Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Prestige Engineering L.L.C: Welding Procedure Specification (WPS)

Caricato da

Sarathiraja SekarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Prestige Engineering L.L.C: Welding Procedure Specification (WPS)

Caricato da

Sarathiraja SekarCopyright:

Formati disponibili

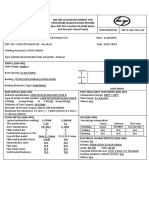

PRESTIGE ENGINEERING L.L.

C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

WELDING PROCEDURE SPECIFICATION ( WPS )

( Section IX, ASME Boiler & Pressure Vessel Code.)

WPS No.

PEL-WPS-13

Rev. No.

Date

: 11/25/2010

Supporting PQR No.

PEL-PQR-23

Rev. No.

Date

: 11/25/2010

GTAW+SMAW

Type

Welding Process(es

: Manual

JOINTS ( QW 402 )

Backing

:With / Without

Joint Design

Backing Material

:Weld Metal/Base Metal

Retainers

:None

Root spacing

As perConstruction Drawing

Root Face

BASE METALS ( QW 403 )

P No.

Group No.: 1

to

P No.

Group No.: 1

OR

Specification and type/grade or UNS Number

to Specification and type/grade or UNS Number

----

: ----

Thickness Range base metal

1.5mm to 20mm for GTAW, 12 mm for SMAW

Fillet

:All Thickness

Maximum Pass Thickness 1/2 in ( 13 mm )

:Yes

No

Other

FILLER METALS ( QW 404 )

Process

GTAW

SMAW

Spec. No. ( SFA)

5.9

5.4

AWS No. ( Class)

ER 316L

E 316L-16

F-No.

A-No.

Size of Filler Metals

1.6, 2.0, 2.4 mm

2.5, 3.2 mm

Filler Metal Product Form

Bare-Solid

NA

Groove

8 mm

20 mm

Fillet

ALL

ALL

Electrode Flux ( Class )

NA

NA

Flux Type

NA

NA

Flux Trade Name

NA

NA

Supplemental Filler metal

NA

NA

Recrushed Slag

NA

NA

Alloy to flux and Alloy element

NA

NA

Electrode Spacing

NA

NA

QW 404.50-Flux

NA

NA

Weld Metal Deposite Thickness Range

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

Electrode/Filler wire Trade Name

ESAB(OK Tigrod 316L)

ESAB(316L-16)

Consumable Insert

NA

NA

Filler Metal Product Form:

NA

NA

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

POSITIONS ( QW 405 )

POST WELD HEAT TREATMENT ( QW 407 )

Position of Groove

All

Temp. Range

NA

Welding Progression

Up Hill

Time Range

NA

Position of fillet

All

Others

Others

PREHEAT ( QW 406 )

Preheat Temp. ( Min. ) C

Ambient

Shielding GTAW

180C

Interpass Temp. (Max.) C

Preheat Maintenance

Other

Percent Composition

GAS ( QW 408 )

Trailing

None

Backing GTAW

Other

Gas

Mixture

Flow Rate

Argon

99.999%

19-25 CFH

Argon

99.999%

20-40 CFH

Travel

Speed

mm/min.

Max Heat Input

KJ/mm*

ELECTRICAL CHARACTERISTICS ( QW 409 )

Filler Metal

Weld

Passes

Process

1-n

1-n

1-n

1-n

GTAW

GTAW

GTAW

SMAW

ER 316L

ER 316L

ER 316L

E 316L-16

1-n

SMAW

E 316L-16

Classification

Current

1.6

2.0

2.4

2.5

Type &

Polarity

DCEN

DCEN

DCEN

DCEP

Amps.

(Range)

80-130

85-140

90-150

60-90

Voltage

8-13

8-14

8-15

20-30

Above 70

Above 70

Above 70

Above 70

2.54

2.62

2.78

4.38

3.2

DCEP

60-120

20-30

Above 55

2.66

Dia (mm )

n-number of pass required

Pulsing Current :

* Applicable only when Impact test is required.

