1.10

3.1.11

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.2.8

3.2.9

3.2.10

3.2.11

4.1

4.1.1

Probability & Statistics

Strength of Materials

Heat and Mass Transfer

Production Process and Technology

Electrical Machines

Engineering Economics

Industrial Management

Group Work and Presentation II

Third Year First Part Specification

Energy Power and Technology

Project Management

Numerical Methods

Control System

Metrology and Measurement

Supply Chain Management

Group Work and Presentation

Elective I (Hydraulics and Pneumatics)

Energy Audit and Efficiency

Introduction to Bio-medical engineering

Power Plant Engineering

Third Year Second Part Specification

Entrepreneurship Development

Communication English

Theory of Mechanics

Design of Machine Element

Concurrent Engineering and Value

Engineering

Maintenance Engineering

Elective II (Human Resource Management)

Basic Accounting & Finance course

New Product Development

Marketing Management

Organizational Behavior.

Fourth Year First Part Specification

Operation Research

46

48

50

52

54

57

59

61

61

64

66

68

70

72

75

75

76

78

80

82

84

87

89

91

93

96

97

99

100

101

103

Tribhuvan University, Institute of Engineering, Thapathali campus

4.1.2

4.1.3

Engineering Ethics and Industrial Law

Plant Layout Design and Operation Health

and Safety

4.1.4

Refrigeration, HVAC System Design

4.1.5

Project

4.1.6

Elective III (Automobile)

4.1.7

Renewable Energy System Design.

4.1.8

Principle of Robotics and Modeling

4.1.9

Fundamental of Bio-Technology.

4.1.10

Mechatonics.

4.1.11

Finite Element Analysis.

4.1.12

Elective IV (Quality Control Management)

4.1.13

Environmental Management System.

4.1.14

Production Planning Design and Control.

4.1.15

Lean manufacturing.

4.1.16

Management Information System.

4.1.17

Strategic and Technology Management.

4.2

Fourth Year First Part Specification

4.2.1

Seminar

4.2.2

Industrial Attachment (On The Job Training:

OJT)

Equivalency Certificate of BIIE with BME

104

107

109

111

112

116

118

119

121

123

126

128

129

131

134

135

136

138

138

Tribhuvan University, Institute of Engineering, Thapathali campus

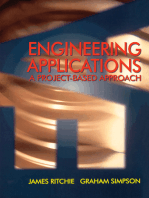

BACHELOR DEGREE IN INDUSTRIAL ENGINEERING

Year : I

Part : I

1

2

3

4

5

6

SH401

CT401

ME401

SH402

CE401

EE401

Engineering Mathematics I

Computer Programming

Engineering Drawing I

Engineering Physics

Applied Mechanics

Basic Electrical Engineering

3

3

1

4

3

3

1

2

1

3

3

2

1.5

Total

5

6

4

7

5

5.5

Total

20

20

80

80

20

20

20

100

80

80

80

400

Total

50

60

20

40

30

25

155

70

100

150

100

150

100

125

725

Year : I

Part : II

1

2

3

4

5

6

SH451

ME451

EX451

SH453

ME452

ME453

Total

3

1

3

3

2

1

1

5

4

5.5

7

20

3

1.5

3

20

20

80

80

60

25

20

1.5

5.5

20

80

25

10

90

320

40

170

Total

Marks

Engineering Mathematics II

Engineering Drawing II

Basic Electronics Engineering

Engineering Chemistry

Fundamental of Thermodynamics And

Heat Transfer

Workshop Technology

Total

Duration

Hours

Assessment

Marks

Marks

Course Title

Examination Scheme

Theory

Practical

Final

Final

Duration

Hours

Course

Code

Assessment

Marks

Teaching Schedule

SN

Remark

Marks

Practical

Final

Duration

Hours

Assessment

Marks

Course Title

Marks

Course

Code

Theory

Final

Duration

Hours

SN

Examination Scheme

Assessment

Marks

Teaching Schedule

80

40

30

100

100

125

150

125

70

50

650

Remark

Tribhuvan University, Institute of Engineering, Thapathali campus

BACHELOR DEGREE IN INDUSTRIAL ENGINEERING

Year : II

Part : I

Engineering Mathematics III

Fluid Mechanic and Machines

Material Science and metallurgy

Work Study and Ergonomics

Economics

Manufacturing Technology

Computer Aided Drawing

Group Work and Presentation I

Total

3

3

3

3

3

3

1

2

1

19

1

1

Total

1.5

1.5

1.5

1.5

3

1

10

5

5.5

4.5

4.5

3

5.5

4

1

33

20

20

20

20

20

20

20

3

3

3

3

3

3

1.5

80

80

80

80

80

80

40

140

19.5

520

Total

100

125

125

125

100

125

100

25

825

25

25

25

25

40

25

165

Year : II

Part : II

3

3

3

3

3

3

3

1

1

1

21

1

1

1

1.5

1.5

3

1.5

1

8.5

Total

4

5.5

5.5

6

5.5

4

4

1

35.5

20

20

20

20

20

20

20

3

3

3

3

3

3

3

80

80

80

80

80

80

80

140

21

560

25

25

25

25

25

125

Total

Remark

Marks

Probability & Statistics

Strength of Materials

Heat and Mass Transfer

Production Process and Technology

Electrical Machines

Engineering Economics

Industrial Management

Group Work and Presentation II

Total

Duration

Hours

Assessment

Marks

SH 552

ME 552

ME 555

IE 552

EE 554

IE 551

IE 553

IE 554

Marks

1

2

3

4

5

6

7

8

Course Title

Examination Scheme

Theory

Practical

Final

Final

Duration

Hours

Course

Code

Assessment

Marks

Teaching Schedule

SN

Remark

Marks

Practical

Final

Duration

Hours

SH 501

IE 503

IE 505

IE 506

IE 501

IE 502

ME 505

IE 504

Assessment

Marks

1

2

3

4

5

6

7

8

Course Title

Marks

Course

Code

Theory

Final

Duration

Hours

SN

Examination Scheme

Assessment

Marks

Teaching Schedule

100

125

125

125

125

100

100

25

825

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

Tribhuvan University, Institute of Engineering, Thapathali campus

BACHELOR DEGREE IN INDUSTRIAL ENGINEERING

Year : III

Part : I

1

2

3

4

5

6

7

8

EE606

IE601

SH603

EE602

IE602

IE603

IE604

IE621

Total

Energy Power and Technology

Project Management

Numerical Methods

Control System

Metrology and Measurement

Supply Chain Management

Group Work and Presentation

Elective I (Hydraulics and Pneumatics)

Total

3

3

3

3

3

3

1

3

22

1

1

1

1

1.5

5.5

4

7

5.5

4.5

4

1

4.5

36

3

1.5

1.5

1

1.5

9

20

20

20

20

20

20

80

80

80

80

80

80

20

140

80

560

Total

25

125

100

125

125

125

100

25

125

850

25

25

25

25

25

150

Year : III

Part : II

Total

1

1

3

2

1.5

3

5

6

5.5

6

3

6

5.5

37

1

3

3

1.5

14

10

20

20

20

20

20

20

130

40

80

80

80

80

80

80

520

25

25

25

50

50

175

Total

Remark

Marks

2

3

3

3

3

3

3

20

Duration

Hours

Entrepreneurship Development

Communication English

Theory of Mechanics

Design of Machine Element

Concurrent Engineering and Value Engineering

Maintenance Engineering

Elective II (Human Resource Management)

Total

Assessment

Marks

IE653

SH651

IE654

IE655

IE651

IE652

IE671

Marks

1

2

3

4

5

6

7

Course Title

Examination Scheme

Theory

Practical

Final

Final

Duration

Hours

Course

Code

Assessment

Marks

Teaching Schedule

SN

Remark

Marks

Practical

Final

Duration

Hours

Assessment

Marks

Course Title

Marks

Course

Code

Theory

Final

Duration

Hours

SN

Examination Scheme

Assessment

Marks

Teaching Schedule

75

125

125

150

100

150

100

825

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

Tribhuvan University, Institute of Engineering, Thapathali campus

BACHELOR DEGREE IN INDUSTRIAL ENGINEERING

Year : IV

Part : I

1 IE701

2 IE702

3 IE703

4 IE704

5

6

7

Duration

Hours

Total

Total

3

3

1.5

4.5

3

20

20

80

80

25

125

100

20

80

50

150

1.5

1.5

5.5

5.5

20

20

80

80

25

25

125

125

20

80

3

3

1

1

18

6

13.5

6

34.5

120

480

100

100

225

75

75

175

900

Year : IV

Part : II

1

2

Total

Seminar

Industrial Attachment (On The Job

Training: OJT)

