Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Model 274 Regulator General Description GD274 - nonUSA PDF

Caricato da

Antonio VelardeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Model 274 Regulator General Description GD274 - nonUSA PDF

Caricato da

Antonio VelardeCopyright:

Formati disponibili

MODEL 274 GAS PRESSURE REGULATOR

General Description

Edition

GD274.06

BRYAN DONKIN RMG CANADA LIMITED

Serving the Gas IndustryWORLDWIDE

MODEL 274 GAS PRESSURE REGULATOR

General Description

Applications

Primarily utilized for commercial and industrial applications

For natural gas and all non-corrosive gaseous media

Various options for specialty applications

Fixed Factor Billing model available for PFM applications, that ensure

outlet pressure accuracy to +/- 1% absolute pressure

Characteristics

Specifically designed for safe, accurate, pressure reduction of gaseous

media

Wide inlet pressure range 1125 psig (0.07-8.5 bar) depending on orifice diameter

Maximum inlet pressure 150 psig (10 bar)

Maximum operating pressure 125 psig (8.5 bar)

Spring-loaded, lever-operated to accommodate changes in inlet pressure

Various interchangeable orifices for ease of maintenance and increased

turndown ratio to accommodate a wide range of flows and pressure conditions (inlet & outlet pressures)

Outlet pressure settings from 6 w.c. to 6 psig (15-420 mbar) over 5

spring ranges

Balanced valve version available for increased accuracy and control

3 different inlet/outlet thread diameters (National or British Pipe Standards NPT, BSPT, BSPP)

2 flanged version available in ANSI150 or PN16 with flat or raised face

profiles

Flanged body available in cast iron, ductile iron or cast steel

Various relief valve assemblies available (full, limited and zero capacity

relief discharge)

1 threaded vent connection

Available with Internal Impulse or Control Line (I.C.L.) or External Impulse

or Control Line Connections (E.C.L.)

Ease of maintenance due to interchangeable diaphragm casing cartridge

Various safety slam-shut valve (SSV) models available for pressure/flow

cut-off protection

Custom designed and pre-fabricated regulator assemblies available

2

MODEL 274 GAS PRESSURE REGULATOR

General Description

Fixed

Factor Billing for PFM applicationsto maintain outlet pressure accuracy

for applications that require downstream

pressure to be held within +/- 1% absolute

pressure

Outlet pressures from 6 w.c. to 6 psig

over 5 spring ranges. Set point can be

adjusted easily with standard socket.

Regulator top cap has the capability of

including the provision for a wire seal.

Under & Over Pressure Safety

Over Pressure Safety Slam-Shut

Slam-Shut Valve (UPCO/OPCO)

options available

Valve (OPCO) options available

Integral

slam-shut valves available to protect

against under (UPCO) and over pressure (OPCO)

conditions in the downstream pipe-work. Slamshut valves also available with low differential

pressure cut-off and thermal trip (T-type) protection feature to shut gas off if regulator is engulfed

in a fire.

threaded vent

connection protected

by screen that is easily

removed to attach

vent extender or ventline.

Pressure

test points available at

inlet & outlet chambers of the body,

as an option.

Reinforced

diaphragm for increased

speed of response and

durability.

Several available

orifice diameters to

accommodate a wide

range of pressure conditions and flow require-

3 different pipe

thread diameters available on an inline (180 )

body designs. 1,

1 or 2 or 1 NPT,

BSPT or BSPP

Available

with full capacity, limited

capacity, no capacity internal relief valve

designs to manage the capability of the

regulator to discharge over pressure gas.

Safety diaphragms also available.

Cartridge

style regulator diaphragm

casing design so retrofitting new regulator

casings is very easy without removing regulator body from the pipe-work.

Atmospheric Pressure

Inlet Pressure

Outlet Pressure

2 flanged connecAvailable

with Internal Impulse or

Control Line (I.C.L.) or External Impulse

or Control Line Connections (E.C.L.)

tions available in ANSI150 or PN16 with flat

Available

with integrated union fitting

with o-ring seal for 100% bubble-tight seal

on both inlet or outlet body connections to

ease and reduce installation labor. Union

available in standard or insulated versions.

MODEL 274 GAS PRESSURE REGULATOR

General Description

Available Constructions

274 R: full internal relief capacity

274 P: no internal relief capacity

274LR-290 OPCO: limited internal relief capacity with integral Over Pressure

Cut-Off safety slam-shut valve

274P-290 OPCO: no internal relief capacity with integral Over Pressure CutOff safety slam-shut valve

274SD-290 OPCO SD: no internal relief capacity with safety diaphragms and

Over Pressure Cut-Off safety slam-shut valve

274LR-309 UPCO/OPCO: limited internal relief capacity with integral Under

and Over Pressure Cut-Off safety slam-shut valve

274P-309 UPCO/OPCO: no internal relief capacity with integral Under and

Over Pressure Cut-Off safety slam-shut valve

274SD-309 UPCO/OPCO: no internal relief capacity with safety diaphragms

and Under and Over Pressure Cut-Off safety slam-shut valve.

PFM version: fixed factor billing or pressure factor metering version for outlet pressure accuracy within 1% absolute pressure. Outlet pressure range

from 2 to 5.5 psig (140 to 385 mbar)

Thermal Protection (T-Type): no internal relief capacity with safety diaphragms and integral safety slam-shut valve (OPCO or UPCO/OPCO) that has

shut-off protection if assembly is engulfed in a fire. Assembly has many steel

component parts.

I.C.L. Type: Internally sensing or internal control line to measure outlet pressure

E.C.L. Type: Externally sensing or external control line required to measure

outlet pressure in downstream pipe-work. Diaphragm casings drilled and

tapped NPT or BSPT to connect downstream sensing line.