None

Tungstan Electrode Size and Type :

2.4 mm, 2% Thoriated for GTAW

Electrode Wire Feed Speed Range

Mode of Metal Transfer for GMAW(FCAW):

NA

NA

Others

TECHNIQUE ( QW 410 )

String or Weave Bead

Both

Orifice,Nozzle or Gas Cup size

6-16 mm ID

Initial and Interpass Cleaning

Degreasing, Brushing, Chipping, Grinding

Method of Back Gouging

Chipping or Grinding (If Necessery)

Oscilation

NA

Contact Tube to Work Distance.

NA

Multiple or Single Pass ( Per Side )

Multiple / Single

Multiple or Single Electrodes

Single for SMAW

Peening

No

Maximum Weave Width

3X Electrode Diameter for SMAW

Closed to out Chamber

Out of Chamber

Travel Speed

Refer Table

Electrode Spacing

None

Time between Root & Hot pass

NA

Manual to Automatic

No

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

Use of thermal process

NA

Others

Prestige Engineering L.L.C(QA/QC Engineer)

QA/QC Manager

Name :

Name :

Sign:

Sign:

Date

Date

AI

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

CEDURE SPECIFICATION ( WPS )

ME Boiler & Pressure Vessel Code.)

AW

11/25/2010

11/25/2010

Manual

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

NA

NA

-

Percent Composition

Flow Rate

19-25 CFH

20-40 CFH

Max Heat Input

KJ/mm*

2.54

2.62

2.78

4.38

2.66

* Applicable only when Impact test is required.

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

AI

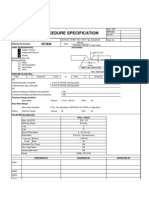

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

WELDING PROCEDURE SPECIFICATION ( WPS )

( Section IX, B31.3 ASME Boiler & Pressure Vessel Code.)

WPS No.

PEL-WPS-13

Rev. No.

Date

: 8/25/2014

Supporting PQR No.

PEL-PQR-23

Rev. No.

Date

: 11/25/2010

GTAW+SMAW

Type

Welding Process(es

: Manual

JOINTS ( QW 402 )

Backing

:With / Without

Joint Design

Backing Material

:Weld Metal/Base Metal

Retainers

:None

Root spacing

As perConstruction Drawing

Root Face

BASE METALS ( QW 403 )

P No.

Group No.: 1

to

P No.

Group No.: 1

OR

Specification and type/grade or UNS Number

to Specification and type/grade or UNS Number

----

: ----

Thickness Range base metal

1.5mm to 20mm

Fillet

:All Thickness

Maximum Pass Thickness 1/2 in ( 13 mm )

:Yes

No

Other

FILLER METALS ( QW 404 )

Process

GTAW

SMAW

Spec. No. ( SFA)

5.9

5.4

AWS No. ( Class)

ER 316L

E 316L-16

F-No.

A-No.

Size of Filler Metals

1.6, 2.0, 2.4 mm

2.5, 3.2 mm

Filler Metal Product Form

Bare-Solid

NA

Groove

8 mm

12 mm

Fillet

ALL

ALL

Electrode Flux ( Class )

NA

NA

Flux Type

NA

NA

Flux Trade Name

NA

NA

Supplemental Filler metal

NA

NA

Recrushed Slag

NA

NA

Alloy to flux and Alloy element

NA

NA

Electrode Spacing

NA

NA

QW 404.50-Flux

NA

NA

Weld Metal Deposite Thickness Range

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

Electrode/Filler wire Trade Name

ESAB(OK Tigrod 316L)

ESAB(316L-16)

Consumable Insert

NA

NA

Filler Metal Product Form:

NA

NA

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

POSITIONS ( QW 405 )

POST WELD HEAT TREATMENT ( QW 407 )

