Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MMS Research Article

Caricato da

Aamir Riaz MalikCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MMS Research Article

Caricato da

Aamir Riaz MalikCopyright:

Formati disponibili

J Intell Robot Syst

DOI 10.1007/s10846-011-9626-9

TORP: The Open Robot Project

A Framework for Module-Based Robots

Alexandre da Silva Simes Esther Luna Colombini

Jackson Paul Matsuura Marcelo Nicoletti Franchin

Received: 17 December 2010 / Accepted: 25 July 2011

Springer Science+Business Media B.V. 2011

Abstract The development of robots has shown

itself as a very complex interdisciplinary research

field. The predominant procedure for these developments in the last decades is based on the

assumption that each robot is a fully personalized

project, with the direct embedding of hardware

and software technologies in robot parts with no

level of abstraction. Although this methodology

has brought countless benefits to the robotics research, on the other hand, it has imposed major

drawbacks: (i) the difficulty to reuse hardware

and software parts in new robots or new versions;

A. S. Simes (B)

Department of Control and Automation Engineering,

UNESP - Univ Estadual Paulista,

Campus of Sorocaba, Sorocaba, Brazil

e-mail: assimoes@sorocaba.unesp.br

(ii) the difficulty to compare performance of different robots parts; and (iii) the difficulty to

adapt development needsin hardware and software levelsto local groups expertise. Large advances might be reached, for example, if physical

parts of a robot could be reused in a different

robot constructed with other technologies by

other researcher or group. This paper proposes a

framework for robots, TORP (The Open Robot

Project), that aims to put forward a standardization in all dimensions (electrical, mechanical and

computational) of a robot shared development

model. This architecture is based on the dissociation between the robot and its parts, and between

the robot parts and their technologies. In this paper, the first specification for a TORP family and

the first humanoid robot constructed following the

TORP specification set are presented, as well as

the advances proposed for their improvement.

M. N. Franchin

Department of Electrical Engineering,

UNESP - Univ Estadual Paulista,

Campus of Bauru, Bauru, Brazil

e-mail: franchin@feb.unesp.br

Keywords Module-based robots

Robotics design framework

Collaborative robots Open Robot Project

Standardization in robotics

E. L. Colombini J. P. Matsuura

ITA - Technological Institute of Aeronautics,

Sao Jose dos Campos, Brazil

1 Introduction

E. L. Colombini

e-mail: esther@ita.br

J. P. Matsuura

e-mail: jackson@ita.br

In the last decades, there has been some important standardization in several areas of computation and automation. However, we are far from

J Intell Robot Syst

this level of standardization in the robotics field.

Robotics today is close to what were PCs in the

late 70s. As it happened to the PCs, the robotics

labs and researchers around the world are facing

exactly the same challenges: high fragmentation,

lack of standardization, complex projects without

established methodologies, lack of practical applications and slow development. Indeed, it is almost

unthinkable nowadays that some part of a robot

can be plugged and work properly in another one,

and this scenario is even worse when considering

human-size robots.

There are some different reasons for this poor

standardization level. First of all, robots are built

with extremely different purposes, that have deep

impact in their architecture. It is unlikely, for

example, that a robot designed to load weight can

have the same physical architecture of a robot

for playing music, even if both are humanoids.

Other contributing factor is that some of the most

important robotics developments are fomented

by private institutions, that are usually restrict

on sharing technical information and accepting

standardization from external institutions. Yet,

robotics operating systems are recently new and

have a low number of users. In some cases these

frameworks also impose some technology constraints to the developers. In fact, the expertise of

different groups in using some kind of hardware or

software technology guides their technical choices

in new projects. Standardization that cannot properly handle with this diversity is doomed to

failure.

As a consequence of this scenario, most of the

new projects must restart almost from scratch,

what limits the knowledge sharing between research centers. However, a change is expected in

the next years. The rush for better robots and

for a speed up in robotics developments is turning mandatory the sharing of expertise among

different groups in the fields necessary to develop

a full robot. A new kind of collaborative research

and development could make possible to use this

expertise diversity, necessary in this interdisciplinary task.