Total

Total

Remark

Marks

Duration

Hours

Assessment

Marks

Marks

Course Title

Examination Scheme

Theory

Practical

Final

Final

Duration

Hours

Cours

e

Code

Assessment

Marks

Teaching Schedule

SN

Remark

Marks

Operation Research

Engineering Ethics and Industrial Law

Plant Layout Design and Operation

Health and Safety

Refrigeration, HVAC System Design

Elective III (Automobile)

Elective IV (Quality Control

Management)

Project

Total

Assessment

Marks

Marks

Course Title

Examination Scheme

Theory

Practical

Final

Final

Duration

Hours

SN

Cours

e

Code

Assessment

Marks

Teaching Schedule

80

20

100

250

50

300

330

70

400

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

Tribhuvan University, Institute of Engineering, Thapathali campus

ENGINEERNG MATHEMATICS I

SH401

Lecture: 3

Tutorial: 2

Practical: 0

Plane analytic Geometry

(11 Hours)

3.1 Transformation of Coordinates; Translation and Rotation.

3.2 Ellipse and Hyperbola; Standers form; tangent form and

Normal.

3.3 General equation of conic in Cartesian and polar forms.

4.

Ordinary Differential equation and their Application: (12 Hours)

4.1 First order and First Degree differential equation.

4.2 Homogenous differential equations

4.3 Linear differential equation.

4.4 Equations reducible to linear differential equations;

Bernoullis equations.

4.5 First order and High order differential equations; Clairauts

equations.

4.6 Second order and first degree linear differential equation

with constant coefficients.

4.7 Second order and first degree linear differential equation

with variable coefficients; Cauchys equations.

4.8 Application in engineering field.

Year: I

Part: I

Course objective

To provide students a round knowledge of calculus and analytic

geometry to apply in their relevant fields.

Course outline

1. Derivatives and their Applications

(14 Hours)

1.1 Introduction

1.2 Higher order Derivatives

1.3 Mean value theorem

1.3.1 Rolles theorem

1.3.2 Lagranges mean value theorem

1.3.3 Cauchy mean value theorem

1.4 Power series of single valued function

1.4.1 Taylors series

1.4.2 Maclaurims series

1.5 Intermediate forms; L. Hospital Rule

1.6 Asymptotes to Cartesian and polar curves

1.7 Pedal equation to Cartesian and polar curves; curvature

and radius of curvature

2.

3.

Integration and its Application

(11 Hours)

2.1 Introduction

2.2 Definite integrals and their properties

2.3 Improper integrals

2.4 Differentiation under integral sign

2.5 Reduction Formula; Beta Gama function

2.6 Application of integrals for finding areas, arc length, surface

and solid of revolution in the plane for polar curves

References:

1. Erwin Kreyszig; Advance Engineering Mathematics, John Wiley

and Son Inc

2. Thomas, Finney; Calculus and Analytical Geometry, AddisonWesley

3. M. B. Singh, B. C. Bajrachrya; Differential Calculus, Sukunda

Pustak Bhander, Nepal

4. M. B. Singh, S. p. shrestha; Applied Mathematics

5. G. D. Pant, G. S. Shrestha; Integral Calculus and Differential

Equations, Sunila Prakashan, Nepal

6. M. R. Joshi, Analytical Geometry, Sukunda Pustak bhandar,

Nepal

7. S. P. Shrestha, H. D. Chaudhary, P. p. Pokhrael; A Text Book of

Engineering Mathematics- Vol-I

8. Santosh Man Maskey; Calculus, Ratna Pustak Bhander, Nepal

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

Tribhuvan University, Institute of Engineering, Thapathali campus

Evaluation Scheme

The Question will overall the chapter in the syllabus. The evaluation

scheme will be as indicated in table below:

Chapter

Hours

Marks Distribution*

1. Derivatives and

14

25

Their Application

2. Integration and its

11

20

Application

3. Plane and

Analytical

8

15

Geometry

4. Ordinary

Differential

12

20

Equation

Total

45

80

*There could minor distribution on marks distribution.

COMPUTER PROGRAMMING

CT401

Lecture: 3

Tutorial:

Practical : 3

Year: I

Part: I

Course objective

To acquaint the student with computer software and high level

programming languages. Emphasis will be given on developing

computer programming skills using programming in C and FORTAN

language.

1. Overview of software & programming languages.

1.1. System software.

1.2. Application software.

1.3. General software features and recent trends.

1.4. Generation of programming language.

1.5. Categorization of high level languages.

(2 hrs)

2. Problem solving using computer.

2.1. Problem analysis.

2.2. Algorithm development and Flowchart.

2.3. Compilation and Execution.

2.4. Debugging and Testing.

2.5. Programming Documentation.

(2hrs)

3. Introduction to C programming.

3.1. Character set, Keywords and Data types.

3.2. Preprocessor Directives.

3.3. Constants and Variables.

3.4. Operators and statements.

(3 hrs)

4. Input and Output

4.1. Formatted input/output.

4.2. Character input/output.

4.3. Programs using input/output statements.

(2hrs)

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

Tribhuvan University, Institute of Engineering, Thapathali campus

5. Control statements

5.1. Introduction.

5.2. The goto, if, ifelse, switch statements.

5.3. The while, do, while, for statements.

(6hrs)

10.3.

Error handling during input/output operation.

6. User-Defined Functions.

(4hrs)

6.1. Introduction.

6.2. Function definition and return statements.

6.3. Function Prototypes.

6.4. Function invocation, call by value and call by reference,

Recursive Functions.

11. Programming Language: FORTRAN.

(8hrs)

11.1.

Character set.

11.2.

Data types Constants and variables.

11.3.

Arithmetic operations, Library Functions.

11.4.

Structure of a FORTRAN Program.

11.5.

Formatted and Unformatted Input/output Statement.

11.6.

Control Structure: Goto, logical IF, Arithmetic IF, Do

loops

11.7.

Array: one dimensional and two dimensional.

7. Array and Strings.

7.1. Defining and Array.

7.2. One-dimensional Arrays

7.3. Multi-dimensional Arrays

7.4. Strings and Strings manipulation

7.5. Passing Array and Strings to Function.

(6hrs)

Laboratory:

Minimum 6 sets of computer programs in (from unit 4 to unit

10) and 2 set in FORTRAN (from unit 11) should be done

individually. (30 Marks out of 50 marks)

Student (maximum 4 persons in a group) should submit mimi

project at the end of course ( 20 out of 50 marks

8. Structures.

8.1. Introduction.

8.2. Processing a Structure.

8.3. Arrays of Structures.

8.4. Arrays within structures.

8.5. Structures and Function.

(4hrs)

9. Pointers

9.1. Introduction.

9.2. Pointer declaration.

9.3. Pointer arithmetic.

9.4. Pointer and Array.

9.5. Passing Pointers to a Function.

9.6. Pointer and Structures.

(4hrs)

10. Data Files.

10.1.

Defining operating and closing a file.

10.2.

Input/output operation on Files.

(4hrs)

References:

1. Kelly & Phol, A book on C, Benjamin/Cumming.

2. Brian W. Keringhan & Dennis M. Richie, The C Programming

Language PHI

3. Bryons S. Gotterfried, Programming with C, TMH

4. Yashavant Kanetkar, Let Us C, BPB

5. D. M. Etter, Structured Fortran & for Engineers and Scientist,

The Benjamin/Cummings Publishing Company, Inc

6. Rama N. Reddy and Carol A. Ziegler, FORTRAN 77 with

Application for Scientist and Engineers, Jaico Publisging

House.