F version: complete with inlet mess filter

Body Sizes and Connection Types

Screwed Type Body

1, 1 & 2 screwed

NPT, BSPT or BSPP threaded types

U-type: with modified inlet union fitting on either inlet and/or outlet

connections

Flanged Type Body

2 flanged inlet/outlet

MODEL 274 GAS PRESSURE REGULATOR

General Description

Pressure Ratings

Maximum Recommended Inlet Pressure

150 psig (10 bar)

Maximum Recommended Operating Pressure

125 psig (8.6 bar) with 5,0, 7.5mm & 10.0mm orifices

75 psig (5 bar) with 15.0mm orifice

60 psig (4 bar) with 20.0mm orifice

15 psig (1 bar) with 25.0mm & 30.0mm orifices

125 psig (8.6 bar) with 30.0mm orifice and balanced valve

Materials of Construction

Screwed Body

Cast Iron

Flanged Body

Cast Iron, Ductile Iron, Cast Steel

Diaphragm Casings

Die Cast Aluminum

Diaphragm

Molded Nitrile Rubber with Nylon

Reinforcing

Valve Head (Seat)

Buna-N Rubber & Polyurethane

Diaphragm Plates

Steel

Orifice

Brass or Stainless Steel (T-type)

Vent Screen

Stainless Steel

Fasteners

Steel

Top Cap (standard)

Aluminum

Weights

w/ screwed body 18 lb. (8.2 kg)

w/ cast iron flanged body - 28 lb. (12.75 kg)

w/ ductile iron flanged body 30 lb. (13.6 kg)

w/ cast steel flanged body 36 lb. (16.4 kg)

w/ 290 OPCO - add 1.1 lb. (0.5 kg)

w/ 309 UPCO/OPCO 2.2 lb. (1.0 kg)

w/ 309 T-Type UPCO/OPCO 4.75 lb. (2.2 kg)

Temperature Rating

-40 to 60 Celsius

-40 to 120 Fahrenheit

o

o

MODEL 274 GAS PRESSURE REGULATOR

General Description

Outlet Pressure Range

Range (imperial)

Range (metric)

Spring Number/Colour

6 14 w.c.

15 35 mbar

960 (grey)

12 - 22 w.c.

30 56 mbar

961 (yellow)

20 - 40 w.c.

50 100 mbar

962 (brown)

1 3 psig

70 210 mbar

963 (orange)

2 6 psig

140 420 mbar

964 (blue)

Relief Pressure Range

Outlet Pressure Spring

Relief Range (imperial)

Relief Range (metric)

960

12 - 34 w.c.

30 85 mbar

961

22 - 50 w.c.

55 125 mbar

962

34 - 68 w.c.

85 170 mbar

963

2 - 5 psig

140 350 mbar

964

3 - 9 psig

210 - 630 mbar

Relief Valve Options

SD-Type

Safety Diaphragm

Pilot-Operated Version for Higher Outlet Pressures and

Flow Capacity, see Model 273PL and 270/3PL Regulator

Technical Bulletins.

6

MODEL 274 GAS PRESSURE REGULATOR

General Description

Outlet

Pressure

Inlet Pressure

psig

SET POINT

7 w.c.

(18 mbar)

Spring 960

(range 6 - 14 w.c.)

(range 15 35 mbar)

DROOP/

BOOST

1 w.c.

2.5 mbar

Accuracy

Class

20%

Orifice Size (millimeters/inches)

bar

5.0mm

7.5mm

10.0mm

15.0mm

20.0mm

30.0mm

30.0mm

BALANCED VALVE

(0.070)

400

(11.3)

800

(22.7)

1000

(28.3)

1500

(42.5)

1750

(49.6)

1700

(48.2)

1700

(48.2)

(0.140)

550

(15.6)

1100

(31.2)

1450

(41.1)

2200

(62.3)

2500

(70.8)

3300

(93.5)

2000

(56.7)

(0.350)

900

(24.5)

1750

(49.6)

2500

(70.8)

3500

(99.2)

4200

(119.0)

5500

(155.8)

4000

(113.3)

10

(0.700)

1200

(34.0)

2300

(65.2)

4000

(113.3)

5500

(155.8)

14000

(396.6)

13000

(368.3)

12000

(340.0)

15

(1)

1600

(45.3)

3000

(85.0)

5000

(141.6)

12000

(340.0)

16000

(453.3)

16000

(453.3)

14000

(396.6)

30

(2)

2200

(62.3)

4700

(133.1)

10000

(283.3)

16000

(453.3)

16000

(453.3)

14000

(396.6)

45

(3)

2700

(76.5)

7200

(204.0)

16000

(453.3)

16000

(453.3)

16000

(453.3)

14000

(396.6)

60

(4)

3400

(96.3)

10000

(283.3)

16000

(453.3)

16000

(453.3)

16000

(453.3)

14000

(396.6)

75

(5)

4200

(119.0)

11000

(311.6)

16000

(453.3)

16000

(453.3)

14000

(396.6)

100

(7)

7000

(198.3)

12500

(354.1)

16000

(453.3)

ft /hr

14000

(396.6)

125

(8.6)

9500

(269.1)

16000

(453.3)

16000

(453.3)

(m /hr)

14000

(396.6)

(43.9)

(0.070)

350

(9.9)

600

(17.0)

800

(22.7)

1100

(31.2)

1600

(45.3)

1650

(46.7)

1550

(0.140)

500

(14.2)

1000

(28.3)

1350

(38.2)

2000

(56.7)

2300

(65.2)

3000

(85.0)

1900

(53.8)

(0.350)

800

(22.7)

1600

(45.3)

2300

(65.2)

3200

(90.7)

4000

(113.3)

5400

(153.0)

3800

(107.6)

DROOP/

BOOST

2 w.c.

