Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A253S80 INT69TM2 Diagnose 71000428 0-Ebook

Caricato da

Marco Tulio Da Silva0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

228 visualizzazioni1 paginaINT69 TM2 diagnosis is a further development of the reliable KRIWAN motor protectors. Its supplementary flexibleresponse protective functions help to improve the availability and extend the service life of a refrigeration system. It automatically saves operational and error data in a non-volatile memory. This data can be retrieved on a PC and analysed for diagnosis.

Descrizione originale:

Titolo originale

A253S80_INT69TM2_Diagnose_71000428_0-Ebook

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoINT69 TM2 diagnosis is a further development of the reliable KRIWAN motor protectors. Its supplementary flexibleresponse protective functions help to improve the availability and extend the service life of a refrigeration system. It automatically saves operational and error data in a non-volatile memory. This data can be retrieved on a PC and analysed for diagnosis.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

228 visualizzazioni1 paginaA253S80 INT69TM2 Diagnose 71000428 0-Ebook

Caricato da

Marco Tulio Da SilvaINT69 TM2 diagnosis is a further development of the reliable KRIWAN motor protectors. Its supplementary flexibleresponse protective functions help to improve the availability and extend the service life of a refrigeration system. It automatically saves operational and error data in a non-volatile memory. This data can be retrieved on a PC and analysed for diagnosis.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

INT69 TM2 Diagnose

INT69 TM2 Diagnose

Application

The motor protector INT69 TM2 Diagnosis is a further development of

the reliable KRIWAN motor protectors. Its supplementary flexibleresponse protective functions help to improve the availability and

extend the service life of a refrigeration system.

The INT69 TM2 Diagnosis automatically saves operational and error

data in a non-volatile memory. This data can be retrieved on a PC and

analysed for diagnosis. The full scope of the diagnosis is achieved by

using a KRIWAN-specific AMS sensor.

This motor protector is mainly employed on compressors which are

qualified acc. to IEC/EN 60335.

Functional description

INT69 TM2 Diagnose

L1

L2

L3

N

PE

INT69 TM2 Diagnose

DP

The temperature monitoring of the motor winding is done with two

evaluation processes:

Static: Switch-off is immediate if the nominal response temperature

of the built-in AMS or PTC sensors is reached.

Dynamic: If the temperature increases unusually quickly, the motor

is switched off immediately even if the temperature is still far below

the nominal response temperature. This prevents excess temperatures from occurring.

A short circuit at an AMS or PTC input also leads to a switch-off. A short

cycling leads to a reset delay.

After expiration of the reset delay and elimination of the error or cooldown, the compressor can be restarted.

For operation in the specified manner, the supply voltage has to be on

permanently on the INT69 TM2 Diagnosis.

Technical specifications

F1

12

14

K1

M

3 AC

F2

11

C

HP

LP

Motor PTC

Wiring diagram

53

10

33

4.5

3.5

2.5

68

80

Dimensions in mm

The mounting, maintenance and operation are to be carried out

by an electrician. The valid European and national standards for

connecting electrical equipment and cooling installations have to

be observed. Connected sensors and connection lines that

extend from the terminal box have to feature at least a basic insulation.

Translation of data sheet 700.00428.0

Permitted ambient temperature

Temperature measuring circuits

- Type

To determine the compressor running times, the INT369

Diagnosis has to be the last protection unit before the compressor

contacter (see wiring diagram). For that, the INT369 Diagnosis

and the safety circuit have to be connected to the same phase of

the same supply network.

- R25,total

- Rtrip, static

- Rreset

- Max. length connection line

Short circuit monitoring system

PTC

Switching frequency overstepping

Reset delay

- Motor temperature static

- Motor temperature dynamic

- Switching frequency overstepping

Reset of reset delay

115-230V~ 50Hz, 120-240V~

60Hz 10% 3VA

-30...+70C

1-2 AMS sensors in series

alternative 1-9 PTC acc. to

DIN 44081, DIN 44082 in series

<1.8k

4.5k 20%

2.75k 20%

30m

Typically <30

3 switch-offs in 30 sec.