In this way, a framework for this kind of development would require: (i) standardization in electrical and mechanical dimensions that allow the

interchangeability of robot parts with flexibility in

technologies; and (ii) availability of software tools,

like graphical interfaces, robotics optimized routines, network communication framework, sensor

data transfer, and so on.

This paper presents the TORP (The Open

Robot Project) framework, an open standard

methodology for modular robots design that aims

to fulfill some of the gaps earlier presented. This

paper is organized as follows: Section 2 provides

an overview of the available robotics frameworks

in several aspects, presenting a general scheme

of these methodologies in order to establish future directions of these technologies. Section 3

presents an overview of the TORP specification

set. Section 4.2 shows examples of TORP applications, detailing the main features of CP01, the

first robot built using TORP methodology while

Section 5 presents some results achieved. Finally,

Section 6 concludes with an assessment of the

results and proposes directions for further investigation and improvements in the framework.

2 Robotics Frameworks: Overview

and Future Directions

Different methodologies have been proposed for

robotic developments in the last decades. The

most common methodology, adopted since the

early days of robotics, tends to focus on sensors

and actuators assembly directly linked with a controller device. In the electrical dimension, power

source is regulated and appropriate voltages are

transferred to sensors, actuators and controller

through a set of cables. Mechanically, devices tend

to be all connected to a robot chassis. Computationally, the main control is located in a personal computer or an embedded device, and there

is usually a low level of separation in software

layers [18]. A schematic diagram of this project

methodology is shown in Fig. 1a. Although many

advances have been possible with this methodology, it has well known limitations in terms of

hardware and software reuse, collaborative development and excessive technology-dependence.

Specially focusing on software reuse, several

frameworks have arisen in the past years. In general lines, these frameworks are cross-platform

J Intell Robot Syst

Fig. 1 Robotics

frameworks general

scheme. a The most

common robotics

framework: low level of

separation between

software layers, electrical

and mechanical devices.

b General scheme of the

robotics operational

systems approach that

arose in the last decade: a

software abstraction level

aims to assure some

independence degree

between code and

devices. Electrical and

mechanical devices

remain with a low

independence level

(a)

open-source environments that operate over some

operational system layer. Most of them, like

PLAYER [7, 23], OROCOS [6], YARP [14] and

CLARATY [20, 30] focus in architectures able

to provide modularity and separation between robotics application code and low level code (memory allocation, threads, communication, etc.).

ORCA [5] proposes a component-based software

approach. Although device drivers for these platforms are not yet available for manufacturers, it

is a growing trend. In communication level, several frameworks also assume a network structure

with central servers, like CARMEN [17], or heterogeneous networks, like ROS [21], Tekkotsu

[29] and Urbi [3, 4]. Some frameworks also propose valuable application level tools and libraries

for robotics domains, like kinematics calculation

tools [6], centralized parameter server [21], image

libraries [14], localization and mapping [21] and so

on. Figure 1b presents a general scheme of these

frameworks.

Although these computational frameworks

represent a complete rupture with previous robot

projects methodologies much more appropriate

for complex developments than the traditional

approach, some important questions remain still

(b)

open. In general lines robot technologies continue to be chosen based on a specific project

philosophy and needs. The excessive intertwine

and mutual dependence between a robot and its

technologies leads to some particular problems:

(i) hardware reuse in different robots or in different versions of the same robot is unthinkable

for fully assembled parts, and is limited to changes

in components level; (ii) technological sharing between different research groups is difficult, since

each group tends to work based on different

technologies; and (iii) performance comparison

between analogue high level parts of different

robots is almost impossible since the parts performance are completely dependent on the whole

robot set. In fact, it is important to remark that

computationmajor concern of today robotics

frameworksrepresents only one of the three robotics dimensions, and quicker developments in

the robotics field could be reached if a framework

would also consider some electrical and mechanical standardization, as technology independent as

possible.

As a next step on the robotics frameworks

discussion, one can hypothesize that a more

useful framework for robotics development and

J Intell Robot Syst

research could be reached based on the following

principles:

1. Project paradigm is shifted from components

level to functional self-contained modules

level;

2. Modules are externally standardized in three

dimensions: electrical, mechanical and computational, but are internally technologyindependent;

3. Main controller may operate remotely according to previous robotics operating systems

principles.