7. Alexis Leon, Mathews Leon, Fundamentals of Information

Technology, Leon Press and Vikas Publishing Housse.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

10

Tribhuvan University, Institute of Engineering, Thapathali campus

Evaluation Scheme

There will be question covering all the chapters in the syllabus.

The evaluation scheme for the question will be as indicated in the table

below.

Chapter(s)

Hours

Mark Distribution*

1,2

4

8

3,4

5

8

5

6

10

6

4

8

7

6

10

8

4

8

9

4

8

10

4

8

11

8

12

Total

45

80

*There may be minor devotion in marks distribution.

ENGINEERING DRAWING I

ME401

Lecture: 1

Tutorial:

Practical: 3

Year: I

Part: I

Course objective

To develop the basic projection concepts with references to points,

lines, planes and geometrical solids. Also to develop sketching and

drafting skills to facilitate communication.

Course outline

1. Instrumental Drawing, Technical Lettering Practices and

Techniques

(14 Hours)

1.1 Equipments and materials

1.2 Description of drawing instruments, auxiliary equipments

and drawing materials.

1.3 Techniques of instrumental drawings.

1.4 Pencil sharpening, securing paper, proper use of T-squares,

Triangles, scales, Dividers, Compass, Erasing shields, French

Curves, Inking pens.

1.5 Lettering strokes, letter proportions, use of pencils and

pens, uniformity and appearance of letters, freehand

techniques, inclined and vertical letters and numerical,

upper cases and lower cases, standards English lettering

forms.

2. Dimensioning

(2 Hours)

2.1 Fundamentals and Techniques.

2.2 Size and location Dimensioning, SI Conversions.

2.3 Use of scales, Measurement units, Reducing and Enlarge

Drawings.

2.4 Placement of Dimensions: alignment and unidirectional.

3. Applied Geometry

(6 Hours)

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

11

Tribhuvan University, Institute of Engineering, Thapathali campus

3.1 Plane geometrical construction: Proportional division of

lines, arc & line tangents.

3.2 Method for drawing standard curves such as ellipses,

parabolas, hyperbolas, involutes, spirals, cycloids and

helices (Cylindrical and conical)

3.3 Techniques to reduce a given drawing (by construction)

4. Basic Descriptive Geometry

(14 hours)

4.1 Introduction to orthographic projection: Principal planes,

Four Quadrants or Angles.

4.2 Projection of points on first, second, third and fourth

quadrants.

4.3 Projection of lines: Parallel to the one of the principal

plane, inclined to one of the principal plane, parallel to

others and inclined to both principal planes.

4.4 Projection of planes: Perpendicular to both principal planes,

Parallel to one of the principal planes, inclined to one of the

principal planes, perpendicular to others and inclined to

both principal planes.

4.5 True length of lines: Horizontal inclined and oblique lines.

4.6 Rules for parallel and perpendicular lines.

4.7 Point view and end view of lines.

4.8 Shortest distance from a point to a line.

4.9 Edge view and true shape of an oblique lines.

4.10 Angle between two intersecting lines.

4.11 Intersection of a lines and a plane.

4.12 Angle between a line and a plane.

4.13 Dihedral angle between two planes.

4.14 Shortest distance between two skew lines.

4.15 Angle between two non-interesting (skew) lines

.

5. Multi view(orthographic) projections

(18 hours)

5.1 Orthographic Projections.

5.1.1 First and Third angle projection.

5.1.2 Principal views: method for obtaining

orthographic view, projection of lines, angles

and plane surfaces, analysis in three views,

projection of curved lines and surfaces, object

orientation and selection of views for best

representation, full and hidden lines.

5.1.3 Orthographic drawings: making an orthographic

drawing, visualizing objects (pictorial view) from

the given view.

5.1.4 Interpretation of adjacent areas, true-length

lines, representation of holes, conventional

practices.

5.2 Sectional

views:

Full,

Half,

broken,

revolved,

removed(detail) sections, phantom of hidden sections,

Auxiliary sectional views, specifying cutting planes for

sections, convention for hidden lines, holes, ribs, spokes.

5.3 Auxiliary views: Basic concept and uses, drawing methods

and types, symmetrical and unilateral auxiliary views.

Projection of curved lines and boundaries, lines of

intersection between two planes, true sixes of dihedral

angles, true sizes and shapes of plane surface.

6. Development Drawing

(18 Hours)

6.1 Introduction and Projection of solids.

6.2 Developments:

general

concepts

and

practical

considerations, development of right or oblique prism,

cylinder, pyramid and cones, developments of truncated

pyramid and cone, Triangulation method for approximately

developed surface, transition pieces for connecting

different shapes, development of sphere.

6.3 Intersection: Lines of intersection of geometric surface,

piercing point of a line and a geometric solid, intersection

lines of two planes, intersection of prism and pyramids,

cylinder and oblique planes. Constructing a development of

using auxiliary view, intersection of two cylinders, a cylinder

& a cone.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

12

Tribhuvan University, Institute of Engineering, Thapathali campus

Practical: 3 Hours/Week: 15 Weeks:

1. Drawing sheet layout: Free hand lettering, Sketching of parallel

lines, circles, Dimensioning.

2. Applied Geometry (Sketch and Instrumental Drawings).

3. Descriptive Geometry I: Projection of points and lines. (4.1 to 403) (

Sketch and instrumental drawings).

4. Descriptive Geometry II: Projection of Planes (404) (Sketch and

Instrumental Drawings).

5. Descriptive Geometry III: Application in three dimensional Space.

(4.5 and 4.15) (Sketch and Instrumental Drawings).

6. Multi view Drawings (5.1) (Sketch and Instrumental Drawings).

7. Multi view, Sectional Drawing and Dimensioning I (5.2) (Sketch and

Instrumental Drawings).

8. Multi view, Sectional Drawing and Dimensioning II (5.2) (Sketch and

Instrumental Drawings).

9. Auxiliary view, sectional drawing and dimensioning (5.3) (Sketch

and Instrumental Drawings).

10. Projection of regular Geometrical solids. (Sketch and Instrumental

Drawings).

11. Development and intersection I (6.1) (Sketch and Instrumental

Drawings).

12. Development and intersection II (6.2) (Sketch and Instrumental

Drawings).

13. Development and intersection III (6.3) (Sketch and Instrumental

Drawings).

5. :A Text Book of Engineering Drawing P. S. Gill. S. K. Kataria and

Sons, India.

6. A Text Book of Engineering Drawing, R. K. Dhawa, A Chand and

Company limited.

Evaluations Scheme

The Evaluation scheme fir final Examination is indicated as follows:

Chapter(s)

Hours

Mark

Distribution*

3

6

3 to 5

4

14

7 to 10

1,2,5

22

14

6

18

14

Total

60

40

*There may be minor deviation in mark distribution.

References:

1. Fundamental of Engineering Drawing, W. J. Luzadder, Prentice

Hall.

2. Engineering Drawing and Graphic Technology. T.E. French, C.J.

Vierck and R.J Foster, Mc Graw Hill Publishing.

3. Technical Drawing, F.E. Giescke, A. Mitchell, H.C. Specer and J. T.

Dygdone, Macmillan Publishinf Co.

4. Elementry Engineering Drawing, N. D. Bhatt, Charotar Publishing

House, India.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

13

Tribhuvan University, Institute of Engineering, Thapathali campus

ENGINEERING PHYSICS

SH402

Lecture: 4

Laboratories: 1

Tutorial : 2

Year: I

Part: I

Course objective

To provide the concept and knowledge of Physics with the

emphasis of present day application. The background of Physics

corresponding to Proficiency Certificate Level is assumed.

Course outline

1. Oscillation:

(7 hours)

1.1 Mechanical oscillation : Introduction of SHM-Review only.

1.2 Free oscillation: Equation, Energy, Spring mass System,

Physical Pendulum, Bar Pendulum and Torsional Pendulum

1.3 Damp and Force Oscillation: Equation, Resonance, and

Quality Factor.

1.4 EM oscillation: LC oscillation, analogy to SHM; Damped

oscillation; Electromagnetic oscillation in LCR circuit; Forced

oscillation: LCR circuit, resonance, Quality Factor.