5min 1min

5min 1min

5min 1min

Main reset >5 sec. only possible if

there is no error current

Relay

- Connection

Refer to wiring diagram

Max. 2.5A C300

- Mechanical service life

Approx. 1 million switching cycles

Interface

Diagnose port (DP)

Protection class acc. to EN 60529 IP00

Connection type

Screw type terminal

Housing material

PA glass-fibre-reinforced

Mounting

Screw mounted

Dimensions

Refer to dimensions in mm

Weight

Approx. 200g

Check base

IEC/EN 60335, IEC/EN 60730

EN 61000-6-3, EN 61000-6-2

EN 61010-1

Overvoltage category II

Pollution level 2

Approval

UL File no. E75899 cURus

VDE certification no. 40022017

Order data

INT69 TM2 Diagnose

Accessories and application

information

Technical changes reserved

22 A 253 S80

see www.kriwan.com

KRIWAN Industrie-Elektronik GmbH Allmand 11 D-74670 Forchtenberg phone ++49-7947-822-0 fax ++49-7947-1288 e-mail: info@kriwan.com home: www.kriwan.com

Product group A

Edition: 710.00428.0

Supply voltage

K1

Potrebbero piacerti anche

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageDa EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNessuna valutazione finora

- Instruction TEC TF7650Documento24 pagineInstruction TEC TF7650turboedNessuna valutazione finora

- ABB Thermistor RelaysDocumento9 pagineABB Thermistor RelaysJJGNessuna valutazione finora

- Intelligent Thermal Management and Fan Control SolutionsDocumento7 pagineIntelligent Thermal Management and Fan Control SolutionsManish GNessuna valutazione finora

- A620s80 81 Int69kf2 PDFDocumento1 paginaA620s80 81 Int69kf2 PDFMIGUEL ÁNGEL TOMÉNessuna valutazione finora

- Rem 610Documento16 pagineRem 610Padmo PadmundonoNessuna valutazione finora

- MPR2000Documento40 pagineMPR2000JoselopezperezNessuna valutazione finora

- NT935 Standard ING R4Documento12 pagineNT935 Standard ING R4JorgeAlvesNessuna valutazione finora

- Application Note - Thyristor Teaching SystemDocumento20 pagineApplication Note - Thyristor Teaching Systemjattends100% (1)

- Acme PIUDocumento4 pagineAcme PIUJay TrivediNessuna valutazione finora

- For 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971Documento6 pagineFor 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971marioalf674150Nessuna valutazione finora

- Instruction Manual: Dossena S.N.CDocumento12 pagineInstruction Manual: Dossena S.N.CRazvan SasuNessuna valutazione finora

- Honeywell Satronic DKG972Documento6 pagineHoneywell Satronic DKG972maccsyNessuna valutazione finora

- DB hrc800 e 9498-737-38613 PDFDocumento4 pagineDB hrc800 e 9498-737-38613 PDFpradeepchennai10_959Nessuna valutazione finora

- Op - Tc544a - Tc244ax - Tc344ax - Dtc204a-2 - Dtc324a-2 - Op294-V05 - 04-07-13Documento3 pagineOp - Tc544a - Tc244ax - Tc344ax - Dtc204a-2 - Dtc324a-2 - Op294-V05 - 04-07-13Raja VeluNessuna valutazione finora

- Ramde RelayDocumento8 pagineRamde RelayculwavesNessuna valutazione finora

- LB 11961Documento7 pagineLB 11961Ayala Eduardo La San RamonNessuna valutazione finora

- Motor Protection ManualDocumento20 pagineMotor Protection ManualNirmal mehtaNessuna valutazione finora

- IR MelexisDocumento52 pagineIR Melexisleomar_bNessuna valutazione finora

- Motan 960Documento11 pagineMotan 960DgfdghfghFfdhgfhjgNessuna valutazione finora

- Power Interface UnitDocumento2 paginePower Interface UnitPushkar MishraNessuna valutazione finora

- Siemens PTC RTD Thermocouples Section7 Rev1Documento16 pagineSiemens PTC RTD Thermocouples Section7 Rev1DelfinshNessuna valutazione finora

