Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Filtration of Grape Juice Sediments

Caricato da

James AlvesCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Filtration of Grape Juice Sediments

Caricato da

James AlvesCopyright:

Formati disponibili

wi n e maki n g

F I L T R A T I ON

Filtration of grape juice sediments:

a new application for cross-flow filters

By Patrik Schonenberger1, Davide De Giorgi1 and Julien Ducruet1,2

1

Engineering School of Enology in Changins, Route de Duillier 50, Case postale 1148, 1260 NYON 1, Switzerland

2

Corresponding author: Dr Julien Ducruet. Email: julien.ducruet@eichangins.ch

Introduction

rape juice for white wine is

usually pre-clarified to a certain

degree before undergoing

alcoholic fermentation. Traditionally,

this pre-clarification has been done by

allowing particles to settle overnight

and racking off the clear juice. The

settled particles (sediments) are

filtered with a filter press or a rotary

vacuum filter to obtain higher yields

of clear juice. These techniques have

proved to be efficient, but contain

inconveniences, such as the removal of

filtration residues (including adjuvants

like diatomaceous earth, perlite, etc.)

which may pose environmental concerns

(Montigaud 2010, Desenne 2004). Other

important concerns in wineries are the

initial dilution of the juice, little filter

versatility, and labour hours for the

cleaning procedure. Rotary vacuum

filters have been studied extensively

over the last 40 years. Some of the

main consequences found for the

filtered juices are linked to the use of

the vacuum itself: decrease of carbon

dioxide concentration and free sulfur

dioxide levels, losses of some desired

volatile compounds (e.g., primary

aromas), and increased risk for juice

oxidation (Riberau-Gayon et al. 1998).

The first cross-flow filters used

in the wine industry were reported

to have heavy impacts on the filtered

wines. Such wines reached lower

scores than wines made from rotary

vacuum-filtered juices, as evaluated by

professional tasting panels (Serrano

and Paezold 1998). In recent studies

with updated filter technology and

improved membrane characteristics,

no differences were found between

wines from cross-flow filtered and

rotary vacuum-filtered juices (Etienne

and Benestau 2000, Cunat et al. 2003).

However, Vernhet et al. (1998) analysed

wine components in the laboratory

and reported lower levels of colloidal

compounds in wines from cross-flow

filtered juices compared with wines from

rotary vacuum-filtered juices. Cunat et

al. (2003) noted in a study that ceramic

28

w w w.w i n eb i z .c om.au

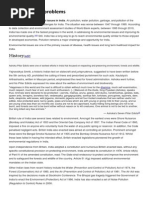

Figure 1. Cross-flow filter FX 3 (Bucher-Vaslin SA, France), equipped with an

adapted module and the corresponding computer software, which allows the

filtration of very dense and viscous juice sediments.

membranes retained more colloids than

membranes made with polysulfone.

Cross-flow filters with adapted

modules for the filtration of dense

sediments appeared on the market

only recently. This new application for

cross-flow filters offers the possibility to

filter wines, juices, and juice sediments

with one device. The present study

was carried out as part of a Bachelor

of Sciences thesis (De Giorgi 2010) at

the School of Enology in Changins,

Switzerland, to evaluate the impact of

this new application on the quality and

composition of the final wines. Crossflow filtration of juice sediments was

compared with the standard filtration

with a rotary vacuum filter.

W i n e & V iticultur e Jo ur n a l MARC H /APRIL 2012

Materials and methods

Two experiments were carried out

with two pre-clarification methods

(gravitational settling and flotation).

After pre-clarification, sediments were

filtered with a rotary vacuum filter and

compared with the filtration from a

cross-flow filter.

Filter technology

A cross-flow filter FX 3 (Bucher

Vaslin SA, France) was equipped

with an adapted module and the

corresponding computer software,

which allows the filtration of very

dense and viscous juice sediments.

The membrane was made of polyether

V27N2

F I L T R A T I ON

sulfone with spaghetti-type capillaries

(internal capillary diameter 3mm).

The filtration surface was 18m2 with

0.2m pore size. Water (cold and hot)

and compressed air were connected

permanently for proper running of the

filter. The computer software controlled

all valve openings (wine, water and air)

and supervised filtration, rinsing, and

cleaning programming (Figure 1).

A rotary vacuum filter (VELO, Italy)

with an integrated vacuum pump and

a filtration surface of 8m2 was used

as the standard procedure. Filtration

media was Seitz Perlite A (Pall

SeitzSchenk Filter Systems GmbH,

Germany).