2. Wave Motion:

(2 hours)

2.1 Wave and particles; wave velocity; particles acceleration;

Type of waves.

2.2 Progressive wave: equation; differential equation.

2.3 Energy, Power and intensity of plane progressive wave.

3. Acoustics:

(3 hours)

3.1 Reverberation; absorption coefficient;

3.2 Sabins Law; condition for good acoustics.

3.3 Ultrasonic: Introduction; production; application; test of

structure and materials; medical uses.

4. Physical Optics:

(12 hours)

4.1 Interference: Introduction coherence; mathematical

analysis; Youngs double slit experiments; Intensity in

double slit interference; interference in thin film and

wedges; Newtons ring; Haidinger fringes.

4.2 Diffraction: Introduction; Fresnel and Fraunhoffers

diffraction; diffraction and intensity due to a single slit;

diffraction grating: introduction, dispersive and resolving;

X-ray diffraction: use of X-ray in material testing.

4.3 Polarization: introduction, double refraction, ordinary and

extraordinary ray; Nichol prism; quarter and half wave

plates; plane, elliptical and optical activity: specific rotationmeasurements and uses.

5. Geometrical Optics:

(3 hours)

5.1 Lenses: Review of rotation through lenses; combination of

two lenses separated by a finite distance.

5.2 Cardinal points: definition with suitable diagram.

5.3 Chromatic aberration: definition, longitudinal chromatic

aberration, circle of least confusion achromatism.

6. Laser and Fiber Optics:

(4 hours)

6.1 Laser: laser and ordinary light; spontaneous and stimulated

emission; optical pumping; He-Ne laser; Semiconductor

Laser; Use of laser; Holography.

6.2 Fiber Optics: Introduction; Propagation of light wave; Type

of optical fiber-step and graded index; fiber transmissionsingle and multimode; self focusing; acceptance angle;

Numerical Aperture; fiber loss; dispersion; application.

7. Electrostatics:

(8 hours)

7.1 Electric charge; Electric force

7.2 Electric field and potential; dipole, quaderpole, line, ring

and disc; Electrostatic potential energy.

7.3 Gauss law its uses in dielectric sphere.

7.4 Capacitor: Parallel plate, cylindrical and spherical; energy

density; capacitor with dielectric: dielectrics and Gauss law.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

14

Tribhuvan University, Institute of Engineering, Thapathali campus

7.5 Charging and discharging of capacitor; high intensity

electrostatic fields; use and hazards.

8. Electromagnetism:

(11 hours)

8.1 Direct Current:

8.1.1 Electric current and current density, microscope

view of Ohms law, resistance and resistivity.

8.1.2 Semiconductor and Superconductor.

8.2 Magnetic Field:

8.2.1 Magnetic flux, magnetic force and torque, Hall

Effect, cyclotron, synchrotron

Magnetic field: Biot Savart law; magnetic field

due to a current in a circular loop,

Amperes law: magnetic field inside and inside a

long straight wire carrying a current;

electromagnetic induction; Faradays law:

Induction and Energy transformation; induced

electric field; self and mutual induction; LR

circuit; energy stored in a magnetic field;

energy density of a magnetic field; induced

magnetic field; displacement current.

9. Electromagnetic Wave:

(5 hours)

9.1 Maxwells equation (differential and integral form); wave

equation in free apace; non conducting and conducting

medium; speed and amplitude of electromagnetic wave; E

and B field; continuity equation; Energy transfer and

pointing vector; radiation pressure.

10. Photon and matter wave:

(5 hours)

10.1 Quantization of Energy: Photon-group velocity and

phase velocity; electrons and matter waves; Schrodinger

wave equation; probability distribution; one dimensional

potential well; wave function and its significance;

uncertainty principle and application; barrier tunneling.

References:

1. Fundamentals of Physics: Halliday, Resnick, Walker (Laatest

Edition)

2. A Text Book of Optics: Brij Lal and Subrahmanyam (Latest

Edition)

3. Modern Enfineering physics: A. S. Basudeva (Latest Edition)

4. Engineering Physics: Gaur and S. L. Gupta (Latest Edition)

5. Wave and Oscillation: Brij Lal and Subrahmanyam (Latest

Edition)

Evaluation Scheme

Unit

Hours

7

No. of

Question

2

Marks

Distribution*

10

Mechanical and

Electromagnetic

Oscillation

Wave motion and

Acoustics

Physical Optics

Geometrical

Optics

Laser and Fiber

Optics

Electrostatics and

Electromagnetism

12

3/4

15

19

6/8

30

Theoretical

Numerical

Electromagnetic

5

1

5

Wave

Photon and

5

1

5

Matter Wave

Total

60

16

80

8

*There could minor distribution on marks distribution

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

15

Tribhuvan University, Institute of Engineering, Thapathali campus

APPLIED MECHANICS

CE401

Lecture: 3

Tutorial: 2

Practical :

Year: I

Part: I

Course objective

This Course is designed to provide basic knowledge of

engineering mechanics to the students of all branches of engineering so

that it would be helpful for them to understand structural engineering

stress analysis principles in later course or to use basics of mechanics in

their branch of engineering. This course shall be considered as as an

introduction: common for all engineering faculties of Tribhuvan

University in the first year of undergraduate. Emphasis has been given

to Statics.

Course outline

1. Introduction:

(2 Hours)

1.1 Definition and Scope of Applied Mechanics.

1.2 Concept of Rigid and Deformed bodies.

1.3 Fundamental concept and principle of mechanics:

Newtonian Mechanics.

2. Basic concept in Statics and Static Equilibrium:

(4 Hours)

2.1 Concept of Particles and Free Body Diagram.

2.2 Physical meaning of Equilibrium and its essence in

structural application.

2.3 Equation of Equilibrium in two dimensions.

3. Force acting on particles and rigid body:

(6 Hours)

3.1 Different type of force: points surface traction and Body

force Translational force and rotational force: Relevant

Examples.

3.2 Resolution and Composition of force: Relevant examples.

3.3 Principles of Transmissibility and Equivalent force:

equivalent force: Relevant Examples.

3.4 Moments and couples: Relevant examples.

3.5 Resolution of force into forces and a couple: Relevant

Examples.

3.6 Resultant of force and moment for a system of force:

Examples.

4. Centre of Gravity, Centroid and Moment of Inertia:

(6 Hours)

4.1 Concepts and calculation of Centre of Gravity and Centroid:

Examples.

4.2 Calculation of Second Moment of Area/Moment of Inertia

and Radius of Gyration: and Relevant usages.

4.3 Use of parallel axis Theorem: relevant examples.

5. Friction:

(2 Hours)

5.1 Laws of friction, Static and dynamic coefficient of friction,

Angle of friction: Engineering example of usage of friction.

5.2 Calculation involving friction in structure: Examples as high

Tension Friction Grip bolts and its free body diagram.

6. Analysis of beam and Frames:

(9 Hours)

6.1 Introduction to structures: Discrete and continuum.

6.2 Concept of load estimating and support Idealization:

Examples and Standard Symbols.

6.3 Use of beams/frames in engineering: Concept of rigid

joints/distribute loads in beams/frames.

6.4 Concept of statically/kinematic ally Determinate and

indeterminate Beams and Frames: Relevant Examples.

6.5 Calculation of axial force, Shear force and bending moment

for Determinate beams and Frames.

6.6 Axial force, Shear force and Bending moment diagram and

Examples for drawing it.

7. Analysis of Plane trusses:

(4 Hours )

7.1 Use of trusses in engineering: Discrete and Continuum.

7.2 Calculation of member of force of Truss by method of

joints: Simple examples.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

16

Tribhuvan University, Institute of Engineering, Thapathali campus

7.3 Calculation of member of force of truss by method of

sections: Simple examples.

8. Kinematics of Particles and Rigid Body:

(7Hours)

8.1 Rectilinear kinematics: Continuous Motion.

8.2 Position, Velocity and Acceleration of a particle and Rigid

body.

8.3 Determination of motion of particle and rigid body.

8.4 Uniform rectilinear motion of particles.

8.5 Uniformly Accelerated Rectilinear motion of particles.

8.6 Curvilinear motion: Rectilinear components with Examples

of Particles.