Position of Groove

All

Temp. Range

NA

Welding Progression

Up Hill

Time Range

NA

Position of fillet

All

Others

Others

PREHEAT ( QW 406 )

Preheat Temp. ( Min. ) C

Ambient

Shielding GTAW

180C

Interpass Temp. (Max.) C

Preheat Maintenance

Other

Percent Composition

GAS ( QW 408 )

Trailing

None

Backing GTAW

Other

Gas

Mixture

Flow Rate

Argon

99.999%

19-25 CFH

Argon

99.999%

20-40 CFH

Travel

Speed

mm/min.

Max Heat Input

KJ/mm*

ELECTRICAL CHARACTERISTICS ( QW 409 )

Filler Metal

Weld

Passes

Process

1-n

1-n

1-n

1-n

GTAW

GTAW

GTAW

SMAW

ER 316L

ER 316L

ER 316L

E 316L-16

1-n

SMAW

E 316L-16

Classification

Current

1.6

2.0

2.4

2.5

Type &

Polarity

DCEN

DCEN

DCEN

DCEP

Amps.

(Range)

80-130

85-140

90-150

60-90

Voltage

8-13

8-14

8-15

20-30

Above 70

Above 70

Above 70

Above 70

2.54

2.62

2.78

4.38

3.2

DCEP

60-120

20-30

Above 55

2.66

Dia (mm )

n-number of pass required

Pulsing Current :

* Applicable only when Impact test is required.

None

Tungstan Electrode Size and Type :

2.4 mm, 2% Thoriated for GTAW

Electrode Wire Feed Speed Range

Mode of Metal Transfer for GMAW(FCAW):

NA

NA

Others

TECHNIQUE ( QW 410 )

String or Weave Bead

Both

Orifice,Nozzle or Gas Cup size

6-16 mm ID for GTAW

Initial and Interpass Cleaning

Degreasing, Brushing, Chipping, Grinding

Method of Back Gouging

Chipping or Grinding (If Necessery)

Oscilation

NA

Contact Tube to Work Distance.

NA

Multiple or Single Pass ( Per Side )

Multiple / Single

Multiple or Single Electrodes

Single for SMAW

Peening

No

Maximum Weave Width

3X Electrode Diameter for SMAW

Closed to out Chamber

Out of Chamber

Travel Speed

Refer Table

Electrode Spacing

None

Time between Root & Hot pass

NA

Manual to Automatic

No

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

Use of thermal process

NA

Others

Prestige Engineering L.L.C(QA/QC Engineer)

QA/QC Manager

Name :

Name :

Sign:

Sign:

Date

Date

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

CEDURE SPECIFICATION ( WPS )

ASME Boiler & Pressure Vessel Code.)

8/25/2014

11/25/2010

Manual

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

NA

NA

-

Percent Composition

Flow Rate

19-25 CFH

20-40 CFH

Max Heat Input

KJ/mm*

2.54

2.62

2.78

4.38

2.66

* Applicable only when Impact test is required.

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

Proposed WELDING PROCEDURE SPECIFICATION ( WPS )

( Section IX, B31.3 ASME Boiler & Pressure Vessel Code.)

WPS No.

PEL-WPS-115

Rev. No.

Supporting PQR No.

Welding Process(es

Rev. No.:

:

GTAW+SMAW

Type

Date

: 16.03.2015

Date

: Manual

JOINTS ( QW 402 )

Backing

:With / Without

Joint Design

Backing Material

:Weld Metal/Base Metal

Retainers

:None

Root spacing

As perConstruction Drawing

Root Face

BASE METALS ( QW 403 )

P No.

Group No.: 1

to

P No.