Grape juice

White Chasselas (Vitis vinifera L. cv

Chasselas) juice from a commercial

vineyard (Chteau dAuvernier,

Switzerland) was used. Enzymes

(10mg/L Depectil Clarification FCE,

Martin Vialatte) and SO2 (80mg/L) were

added to the juice before the application

of the treatments. The fraction of the

juice that was floated before filtration

received 200mg/L gelatin (proVgreen

Extra, Martin Vialatte) prior to

flotation, in addition to the enzymes and

wi n e maki n g

the SO2. No other product was added to

the juice. One fraction of the juice was

pre-clarified overnight by gravitational

settling at ambient temperature

(16C). A second fraction was preclarified by flotation, using a Turboflot

ECO 5000 (Kunzmann and Hartmann,

Germany) with an average flow rate of

7500L/h. Flotation gas was nitrogen.

The sediments of both pre-clarification

methods were then filtered using both

cross-flow and rotary vacuum filtration.

Inherent to rotary vacuum filtration, the

first fraction of the juice was diluted

and not used for the winemaking.

separately with 0.2g/L Vitilevure Quartz

(Saccharomyces cerevisiae galactose,

Station Oenotechnique de Champagne,

France). For the malolactic

fermentation, 0.01g/L Vitilactic F

(Martin Vialatte, France) was added to

the wines. SO2 at a rate of 50mg/L was

added after malolactic fermentation,

and the wines were then stored at 2C

for a period of six weeks for physical

stabilisation. Wines were pre-filtered

with AF100 filter pads (Filtrox AG,

Switzerland) and, before bottling, were

sterile filtered with AF130 filter pads

(Filtrox AG, Switzerland).

Winemaking

Special care was taken to use only

juice fractions with the same sugar

levels (total soluble solids) before

and after filtration. After filtration,

wines were replicated three times in

stainless steel tanks (each containing

200L of juice). Standard procedures

for white Chasselas wine production in

Switzerland were applied, and attempts

were made to keep the temperatures

identical in all tanks, i.e., alcoholic

fermentation at 18C and malolactic

fermentation at 16C. For the alcoholic

fermentation, all tanks were inoculated

Chemical analysis

The sugar content of the juice

was measured with a standard

refractometer. Alcohol content,

titratable acidity, tartaric acid, malic

acid, lactic acid, and volatile acidity

were analysed with a WineScanTM (FOSS

Analytical, Hilleroed, Denmark) which

uses Fourier Transform Infrared (FTIR)

Spectroscopy. The FTIR analysis was

carried out with the clear fraction of

the juice after centrifuging the samples

for 10 minutes at 5000rpm. Samples

were also centrifuged for calculating

the proportion of dry matter in the total

Winemakers bottling

for winemakers

With ten winemakers working across six sites, Portavin

is close to market and transport hubs, saving time,

money and the environment.

Portavin caring for your wine from tank to shelf

Adelaide

Auckland

(08) 8447 7555 (09) 582 0090

Margaret River

(08) 9755 0500

Melbourne

(03) 9584 7344

Perth

Sydney

(08) 9437 1033 (02) 9722 9400

www.portavin.com.au

portavin@portavin.com.au

V2 7N 2

W i n e & V iticultur e Jo ur n a l MARC H /APRIL 2012

www.w inebiz. com . au

29

wi n e maki n g

F I L T R A T I ON

Table 1. Chemical analyses of the initial juice after pre-clarification by gravitational settling and flotation.

Juice analysis

total soluble solids (Brix)

Titratable acidity (g/L)

pH

Dry matter (% of total volume)

After gravitational settling

19.1

7.10

3.29

8.78

After flotation

19.1

7.30

3.22

28.25

volume. The volume of the centrifuge

deposit was divided by the initial total

volume to obtain the percentage of dry

matter.

Statistical analysis

Data were subjected to the analysis

of variance (ANOVA) and F-test. The coefficient of variation (CV) was calculated

to obtain the relative percentage of

the standard deviation (Excel 2007,

Microsoft, Redmond, WA).

Sensory evaluation

The bottled wines were stored for

three months before being exposed

to sensory evaluation by an expert

panel. Two panels of 24 and 16

judges, respectively, were present

at two tasting sessions. Quantitative

Descriptor Analysis profile (QDA) with

10 different terms was employed to

describe the wines.

Results and discussion

Chemical analyses of the initial

juices are shown in Table 1 (total

soluble solids, titratable acidity, pH,

and dry matter as a percentage of

the total volume). The two types of

sediments obtained by flotation and

gravitational settling were distinctly

different: sediments from flotation

were denser and more viscous than

sediments from gravitational settling

(28.25% versus 8.78% dry matter of

total volume, Table 1). Both filtration

techniques cleared the juice to a

very low but comparable level of

suspended material (<1.00% dry matter

of total volume, data not shown). A

temperature rise of 6C was observed

in the juice during cross-flow filtration

(data not shown) and needs some

consideration. Similar differences for

input and output temperatures for

cross-flow filtered wines have been

reported previously in comparative

studies (Ducruet et al. 2006). Cross-flow

filtration may negatively affect a juice

with a higher input temperature. It is

preferable to conduct the filtration with

an initial juice temperature below 16C

to reach a maximum temperature of

22C at the output side of the filter.