5.0 mbar

10

(0.700)

1100

(31.2)

2150

(60.9)

3700

(104.8)

5200

(147.3)

14000

(396.6)

12000

(339.9)

11000

(311.6)

15

(1)

1400

(39.7)

2700

(76.5)

4700

(133.1)

12000

(339.9)

16000

(453.3)

16000

(453.3)

14000

(396.6)

30

(2)

2100

(59.5)

4400

(124.6)

10000

(283.3)

16000

(453.3)

16000

(453.3)

14000

(396.6)

Accuracy

Class

20%

45

(3)

2500

(70.8)

6900

(195.5)

16000

(453.3)

16000

(453.3)

16000

(453.3)

14000

(396.6)

60

(4)

3150

(89.2)

9000

(255.0)

16000

(453.3)

16000

(453.3)

16000

(453.3)

14000

(396.6)

16000

(453.3)

SET POINT

10 w.c.

(25mbar)

Spring 960

(range 6 - 14 w.c.)

(range 15 35 mbar)

SET POINT

14 w.c.

(35 mbar)

75

(5)

3800

(107.6)

10000

(283.3)

16000

(453.3)

14000

(396.6)

100

(7)

6000

(170.0)

11000

(311.6)

16000

(453.3)

ft /hr

14000

(396.6)

125

(8.6)

8000

(226.6)

15000

(424.9)

16000

(453.3)

(m /hr)

14000

(396.6)

(0.070)

350

(9.9)

550

(15.6)

700

(19.8)

1000

(28.3)

1450

(41.1)

1600

(45.3)

1400

(39.6)

(0.140)

450

(12.7)

900

(25.5)

1100

(31.2)

1750

(49.6)

2200

(62.3)

2800

(79.3)

1700

(48.2)

Spring 961

(range 12 - 22 w.c.)

(range 30 56 mbar)

(0.350)

850

(24.1)

1500

(42.5)

1850

(52.4)

2650

(75.1)

3200

(90.7)

5200

(147.3)

3500

(99.2)

DROOP/

BOOST

3 w.c.

7.5 mbar

10

(0.700)

1150

(32.6)

2000

(56.7)

3000

(85.0)

4400

(124.6)

12500

(354.1)

12500

(354.1)

11000

(311.6)

15

(1)

1400

(39.7)

3100

(87.8)

3900

(110.5)

5500

(155.8)

15000

(424.9)

16000

(453.3)

14000

(396.6)

30

(2)

2000

(56.7)

4100

(116.1)

9000

(255.0)

17000

(481.6)

23000

(651.6)

14000

(396.6)

Accuracy

Class

20%

45

(3)

2600

(73.7)

5500

(155.8)

12000

(339.9)

21500

(609.1)

24000

(679.9)

14000

(396.6)

60

(4)

3300

(93.5)

8800

(249.3)

14500

(410.8)

21500

(609.1)

24500

(694.1)

14000

(396.6)

75

(5)

3700

(104.8)

10500

(297.5)

17500

(495.8)

21500

(609.1)

14000

(396.6)

100

(7)

4200

(119.0)

12000

(339.9)

17500

(495.8)

ft /hr

14000

(396.6)

125

(8.6)

5500

(155.8)

15000

(424.9)

17500

(495.8)

(m /hr)

14000

(396.6)

HIGHLIGHTED AREAS MUST BE SERVICED BY AN EXTERNAL CONTROL LINE (E.C.L.)

Scfh (ft /hr) - natural gas, 0.6 sg

Scmh (m /hr) - natural gas, 0.6 sg

2

MODEL 274 GAS PRESSURE REGULATOR

General Description

Outlet

Pressure

Inlet Pressure

psig

SET POINT

18 w.c.

(46 mbar)

Spring 961

(range 12 - 22 w.c.)

(range 35 56 mbar)

DROOP/

BOOST

4 w.c.

10 mbar

Accuracy

Class

20%

SET POINT

28 w.c.

(70mbar)

Spring 962

(range 20 - 40 w.c.)

(range 50 100 mbar)

DROOP/

BOOST

6 w.c.

15.0 mbar

Accuracy

Class

20%

SET POINT

2 psig

(140 mbar)

Spring 963

(range 1 3 psig)

(range 70 210 mbar)

DROOP/

BOOST

11 w.c.

28 mbar

Accuracy

Class

20%

Orifice Size (millimeters/inches)

bar

5.0mm

7.5mm

10.0mm

15.0mm

20.0mm

30.0mm

30.0mm

BALANCED VALVE

(0.070)

350

(9.9)

500

(14.2)

750

(21.2)

1000

(28.3)

1500

(42.5)

1600

(45.3)

1350

(38.2)

(0.140)

450

(12.7)

850

(24.1)

1000

(28.3)

1700

(48.2)

2200

(62.3)

3000

(85.0)

1550

(43.9)

(0.350)

850

(24.1)

1450

(41.1)

1800

(51.0)

2500

(70.8)

3000

(85.0)

5200

(147.3)

3300

(93.5)

10

(0.700)

1150

(32.6)

2000

(56.7)

3000

(85.0)

4000

(113.3)

12500

(354.1)

13000

(368.3)

11000

(311.6)

15

(1)

1400

(39.7)

3000

(85.0)

3600

(102.0)

5500

(155.8)

14500

(410.8)

16000

(453.3)

14000

(396.6)

30

(2)

2000

(56.7)

4200

(119.0)

8500

(240.8)

17000

(481.6)

22000

(623.2)

14000

(396.6)

45

(3)

2550

(72.2)

5500

(155.8)

12000

(339.9)

21500

(609.1)

22500

(637.4)

14000

(396.6)

60

(4)

3200

(90.7)