Group No.: 1

OR

Specification and type/grade or UNS Number

to Specification and type/grade or UNS Number

----

: ----

Thickness Range base metal

Groove: 5 mm to 200 mm

Fillet

:All Thickness

Maximum Pass Thickness 1/2 in ( 13 mm )

:Yes

No

Other

FILLER METALS ( QW 404 )

Process

GTAW

SMAW

Spec. No. ( SFA)

5.9

5.4

AWS No. ( Class)

ER 308

E 308-16

F-No.

A-No.

Size of Filler Metals

1.6, 2.0, 2.4 mm

2.5, 3.2 mm

Filler Metal Product Form

Bare-Solid

NA

Groove

8 mm*

32 mm*

Fillet

ALL

ALL

Electrode Flux ( Class )

NA

NA

Flux Type

NA

NA

Flux Trade Name

NA

NA

Supplemental Filler metal

NA

NA

Recrushed Slag

NA

NA

Alloy to flux and Alloy element

NA

NA

Electrode Spacing

NA

NA

QW 404.50-Flux

NA

NA

Weld Metal Deposite Thickness Range

* actual thk

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

Electrode/Filler wire Trade Name

ESAB(OK Tigrod 308)

ESAB(308-16)

Consumable Insert

NA

NA

Filler Metal Product Form:

NA

NA

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

POSITIONS ( QW 405 )

POST WELD HEAT TREATMENT ( QW 407 )

Position of Groove

All

Temp. Range

NA

Welding Progression

Up Hill

Time Range

NA

Position of fillet

All

Others

Others

PREHEAT ( QW 406 )

Preheat Temp. ( Min. ) C

Ambient

Shielding GTAW

180C

Interpass Temp. (Max.) C

Preheat Maintenance

Other

Percent Composition

GAS ( QW 408 )

Trailing

None

Backing GTAW

Other

Gas

Mixture

Flow Rate

Argon

99.999%

19-25 CFH

Argon

99.999%

20-40 CFH

Travel

Speed

mm/min.

Max Heat Input

KJ/mm*

ELECTRICAL CHARACTERISTICS ( QW 409 )

Filler Metal

Weld

Passes

Process

1-n

1-n

1-n

1-n

GTAW

GTAW

GTAW

SMAW

ER 308

ER 308

ER 308

E 308-16

1-n

SMAW

E 308-16

Classification

Current

1.6

2.0

2.4

2.5

Type &

Polarity

DCEN

DCEN

DCEN

DCEP

Amps.

(Range)

80-130

85-140

90-150

60-90

Voltage

8-13

8-14

8-15

20-30

Above 70

Above 70

Above 70

Above 70

2.54

2.62

2.78

4.38

3.2

DCEP

60-120

20-30

Above 55

2.66

Dia (mm )

n-number of pass required

Pulsing Current :

* Applicable only when Impact test is required.

None

Tungstan Electrode Size and Type :

2.4 mm, 2% Thoriated for GTAW

Electrode Wire Feed Speed Range

Mode of Metal Transfer for GMAW(FCAW):

NA

NA

Others

TECHNIQUE ( QW 410 )

String or Weave Bead

Both

Orifice,Nozzle or Gas Cup size

6-16 mm ID for GTAW

Initial and Interpass Cleaning

Degreasing, Brushing, Chipping, Grinding

Method of Back Gouging

Chipping or Grinding (If Necessery)

Oscilation

NA

Contact Tube to Work Distance.

NA

Multiple or Single Pass ( Per Side )

Multiple / Single

Multiple or Single Electrodes

Single for SMAW

Peening

No

Maximum Weave Width

3X Electrode Diameter for SMAW

Closed to out Chamber

Out of Chamber

Travel Speed

Refer Table

Electrode Spacing

None

Time between Root & Hot pass

NA

Manual to Automatic

No

PRESTIGE ENGINEERING L.L.C

Industrial Area No: 10, Sharjah-United Arab Emirates

Tel No.: +97165349951, Fax: +97165349952

Use of thermal process

NA

Others

Prestige Engineering L.L.C(QA/QC Engineer)

QA/QC Manager

Name :

Name :

Sign:

Sign:

Date

Date

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

PROCEDURE SPECIFICATION ( WPS )

ASME Boiler & Pressure Vessel Code.)