The chemical analyses of the finished

wines showed no significant differences

for alcohol content, acidity levels, and

volatile acidity (Tables 2 and 3).

Significantly lower absorbance at

280nm was observed in wines made

from rotary vacuum-filtered juices

compared with those from cross-flow

filtered juices (Tables 2 and 3). The

absorbance at 280nm is an indication

for total polyphenols in the juice. If

rotary vacuum filtration caused more

polyphenol oxidation than crossflow filtration (Riberau-Gayon et al.

1998), one portion of these oxidised

Filtration & Purification Specialists

For all of your winery and beverage processing needs.

Premium quality filtration solutions and specialists you can trust.

Complete filtration solutions from water to wine

Premium BECO sheets & lenticular modules

Turnkey filtration systems

Australias largest range of filter housings

SIHA biotechnology & wine additives

H 2O

30

w w w.w i n eb i z .c om.au

CALL FOR MORE INFORMATION

Blue H2O Filtration Pty Ltd

29 Dalgety Street Oakleigh VIC 3166

Ph +61 3 9564 7029 Fax +61 3 9564 7039

info@blueh2o.com.au www.blueh2o.com.au

W i n e & V iticultur e Jo ur n a l MARC H /APRIL 2012

V27N2

F I L T R A T I ON

wi n e maki n g

Table 2. Chemical analyses of the final wines made from juice obtained by gravitational settling. Juice was filtered, vinified,

stabilised, and stored for three months in the bottle.

Wine

analysis

Alcohol

(% volume)

Tartatic acid

(g/L)

Malic acid

(g/L)

Lactic acid

(g/L)

Acetic acid

(g/L)

Volatile

acidity (g/L)

Absorbance (280 nm)

Chromtic intensity

(absorbance 420 nm)

Juice obtained by gravitational settling

Rotary

vacuum

filter

10.9

1.73

0.41

1.94

0.23

0.42

5.267

0.143

Cross-flow

filter

11.1

1.70

0.47

2.25

0.18

0.42

6.000

0.154

significance

CV %

ns

ns

ns

ns

ns

ns

**

ns

3.05

3.62

4.45

3.77

21.25

3.09

2.33

19.24

*, **, ***, ns: Main effects significant at P < 0.05, P < 0.01, P < 0.001, or not significant, respectively.

Table 3. Chemical analyses of the final wines made from juice obtained by flotation. Juice was filtered, vinified, stabilised, and stored

for three months in the bottle.

Wine

analysis

Alcohol

(% volume)

Tartaric acid

(g/L)

Malic acid

(g/L)

Lactic acid

(g/L)

Acetic acid

(g/L)

Volatile

acidity (g/L)

Absorbance (280 nm)

Chromatic intensity

(absorbance 420 nm)

Juice obtained by flotation

Rotary

vacuum

filter

11.3

1.67

0.48

2.05

0.28

0.47

5.650

0.223

Cross-flow

filter

11.2

1.65

0.51

2.18

0.13

0.43

6.310

0.126

Significance

ns

ns

ns

ns

**

ns

0.04

0.04

0.22

4.73

18.62

8.51

7.52

45.77

CV %

*, **, ***, ns: Main effects significant at P < 0.05, P < 0.01, P < 0.001, or not significant, respectively.

FILCHEM

A Complete Range

of Filter Media

Ertel Alsop lenticular

cartridges & sheets

Graver membrane

cartridges

Celite DE

Harborlite Perlite

Diacel cellulose

Activated Carbon

Filchem Australia Pty. Ltd

1 800 33 1125

V2 7N 2

Fast and ACCURATE results for wine analysis with the

Thermo range of Gallery and Arena Discrete Analysers

Compact design occupies a small footprint

and is fully self-contained.

Flexible loading capacity up to 45 samples

or 30 reagents simultaneously.

All necessary steps are automated, providing

a walk-away time up to two hours.

For more information on this product,

contact us by email at sales.

daniel.hoger@thermofisher.com

www.thermofisher.com.au

1800 333 110

Thermo Scientific Gallery

Photometric Analyzer

Moving science forward

W i n e & V iticultur e Jo ur n a l MARC H /APRIL 2012

www.w inebiz. com . au

31

wi n e maki n g

F I L T R A T I ON

suggested that other factors than the

application of the treatments may have

influenced these data (Table 3).