8500

(240.8)

14000

(396.6)

21500

(609.1)

22500

(637.4)

14000

(396.6)

75

(5)

3600

(102.0)

10500

(297.5)

16500

(467.4)

21500

(609.1)

14000

(396.6)

100

(7)

4000

(113.3)

12500

(354.1)

16500

(467.4)

ft /hr

14000

(396.6)

125

(8.6)

5400

(153.0)

14500

(410.8)

16500

(467.4)

(m /hr)

14000

(396.6)

(45.3)

(0.140)

400

(11.3)

800

(22.7)

1000

(28.3)

1600

(45.3)

2200

(62.3)

2700

(76.5)

1600

(0.350)

700

(19.8)

1400

(39.7)

1750

(49.6)

2400

(68.0)

2900

(82.2)

5300

(150.1)

3400

(96.3)

10

(0.700)

1100

(31.2)

2000

(56.7)

2600

(73.6)

3600

(102.0)

4800

(136.0)

5500

(155.8)

3900

(110.5)

15

(1)

1400

(39.7)

2400

(68.0)

3300

(93.5)

4700

(133.1)

6000

(170.0)

16000

(453.3)

11000

(311.6)

30

(2)

2200

(62.3)

3700

(104.8)

5500

(155.8)

15000

(424.9)

20000

(566.6)

14000

(396.6)

45

(3)

2600

(73.7)

5400

(153.0)

11500

(325.8)

25000

(708.2)

24000

(679.9)

14000

(396.6)

60

(4)

3300

(93.5)

9100

(257.8)

14500

(410.8)

26500

(750.7)

26500

(750.7)

14000

(396.6)

75

(5)

4000

(113.3)

10500

(297.5)

18000

(509.9)

26500

(750.7)

14000

(396.6)

100

(7)

5400

(153.0)

12500

(354.1)

20500

(580.7)

ft /hr

14000

(396.6)

125

(8.6)

7000

(198.3)

15500

(439.1)

24000

(679.9)

(m /hr)

14000

(396.6)

(0.350)

600

(17.0)

1100

(31.2)

1450

(41.1)

2200

(62.3)

2600

(73.7)

3500

(99.1)

2200

(62.3)

10

(0.700)

1050

(29.7)

1800

(51.0)

2000

(56.7)

2900

(82.2)

3000

(85.0)

4600

(130.1)

3800

(107.6)

15

(1)

1300

(36.8)

2250

(63.7)

2550

(72.2)

4400

(124.6)

4750

(134.6)

13000

(368.3)

11000

(311.6)

30

(2)

2000

(56.7)

3800

(107.6)

4200

(119.0)

9200

(260.6)

12500

(354.1)

14000

(396.6)

45

(3)

2600

(73.7)

5000

(141.6)

5700

(161.5)

16000

(453.3)

22000

(623.2)

14000

(396.6)

60

(4)

3250

(92.1)

5700

(161.5)

12500

(354.1)

22500

(637.4)

24000

(680.0)

14000

(396.6)

22500

(637.4)

75

(5)

3800

(107.6)

10000

(283.3)

16000

(453.3)

14000

(396.6)

100

(7)

4200

(119.0)

12500

(354.1)

18500

(524.1)

ft /hr

14000

(396.6)

125

(8.6)

5300

(150.1)

15000

(424.9)

21500

(609.1)

(m /hr)

14000

(396.6)

HIGHLIGHTED AREAS MUST BE SERVICED BY AN EXTERNAL CONTROL LINE (E.C.L.)

Scfh (ft /hr) - natural gas, 0.6 sg

Scmh (m /hr) - natural gas, 0.6 sg

2

MODEL 274 GAS PRESSURE REGULATOR

General Description

Outlet

Pressure

Spring 964

(range 2 6 psig)

(range 140 420 mbar)

SET POINT

5 psig

(350 mbar)

DROOP/

BOOST

1 psig

70 mbar

Accuracy

Class

20%

Inlet Pressure

Orifice Size (millimeters/inches)

psig

bar

5.0mm

7.5mm

10.0mm

10

(0.700)

750

(21.2)

1550

(43.9)

1800

15

(1)

1000

(28.3)

2150

(60.9)

30

(2)

2000

(56.7)

2900

(82.2)

45

(3)

2500

(70.8)

4000

60

(4)

3000

(85.0)

5000

75

(5)

3500

(99.2)

100

(7)

4000

125

(8.6)

4500

15.0mm

(51.0)

2400

2200

(62.3)

3600

(102.0)

(113.3)

4800

(141.6)

6300

7300

(206.8)

(113.3)

9000

(127.5)

12000

20.0mm

30.0mm

(68.0)

3100

(87.8)

3000

(85.0)

3800

5000

(141.6)

8500

(136.0)

8000

(226.6)

11500

(178.5)

12000

(339.9)

16500

8500

(240.8)

16500

(467.4)

21000

(255.0)

11000

(339.9)

15500

30.0mm

BALANCED VALVE

3600

(102.0)

2900

(82.2)

(107.6)

4800

(240.8)

12500

(136.0)

3900

(110.5)

()

12000

(339.9)

(325.8)

14000

(396.6)

(467.4)

14000

(396.6)

()

14000

(396.6)

(311.6)

ft /hr

14000

(396.6)

(439.1)

(m /hr)

14000

(396.6)

Pressure Factor Metering (1% Absolute Pressure)

Measurement Canada Approval AG-0539

Spring 963

(range 1 3 psig)

(range 70 210 mbar)

SET POINT

2.0 psig

(140 mbar)

DROOP/

BOOST

0.16 psig

11 mbar

Accuracy

Class

1% ABS

P.F.M.