16.03.2015

Manual

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

NA

NA

-

Percent Composition

Flow Rate

19-25 CFH

20-40 CFH

Max Heat Input

KJ/mm*

2.54

2.62

2.78

4.38

2.66

* Applicable only when Impact test is required.

E ENGINEERING L.L.C

No: 10, Sharjah-United Arab Emirates

65349951, Fax: +97165349952

Potrebbero piacerti anche

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Documento2 pagineWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNessuna valutazione finora

- Wps p91 - BhelDocumento2 pagineWps p91 - BhelAshish Gupta100% (4)

- WPS 03Documento2 pagineWPS 03mansoor_an100% (1)

- 1035 03Documento2 pagine1035 03Anuj ShahiNessuna valutazione finora

- Welding Procecure SpecificationDocumento9 pagineWelding Procecure SpecificationNwoha PeterNessuna valutazione finora

- Graycor WPS 19 SampleDocumento5 pagineGraycor WPS 19 SampleRaul SebastiamNessuna valutazione finora

- PQR With-PwhtDocumento2 paginePQR With-PwhtKarthikNessuna valutazione finora

- Saudi Aramco WPS Procedure ApprovalDocumento7 pagineSaudi Aramco WPS Procedure ApprovalAkansha SharmaNessuna valutazione finora

- PQRDocumento2 paginePQRafqzfieNessuna valutazione finora

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocumento1 paginaIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNessuna valutazione finora

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Documento2 pagineLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNessuna valutazione finora

- AES-W-016 welding filler metalsDocumento2 pagineAES-W-016 welding filler metalsmalika_00Nessuna valutazione finora

- Asme PQR DemoDocumento3 pagineAsme PQR DemoMuthusamy AyyanapillaiNessuna valutazione finora

- WPS - D1.1Documento1 paginaWPS - D1.1Nam_HitechNessuna valutazione finora

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocumento1 paginaWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- Asme Sec Ix (Welder Qualification)Documento39 pagineAsme Sec Ix (Welder Qualification)VinodNessuna valutazione finora

- WPS 204 NewDocumento6 pagineWPS 204 Newarockiyathass100% (1)

- WPS (1) 1Documento5 pagineWPS (1) 1Pedro José PadillaNessuna valutazione finora

- WPS for Welding SA-335 P11 to SA-234 WP11Documento3 pagineWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNessuna valutazione finora

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Documento2 pagineASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- PQR Super-Duplex ReferenceDocumento48 paginePQR Super-Duplex ReferencetalhaNessuna valutazione finora

- WPS FGPDocumento1 paginaWPS FGPShabbir HussainNessuna valutazione finora

- WPS 316 L PDFDocumento4 pagineWPS 316 L PDFIrinaNessuna valutazione finora

- WPQR Welding Procedure QualificationDocumento3 pagineWPQR Welding Procedure QualificationThanasis KyrgiazoglouNessuna valutazione finora

- Linde Rates For Welding Test Services-2018Documento2 pagineLinde Rates For Welding Test Services-2018Hoque AnamulNessuna valutazione finora

- Essential Variables for Welder QualificationDocumento12 pagineEssential Variables for Welder QualificationMahmoud Alwasif100% (2)

- Weld Procedure Specification (WPS)Documento2 pagineWeld Procedure Specification (WPS)Senthil Kumaran0% (1)

- WPQ-1083 3G PDFDocumento2 pagineWPQ-1083 3G PDFduendex360100% (1)

- Sample API 1104 WpsDocumento1 paginaSample API 1104 Wpsippon_osoto100% (1)

- Gta+sma PQRDocumento3 pagineGta+sma PQRRahul MoottolikandyNessuna valutazione finora