The QDA profiles of the tasting panels

showed few differences in the final

wines (Figures 2 and 3). Cross-flow

filtration of juice sediments produced

wines with less intense odours and more

pronounced acidity levels compared with

wines from rotary vacuum-filtered juice

sediments.

Conclusion

Figure 2. Quantitative Descriptor Analysis profile (QDA) of the final wines made

with juice obtained by gravitational settling (*, **, ***: Main effects significant at

P < 0.05, P < 0.01, P < 0.001).

polyphenols might have flocculated

and immediately filtered out of the

juice, which did lower total polyphenols

in rotary vacuum-filtered juices. The

portion of the remaining oxidised

polyphenols (indicated by chromatic

intensity) was not different in both

filtration techniques, if the juice was

obtained by gravitational settling (Table

2). On the other hand, if the juice was

obtained by flotation, the portion of

the oxidised polyphenols (indicated by

chromatic intensity) and acetic acids

were increased in rotary vacuumfiltered juices (Table 3). However, a high

CV of 18.62% and 33.3%, respectively,

MaloBacti MLF

Cross-flow filters offer several

possibilities to facilitate cellar work.

They produce less filtration residues

and may free labour hours through

automation during intense harvest time.

Cross-flow filters are more versatile

than rotary vacuum filters; one filter

may be used for wine, juice, and juice

sediment filtration. However, initial

investments are more substantial for

a cross-flow filter. Some products

(e.g., bentonite, activated charcoal)

may not be added to the juice before

cross-flow filtration, in order to prevent

the membrane from plugging. These

experiments were carried out with

one grape variety and one vintage.

Innovation.

Performance.

Proximity.

Better equipment

is the key to success

Delta

Fruit receival

MAXIMUM SECURITY MALOs

The only strains on the market with a pH test that

confirms viability of active bacteria prior to inoculation!

Bucher

Presses

Flavy

MaloBacti CN1

Cross flow filtration

Citric negative MLF

Flavy

MaloBacti HF2

Cross ow ltration

Colour protection & flavour management

Our dealership network Australia and New Zealand

MaloBacti AF3

Elevated phenolics & high alcohol

MAXBacti

New large volume concept

MaloControl

SALES NZ

Viniquip

SALES VIC/TAS/ACT

Vinvicta

Horst Klos

Steve Jenkinson

Our dealership network Australia and

New Zealand

Tel: (06) 879 7799

T: 1300 360 353

SALES & SERVICE WA

SWAT trading

Rob Menzies

T: (08) 9755 5766

South Australia and

Western Australia:

SWAT Trading

Tel: 08 9755 5766

New

South WalesSERVICE

and & PARTS

SALES SA

Filters SA

APV Australia

Queensland:

T: (08) 8388 3999

Les Jarvis

Wine Energy

T: 1800 100 278

Tel: 0407 400 728

Victoria and Tasmania:

Vinvicta Products

Tel: 03 9464 7414

Po Box

1051, Glen Waverley, 3150, tel 1300 Bucher

New

Zealand:

National Sales

Manager: Peter Keeghan

Viniquip

International:

tel.

0417

816 024

Email: peter.keeghan@buchervaslin.com

Tel: +64 9578

3740

SERVICE & PARTS

APV New Zealand

Grant Dewson

T: 800 500 278

Bucher Vaslin Australia

Complete MLF supplement

For further information, please contact Kauri NZ Ltd.

NZ Tel: 0800 KAURIWINE AUS Tel: 1800 127 611

NZ Fax: 04 910 7415

AUS Fax: 1800 127 609

Email: winery@kauri.co.nz Web: www.kauriwine.com

32

w w w.w i n eb i z .c om.au

Bucher Vaslin Australia Pty Ltd

PO Box 1051,

Glen Waverley, 3150

Samuel Plumejeau

Tel: 0427 655 800

W i n e & V iticultur e Jo ur n a l MARC H /APRIL 2012

www.buchervaslin.com

Seesuccess

us atis our

Winetech

Your

priority

July 29th to August 1st in Adelaide

www.buchervaslin.com

Your success is our priority

V27N2

F I L T R A T I ON

wi n e maki n g

Further studies need to be done to better

understand the behaviour of the juices

and finished wines over time after using

cross-flow filter technology.

Acknowledgements

The project was conducted as part of

Davide De Georgis Bachelor of Science

thesis, which was supervised by Dr

Julien Ducruet. We greatly appreciated

the technical assistance of M. Droz

Frdrique (Chteau dAuvernier,

Switzerland) and M. Erik Dobrovolski

(Bucher Vaslin SA, France).