Spring 964

(range 2 - 6 psig)

(range 140 420 mbar)

SET POINT

5.0 psig

(350 mbar)

DROOP/

BOOST

0.2 psig

14 mbar

Accuracy

Class

1% ABS

P.F.M.

psig

bar

10

(0.700)

20

Orifice Size (millimeters/inches)

7.5mm

10.0mm

385

(10.9)

195

(55.2)

(1.4)

710

(20.1)

965

(27.3)

30

(2)

1355

(38.4)

1225

(34.7)

40

(2.7)

1805

(51.1)

2515

(71.2)

50

(3.4)

2900

(82.2)

1740

(49.3)

60

(4.1)

3160

(89.5)

6065

(171.8)

70

(4.8)

4835

(137.0)

6450

(182.7)

80

(5.4)

6125

(173.5)

7355

(208.3)

90

(6.1)

7870

(222.9)

8255

(233.9)

Inlet Pressure

Orifice Size (millimeters/inches)

psig

bar

10

(0.700)

195

(55.2)

195

(55.2)

20

(1.4)

320

(9.1)

255

(7.2)

30

7.5mm

10.0mm

(2)

710

(20.1)

710

(20.1)

40

(2.7)

710

(20.1)

775

(22.0)

50

(3.4)

1095

(31.0)

1095

(31.0)

60

(4.1)

1290

(36.5)

1225

(34.7)

70

(4.8)

1485

(42.1)

2645

(74.9)

80

(5.4)

2000

(56.7)

3610

(102.3)

90

(6.1)

2385

(67.6)

4320

(122.4)

Scfh (ft /hr) - natural gas, 0.6 sg

Scmh (m /hr) - natural gas, 0.6 sg

ft /hr

(m /hr)

Inlet Pressure Set Point40 psig

Outlet Pressure

Inlet Pressure

Inlet Pressure Set Point40 psig

Outlet Pressure

ft /hr

(m /hr)

3

MODEL 274 GAS PRESSURE REGULATOR

General Description

Capacity Calculation or Correction Factors for Other Gases

Gas Type

Specific Gravity

Correction Factor (CF)

Air

1.00

0.77

Butane

2.01

0.55

Carbon Dioxide (Dry)

1.52

0.63

Carbon Monoxide (Dry)

0.97

0.79

Natural Gas

0.60

1.00

Nitrogen

0.97

0.79

Propane

1.53

0.63

Propane-Air-Mix

1.20

0.71

Vent and Body Orientations

Orientation Body Position Letter

followed by Vent Position Number

For Other Correction

Factors

0.6

Sg of Gas

10

MODEL 274 GAS PRESSURE REGULATOR

General Description

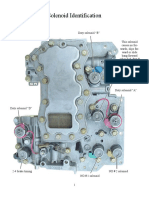

Sectional Diagrams

Inlet Pressure

Outlet Pressure

Atmospheric

274 R (screwed body)

274 290 OPCO

274 309 T OPCO

11

MODEL 274 GAS PRESSURE REGULATOR

General Description

Dimensional Drawings

274 (screwed body)

274 (flanged body)

Overall Length 18

Overall Length 20"

274290 (screwed body)

274290 (flanged body)

Overall Length 25"

Overall Length 25"

274309 (screwed body)

274309 (flanged body)

Overall Length 27"

Overall Length 27"

11

3"

5"

10"

3"

4"

6"

7"

4"

8"

12"

12

MODEL 274 GAS PRESSURE REGULATOR

General Description

External Control Line Versions (E.C.L.)

Regulators with an external control line have the throat of the regulator blocked with

a seal and the outlet pressure measuring chamber (lower diaphragm casing) drilled

and tapped for an outlet pressure sensing line. It is recommended that the sensing

point is a minimum of 5 times the outlet pipe diameter downstream of the regulator.

Sensing outlet pressure via an external control line enables the regulator to response

more accurately to the downstream system.

Throat Seal

External Control Line Connection

(tapped )

Diagram of Regulator Station and Recommended Location

of External Control Line (E.C.L.) Connections

13

MODEL 274 GAS PRESSURE REGULATOR

General Description

Internal Relief Valve and Safety Slam Shut Valve Options

Regulators for Reduced Clearances or Venting Limitations

Please contact one of our representatives for more detailed information

Regulators for Indoor Installations without Requirement for Vent-Line

Please contact one of our representatives for more detailed information

Internal Safety Relief Valve (SRV) Description

The SRV is designed to monitor the pressure in the outlet chamber or downstream

of the regulator and to relieve by either venting gas leakages or full flow capacity

(depending on the device design) into the atmosphere in the event of an overpressure condition.

If the pressure in the measuring chamber exceeds the force of the set point spring

of the relief valve, the diaphragm rises and opens the relief valve. The gas then

flows from the outlet pressure line to atmosphere or another desired location.

The relief gas pressure and flow is discharged until the pressure is returned to the

predetermined safe level.

The safety relief pressure of the internal relief valve occurs slightly above the set

pressure of the main spring or outlet pressure

Safety Slam Shut Valve (SSV) Description

The SSV is designed to monitor the outlet pressure and to interrupt the gas flow, if

preset limits are exceeded.

This preset pressure is adjustable in the field.

If the measured pressure reaches the set point of the SSV, a release mechanism is

triggered and the SSV closes the valve on the inlet pressure side of the regulator.

This closing function completely blocks the forward movement of gas past the SSV.

Safety slam shut valves are available in over pressure cut off (OPCO) protection or

under and over pressure cut off (UPCO/OPCO) protection.

After the SSV is tripped, the condition that triggered the closing of the valve must be

addressed and then the SSV can be manually reset.

Thermal trip protection is also available as an option to shut the gas flow off, if the

safety slam shut valve is exposed to high temperatures or engulfed in a fire (T-Type).