It is important to remark that this set of principles keeps strong relation with those adopted

in PCs, since technologies changes in components

level no longer affect computers functionalities

due to electrical and mechanical standardization

in data buses, plugs and power sources.

Two other concepts are important to overcome

the compatibility issues in the design of the robots.

First, collaborative development is usually associated to the open-source development, that

is, developments where knowledge is publicly

shared as open-software and/or open-hardware.

E-puck robot [16] is a desktop-size open-software

and open-hardware differential wheeled mobile

robot designed for micro-engineering education.

Molecube [34] are modular-based open-software

and open-hardware low-cost cube robots envisioned as a universal element in order to build

more complex structures, as an alternative to a

variety of specialized machines.1 One of the most

recent robots in this line is the PR2 [32], a generalpurpose wheeled robot platform with two arms,

head and gripers that can serve as a base for

further development in robotics. This project incorporates some of the new strategies of robotics,

like the open-source in hardware and software,

and is fully-integrated with ROS software libraries

[22]. By eliminating the need to first build a

hardware system and then re-implement code,

the PR2 allows software experts to immediately

1 In

the context of projects hereby presented, openhardware refers to a basic hardware electromechanical

publishing, and not a collaboratively constructed hardware.

create new functionality on the robot. It also stimulates groups to build new parts of the robot, like

grippers, and to develop open-source software.

Although it is an extremely flexible and an up

to date platform, it does not allow some studies,

like for legged systems, since the pre-designed

platform naturally imposes several constraints in

the robot physical structure.

Another important growing tendency is reconfigurable robotics [33], term usually related

to the possibility of multiple mechanical configurations of robot modules through mechanical

connections. It is usually based on the existence

of some kind of mechanical standard plug. In [8]

modules can be connected or disconnected manually, and by adding and removing the modules

one can build a robotic fish with different morphologies. In [26, 27] reconfiguration is carried out

through dynamic connection and disconnection of

modules and rotation of their DOF, which are

applied over adaptive furniture. For [12], flexible

tiles are interconnected by magnets and communicate using infra-red. It is used to engage and

motivate user to perform physical activities in

hospitals, whereas [2] uses passive lockable cylindrical joints to permit changing kinematic parameters in robotic manipulators. An interesting

combination of electrical and mechanical plug was

proposed in Molecube [35]. Due to a unified interface, since a robot cube is mechanically connected

to a next cube, they are also electrically plugged.

Although universal mechanical plugs have not

been proposed for high-size humanoid robotics,

this idea must be taken into consideration.

2.1 Humanoid Robot Projects

and Related Approaches

As an example to expose the problems concerned

with a robot design, an analysis of humanoid robot

projects will be presented.

Some important projects of humanoid robots

have been highlighted in recent robotics history,

many of them correlated with the present work

in several aspects. Some well known humanoid

projects are ASIMO [24], HRP-2 [10, 11], HUBO

[9] and REEM-B [25]. In order to perform human

like actions, it is natural to expect that humanoid

J Intell Robot Syst

robots approximate humans in several aspects like

size, mass, torque, velocity and so on. Considering

constructive aspects, these robots vary from 30

[24] to 66 [9] DOF, are from 1.2 to 1.5 m tall and

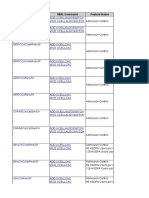

capable to walk up to 6 km/h. As shown in Table 1,

one can say that todays robots power is the same

order of magnitude as human muscle power [19,

25], although these robots are smaller and slower

than humans, and have a worst power/weight relation in actuators (150 W/kg of todays motors [13]

against 500 W/kg of human muscles [31]).