References

Cunat, P.; Lorenzini, F. and Bregy, C.A. (2003)

Comparaison de membranes en cramique et

polysulfone pour la microfiltration tangentielle des

vins. Revue Suisse de Viticulture, Arboriculture,

Horticulture 35(6):110-119.

DeGiorgi, D. (2010) Etude de la filtration

tangentielle des bourbes compare aux techniques

existantes. BS Thesis, Engineering School of Enology

in Changins, Switzerland.

Desenne, A. (2004) Les filtrations: une

pollution diffrente selon le typ de filtre. Chambre

dagriculture de la Gironde service vigne et vin.

http://www.matevi-france.com/welcome_menu.

asp?tp=choix_experimentation [accessed 10/02/2010]

Ducruet, J.; Silvestri, A.-C. and Hyppenmeyer,

P. (2006) Etude comparative de diffrents filtres

tangentiels en nologie. Revue Suisse de Viticulture,

Arboriculture, Horticulture 38(5):297-302.

Chimie du vin stabilisation et traitements. Edition

Dunod: 383-427.

Etienne, F. and Benestau, F. (2000) Filtration

tangentielle: impact sur la qualit des vins. Revue

des nologues 27(96):13-15.

Serrano, M. and Paetzold, M. (1998) Incidence des

filtrations sur la composition chimique et les qualits

organoleptiques des vins. Journal International des

sciences de la vigne et du vin. Traitements physiques des

mots et des vins. Filtration. N hors srie. pp 53-57.

Montigaud, I. (2010) Les terres de filtration

pourraient finir en compost. Russir Vigne. N164:

35.

Riberau-Gayon, P.; Glories, Y.; Maujan, A. and

Dubourdieu, D. (1998) La clarification des vins par

filtration et centrifugation. Trait dnologie. Vol 2.

Conventional

WIN

EB

AR

of

ort

nsp

tra

nd

ga

lin

ACKS

LR

RE

Flexibil

ity f

or s

tac

kin

g,

ha

nd

Figure 3. Quantitative Descriptor Analysis profile (QDA) of the final wines made

with juice obtained by flotation (*, **, ***: Main effects significant at P < 0.05,

P < 0.01, P < 0.001).

arrels

wine b

Proudly designed and manufactured by

JOHN FALLAND AUSTRALIA

Setting Standards Since 1961

Moppa Road South, Nuriootpa, SA 5355

Ph: (08) 8562 1533 Fax: (08) 8562 2103

Email: john@jfallandaust.com.au

Website: www.jfallandaust.com.au

Fabricated 20 years

ago and still popular

Over 270,000

made for over 1200

wineries

Stack five high with

your forklift

Lifetime galvanized

finish

Competitive prices

Reg Design No

117931

Vernet, A.; Moutounet, M. and Escudier, J-L.

(1998) Microfiltration tangentielle des vins. Journal

international des sciences de la vigne et du vin.

Traitements physiques des mots et des vins. Filtration.

N hors srie 45-52.

WVJ

or

Barrel Master

Superior rack

on rack stack

system

Simple,

uncluttered

design

Visible & easy

rack locating

system

No weight on

barrels

Static or barrel

rolling options

Reg Design

No 154262

New Zealand sales and distribution:

KAURI NEW ZEALAND LIMITED

Ph: 04 476 0105 Fax: 04 476 0161

PO Box 17-385,

. Karori, Wellington.

V2 7N 2

W i n e & V iticultur e Jo ur n a l MARC H /APRIL 2012

www.w inebiz. com . au

33

Potrebbero piacerti anche

- Galvanic CellsDocumento4 pagineGalvanic CellsshariziNessuna valutazione finora

- Business Environment PDFDocumento420 pagineBusiness Environment PDFSurjan SinghNessuna valutazione finora

- Module-3 E-Commerce: Amity School of BusinessDocumento53 pagineModule-3 E-Commerce: Amity School of BusinessAmol AgrawalNessuna valutazione finora

- Cell Galvanic PDFDocumento10 pagineCell Galvanic PDFWilliam FernandoNessuna valutazione finora

- Experiment-3: Galvanic SeriesDocumento4 pagineExperiment-3: Galvanic SeriesChayon MondalNessuna valutazione finora

- ScienceDocumento3 pagineScienceNuha ScssrNessuna valutazione finora

- Electrochemical Cell in ChemistryDocumento20 pagineElectrochemical Cell in ChemistryKh See100% (1)

- Environmental ProblemsDocumento10 pagineEnvironmental ProblemsJared AllenNessuna valutazione finora

- Lab Report Final 5206Documento12 pagineLab Report Final 5206Tanvir AhamedNessuna valutazione finora

- Lesson 7 The Phenomenon of DeathDocumento15 pagineLesson 7 The Phenomenon of DeathJOSEPHINE PUDANessuna valutazione finora