Please contact one of our representatives for the technical brochure on all of our

safety slam shut valves.

14

MODEL 274 GAS PRESSURE REGULATOR

General Description

Commissioning and Installation Instructions

Please contact one of our representatives for the installation and commissioning instructions. Additionally, the commissioning and installation instructions are found in

each box that the equipment is shipped in and can be downloaded from the website.

Ordering Information

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Inlet pressure (minimum and maximum)

Outlet pressure requirement

Flow requirement (minimum and maximum)

Type of gas

Temperature

Pipe connections (inlet and outlet)

Internal or external impulse (sensing)

Safety options or requirements (SRV and/or SSV)

Vent and body orientation

Other critical information (system design or description)

Product Portfolio

Pressure regulators for every application from domestic, commercial, industrial to

transmission line, city gate stations and other gas utility applications.

Safety relief valves

Safety slam shut valves

Metering equipment (rotary displacement, turbine, vortex shedding, ultrasonic)

Volume correctors (temperature and pressure)

Filters

Underground pressure regulator and metering modules

Ball valves

Station design and assembly (prefabricated stations, skid-mounted assemblies,

small regulator/meter-set assemblies)

Flame arrestors

Data logging and software

Check and non-return valves

Training and after-sales service

15

MODEL 274 GAS PRESSURE REGULATOR

General Description

Contact Information

Bryan Donkin RMG Canada Limited

50 Clarke Street South, Woodstock, Ontario, Canada N4S 7Y5

Phone: +1-519-539-8531

Fax: +1-519-537-3339

Email: neil@bdrmgcanada.com

Website: www.rmg.com

RMG Regel + Messtechnik GmbH

Osterholzstrasse 45, D-34123, Kassel, Germany

Phone: +49-561-5007-0

Fax: +49-561-5007-107

Website: www.rmg.com

Bryan Donkin RMG Gas Controls Limited

Enterprise Drive, Holmewood, Chesterfield S42 5UZ England

Phone: +44-1246-501501

Fax: +44-1246-501-500

Website: www.rmg.com

Distributor Information

16

Potrebbero piacerti anche

- 4 Ataxle PDFDocumento22 pagine4 Ataxle PDFAnonymous XTkln6H100% (1)

- ABB SWBD VD4 Brochure PDFDocumento6 pagineABB SWBD VD4 Brochure PDFanand_girgaonkarNessuna valutazione finora

- Relief ValveDocumento2 pagineRelief ValveAdil AzizNessuna valutazione finora

- Method Statement - Refrigerant Pipeline Pressure - Test - ProcedureDocumento10 pagineMethod Statement - Refrigerant Pipeline Pressure - Test - ProcedureBibin VijayakumarNessuna valutazione finora

- The Weir Direct-Acting Feed Pump - Working InstructionsDa EverandThe Weir Direct-Acting Feed Pump - Working InstructionsNessuna valutazione finora

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationDa EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationValutazione: 4.5 su 5 stelle4.5/5 (21)

- Gas Pressure RegulatorDocumento12 pagineGas Pressure RegulatorSarah DeanNessuna valutazione finora

- TankerDocumento60 pagineTankerlopezdestructionNessuna valutazione finora

- Document 1Documento14 pagineDocument 1bismarckandresNessuna valutazione finora

- Ricardo R4105ZD-61kW Genset Spec SheetDocumento2 pagineRicardo R4105ZD-61kW Genset Spec SheetRonald Booc100% (3)

- As 0201 Gauge Valves and Pressure Gauge Accessories enDocumento36 pagineAs 0201 Gauge Valves and Pressure Gauge Accessories enTomas PinheiroNessuna valutazione finora

- Dean Brochure High TempDocumento10 pagineDean Brochure High TempAntonio VelardeNessuna valutazione finora

- Grove G9 Wafer Gate ValveDocumento9 pagineGrove G9 Wafer Gate Valvetxlucky80Nessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Boiler Feed and Pump Sizing - C-B and Grundfos July 2016Documento63 pagineBoiler Feed and Pump Sizing - C-B and Grundfos July 2016Jose Lorenzo Toral100% (2)

- ASTM Pumping TestDocumento125 pagineASTM Pumping TestErnesto Heinze100% (1)

- Pressure Regulator Control Valve Sizing PetroDocumento16 paginePressure Regulator Control Valve Sizing PetroCH1253Nessuna valutazione finora

- WEBINAR: Ballast Water Management - Be Ready For The Discharge Standard D-2Documento32 pagineWEBINAR: Ballast Water Management - Be Ready For The Discharge Standard D-2sukhjit78Nessuna valutazione finora

- SFS Products BrochureDocumento14 pagineSFS Products BrochureJoshuaNessuna valutazione finora

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDa EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsValutazione: 4 su 5 stelle4/5 (6)

- Regulador American Meter PDFDocumento6 pagineRegulador American Meter PDFjmcg1974Nessuna valutazione finora

- Instrument ManifoldsDocumento16 pagineInstrument ManifoldsAmet koko TaroNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Gas Pressure Regulator Series 240Pl: Serving The Gas Industry WorldwideDocumento11 pagineGas Pressure Regulator Series 240Pl: Serving The Gas Industry WorldwideSandro RuizNessuna valutazione finora

- Witt-Gasetechnik: Dome Pressure Regulator 757 LeDocumento2 pagineWitt-Gasetechnik: Dome Pressure Regulator 757 LeSilviu ModigaNessuna valutazione finora

- PRH04-300 FLG PDFDocumento5 paginePRH04-300 FLG PDFengp3077Nessuna valutazione finora

- Kunkle OverviewDocumento8 pagineKunkle Overviewsamix999Nessuna valutazione finora