Considering the increasing complexity of humanoid robotics developments, it is more and

more unlikely that a single research center can be

capable of developing the whole chain of needs

required by such a complex project. In fact, robots development paradigm seems evolving from

centralized developments to a collaborative approach. One of the most important platforms in

this paradigm is iCub [15], project funded by the

European Commission that aims to study cognition through the implementation of a humanoid

robot the size of a 3.5 year old child, through the

RobotCub framework. Some of the RoboCubs

partners adopt the YARP open-source library

[14]. Although it is a collaborative robotics project, collaboration in RobotCub is mainly focused on computational developments for robot

cognition based on a predefined hardware.

Regarding the mechanical aspects of a robotics

project, one of the trends is the research of universal and flexible connectors. Some of the desired

characteristics of a standard mechanical plug are:

(i) the ability to quick plug with no need of extra

Table 1 Power, speed and torque requirements in human

degrees of freedom, excluding head, hands and feet, versus

humanoid robot actuators power

Joint

Shoulder

Elbow

Wrist

Hip

Knee

Ankle

Estimated

Human

Hubo

Peak power

(W)

Velocity

(rpm)

Torque

(N.m)

Robot

(W)

110

110

30

600

600

50

3.000

350

150

150

300

150

150

70

40

20

140

160

110

270

90

22

330

300

180

2.384

tools; (ii) it must be unique or keep compatibility

with all similar connections in robot, independent

on its size or mechanical requirements; and (iii)

it must be robust in terms of mechanical efforts

(looseness, torque, rotation, etc.). These are absolutely nontrivial goals considering humanoid robots mechanical characteristics.

It can be observed that there must be a standardization in all three dimensions (electrical,

mechanical and computational) to enable cooperative and collaborative design and implementation of complex humanoid robot projects. The

TORP specification set could be a solution.

3 The Open Robot Project Framework

TORP is a framework, ruled by GNU General

Public License (GPL), to build robots that follow

a common philosophy in their design: the TORP

Specification Set.

Shifting from the components level, usually

proposed by traditional robotics frameworks

(Fig. 1a and b), to the functional level, a TORP

robot is a collection of independent, replaceable

and specialized parts (modules) that are as selfcontained as possible and that jointly produce

an artificial creature. For example, consider an

arm of a humanoid robot. In a TORP robot, all

the mechanics, electrical devices and processing

units necessary to assure that this robot arm can

execute its functions must be fully contained in

the very robot arm. Furthermore, the robot can

be seen as a communication network that hosts

a society of mechanically-electrically independent

parts. All these parts are responsible for collecting information (internal and external) that can

be important to perform its own tasks and for

offering all its services to the robot network. In

order to assure that these parts can be capable to

suitably and harmonically cooperate to produce a

more complex entity, some electrical, mechanical,

computational and communication requirements

(the TORP Specification Set) must be simultaneously respected by all families of TORP robots. A

TORP family is defined as a set of modules that

share the same values for all dimensions in the

TORP specification set.

J Intell Robot Syst

3.1 TORP Specifications Set

specification seen in Fig. 2b determines that there

is a common power source for the modules and

that each one is responsible for regulating the

power to meet the modules components needs. A

standard electrical plug is used for all modules. Finally, the mechanical dimension (Fig. 2c) presents

the modules connected to the main chassis or

to each other through a standard plug. The next

subsections describe details on each dimension.

The framework proposed in this paper follows

the schematics of Fig. 2. In this model, three dimensions are considered to fully describe a robot project: the mechanical, the electrical and the

computational dimension. In the computational

dimension (Fig. 2a) it is stated that all modules

are responsible for containing the knowledge on

how to control its parts according to the chosen

components. The only restriction in this model

refers to the fact that all modules have to speak

a common protocol, defined in Section 3.4.1, and

that they have to communicate through a network. There is no restriction whether the main

controller should be embedded or not. Hence,

a Robotics Operating System could be used to

properly deal with the modules coordination, as

well as a Graphics User Interface. The electrical

(a)

Fig. 2 TORP framework general scheme, with focus on

fully self-contained modules. a Computational architecture. Modules interact in a network with a high level main

control. Drivers and low level processing are fully embedded in module. b Electrical architecture. Each module

3.2 Mechanical Dimension

The main concept in the mechanical dimension

is the module. Each module must be chosen according to its typical function and it must be

completely independent on the other modules.