- Temperature Controller T2612 Instruction ManualDocumento16 pagineTemperature Controller T2612 Instruction ManualtduskoNessuna valutazione finora

- Ramde Motor Protection RelayDocumento8 pagineRamde Motor Protection RelayishhumzpNessuna valutazione finora

- Esm-7710 Man Env04Documento44 pagineEsm-7710 Man Env04itsirc67Nessuna valutazione finora

- 389 - R10 - Moni 200H eDocumento4 pagine389 - R10 - Moni 200H eJohn Arllan DiestroNessuna valutazione finora

- FinalDocumento25 pagineFinaljiggar agarwal0% (1)

- Int69 Vsy-Ii Protection ModuleDocumento1 paginaInt69 Vsy-Ii Protection Moduleamir12345678Nessuna valutazione finora

- A263 - INT69 TM2 - Diagnose - 71000448 - 0Documento2 pagineA263 - INT69 TM2 - Diagnose - 71000448 - 0bnx5dkq786Nessuna valutazione finora

- Automatic Temperature Control in Furnace Using PLCDocumento19 pagineAutomatic Temperature Control in Furnace Using PLCAhammedali Ch0% (1)

- Pixsys ATR 142Documento47 paginePixsys ATR 142froilan ochoaNessuna valutazione finora

- DKG 972Documento6 pagineDKG 972David RamirezNessuna valutazione finora

- Fludex EOC SystemDocumento11 pagineFludex EOC SystemSholhan Aziz100% (2)

- SCR Power Controller ManualDocumento28 pagineSCR Power Controller ManualJorge PeraltaNessuna valutazione finora

- 118L Digital BulletinDocumento4 pagine118L Digital Bulletinmbk.2k3Nessuna valutazione finora

- Tyco 3ph EnglishDocumento13 pagineTyco 3ph Englishacroali0% (1)

- OZ9939GNDocumento12 pagineOZ9939GNEduardo SierraNessuna valutazione finora

- Electronic Module For Copeland Scroll Compressor Motor Protection Technical Information en GB 4839514Documento5 pagineElectronic Module For Copeland Scroll Compressor Motor Protection Technical Information en GB 4839514Jose OviedoNessuna valutazione finora

- Datasheet 90621xxxDocumento46 pagineDatasheet 90621xxxdrdandeNessuna valutazione finora

- Electronic Pressure Switch & Transmitter: General SpecificationDocumento4 pagineElectronic Pressure Switch & Transmitter: General Specificationhuu thanh nguyenNessuna valutazione finora

- St34-g Sunrise ManualDocumento32 pagineSt34-g Sunrise Manualandres100% (1)

- Sirtrans T Pt100Documento24 pagineSirtrans T Pt100nicoroman73_2Nessuna valutazione finora

- IR Sensor Thermometer MLX90614 Datasheet Download Link 5152Documento49 pagineIR Sensor Thermometer MLX90614 Datasheet Download Link 5152Enderson PeraltaNessuna valutazione finora

- PTC ReissmannDocumento8 paginePTC ReissmannAndré Carlos CorenzanNessuna valutazione finora

- ThermocoupleDocumento18 pagineThermocoupleMuhammad IftikharNessuna valutazione finora

- SM 592.2 Caja de Control ElectromagneticaDocumento6 pagineSM 592.2 Caja de Control ElectromagneticaHectorI.GoCaNessuna valutazione finora

- MM 2Documento8 pagineMM 2John Arllan DiestroNessuna valutazione finora

- ST34-G Meter Technical ManualDocumento32 pagineST34-G Meter Technical ManualPedro Andrés GarzonNessuna valutazione finora

- Altec: Instruction ManualDocumento33 pagineAltec: Instruction Manualfrankie35Nessuna valutazione finora

- MLX90614 Rev001Documento35 pagineMLX90614 Rev001JavierPariNessuna valutazione finora

- Man Cseries 22862CDocumento31 pagineMan Cseries 22862Cthanna9783Nessuna valutazione finora

- La 42072Documento5 pagineLa 42072の選択 ウィル100% (1)