- WeldDocs WPSDocumento2 pagineWeldDocs WPSMDSIKKU_2005Nessuna valutazione finora

- PWPS WPS CAP 039 PQR 035Documento15 paginePWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNessuna valutazione finora

- Welding Procedure Specification (WPS) : N.A N.ADocumento1 paginaWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiNessuna valutazione finora

- Welder qualification test recordDocumento3 pagineWelder qualification test recordTuTuy AnNessuna valutazione finora

- Storing and Redrying Electrodes-Lincoln ElectricDocumento3 pagineStoring and Redrying Electrodes-Lincoln ElectricjasminneeNessuna valutazione finora

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocumento1 paginaWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- SMAW DuniDocumento4 pagineSMAW DuniMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Form Wps JBL09-2011Documento2 pagineForm Wps JBL09-2011fawad aliNessuna valutazione finora

- Limak - Sawaed WpsDocumento1 paginaLimak - Sawaed WpsAlam MD SazidNessuna valutazione finora

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocumento3 pagineIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNessuna valutazione finora

- WPS CuNiDocumento1 paginaWPS CuNiDieter Huaman ToscanoNessuna valutazione finora

- Fit Up Welding Visual Inspection ReportDocumento2 pagineFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Wps PQRDocumento7 pagineWps PQRsobariNessuna valutazione finora

- Welding Procedure Specification (WPS) : in The Outer TubeDocumento1 paginaWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNessuna valutazione finora

- QAP For PQR'S - For Impact TestingDocumento3 pagineQAP For PQR'S - For Impact TestingDries VandezandeNessuna valutazione finora

- Gtaw 106Documento2 pagineGtaw 106ganeshkumarg_1Nessuna valutazione finora

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Documento12 paginePoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNessuna valutazione finora

- Welding Procedure SpecificationDocumento3 pagineWelding Procedure SpecificationAhmed saber100% (1)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocumento2 pagineProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNessuna valutazione finora

- Request for Welding Procedure ApprovalDocumento10 pagineRequest for Welding Procedure ApprovalAlam MD SazidNessuna valutazione finora

- Asme Sec 9 - ADocumento144 pagineAsme Sec 9 - Aروشان فاطمة روشانNessuna valutazione finora

- Welding Procedure Qualification Record: Shipyard LogoDocumento4 pagineWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocumento1 paginaPDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNessuna valutazione finora

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 pagineWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNessuna valutazione finora

- PWPS - GTSM-73 Rev-ADocumento5 paginePWPS - GTSM-73 Rev-AVimin PrakashNessuna valutazione finora

- WPS GTAW Stainless SteelDocumento4 pagineWPS GTAW Stainless SteelAnand NarayananNessuna valutazione finora

- WPSDocumento2 pagineWPSJuli Agus50% (2)

- WPS GTAW Stainless SteelDocumento2 pagineWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDocumento5 pagineMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- Untitled Extract PagesDocumento1 paginaUntitled Extract PagesSarathiraja SekarNessuna valutazione finora

- JPSBS0001Documento2 pagineJPSBS0001Pisith NilsonthiNessuna valutazione finora

- ISO 10025 & 10027 Steel SymbolsDocumento0 pagineISO 10025 & 10027 Steel SymbolsbreeeeezzzzzeNessuna valutazione finora

- Department of Labor: Elect SafetyDocumento2 pagineDepartment of Labor: Elect SafetyUSA_DepartmentOfLaborNessuna valutazione finora

- Nitrogen Pressure Test - Calculation PDFDocumento2 pagineNitrogen Pressure Test - Calculation PDFSarathiraja Sekar63% (8)

- Nitrogen Pressure Test - Calculation PDFDocumento2 pagineNitrogen Pressure Test - Calculation PDFSarathiraja Sekar63% (8)

- Brinell TesterDocumento12 pagineBrinell TesterSarathiraja SekarNessuna valutazione finora