- Problems in Getting F12Documento1 paginaProblems in Getting F12Erwin CabangalNessuna valutazione finora

- Adjusting EntriesDocumento21 pagineAdjusting EntriesRegine ChuaNessuna valutazione finora

- Laboratory ExperimentsDocumento9 pagineLaboratory ExperimentsSandra MacatangayNessuna valutazione finora

- A Study of The Factors AffectingDocumento9 pagineA Study of The Factors AffectingEman AlkurdNessuna valutazione finora

- UNEP Report On Single Use Plastic PDFDocumento108 pagineUNEP Report On Single Use Plastic PDFAdrian JBrgNessuna valutazione finora

- Name Course & Year: ApparatusDocumento9 pagineName Course & Year: ApparatusJE SalmaNessuna valutazione finora

- Step Response of First Order System Expt ChE Lab 2Documento5 pagineStep Response of First Order System Expt ChE Lab 2simonatics08Nessuna valutazione finora

- Experiment ReportDocumento16 pagineExperiment ReportichaNessuna valutazione finora

- CH 17Documento43 pagineCH 17ዝምታ ውስጤ ነውNessuna valutazione finora

- Determination of Moisture Content or Total SolidsDocumento12 pagineDetermination of Moisture Content or Total SolidsfikerykNessuna valutazione finora

- Gravimetric Determination of Barium SulfateDocumento3 pagineGravimetric Determination of Barium SulfateArmiee InfiniteNessuna valutazione finora

- Chapter 2 Water QualityDocumento64 pagineChapter 2 Water QualityLogarithemNessuna valutazione finora

- Lab Report 3Documento9 pagineLab Report 3JaneXuanVictoriaNessuna valutazione finora

- Chapter 10Documento13 pagineChapter 10Khay OngNessuna valutazione finora

- Ejercicios Del Tema 1 y Tema 2 - Estatica Beer Jhonson 9edDocumento11 pagineEjercicios Del Tema 1 y Tema 2 - Estatica Beer Jhonson 9edJean Pierre MoralesNessuna valutazione finora

- Bar SoapDocumento40 pagineBar SoapMikaella ManzanoNessuna valutazione finora

- Cebu City Department of ChemistryDocumento7 pagineCebu City Department of ChemistryGeorgette RepunteNessuna valutazione finora

- CHEM 1221: Neutralization Titration Problem SetDocumento2 pagineCHEM 1221: Neutralization Titration Problem SetJohn Kristoffer RoblezaNessuna valutazione finora

- Extraction, Purification, and Determination by HPLC of Quercetin in Some Italian WinesDocumento5 pagineExtraction, Purification, and Determination by HPLC of Quercetin in Some Italian WinesYati NurhayatiNessuna valutazione finora

- The Journal of Supercritical FluidsDocumento9 pagineThe Journal of Supercritical FluidsNaraku MirokuNessuna valutazione finora

- Kiwi Spirits With Stronger Oral and Fruity Characters Were Obtained With A Packed Column Distillation SystemDocumento8 pagineKiwi Spirits With Stronger Oral and Fruity Characters Were Obtained With A Packed Column Distillation SystemmeriseptsihiteNessuna valutazione finora

- Quality of Fruit Nectars and Wines On The Local Market: Harmonization With Quality StandardsDocumento8 pagineQuality of Fruit Nectars and Wines On The Local Market: Harmonization With Quality Standardsilicradmila320Nessuna valutazione finora

- Articol BunDocumento6 pagineArticol BunRăzvan PomparăuNessuna valutazione finora

- Phenolics, Aroma Profile, and Antioxidant Activity of Italian Dessert Passito Wine From Saracena (Italy)Documento6 paginePhenolics, Aroma Profile, and Antioxidant Activity of Italian Dessert Passito Wine From Saracena (Italy)Nórida Pájaro GómezNessuna valutazione finora

- Wong 2003Documento14 pagineWong 2003VincentNessuna valutazione finora

- Experimental Design For Extraction and Quantification of Phenolic Compounds and Organic Acids in White "Vinho Verde" GrapesDocumento8 pagineExperimental Design For Extraction and Quantification of Phenolic Compounds and Organic Acids in White "Vinho Verde" Grapesfear1fear2Nessuna valutazione finora

- Washing The Grapes Before Crushing: Effects On Contaminants and FermentationDocumento11 pagineWashing The Grapes Before Crushing: Effects On Contaminants and FermentationPhuongMai LeNessuna valutazione finora

- Wine Nano Filtration 9435Documento7 pagineWine Nano Filtration 9435Dr. Vikhar KhanNessuna valutazione finora