- MCU-UNT-MMI Manual PDFDocumento37 pagineMCU-UNT-MMI Manual PDFKUNALJAYNessuna valutazione finora

- Heat Treat CatalogDocumento20 pagineHeat Treat CatalogGabriel Gonzalez100% (1)

- MODEL PC-252 - Transformer Temperature IndicatorDocumento6 pagineMODEL PC-252 - Transformer Temperature IndicatorMKNessuna valutazione finora

- 7XV5662!2!5AD10 Manual Ziehl TR600 enDocumento10 pagine7XV5662!2!5AD10 Manual Ziehl TR600 enEddy Fernando Queca CadizNessuna valutazione finora

- Abt Meter SpecificationsDocumento11 pagineAbt Meter SpecificationsriteshnaikNessuna valutazione finora

- MKC - PKCDocumento12 pagineMKC - PKCTymbark MaspexNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- DatasheetDocumento15 pagineDatasheetjuniorcanaa2011Nessuna valutazione finora

- PP Comp GuideDocumento2 paginePP Comp GuideMarco Tulio Da SilvaNessuna valutazione finora

- A622 INT69SU2 71000394 0-Ebook PDFDocumento1 paginaA622 INT69SU2 71000394 0-Ebook PDFMarco Tulio Da Silva100% (1)

- A622 INT69SU2 71000394 0-Ebook PDFDocumento1 paginaA622 INT69SU2 71000394 0-Ebook PDFMarco Tulio Da Silva100% (1)

- Sample Application Circuit (2x120W Min AF Power Amplifier STK4241V)Documento2 pagineSample Application Circuit (2x120W Min AF Power Amplifier STK4241V)Marco Tulio Da SilvaNessuna valutazione finora

- 30 LED Projects Book PDFDocumento46 pagine30 LED Projects Book PDFBien Morfe100% (2)

- Vu MeterDocumento6 pagineVu MeterMarco Tulio Da SilvaNessuna valutazione finora

- Tda 7052Documento8 pagineTda 7052trc_wmNessuna valutazione finora

- Water Level BuzzerDocumento1 paginaWater Level BuzzerSree Rag100% (1)

- An 1138Documento18 pagineAn 1138Marco Tulio Da SilvaNessuna valutazione finora

- Data Sheet: TDA1510AQDocumento12 pagineData Sheet: TDA1510AQGerardo PonceNessuna valutazione finora

- An 1138Documento18 pagineAn 1138Marco Tulio Da SilvaNessuna valutazione finora

- Data Sheet: PNP Switching TransistorsDocumento8 pagineData Sheet: PNP Switching TransistorsvdăduicăNessuna valutazione finora

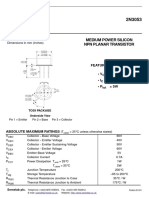

- 2N3053 PDFDocumento2 pagine2N3053 PDFGhofur Al MusthofaNessuna valutazione finora

- Data Sheet: TDA1558QDocumento11 pagineData Sheet: TDA1558QMarco Tulio Da SilvaNessuna valutazione finora

- TL 071Documento18 pagineTL 071Armando GuerraNessuna valutazione finora

- pcd8544 NOKIA3310Documento32 paginepcd8544 NOKIA3310Nishant BhartiNessuna valutazione finora

- Research Title Approval FormDocumento2 pagineResearch Title Approval FormJames EdlynNessuna valutazione finora

- Building Construction Costs Handbook 2019-2020Documento89 pagineBuilding Construction Costs Handbook 2019-2020Rotich philipNessuna valutazione finora

- Indian Standard: Methods of Test For Aggregates For ConcreteDocumento22 pagineIndian Standard: Methods of Test For Aggregates For ConcreteAnuradhaPatraNessuna valutazione finora

- Resume FixedDocumento2 pagineResume Fixedapi-356691606Nessuna valutazione finora

- Haggling As A Socio-Pragmatic Strategy (A Case Study of Idumota Market)Documento15 pagineHaggling As A Socio-Pragmatic Strategy (A Case Study of Idumota Market)Oshoja Tolulope OlalekanNessuna valutazione finora