9. Kinetics of Particles and Rigid Body: Forces and Acceleration:

(5 Hours)

9.1 Newtons second law of motion and momentum.

9.2 Equation of motion and Dynamic equilibrium: Relevant

Examples.

9.3 Angular momentum and Rate of Change.

9.4 Equation of motion-Rectilinear and Curvilinear.

9.5 Rectilinear: Tangential and Normal Components and polar

Coordinates: Radial and Transverse Components.

Tutorials:

There shall be related tutorials exercised in class and given as regular

homework exercises. Tutorial can be as following for each specified

chapters.

1. Introduction

A. Theory; Definition and Concept type questions.

2. Basic concept in Statics and Static Equilibrium.

A. Theory; Definition and Concept type questions.

3. Concept of Force acting Structure & force acting on particles and

rigid body.

A. Practical examples: numerical examples, practical example type

questions.

4.

5.

6.

7.

8.

9.

B. There can be tutorials for each sub-section.

Centre of Gravity, Centroid and Moment of Inertia.

A. Concept type, numerical examples and practical examples type

questions.

Friction.

A. Definition type, practical example type and numerical example

type questions.

Analysis of beam and Frames.

A. Concept type, definition type, numerical example type

questions.

B. There can be tutorial for each sub-sections.

Analysis of Plane trusses.

A. Definition type, numerical example type questions.

B. There can be tutorial for each sub-sections

Kinematics of Particles and Rigid Body.

A. Concept type, definition type, numerical example type

questions.

B. There can be tutorial for each sub-sections.

Kinetics of Particles and Rigid Body: Forces and Acceleration.

A. Concept type, definition type, numerical example type

questions.

B. There can be tutorial for each sub-sections.

References:

1. Mechanics of Engineering- Statics and Dynamics, F. P. Beer

and E. R. Johnston. Jr. 4th Edition, Mc Graw Hill, 1987.

2. Engineering Mechanics- Statics and Dynamics, R.C. Hibbeler,

Ashok Gupta. 11th Eidtion, New Delhi, Pearson , 2009.

3. Engineering Mechanics- Statics and Dynamics, I.C. Jong and

B.G. Rogers.

4. Engineering Mechanics- Statics and Dynamics, D. K. Anand

and P. F. Cunnif.

5. A Text Book Of Engineering Mechanics, R. S. khurmi.

6. Applied Mechanics and strength of materials, R.S.Khurmi.

7. A Text Book of Applied Mechanics, I.B Prasad.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

17

Tribhuvan University, Institute of Engineering, Thapathali campus

8. Engineering Mechanics- Statics and Dynamic, Shame, I.H 3rd,

New Delhi Prentice Hall of india, 1990.

The question covers all the chapters in the syllabus. The Evaluation

scheme will be indicated below:

Chapter

Hours

Mark

Distribution*

3

8

Introduction:

2

Basic concept in Statics and Static

4

Equilibrium

Force acting on particles and rigid body

6

12

Centre of Gravity, Centroid and Moment of

6

12

Inertia

Friction

2

4

Analysis of beam and Frames

9

13

Analysis of Plane trusses

4

8

Kinematics of Particles and Rigid Body

7

10

Kinetics of Particles and Rigid Body: Forces

5

10

and Acceleration

Total

45

80

*There may be minor deviation on mark distribution.

BASIC ELECTRICAL ENGINEERING

EE401

Lecture: 3

Tutorial: 1

Practical : 1.5

Year: I

Part: I

Course objective

After completing this course the student will be understand the

fundamental concept of DC, AC, & 3-phase electrical circuits.

Course outline

1. General Electrical System:

(6 hours)

1.1 Constituents part of an electrical system (source, load,

communication & control)

1.2 Current flow in a circuit

1.3 Electromotive force and potential difference.

1.4 Electrical units

1.5 Ohms law

1.6 Resistors, Resistivity

1.7 Temperature rise & Temperature coefficient of Resistance

1.8 Voltage & current source.

2. DC circuits:

2.1 Series circuits

2.2 Parallel Networks

2.3 Krichhofs laws

2.4 Power and Energy

(4 hours)

3. Network Theorems:

(12 hours)

3.1 Application of krichhofs law in network solution.

3.1.1 Nodal analysis.

3.1.2 Mesh analysis

3.2 Star-Delta &Delta-Star transformation.

3.3 Superposition theorem.

3.4 Thevninn;s theorem.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

18

Tribhuvan University, Institute of Engineering, Thapathali campus

3.5 Nortans Theorem.

3.6 Maximum power transfer theorem.

3.7 Reciprocity theorem.

4. Inductance & Capacitance in electric circuit:

(4 Hours).

4.1 General concept of capacitance

4.1.1 Charge & Voltage.

4.1.2 Capacitance in Series and Parallel

4.2 General concept of Inductance

4.2.1 Inductive and Non-Inductive circuit

4.2.2 Inductance in series and parallel.

5. Alternating Quantities:

(2 Hours)

5.1 AC system.

5.2 Wave form, terms and definitions.

5.3 Average and rms values of current & voltage.

5.4 Phasor representation

6. Single Phase AC circuits:

(16 Hours)

6.1 AC in Resistive circuits

6.2 Current & Voltage in an inductive circuits

6.3 Current and voltage in an capacitive circuits

6.4 Concept of complex impedance and admittance.

6.5 Ac series and parallel circuit.

6.6 RL, RC and RLC circuit analysis & phasor representations.

7. Power in AC circuits:

(4 Hours)

7.1 Power in resistive circuits.

7.2 Power in inductive and capacitive circuits.

7.3 Power in circuit with resistive and reactance

7.4 Active and Reactive power.

7.5 Power factor, its practical importance.

7.6 Improvement of power factor.

7.7 Measurement of power in a single-phase AC circuit.

8.2 Phasor representation of star and delta connections.

8.3 Phase and line quantities.

8.4 Voltage and current computation in three phase balance

and unbalance circuit.

8.5 Real and reactive power consumption.

8.6 Measurement of power & power factor in 3-phase system.

Laboratory works:

1. Measurement of voltage, current and power in DC circuit.

Verification Ohms law. Temperature effects in resistance.

2. Kirchhoffs Voltage and current law. Evaluate power from V & I.

Note Loading Effect of Meter.

3. Measurement amplitude, Frequency and time with oscilloscope.

Calculate and verify average and rms value. Examine phase relation

in RL & RC circuit.

4. Measurement of Alternationg Quantities, R, RL, RC circuit with AC

Excitation, AC power, power factor, VARs, Phasor diagram.

5. Three-phase AC circuit, Measure currents and voltage in threephase balanced AC circuits, Prove Y-D transformation, Exerciese on

phasor diagram for three-phase circuit.

6. Measurement of current, Voltage and Power in a R, RL, and Rc

three-phase circuit Watt ratio curve.

Reference:

1. J. R. Cogdell, Foundations of Electrical Engineering printic hall,

Englewood Chiffs, New Jersy, 1990

2. I. M. Smith Haughes Electrical Technology Addision-Wesly, ISR

Reprint 2000

8. Three-phase circuit analysis:

(6 hours)

8.1 Basic concept and advantage of three phase circuit

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

19

Tribhuvan University, Institute of Engineering, Thapathali campus

Evaluation Scheme

Chapter

Hours

Marks Distribution*

General Electrical System

6

10

DC Circuit

4

5

Network Theorem

12

25

Inductance and Capacitance in

4

5

electric circuit

Alternating Quantities

2

15

Single phase AC circuit

6

Power in AC circuits

4

10

Three phase circuit analysis

6

10

Total

44

80

*There could minor distribution on marks distribution.

***

ENGINEERING MATEMATICS II

SH451

Lecture: 3

Tutorial: 2

Year: I

Part: II

Course Objective:

i) To develop the skill of solving differential equations and to

provide knowledge of algebra and calculus.

ii) To make students familiar with calculus of several variables

and infinites series

1. Calculus of two or more variables.

(6Hrs)

1.1. Introduction: Limit and continuity.

1.2. Partial derivatives

1.2.1.Homogenous function, Eulers theorem for the function of

two and three variables.