- PRH 04Documento6 paginePRH 04Heny MarthaNessuna valutazione finora

- BelGAS P627 2014 RegulatorDocumento10 pagineBelGAS P627 2014 RegulatorkaviarasuNessuna valutazione finora

- PRH09 PDFDocumento4 paginePRH09 PDFengp3077Nessuna valutazione finora

- 14 400E 6DC Final Valvula BermadDocumento4 pagine14 400E 6DC Final Valvula Bermadmax_powerNessuna valutazione finora

- Pressure Releif ValveDocumento24 paginePressure Releif Valvemtalha_loveNessuna valutazione finora

- Amco CR4000Documento4 pagineAmco CR4000Arwin TroconisNessuna valutazione finora

- Regulador 1253 B - American M.Documento8 pagineRegulador 1253 B - American M.Jheysson FloresNessuna valutazione finora

- OpGL Globe ValveDocumento20 pagineOpGL Globe Valvemanmohansingh1999Nessuna valutazione finora

- Big Joe Type 630 d100121x012Documento16 pagineBig Joe Type 630 d100121x012lorgio_moroNessuna valutazione finora

- 1190 TANK BLANQUETING REGULATOR Bulletin PDFDocumento12 pagine1190 TANK BLANQUETING REGULATOR Bulletin PDFM Betzabe MoraNessuna valutazione finora

- Valve ActuatorDocumento8 pagineValve Actuatornixsol75Nessuna valutazione finora

- Broady 3500 BrochureDocumento12 pagineBroady 3500 Brochureahmedm2020Nessuna valutazione finora

- 274 Regulator Technical BulletinDocumento11 pagine274 Regulator Technical BulletinJonathan S. R.Nessuna valutazione finora

- 299HDocumento20 pagine299HJulian Esteban Arnaiz VargasNessuna valutazione finora

- PressureDocumento84 paginePressureHangloque GabanoNessuna valutazione finora

- Fainger Leser Catalogue' 11Documento68 pagineFainger Leser Catalogue' 11rudrakrNessuna valutazione finora

- Gascat CatalogoDocumento8 pagineGascat CatalogoleoNessuna valutazione finora

- Pressure Vacuum BleedersDocumento4 paginePressure Vacuum BleedersGustavo AlcaNessuna valutazione finora

- DS J125 1 enDocumento4 pagineDS J125 1 enhataefendiNessuna valutazione finora

- Cla-Val, Relief VanaDocumento2 pagineCla-Val, Relief Vanadeyson galeanoNessuna valutazione finora

- 50B4KGDocumento2 pagine50B4KGonin007Nessuna valutazione finora

- Cokebuster: A Proven SolutionDocumento11 pagineCokebuster: A Proven Solutionengg_mech77Nessuna valutazione finora

- E 50B 4KG1 - Fire PDFDocumento2 pagineE 50B 4KG1 - Fire PDFdocrafiNessuna valutazione finora

- GP Rotork ActuatorsDocumento8 pagineGP Rotork ActuatorsSuara84Nessuna valutazione finora

- SRC Alpha Version1 PDFDocumento26 pagineSRC Alpha Version1 PDFRajat JainNessuna valutazione finora

- Ratio Pressure Reducing ValvesDocumento4 pagineRatio Pressure Reducing Valveskanem1Nessuna valutazione finora

- Mallard IOM Series 5600Documento13 pagineMallard IOM Series 5600Nacho.pNessuna valutazione finora

- E 90 21 - FireDocumento2 pagineE 90 21 - Firepequenita34Nessuna valutazione finora

- Breather Valve - Pressure-Vaccuem Relief ValveDocumento2 pagineBreather Valve - Pressure-Vaccuem Relief Valvevphor85Nessuna valutazione finora

- Bulletin 1301Documento8 pagineBulletin 1301Syed Haris Bin AkhterNessuna valutazione finora

- Trampadevapor Flotador y TermostaticaDocumento9 pagineTrampadevapor Flotador y TermostaticaLuis Gutiérrez AlvarezNessuna valutazione finora

- Flow Control Worcester ControlsDocumento8 pagineFlow Control Worcester Controlsviller_lpNessuna valutazione finora

- 3105 B 26Documento3 pagine3105 B 26ParIs MoRanNessuna valutazione finora

- MS 01 141Documento8 pagineMS 01 141arlumNessuna valutazione finora

- Disc ValvesDocumento8 pagineDisc ValvesMahesh KumarNessuna valutazione finora

- PRS 09i EX PDFDocumento5 paginePRS 09i EX PDFengp3077Nessuna valutazione finora

- Model BPS-09: Back Pressure-Reducing ValveDocumento4 pagineModel BPS-09: Back Pressure-Reducing Valveengp3077Nessuna valutazione finora

- Logos-Bac Ninh-Spec Sprinkler-HydrantDocumento5 pagineLogos-Bac Ninh-Spec Sprinkler-HydrantAn TamNessuna valutazione finora

- Cashco IndustrialGasValveLitDocumento20 pagineCashco IndustrialGasValveLitkasparob25Nessuna valutazione finora

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- GasMultiBloc - Regulador MB-D (LE) 403 - 053 B01Documento6 pagineGasMultiBloc - Regulador MB-D (LE) 403 - 053 B01oscarin071Nessuna valutazione finora

- Honeywell WSK-24 Wireless Occupancy SolutionDocumento16 pagineHoneywell WSK-24 Wireless Occupancy SolutionAntonio VelardeNessuna valutazione finora

- ZoneValveTechSpec LA enDocumento2 pagineZoneValveTechSpec LA enAntonio VelardeNessuna valutazione finora

- GasMultiBloc - Regulador MB-D (LE) 415-420 B01Documento6 pagineGasMultiBloc - Regulador MB-D (LE) 415-420 B01Antonio VelardeNessuna valutazione finora