- Fication and Concentration of Pomegranate Juice (Punica Granatum L.)Documento8 pagineFication and Concentration of Pomegranate Juice (Punica Granatum L.)Helton SilvaNessuna valutazione finora

- 1 s2.0 S0956713522000664 MainDocumento11 pagine1 s2.0 S0956713522000664 Maingiasugioi64Nessuna valutazione finora

- Chemical Assessment of White Wine During Fermentation ProcessDocumento5 pagineChemical Assessment of White Wine During Fermentation Processurcan_deliaNessuna valutazione finora

- Ethanol and Ethyl Acetate Production During The Cider Fermentation From Laboratory To Industrial ScaleDocumento6 pagineEthanol and Ethyl Acetate Production During The Cider Fermentation From Laboratory To Industrial ScaleArif Hidayat100% (1)

- Pesticides in The Distilled Spirits of Wine and Its ByproductsDocumento5 paginePesticides in The Distilled Spirits of Wine and Its ByproductsEva TuáNessuna valutazione finora

- A Nalysis of Wine Phenolics by High-Performance Liquid Chromatography Using A Monolithic Type ColumnDocumento7 pagineA Nalysis of Wine Phenolics by High-Performance Liquid Chromatography Using A Monolithic Type ColumnErica ResendeNessuna valutazione finora

- 67 Determination of Sugars and Sorbitol (HPLC) Rev 2005Documento5 pagine67 Determination of Sugars and Sorbitol (HPLC) Rev 2005Marcelle Fernandes da SilvaNessuna valutazione finora

- Nanofiltration and Reverse Osmosis in WinemakingDocumento5 pagineNanofiltration and Reverse Osmosis in WinemakingfasihaNessuna valutazione finora

- Technical Report - Determination of Benzoic Acid in Soft DrinkDocumento18 pagineTechnical Report - Determination of Benzoic Acid in Soft Drinkmohamad ashaziq100% (14)

- 2005v85no14p2391 2396Documento6 pagine2005v85no14p2391 2396jimmyboyjrNessuna valutazione finora

- Apple Wine PDFDocumento27 pagineApple Wine PDFAli Dandamun50% (4)

- Continuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesDocumento6 pagineContinuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesLoc VotuongNessuna valutazione finora

- JenniferPatiño ArtFerLote - 01 13-05-20 PDFDocumento4 pagineJenniferPatiño ArtFerLote - 01 13-05-20 PDFJennifer A. PatiñoNessuna valutazione finora

- Wine-Making by Cell-Recycle-Batch Fermentation Process : Short ContributionDocumento4 pagineWine-Making by Cell-Recycle-Batch Fermentation Process : Short ContributionJennifer A. PatiñoNessuna valutazione finora

- Article:: Ii. Oxidation of Sugars by An Carbohydrate Metabolism of Citrus FruitsDocumento7 pagineArticle:: Ii. Oxidation of Sugars by An Carbohydrate Metabolism of Citrus FruitsJeremia Kevin EmEmNessuna valutazione finora

- Bioconf-Oiv2016 02002Documento6 pagineBioconf-Oiv2016 02002diamita BernardinaNessuna valutazione finora

- The Analysis of Vodka - A ReviewDocumento11 pagineThe Analysis of Vodka - A ReviewTânia PinheiroNessuna valutazione finora

- Halal Food and Metrology: Ethyl Alcohol Contents Of: J. Chem. Metrol. 7:1 (2013) 7-9Documento3 pagineHalal Food and Metrology: Ethyl Alcohol Contents Of: J. Chem. Metrol. 7:1 (2013) 7-9Aam KurniasihNessuna valutazione finora

- Extraction and Fractionation of Bioactive Compounds From Aromatic PlantsDocumento6 pagineExtraction and Fractionation of Bioactive Compounds From Aromatic PlantsAravind KamathNessuna valutazione finora

- Flash Bio Thermo Extraction - What Can It Do For You? - by Paul BaggioDocumento3 pagineFlash Bio Thermo Extraction - What Can It Do For You? - by Paul BaggioTheBeverageFoodGroupNessuna valutazione finora

- 0352 51391001045iDocumento15 pagine0352 51391001045iRita RosadoNessuna valutazione finora

- Artigo RomaDocumento8 pagineArtigo RomaengrdharmyNessuna valutazione finora

- Filtration of Grape Juice SedimentsDocumento6 pagineFiltration of Grape Juice SedimentsJames AlvesNessuna valutazione finora

- Guide To Red Wine MakingDocumento74 pagineGuide To Red Wine MakingSladjan Maslac100% (1)

- Starting Your Own Wine BusinessDocumento50 pagineStarting Your Own Wine Businesscongsang099970Nessuna valutazione finora