1.2.2.Total derivatives

1.3. Extrema of function of two and three variables: Lagranges

Multiplier.

2. Multiples Integrals.

(6Hrs)

2.1. Introduction

2.2. Double integrals in Cartesian and polar form; change of order of

integration.

2.3. Tripal integrals in Cartesian, cylindrical and spherical

coordinates.

2.4. Area and volume using double and triple integrals.

3. Three dimensional Solid Geometry.

3.1. The straight line; Symmetric and general form

3.2. Coplanar Lines

3.3. Shortest distance

3.4. Sphere

3.5. Plane section of a sphere by planes

3.6. Tangent planes and lines to the spheres

(11Hrs)

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

20

Tribhuvan University, Institute of Engineering, Thapathali campus

3.7. Right circular cone.

3.8. Right circular cylinder.

Evaluation Scheme:

4. Solution of Differential Equation in Series and Special Function.

(9Hrs)

4.1. Solution of differential equation by power series method.

4.2. Legendres equation.

4.3. Legendres polynomial functions; Properties and applications.

4.4. Bessels equations.

4.5. Bessels function of first and second kinds; properties and

applications.

5. Vector algebra and Calculus

5.1. Introduction

5.2. Two and three dimensional vectors

5.3. Scalar product and Vector product.

5.4. Reciprocal system of vectors

5.5. Application of vectors: Lines and planes.

5.6. Scalar and vector fields

5.7. Derivatives- Velocity and Acceleration.

5.8. Directional derivatives.

6. Infinite Series.

6.1. Introduction

6.2. Series with positive term.

6.3. Convergence and divergence.

6.4. Alternative series. Absolute convergence

6.5. Radius and interval of convergence.

S.No.

1

2

3

4

5

6

Chapter

Hour

Mark Distribution*

1

6

10

2

6

10

3

11

20

4

9

15

5

8

15

6

5

10

Total

60

80

*There could minor distribution on marks distribution.

(8Hrs)

(5Hrs)

References:

1. Erwin Kreysizig, Advanced Engineering Mathematics, John Wiley

and Sons Inc.

2. Thomas, Finney, Calculus and Analytical Geometry Addison- Wesly.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

21

Tribhuvan University, Institute of Engineering, Thapathali campus

ENGINEERING DRAWING II

ME451

Lecture: 1

Tutorial:

Practical: 3

Year: I

Part: II

Course objective

To make familiar with the conventional practice of sectional views. To

develop the basic concept and skill of pictorial drawing and working

drawings. Also to make familiar with standard symbols of different

engineering fields.

Course outline

1. Conventional practice for Orthographic and Sectional views.

(12 Hours)

1.1 Conventional practice in orthographic views: Half and

Partial view, Treatment of Unimportant Intersections,

Aligned views, Treatment for Radially Arranged Features,

Representation of Fillets and Rounds.

1.2 Conventional Practice in Sectional views: Convention for

ribs, Web and spokes in sectional view, broken section,

removed section, revolved section, offset section, phantohi

section and Auxiliary sectional views.

1.3 Simplified representation of standard Machine Elements.

2. Pictorial Drawings

(20 Hours)

2.1 Classification: Advantage and Disadvantages.

2.2 Axonometric Projection: Isometric Projection and Isometric

Drawings.

2.2.1 Procedure for making an isometric Drawing.

2.2.2 Isometric and Non-Isometric Lines, Isometric

and Non-Isometric Surfaces.

2.2.3 Angles in Isometric Drawings.

2.2.4 Circles and Circular Arcs in Isometric Drawings.

2.2.5 Irregular Curves in Isometric Drawings.

2.2.6 Isometric Sectional Views.

2.3 Oblique Projection and Oblique Drawings.

2.3.1 Procedure for making oblique drawings.

2.3.2 Rules for placing objects in oblique drawings

2.3.3 Angles, Circles and Circular Arcs in oblique

drawings.

2.4 Prospective Projection.

2.4.1 Terms used in prospective projection.

2.4.2 Parallel and Angular prospective.

2.4.3 Selection of station points.

3. Familiarization with Different Components and Conventions:

(8 Hours)

3.1 Limit Dimensioning and Machining Symbols.

3.1.1 Limit Fit and Tolerances.

3.1.2 Machining Symbols and Surface Finish.

3.2 Threads, Bolts and Nuts.

3.2.1 Thread terms Nomenclature, Forms of Screw

Threads.

3.2.2 Detailed and simplified Representation of

Internal and External Threads.

3.2.3 Thread Dimensioning.

3.2.4 Standard Bolts and Nuts: Hexagonal Head and

Square Head.

3.2.5 Conventional symbol for Bolts and Nuts.

3.3 Wildings and Riveting.

3.3.1 Types of welded joints and Types of weld,

Welding symbols.

3.3.2 Forms and Proportions for Rivet Heads, Rivet

symbols, Types of Riveted Joints: Lap Joints,

Butt Joints.

3.4 Familiarization with Graphical Symbol and conventions in

Different Engineering Fields.

3.4.1 Standard symbols for civil, structural and

Agricultural Components.

3.4.2 Standard symbols for Electrical, Mechanical and

Industrial Components.

3.4.3 Standard

symbols

for

Electronics,

Communications and Computer Components.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

22

Tribhuvan University, Institute of Engineering, Thapathali campus

3.4.4 Topographical symbols.

3.5 Standard piping symbols and piping Drawings.

4. Detailed and Assembly Drawings:

(20 Hours)

4.1 Introduction to Working Drawing.

4.2 Component of working drawings: Drawing layout, Bill of

Material, Drawing Numbers.

4.3 Detailed Drawings.

4.4 Assembly Drawings.

4.5 Practice of assembly and Details drawings: V-block Clamp,

Centering cone, Couplings, Bearings, Ant vibrating Mounts,

Stuffing Boxes, Screw Jacks etc.

References:

1. Fundamental of Engineering Drawing W. J. Luzadder, Prentice

Hall. 11th edition.

2. engineering Drawing and Graphic Technology, T.E. French, C.J.

Vierik, and R.J. Foster, Mc Graw Hill Publisher C. 1992.

3. Technical Drawing, F.E Giescke, A. Mitchellam, H.C. Spenser and

J.T. Dygdone, Macmillan Publishing Co. 10th Edition.

4. Machine Drawing N.D. Bhatt, Charotar Publishing House India,

1991.

5. Machine Drawing, P.S. Gill, S.K.Katria and Son, India, 7th edition,

2008

6. Machine Drawing, R.K. Dhawan, S. chand and Company limited,

India, 1992.

Practical: 3 hours/week

1. Conventional Practice for Orthographic and sectional views (Full

and Half sections)

2. Conventional Practice for Orthographic and sectional views (Other

type sections)

3. Isometric Drawings.

4. Isometric Drawings. (Consisting of Curves and Sections)

5. Oblique drawings.

6. Familiarization with Graphical Symbols. (Limit, Fit, Tolerances and

Surface roughness symbols)

7. Familiarization with Graphical Symbols. (Symbol for different

engineering Fields)

8. Detailed drawings.

9. Assembly drawings I.

10. Assembly drawings II.

11. Building Drawings.

Evaluation Scheme

The evaluation scheme for the final examination is indicated bellows:

Chapter

Hours

Mark Distribution*

1

12

6 to 8

2

20

13 to 15

3

8

5

4

20

13 to 15

Total

60

40

*There may be minor deviation in mark distribution

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

23

Tribhuvan University, Institute of Engineering, Thapathali campus

BASIC ELECTRONICS ENGINEERING

EX451

Lecture: 3

Tutorial: 1

Practical: 1.5

Year: I

Part: II

Course objective:

1. To understand the language of electronics, electrons and their

functionality.

2. Basic understand of analog systems and their applications.

3. Basic understand of digital systems and their applications

Course outline

1. Basic Circuit concepts:

(Hours)

1.1 passive components; Resistance, Inductance, Capacitance,

series, parallel combinations, Kirchhoffs law: voltage,

current linearity.

1.2 Signal source: Voltage and current source; nonideal source;

representation under assumption of linearity; control

source: VCVS, CCVS, VCCS, CCCS: concept of gain, transconductance, trans-impedance.