- Valvula MB Dle 405 b01 PDFDocumento6 pagineValvula MB Dle 405 b01 PDFCarlos Castillo UrrunagaNessuna valutazione finora

- Insight-Plus Datasheet PDFDocumento4 pagineInsight-Plus Datasheet PDFAntonio VelardeNessuna valutazione finora

- GasMultiBloc Regulador MB-D (LE) 405-412 B07Documento6 pagineGasMultiBloc Regulador MB-D (LE) 405-412 B07Antonio VelardeNessuna valutazione finora

- GasMultiBloc - Regulador MB-D (LE) 403 - 053 B01Documento6 pagineGasMultiBloc - Regulador MB-D (LE) 403 - 053 B01oscarin071Nessuna valutazione finora

- Herculine Serie 2000Documento2 pagineHerculine Serie 2000Antonio VelardeNessuna valutazione finora

- GasMultiBloc - Regulador MB-D (LE) 415-420 B01Documento6 pagineGasMultiBloc - Regulador MB-D (LE) 415-420 B01Antonio VelardeNessuna valutazione finora

- Be SV60Documento88 pagineBe SV60Antonio VelardeNessuna valutazione finora

- Cross Refernce PDFDocumento40 pagineCross Refernce PDFAntonio VelardeNessuna valutazione finora

- Cross Refernce PDFDocumento40 pagineCross Refernce PDFAntonio VelardeNessuna valutazione finora

- 63 1313 PDFDocumento2 pagine63 1313 PDFAntonio VelardeNessuna valutazione finora

- Serie 70-100Documento4 pagineSerie 70-100Antonio VelardeNessuna valutazione finora

- ASCO 8210r3Documento6 pagineASCO 8210r3Ricardo RodrigoNessuna valutazione finora

- Serie 94aDocumento1 paginaSerie 94aAntonio VelardeNessuna valutazione finora

- Dean Manual RADocumento24 pagineDean Manual RAAntonio VelardeNessuna valutazione finora

- Lift Inspection ReportDocumento6 pagineLift Inspection ReportUmer FarooqNessuna valutazione finora

- Introduction To Boltzmann LearningDocumento2 pagineIntroduction To Boltzmann LearningnvbondNessuna valutazione finora

- NAD Factory Default and Software CheckDocumento13 pagineNAD Factory Default and Software CheckNorma FloresNessuna valutazione finora

- Fastcap 22 630v PDFDocumento1 paginaFastcap 22 630v PDFDarrenNessuna valutazione finora

- Three-Phase Induction Motor Dynamic Mathematical ModelDocumento3 pagineThree-Phase Induction Motor Dynamic Mathematical Modelsajs201100% (3)

- ERPtips SAP Training Manual SAMPLE CHAPTER From Basic PayrollDocumento20 pagineERPtips SAP Training Manual SAMPLE CHAPTER From Basic Payrollravibabu1620Nessuna valutazione finora

- Drawings Phase IIDocumento12 pagineDrawings Phase IIY Go GltdNessuna valutazione finora

- Performance of Gesture Controlled DroneDocumento11 paginePerformance of Gesture Controlled DroneKrishna SivaNessuna valutazione finora

- Microsoft Word - Exercise 3 Subsea P&PDocumento5 pagineMicrosoft Word - Exercise 3 Subsea P&PKRNessuna valutazione finora

- Concrete Pumping Cop 2005 PDFDocumento27 pagineConcrete Pumping Cop 2005 PDFShoaib HassanNessuna valutazione finora

- Assignment Concurrent ProgrammingDocumento7 pagineAssignment Concurrent ProgrammingKien HawNessuna valutazione finora

- Ra CocnatsDocumento13 pagineRa CocnatsloyioNessuna valutazione finora

- Adobe Transaction No 0991059129 20190125Documento2 pagineAdobe Transaction No 0991059129 20190125Mohamed WinnēriNessuna valutazione finora

- Swiss FCM Ordinance - EuPIA QDocumento6 pagineSwiss FCM Ordinance - EuPIA Qiz_nazNessuna valutazione finora

- ANTENASDocumento10 pagineANTENASGreo HernandezNessuna valutazione finora

- Ford Fiesta Specifications: Exterior DimensionsDocumento2 pagineFord Fiesta Specifications: Exterior DimensionsBuhuntuUhuNessuna valutazione finora

- 2020.04.24 BC thamtratonghop TKCS Trường Fulbright Lần 1Documento32 pagine2020.04.24 BC thamtratonghop TKCS Trường Fulbright Lần 1Khac Hoang PhamNessuna valutazione finora

- Dometic RM4185 6405 PDFDocumento20 pagineDometic RM4185 6405 PDFcarlosrei2Nessuna valutazione finora

- DIS2116 ManualDocumento88 pagineDIS2116 ManualHưng Tự Động HoáNessuna valutazione finora

- Chapter 6 PDFDocumento26 pagineChapter 6 PDFDayang Azraa AfeefaaNessuna valutazione finora

- Based On CIRIA Report 108:1985: Formwork Load Calculator - ResultsDocumento4 pagineBased On CIRIA Report 108:1985: Formwork Load Calculator - Resultsyassir dafallaNessuna valutazione finora

- C ElanchezhianDocumento8 pagineC ElanchezhiankeshavuvceNessuna valutazione finora

- Safety Data Sheet: Ingredient Einecs Concentration Symbol(s) Risk Phrases ( )Documento9 pagineSafety Data Sheet: Ingredient Einecs Concentration Symbol(s) Risk Phrases ( )panagiotis_panagio_2Nessuna valutazione finora

- Server and Workstation AdministrationDocumento454 pagineServer and Workstation AdministrationScott CarneyNessuna valutazione finora