- EER Model: Enhance Entity Relationship ModelDocumento12 pagineEER Model: Enhance Entity Relationship ModelHaroon KhalidNessuna valutazione finora

- Basic Task 315Documento9 pagineBasic Task 315gaikwadamitag1Nessuna valutazione finora

- Semiconductor Application Library ManualDocumento494 pagineSemiconductor Application Library ManualValerioApicellaNessuna valutazione finora

- Pests and Diseases Identification in MangoDocumento4 paginePests and Diseases Identification in MangoBaino Olpugad Gerald100% (1)

- Risk Management Q1Documento8 pagineRisk Management Q1Parth MuniNessuna valutazione finora

- S1 Mock 2Documento13 pagineS1 Mock 2Abdulrahman HatemNessuna valutazione finora

- Soft-Starter: Programming ManualDocumento162 pagineSoft-Starter: Programming ManualThaylo PiresNessuna valutazione finora

- Service Manual: DDX24BT, DDX340BTDocumento94 pagineService Manual: DDX24BT, DDX340BTDumur SaileshNessuna valutazione finora

- Vichinsky Et Al.2019Documento11 pagineVichinsky Et Al.2019Kuliah Semester 4Nessuna valutazione finora

- Uvm UnderstandingDocumento8 pagineUvm UnderstandingLokesh KumarNessuna valutazione finora

- RQM - P: Series 60 Subplate Mounting RQM3-P ISO 6264-06 RQM5-P ISO 6264-08 RQM7-P ISO 6264-10Documento4 pagineRQM - P: Series 60 Subplate Mounting RQM3-P ISO 6264-06 RQM5-P ISO 6264-08 RQM7-P ISO 6264-10Jorge MendozaNessuna valutazione finora

- Tankless Vs TankDocumento2 pagineTankless Vs TankClick's PlumbingNessuna valutazione finora

- Define-Phase Yellow BeltDocumento52 pagineDefine-Phase Yellow BeltBhadri NarayananNessuna valutazione finora

- Lecture Notes 10: Fading Channels ModelsDocumento19 pagineLecture Notes 10: Fading Channels ModelsayushNessuna valutazione finora

- Olympic Highway Intersection Upgrades Community Update 09 2021Documento5 pagineOlympic Highway Intersection Upgrades Community Update 09 2021Rex MartinichNessuna valutazione finora

- Ineo+ 200 Parts Guide ManualDocumento90 pagineIneo+ 200 Parts Guide ManualOláh GyörgyNessuna valutazione finora

- The Law of CosinesDocumento4 pagineThe Law of Cosinesapi-213604106Nessuna valutazione finora

- Quickspecs: HP Probook 440 G2 Notebook PCDocumento51 pagineQuickspecs: HP Probook 440 G2 Notebook PCAseemSharanNessuna valutazione finora

- Ruskin As A Social Reformer - Docx ADocumento2 pagineRuskin As A Social Reformer - Docx AAtif Hayat50% (2)

- The Impact of Employees' Commitment Towards Food Safety at Ayana Resort, BaliDocumento58 pagineThe Impact of Employees' Commitment Towards Food Safety at Ayana Resort, Balirachelle agathaNessuna valutazione finora

- Matrix Analysis of Networks: J. R. LucasDocumento63 pagineMatrix Analysis of Networks: J. R. LucasNethmini SamarawickramaNessuna valutazione finora

- Philosophical Warfare and The Shadow of IdeasDocumento5 paginePhilosophical Warfare and The Shadow of IdeasDavid MetcalfeNessuna valutazione finora

- Group 2 PBA - ScriptDocumento6 pagineGroup 2 PBA - ScriptruciNessuna valutazione finora

- Chapter 1 To7 With Course OutlineDocumento34 pagineChapter 1 To7 With Course Outlinerk_kamatchi3483Nessuna valutazione finora

- Removal Processes and Machine Tools: Indian Institute of Technology DelhiDocumento28 pagineRemoval Processes and Machine Tools: Indian Institute of Technology DelhiEthan HuntNessuna valutazione finora