1.3 Superposition theorem: Thevenins theorem: Norton's

theorem.

1.4 Introduction to filter.

2. Diodes:

(Hpurs)

2.1 Semiconductor diode characteristics.

2.2 Modeling the semiconductor diodes.

2.3 Diode circuits: clipper: clamper circuits.

2.4 Zender diode, LED, photodiode, varacter diode, Tunnel

diodes.

2.5 DC power supply rectifier-half wave, fall wave(centre

tapped, bridge), Zender regulated power supply.

3. Transistor:

3.1 BIT configuration and basing small and large signal model.

3.2 T and model.

3.3 Concept of differential amplifier using BJT.

3.4 BJT as switch and logic circuits.

3.5 Construction and working principle of MOSFET and CMOS.

3.6 MOSFET as logic circuits.

3.7

4. The operational amplifier and Oscillator. ( Hours)

4.1 Basic model, virtual ground concept: inverting amplifier;

non-inverting amplifier, integrator; differentiator, summing

amplifier and their applications.

4.2 Basic feedback theory; positive and negative feedback;

concept of stability; oscillator.

4.3 Wave form generator using op-amp for square wave,

triangular wave wean bridge oscillator for sinusoidal

waveform.

5. Communication system:

(Hours)

5.1 Introduction

5.2 Wired and wireless communication system.

5.3 EMW and propagation, antenna, broadcasting and

communication.

5.4 Internet / intranet.

5.5 Optical fiber.

6. Digital Electronics:

( Hours)

6.1 Number system Binary Arithmetic.

6.2 Logic gates: OR, NOT, AND, NOR, NAND, XOR, XNOR, gate;

truth tables.

6.3 Multiplexers; Demux, Encoder, Decoder.

6.4 Logic function representation.

6.5 Combinational circuits: SOP, POS from K-map.

6.6 Latch, flip-flop; S-R flip-flop; JK master slave flip-flop; D-flipflop.

6.7 Sequential circuits: enteric block diagram; sift registers;

counters.

(Hours)

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

24

Tribhuvan University, Institute of Engineering, Thapathali campus

7. Application of Electronic system:

( Hours)

7.1 Instrumentation System: Transducer, Strain gauge, DMM,

Oscilloscope.

7.2 Regulated power supply.

7.3 Remote control, character display, clock, counter,

measurements, data logging, audio video system.

Laboratory:

1. Familiarization with passive components, function generator

and oscilloscope.

2. Diode characteristics, rectifiers, Zener diodes.

3. Bipolar junction transistor characteristics and single stage

amplifier.

4. Voltage amplifiers using op-amp, comparators, schmitt.

5. Wave generators using op-amp.

6. Combinational and sequential circuits.

Evaluation Scheme

There will be question covering all the chapter in the syllabus.

The evaluation scheme for the question will be indicated in the table

below:

Chapter

Hours

Mark

distribution*

1. Basic Circuit concepts

2. Diodes.

3. Transistor.

4. The operational amplifier and

Oscillator.

5. Communication system

6. Digital Electronics.

7. Application of Electronic system.

Total

*There may be minor deviation in mark distribution

References:

1.

2.

3.

4.

5.

Jvh;k

Bsdjlfhpsdu

Sdhfps

Nsdlifps

Sdn;uifh

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

25

Tribhuvan University, Institute of Engineering, Thapathali campus

ENGINEERING CHEMISTRY

SH453

Lecture: 4

Laboratories: 1

Tutorial : 3

Year: I

Part: II

Course objective

To develop the basic concept of physical chemistry, Inorganic

chemistry and Organic chemistry relevant to problems in engineering.

Course outline

1. Electro-chemistry and Buffer:

(6 hours)

1.1 Electro-chemical cells.

1.2 Electrode Potential and Standard Electrode Potential.

1.3 Measurement of electrode potential.

1.4 Nermst equation.

1.5 EMF of cells.

1.6 Application of electro-chemical and electrolytic cells.

1.7 Electrochemical series and its application.

1.8 Buffer: its type and mechanism.

1.9 Hendersons equation for pH of buffer and related

problems.

1.10 Corrosions and its types.

1.11 Factor influencing corrosion.

1.12 Prevention of corrosion.

2. Catalyst:

(4 Hours)

2.1 Introduction

2.2 Action of catalyst (Catalyst promoters and Catalytic

Poisons)

2.3 Characteristic of catalyst.

2.4 Types of catalyst.

2.5 Theories of catalysis.

2.6 Industrial application of catalyst.

3. Environmental Chemistry:

(5 Hours)

3.1 Air pollution.

3.2 Air Pollutants:

3.2.1 Gases Sox, NOx, CO, CO2, O3 and hydrocarbons.

3.2.2 Particulates dust, smokes and fly ash.

3.3 Effects of air pollutants on human beings and their possible

remedies.

3.4 Ozone depletion and its photochemistry.

3.5 Water pollutions (Ref of surface water and pound water)

3.6 Water pollutants (Ref of surface water) their adverse effect

and remedies.

3.7 Soil Pollution.

3.8 Pollutants of soil, their adverse effect and possible

remedies.

4. Engineering polymers

(6 hours)

4.1 Inorganic polymers.

4.2 General properties of inorganic polymers.

4.3 Polyphosphazines.

4.4 Sulpher based polymers.

4.5 Chalcogenide glasses.

4.6 Silicones.

4.7 Organic polymers.

4.8 Types of organic polymers.

4.9 Preparation and application of:

4.9.1 Polyurethane

4.9.2 Polystyrene.

4.9.3 Ployvinylchlorides

4.9.4 Teflon

4.9.5 Nylon 6,6

4.9.6 Bakelite

4.9.7 Epoxy Resin

4.9.8 Fiber Reinforced Polymer.

4.10 Concept of bio-degradable, Non-bio-degradable and

conduction polymers.

5. 3-D Transition elements and their applications:

5.1 Introduction

(5 hours)

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

26

Tribhuvan University, Institute of Engineering, Thapathali campus

5.2

5.3

5.4

5.5

5.6

5.7

5.8

Electronic Configurations

Variable oxidation states

Complex formation tendency

Color formation

Magnetic properties

Alloy formation

Application of 3-D transition elements.

6. Coordination Complexes:

(5 Hours)

6.1 Introduction

6.2 Terms used in coordination complexes.

6.3 Werners Theory of coordination complexes.

6.4 Sidgwicks model and sidgwicks effective atomic number

rules.

6.5 Nomenclature of coordination compounds (neutral type,

simple cation and complex anion and complex cation and

simple anion type)

6.6 Valence Bond Theory of Complexes.

6.7 Application of valence bond theory in the formation of:

6.7.1 Tetrahedral complexes.

6.7.2 Square planner complexes.

6.7.3 Octahedral complexes.

6.8 Limitation of valance bond theory.

6.9 Application of coordination complexes.

7. Explosives:

(3 Hours)

7.1 Introductions.

7.2 Types of explosives: Primary, Low and high explosives.

7.3 Preparation and application of TNT, TNG, Nitrocellulose and

Plastic explosives.

8. Lubricants and Paints:

(3 hours)

8.1 Introduction.

8.2 Function of lubricants.

8.3 Classification of lubricants (Oils, Greases and Solids).

8.4 Paints.

8.5 Types of Paints.

8.6 Application of paints.

9. Stereochemistry:

(4 Hours)

9.1 Introduction.

9.2 Geometrical Isomerism (Cis, Trans Isomerism) Z and E

concept of Geometrical isomerism.

9.3 Optical isomerism with references to two asymmetrical

carbon centre molecules.

9.4 Terms optical activity, Enantiomers, Diastereomers, Meso

structures, Racemic mixture and Resolution.

10. Reaction mechanism in organic reaction:

(4 hours)

10.1 Substution reaction.

10.2 Types of substation reaction SN1 and SN2.

10.3 Elimination reaction.

10.4 Types of elimination reaction E1 and E2.

10.5 Factor governing SN1, SN2, E1 and E2 reactiion

mechanism path.

References:

1.

2.

3.

4.

5.

6.

Engineering Chemistry By Jain and Jain.