In a humanoid robot, for example, the following modules would be recommended: head, chest,

legs, arms, hands. However, a robot designer is

(b)

(c)

is responsible for internal voltage regulation for its own

needs and it can provide electrical connection to other

modules. c Mechanical architecture. Modules can be connected to main chassis or other modules using a quick

connect standard mechanical plug

J Intell Robot Syst

free to use any number or type of modules and

these modules can change over time. For instance,

a project of a humanoid robot that has a single

module arm that contemplates the hand can be

replaced, in a new version, by two separate modules: arm and hand. The modules are encouraged

to keep all its elements (mechanical, electrical,

computational and communication) inside of its

own mechanical structure, allowing a quick and

easy handle of the module. In the same direction,

modules must have a structural rigid material able

to properly attach all its internal units, except in

the case of the internal module, which is allowed

to plug its sensors, actuators and/or wires in the

external module.

To allow connections between modules, a

TORP mechanical plug (TMP) must be defined.

In this way, modules cannot be connected to

other modules except by using standard mechanical plugs. This practice assures that any module

will be able to physically connect into any TORP

robot, part or version of that specific family. The

TMP should meet the family project needs. Furthermore, since modules can be plugged in complex ways, there must be a classification of these

connections types.

In this framework, a module must be classified

according to the following:

1. Connection with previous module: Defines

how the current module connects to previous

modules. There are two possibilities:

(a) External: the module (A) is physically

connected to a previous module (B) using the TMP, and A is physically external to B;

(b) Internal: the module (A) is fully internal to the previous module (B). Internal

modules do not need to be connected

using the TMP. This is allowed only to

extremely simple and light modules (typically those that have only an electrical

board connected to some special sensor

without any mechanics and so on). In this

case, the connection between modules

can be made through screws.

2. Connection with next modules: Defines the

number of modules that can be connected to

the current module and how this connection

occurs. Following this specification, the current

module can be classified in two different ways:

(a) Expansible of order N: this module offers N TMPs that can be used by other

modules;

(b) Terminal: this module does not provide

TMP connections to other modules.

The modules and TMPs must carry precise

information regarding some special features that

should physically be written in their structure:

1. TMP label: any material can be used to construct the TMP. However, different materials

imply in different mechanical properties, and,

hence, the maximum number of allowed connected modules depends on the mechanical

plug material. In this way, TMPs must carry

the maximum load (N) and torque (N.m) that

can be supported by this mechanical plug.

2. Module label: every single module must carry

precise information (physically written in the

module) regarding its own load (in N), length

(in m) and degrees of freedom. This information can be used to control the module.

3.3 Electrical Dimension

Although standardization is proposed in the electrical dimension, there are no constraints for the

electronic boards or on-board software used by

the modules. Instead, only a common protocol is

established, and the implementation technology is

completely free. There is a main power source,

used by all modules and each module is responsible both for re-configuring the power to meet its

own needs as well as for by-passing the original

power to the next module connected to it, if there

is such module.

In this way, each single module is electrically

independent on the others and they should be

classified according to:

Module type: according to the electrical role

that it plays in the system, a module must

belong to one of these electrical patterns:

Expansible of order N: this module receives electrical energy from other modules,

J Intell Robot Syst

and will provide electrical connection with

the original power to N other modules

(that must be mechanically connected

to it)

Terminal: this module receives electrical energy from other modules, but does

not provide electrical connection to other

modules

Initial: this module will transfer electrical

energy from the power source to other

modules. In this case, it will also be expansible of order N.

In order to respect the independence of each

module, some other important characteristics

must be considered:

Standard electrical plug: there should be a

standard plug as the only allowed electrical

connection for modules.

Allowed electrical connections: each module

is allowed to connect only to the plug provided

by the immediately previous module, and it

must provide a fully functional electric plug

to the next module(s), except in the case of a

terminal type module;

Power: the maximum power available to the

robot has to be specified in the family project

and cannot be exceeded;

Voltage: all robot modules will receive the

same standard voltage, determined according

to the family robot design. The module must

internally transform this voltage according to

its own needs;

Current: the maximum allowed current for

the whole robot is set in the family project.