- JPSBS0001Documento2 pagineJPSBS0001Pisith NilsonthiNessuna valutazione finora

- 02 Employee Workplace Rights Osha3021Documento32 pagine02 Employee Workplace Rights Osha3021api-309082881Nessuna valutazione finora

- OSHA Fact Sheet - Amputation PDFDocumento2 pagineOSHA Fact Sheet - Amputation PDFSarathiraja SekarNessuna valutazione finora

- MBA Jobs Salary Trends Report 2015Documento45 pagineMBA Jobs Salary Trends Report 2015pablorsNessuna valutazione finora

- Illinois Motorcycle Operator Manual PDFDocumento44 pagineIllinois Motorcycle Operator Manual PDFSarathiraja SekarNessuna valutazione finora

- Consejos para Prevencion de Accidentes en El TrabajoDocumento3 pagineConsejos para Prevencion de Accidentes en El TrabajoSUPER INDUSTRIAL ONLINENessuna valutazione finora

- Maintenance PDFDocumento32 pagineMaintenance PDFkaduwdNessuna valutazione finora

- ISO 14001 - 2015 An Improved Tool For SustainabilityDocumento14 pagineISO 14001 - 2015 An Improved Tool For Sustainabilitysutawijaya_masNessuna valutazione finora

- IDip Guide Nov 15 Spec v2 With Covers3062016101012Documento109 pagineIDip Guide Nov 15 Spec v2 With Covers3062016101012Sarathiraja Sekar100% (1)

- ISO31000yNS AustralianaDocumento61 pagineISO31000yNS AustralianaMarco Antonio GuillenNessuna valutazione finora

- Data SheetDocumento1 paginaData SheetSarathiraja Sekar100% (1)

- Nitrogen Pressure Test - Calculation PDFDocumento2 pagineNitrogen Pressure Test - Calculation PDFSarathiraja Sekar63% (8)

- CE Quiz 3Documento8 pagineCE Quiz 3Sarathiraja SekarNessuna valutazione finora

- QM ZG628TDocumento15 pagineQM ZG628TSarathiraja SekarNessuna valutazione finora

- Vagt EnglishDocumento8 pagineVagt EnglishSarathiraja SekarNessuna valutazione finora

- 3 Coat SpecsDocumento4 pagine3 Coat SpecsSarathiraja SekarNessuna valutazione finora

- Autoclave CatalogueDocumento12 pagineAutoclave CataloguecristianoclemNessuna valutazione finora

- Kaizen - ASQ - GHS Case StudyDocumento4 pagineKaizen - ASQ - GHS Case StudySarathiraja SekarNessuna valutazione finora

- SQC QZ2Documento10 pagineSQC QZ2Sarathiraja SekarNessuna valutazione finora

- QM ZG628TDocumento15 pagineQM ZG628TSarathiraja SekarNessuna valutazione finora

- Quiz Ec2 (HRM)Documento4 pagineQuiz Ec2 (HRM)Sarathiraja SekarNessuna valutazione finora

- Basic Training On Height SafetyDocumento1 paginaBasic Training On Height SafetySarathiraja Sekar0% (1)

- Specs For Graphite in CruciblesDocumento16 pagineSpecs For Graphite in CruciblesjleydencoNessuna valutazione finora

- 5-194 - Kru276 Eng PDFDocumento1 pagina5-194 - Kru276 Eng PDFMoslemNessuna valutazione finora

- Water For RayonDocumento51 pagineWater For RayonAditya ShrivastavaNessuna valutazione finora

- Safety Data Sheet for Omicron 636 Oil 4-Point SprayDocumento7 pagineSafety Data Sheet for Omicron 636 Oil 4-Point SprayMiss IndependentNessuna valutazione finora

- Acids Bases Buffers ALL PPQDocumento139 pagineAcids Bases Buffers ALL PPQ2k2g6x42q9Nessuna valutazione finora