A Text Book of Engineering Chemistry by Shashi Chawala.

A new concise Inorganic chemistry by J. D. Lee.

Principle of physical Chemistry by Marron and Prutton.

Essential of Physical chemistry by Bahl and Tuli.

Advance Inorganic Chemistry Vol. 1 and Vol 2 by Satya Prakash and

Tuli.

7. Organic chemistry by Morrison and Boyd.

8. Selected topic in Physical chemistry by Moti Kaji Sthapit.

9. Environmental Engineering by Peavy, Rowe and Tchobanoglous.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

27

Tribhuvan University, Institute of Engineering, Thapathali campus

Chemistry Practical Course for All

Practical: 3 Period/Week:

1. Compare the alkalinity of different water sample by double

indicator method.

(6

Periods)

2. Determine the temporary and permanent hardness of water by

EDTA complex metric method.

(3

Periods)

3. Determine residual and combined chlorine present in the

chlorinated sample of water by Iodometric method.

(6 Periods)

4. Prepare organic polymers Nylon 6,6/Bakelite in the laboratory. (3

Periods)

5. Determine the pH of different sample of buffer solution by

universal

indicator

method.

(6 Periods)

6. Prepare inorganic complexes in the laboratory.

(3

Periods)

7. Determine the surface tension of the given detergent solution and

compare its cleansing power with other detergent solution. (6

Periods)

8. Construct electrochemical cells in the laboratory and measure the

electrode potential of it. (6 Periods)

9. Estimate the amount of iron present in the supplied sample of

ferrous salt using standard potassium permanganate solution.

(redux titration)

.

(6 Periods)

Evaluation Scheme

``

There will be question covering all the chapters in the syllabus.

The evaluations scheme for the question will be as indicated in the table

below:

Chapter

Hours

Mark

Distribution*

Electro chemistry and Buffer

6

10

Catalyst

4

5 or 10

Environmental Chemistry

5

10

Engineering Polymers

6

10

3-D Transition elements and their

5

10

application

Coordination complexes and their

5

10

application

Explosives

3

5

Lubricants and Paints.

3

5

Stereoisomerism

4

5 or 10

Reaction

mechanism

in

organic

4

5 or 10

mechanism

Total

45

80

*There may be minor deviation in mark distribution.

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

28

Tribhuvan University, Institute of Engineering, Thapathali campus

FUNDAMENTAL OF THERMODYNAMICS AND HEAT TRANSFER

ME452

Lectures: 3

Tutorial: 1

Practical: 1.5

Year: I

Part: II

Course objective:

After the completion of this course, student will be able to

understand basic concept, laws of thermodynamics and Heat transfer

and their applications as well.

1. Introduction:

(4Hrs)

1.1. Definition and Scope of Engineering Thermodynamics

1.2. Value of Energy Society.

1.3. Microscopic Versus Macroscopic Viewpoint.

1.4. Concepts and Definitions.

1.4.1.System, Surroundings, Boundary and Universe; Closed

System, Open system and Isolated system.

1.4.2.Thermodynamic Properties: Intensive, Extensive and

Specific Properties.

1.4.3.Thermodynamics Equilibrium

1.4.4.Sate, Process and Path; Qusi-equilibrium process,

Reversible and Irreversible Process.

1.4.5.Common Properties: Pressure: Pressure, Specific Volume,

and Temperature.

1.5. Zeroth law of Thermodynamics, Equality of Temperature.

2. Energy and Power Transfer:

(3Hrs)

2.1. Energy and its meaning.

2.2. Stored Energy and Transient Energy; Total energy

2.3. Energy Transfer

2.3.1.Heat Transfer

2.3.2.Work transfer

2.4. Expressions for displacement work transfer.

2.5. Power.

3. Properties of Common substances:

(6Hrs)

3.1. Pure substance and state postulate.

3.2. Ideal gas and ideal gas relations.

3.3. Two phase (Liquid and vapor) systems: Phase change; Subcooled Liquid, Saturated liquid, Wet Mixture, Critical point,

Quality, Moisture Content, Saturated Vapor and Superheated

vapor.

3.4. Properties of two phase mixture.

3.5. Other Thermodynamic properties: Internal energy, Enthalpy

and Specific Heats.

3.6. Development of Data: Graphical Data Presentation and Tabular

Data Presentation.

4. First law of Thermodynamics:

( 8Hrs)

4.1. First law of Thermodynamics for Control Mass; First law of

Thermodynamics for Control Mass Undergoing Cyclic Process.

4.2. First law of Thermodynamics for Control Volume.

4.3. Control Volume Analysis: Steady state analysis and Unsteady

state analysis.

4.4. Control Volume application: Steady and Unsteady work

application and Steady and Unsteady Flow applications.

4.5. Other statement of First law.

5. Second Law of Thermodynamics:

(8Hrs)

5.1. Necessity of Formulation of Second law.

5.2. Entropy and Second law of Thermodynamics for an Isolated

system.

5.3. Reversible and Irreversible Process.

5.4. Entropy and Process Relation for an Ideal Gases and

Incompressible substances.

5.5. Control Mass and Control Volume Formulation of Second law.

5.6. Isentropic process for an Ideal gas and for incompressible

Substances.

5.7. Carnot Cycle and Carnot Efficiency.

5.7.1.Heat Engine and Thermal Efficiency, Heat pump,

Refrigerator and coefficient of performance (COP)

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

29

Tribhuvan University, Institute of Engineering, Thapathali campus

5.8. Kelvin-plank and Calusius Statement of the Second law of

Thermodynamics and their Equivalence.

6. Thermodynamic Cycles:

6.1. Classification of Cycles.

6.2. Air Standard Analysis.

6.2.1.Otto Cycles.

6.2.2.Diesel Cycles.

6.2.3.Brayton Cycles.

6.3. Rankine Cycles.

6.4. Vapor Compression Refrigeration Cycles.

(8Hrs)

7. Introduction to Heat Transfer:

(8Hrs)

7.1. Basic concepts and Modes of Heat Transfer.

7.2. One dimensional steady state heat conduction through a plane

wall.

7.3. Radial steady state Heat conduction through a Hollow cylinder.

7.4. Heat flow through composite structure.

7.4.1.Composite plane wall.

7.4.2.Multilayer Tubes.

7.5. Electrical analogy for thermal Resistance.

7.6. Combined Heat transfer and over all heat transfer Coefficient

for plane wall and Tubes.

7.7. Nature of convection; Free convection and Forced convection.

7.8. Heat Radiation, Stefans, law, Absorptive, Reflectivity and

transitivity; Black Body, White Body and Gray Body.

Lab Works:

1.

2.

3.

4.

5.

Temperature Measurements.

Experiment Related to First Law.

Heat Pump.

Heat Conduction.

Heat Radiation.

References:

1. Engierrring Thermodynamics, E. Rathakrishnan, TaTa Mc Graw

Hill.

2. Fundamental of Engineering Thermodynamics, J.R. Howell & R.O.

Buckius, Mc Graw Hill Publishers.

3. Fundamental of Thermodynamics, V. Wylen. Sonntag &

Borgnakke, 6th edition.

4. Fundamental of Engineering Thermodynamics, M.J. moran & H.N.

Shapiro, 5th edition,John Wiley & Sons, Inc.

5. Thermodynamics: An Engineering Approach, Y.A. Cengel & M. A.

Boles, 5 th editon. Mc Graw Hill, 2006.

6. Heat Transfer, J. P. Holman, Mc Graw Hill.

7. Heat Transfer: A practical Approach, Y. A. Cengel, 2nd Edition, Mc

Graw Hill.

Evaluations Scheme:

The evaluations for the final theory examination are indicated below:

Marks

Chapter

Hours

Distribution*

1

4

10

2

4

4

3

6

12

4

8

14

5

9

14

6

8

14

7

6

12

Total

80

*There may be minor deviation in mark distribution

Curriculum of Bachelor in Industrial Engineering Revised at 2066 B. S.

30

Tribhuvan University, Institute of Engineering, Thapathali campus

WORKSHOP TECHNOLOGY

ME453

Lectures: 1

Tutorial:

Practical: 3

Year: I

Part: II