Since an expansible type module can be connected to an unknown number of other modules, all expansible module wires must be

dimensioned to attend the whole robot electrical requirement. Terminal type modules wires

can be dimensioned according to their own

needs.

Visual identification: The module current consumption must be clearly identified (physically written) in the module in order to allow

people to visually inspect and evaluate the

possible insertion of this module in the main

robot (composed by other modules) while replacing robot parts;

Wires and cables position: the allowed positions of modules wires and cables will depend

on the type of the physical position of the

module in the robot (see Section 3.2). For

connected modules all wires and cables (and

also modules sensors and actuators) must mechanically fit the robot module. As for internal modules, if a module A is internal to a

module B, some of the A modules sensors,

actuators and wires are allowed to be external

to the module A. In this case, all wires (and

also sensors and actuators) of module A must

mechanically fit module B.

3.4 Computational Dimension

In the TORP structure, a robot is a set of nodes

in a network. Hence, each single robot module

carries its own computational unit that has no

limitation on the technology besides the fact that

it has to connect to other modules through a

common network protocol, defined for the project

family. Although all kinds of computer boards or

microprocessors boards can be used, the following

requirements must be respected:

1. Position: the computational unit must physically fit the module. There is an exception for

the main controller, that can be embedded in

the robot or not;

2. Functionality: the computational unit must be

able to fully control all module sensors and

actuators;

3. Communication capability: the computational

unit must be able to communicate with other

modules according to the TORP communication protocol;

4. Alone/network use: the module must be able

to work in the robot network as well as

in a stand-alone mode (without the other

modules);

5. Services: the computational unit must provide

services to the robot network, that can be

used by other instances and unities. These

services are regulated by the communication

protocol;

6. Internal states and monitoring: the computational unit must be able to provide, at all time,

full information regarding the module, that is,

J Intell Robot Syst

an up to date table of its proprioceptive and

exteroceptive information. In other words, the

module must keep up to date internal states

with information continuously obtained from

its sensors and actuators, as well as monitoring

status information (board temperature, module inclination, etc.).

The coordination of the set of modules, hereby

called the main controller, can be represented as

a device embedded in the robot in one of its

modules or as a device remotely linked to the

robot through the network. It is important to

remark that the communication protocol is technology independent and it is implemented over

a network protocol defined for a specific TORP

family.

3.4.1 Communication Protocol

In order to allow the communication among the

modules, a communication protocol was established. This protocol considers that the TORP

modules communicate among them according to

the network structure presented in Fig. 3. In this

structure, each module with its native processor

unit is linked to the others through a network

such as Ethernet, CAN, etc. The controller presented can be a module in the robot or an external

Fig. 3 Different network

configurations for a

TORP family.

Left Architecture with an

external non-embedded

controller running over

Ethernet. (Center)

Architecture with an

external non-embedded

controller running over

CAN. Right Architecture

with internal embedded

controller running over

Ethernet

computer that will run as the main coordinator

of the system. In the protocol, every time a new

module is plugged into the system it has to be

registered in the network. Then, a connection to

the main controller is established and data can be

sent following the TORP protocol.

There are seven types of messages that can be

communicated: CHECKIN, ACTION, GETSTATUS, STATUS, SETCONF, CONF and CHECKOUT. Each one of these messages exchange

information between the modules and the main

controller. A set of messages sent to/from a module should be enough to return all information

required and to perform all actions for that module. Every message should end with a ENTER

character.

1. CHECKIN message: this message is sent by

the module when it is plugged in the network.

Its structure is: CHECKIN [MODULE name]

[IP value PORT n] [TYPE type(EXPANSIBLE/TERMINAL)] [SONS n(used only for

expansible)] [FATHER moduleName] [TMP

id POS x,y,z] [TMP idn POS x,y,z] [MOUNT

n] [MAXCURRENT value(float)] [VOLUME v] [MASS m] [CG cg] [IX ix] [KX kx]

[SENSOR type NAME n POS x,y,z] ... [SENSOR typen NAME n POS x,y,z] [ACTUATOR type NAME n POS x,y,z DIR x,y,z] ...