- Thermal Efficiency Fired HeaterDocumento5 pagineThermal Efficiency Fired Heatermuhammad_asim_10Nessuna valutazione finora

- Flux Cored Wires for Welding High Strength SteelDocumento71 pagineFlux Cored Wires for Welding High Strength SteelCristian Camilo QuirogaNessuna valutazione finora

- Copper ExtractionDocumento67 pagineCopper ExtractionJohnny Kao50% (2)

- Pengelasan - 2 - Materials - 1Documento82 paginePengelasan - 2 - Materials - 1Reza Rachman DarmawanNessuna valutazione finora

- Foaming of Rubber Wood Plastic CompositeDocumento65 pagineFoaming of Rubber Wood Plastic CompositeAwad M. El ArabyNessuna valutazione finora

- 6-MS00063643 Polyols-SF06 0313 MADocumento28 pagine6-MS00063643 Polyols-SF06 0313 MAHugo WizenbergNessuna valutazione finora

- Stainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicalDocumento20 pagineStainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicaljjdNessuna valutazione finora

- Kinetics Study of Ester Hydrolysis in The Presence of HCL at Room Temperature Room TemperatureDocumento10 pagineKinetics Study of Ester Hydrolysis in The Presence of HCL at Room Temperature Room TemperatureJuan RobinsonNessuna valutazione finora

- What Is Polyester Fiber? What Is Understood by Thermoplastic and Thermoset Polyester?Documento5 pagineWhat Is Polyester Fiber? What Is Understood by Thermoplastic and Thermoset Polyester?MOJAHID HASAN Fall 19Nessuna valutazione finora

- Copper AlloysDocumento61 pagineCopper Alloysbvalinhas100% (2)

- Order For SDIDocumento18 pagineOrder For SDIحسن علي فالح حسنNessuna valutazione finora

- Balancing Chemical EquationsDocumento10 pagineBalancing Chemical EquationsHannah SantiagoNessuna valutazione finora

- GBT-1220-2007-stainless Steel BarsDocumento23 pagineGBT-1220-2007-stainless Steel BarsKepeNessuna valutazione finora

- Chemguard C6IC1 6% Afff Concentrate: DescriptionDocumento2 pagineChemguard C6IC1 6% Afff Concentrate: Descriptionaprk_paulrajNessuna valutazione finora

- Fire ExtinguisherDocumento17 pagineFire ExtinguisherMelvin Jason StephenNessuna valutazione finora

- Analysis of Mohr’s Method for Determining Chloride Ion Concentration in CheeseDocumento5 pagineAnalysis of Mohr’s Method for Determining Chloride Ion Concentration in CheeseKingsley WongNessuna valutazione finora

- Reteta p2pDocumento2 pagineReteta p2pJohn JohnNessuna valutazione finora

- List of Indian StandardsDocumento134 pagineList of Indian StandardsEalumalai Muthu0% (1)

- ASTM A 751 - 07aDocumento6 pagineASTM A 751 - 07analakasaNessuna valutazione finora

- B221M 1388261-1Documento16 pagineB221M 1388261-1hh774747Nessuna valutazione finora

- Dice Cards Alchemist's Apprentice v1.0Documento4 pagineDice Cards Alchemist's Apprentice v1.0marcos navas godoNessuna valutazione finora

- Science Form 3 July TestDocumento7 pagineScience Form 3 July TestNorafiza Hashim100% (1)

- Study of Glass Transition Temperatures in Sugar MixturesDocumento4 pagineStudy of Glass Transition Temperatures in Sugar MixturessamiNessuna valutazione finora

- Grade 6: Unit 2: MixtureDocumento43 pagineGrade 6: Unit 2: MixtureEmylie Alvarez LantoriaNessuna valutazione finora

- Araldite: General Bonding AdhesivesDocumento6 pagineAraldite: General Bonding AdhesivesvkmsNessuna valutazione finora