- A Review of The Analytical Methods To Determine Organic Acids in Grape Juice-F BUNDocumento14 pagineA Review of The Analytical Methods To Determine Organic Acids in Grape Juice-F BUNRogerBucurNessuna valutazione finora

- Bactozym SG: Enzymatic Mixture For Controlling Malolactic FermentationDocumento1 paginaBactozym SG: Enzymatic Mixture For Controlling Malolactic FermentationAnonymous hP6ab2D1ppNessuna valutazione finora

- Pinot Meunier Tasting Notes - The ChampagnistDocumento75 paginePinot Meunier Tasting Notes - The ChampagnistMichiel Sebastiaan DemareyNessuna valutazione finora

- Lactobacillus SPP.: Lactobacillus Plantarum: Taxonomy, Identification, and Genetics of The SpeciesDocumento8 pagineLactobacillus SPP.: Lactobacillus Plantarum: Taxonomy, Identification, and Genetics of The SpeciesAlex CárdenasNessuna valutazione finora

- 2013 Vinquiry HarvestHandbookDocumento52 pagine2013 Vinquiry HarvestHandbookCojocaru GeorgeNessuna valutazione finora

- Fermented Beverage Production PDFDocumento437 pagineFermented Beverage Production PDFlamarqueg100% (5)

- Wine BookDocumento179 pagineWine Bookdalyj2009100% (2)

- Brouwland Catalog enDocumento214 pagineBrouwland Catalog enACB100% (1)

- Mango Fruit WineDocumento10 pagineMango Fruit WineSheryn Ann CaguladaNessuna valutazione finora

- Starter CulturesDocumento11 pagineStarter CulturesMarcelina Mendoza SalazarNessuna valutazione finora

- Lactobacillus Plantarum As A Malolactic Starter Cul - 2019 - Electronic JournalDocumento9 pagineLactobacillus Plantarum As A Malolactic Starter Cul - 2019 - Electronic Journaldua satuNessuna valutazione finora

- Ebook Monitoring The Winemaking Process From Grapes To WineDocumento133 pagineEbook Monitoring The Winemaking Process From Grapes To WineNuno SousaNessuna valutazione finora

- ၀ိုင္ျပဳလုပ္ျခင္း PDFDocumento44 pagine၀ိုင္ျပဳလုပ္ျခင္း PDFSł TĥűNessuna valutazione finora

- FermentationDocumento24 pagineFermentationUsman HaiderNessuna valutazione finora

- Apple WineDocumento6 pagineApple WinemohamedNessuna valutazione finora

- Isolation and Identification of The Genera AcetobacterDocumento9 pagineIsolation and Identification of The Genera AcetobacterervinamelaNessuna valutazione finora

- AROMA Compounds in WineDocumento13 pagineAROMA Compounds in WineAt YugovicNessuna valutazione finora

- Progress in Electrochemical (Bio) Sensors For Monitoring Wine ProductionDocumento39 pagineProgress in Electrochemical (Bio) Sensors For Monitoring Wine ProductionPulkit ShrivastavaNessuna valutazione finora

- The Occurrence of Malolactic Fermentation in Brandy Base Wine and Its Influence On Brandy QualityDocumento9 pagineThe Occurrence of Malolactic Fermentation in Brandy Base Wine and Its Influence On Brandy QualityNatalia Valentina Toledo AguilarNessuna valutazione finora

- Wine MakingDocumento31 pagineWine Makinganon_biochemistrystudent100% (1)

- Introduction To Wine: Student Lungu CiprianDocumento17 pagineIntroduction To Wine: Student Lungu CiprianDan GrigorescuNessuna valutazione finora

- Food Chemistry: Dai Chen, Shao-Quan LiuDocumento8 pagineFood Chemistry: Dai Chen, Shao-Quan LiuGabriel F RuedaNessuna valutazione finora

- Biogenic Amines in Red Wine The Impact oDocumento13 pagineBiogenic Amines in Red Wine The Impact ocoyote1962Nessuna valutazione finora

- High-Throughput Sequencing of Microbial Community Diversity in Soil, Grapes, Leaves, Grape Juice and Wine of Grapevine From ChinaDocumento17 pagineHigh-Throughput Sequencing of Microbial Community Diversity in Soil, Grapes, Leaves, Grape Juice and Wine of Grapevine From ChinaDaniel ImanuelNessuna valutazione finora

- Make CiderDocumento25 pagineMake CiderΜπάμπης ΦαγκρήςNessuna valutazione finora

- Workbook PDFDocumento70 pagineWorkbook PDFGaudence walecNessuna valutazione finora

- PediococcusDocumento19 paginePediococcusgaffodio hadrienNessuna valutazione finora