J Intell Robot Syst

[ACTUATOR typen NAME n POS x,y,z

DIR x,y,z] where:

MODULEthe module name

TYPEthe module type: expansible or

terminal

SONSthe module maximum number

of sons

FATHERthe module in which the current module is mounted

TMPnthe id and position of the standard mechanical plug in the module

MOUNTid of the fathers standard plug

where the module is connected

MAXCURRENTthe maximum current

required by the module in A

VOLUMEthe volume of the module

(mm3)

MASSthe mass of the module (kg)

CGthe gravity center of the module

IXthe moment of inertia of the module

KXspin radius

SENSORthe list of sensors with the

quantity of each sensor present in the

module and their relative position to

the standard plug of the module

ACTUATORthe list of actuators with

the quantity of each one present in the

module and their relative position to the

standard plug of the module

2. ACTION message: this message is sent by

the main controller to the module any time

it needs an action to be performed by the

existing actuators. Every action message returns an OK message (zero) or an ERROR

message (non-zero). There are many action

messages possible, according to the actuators

registered in the system, and others can be

added without any loss in the protocol. The

following ACTION messages were designed

by abstracting the most important features of

the common actuators used in robotics.

ACTION [MOVE MOTORTYPE] [NAME

id] [DEGREES n]... [NAME id] [DEGREES n]

ACTION [MOVE MOTORTYPE] [NAME

id] [DEGREES n] [SPEED s] ... [NAME

idn] [DEGREES nn] [SPEED sn]

ACTION [MOVE MOTORTYPE] [NAME

id] [DEGREES n] [TIME t] ... [NAME

idn] [DEGREES nn] [TIME tn]

ACTION [STOP MOTORTYPE] [NAME

id] ... [NAME idn]

ACTION [TORQUE MOTORTYPE]

[NAME id] [VALUE ON/OFF] ... [NAME

idn] [VALUE ON/OFF]

ACTION [LED MOTORTYPE] [NAME

id] [VALUE ON/OFF] ... [NAME id]

[VALUE ON/OFF]

ACTION [DISPLAY IMAGEDEVICE]

[NAME id] [IMAGE name] ... [NAME

idn] [IMAGE namen]

ACTION [CLEAR IMAGEDEVICE]

[NAME id] ... [NAME idn]

ACTION [PLAY IMAGEDEVICE]

[NAME id] [Video name] ... [NAME idn]

[Video namen

ACTION [PAINT LEDRGB] [NAME id]

[VALUE R,G,B]... [NAME idn] [VALUE

R,G,B]

ACTION [CLEAR LEDRGB] [NAME

id] ... [NAME idn]

ACTION [SOUNDON/OFF SPEAKER]

[NAME id] ... [SOUNDON/OFF SPEAKER] [NAME id]

ACTION [PLAY SPEAKER] [NAME id]

[VALUE ...] ... [NAME id] [VALUE ...]

ACTION [PLAYFILE SPEAKER] [NAME

id] [VALUE FILENAME] ... [NAME id]

[VALUE FILENAME]

3. GETSTATUS message: this message is sent

by the main controller to a sensor in order

to acquire information regarding its readings.

The GETSTATUS message is followed by an

STATUS message from the module containing the required information.

GETSTATUS [SENSOR type] [NAME

id] ... [SENSOR typen] [NAME idn]

4. STATUS message: this message is sent by a

sensor or actuator that contains sensors to

the controller any time a GETSTATUS message is received. The current list of sensors

registered is formed by: gps, sonar, infra-red,

touch, compass, accelerometer, force, temperature, camera, microphone. There is also the

J Intell Robot Syst

possibility of having the sensors from the motors sending their status. Additional sensors

can be included in the list.

GpsSTATUS [SENSOR GPS] [NAME

id] [DATA n,n]

SonarSTATUS [SENSOR SONAR]

[NAME id] [DATA distance]

IRSTATUS [SENSOR IR] [NAME id]

[DATA distance]

TouchSTATUS [SENSOR TOUCH]

[NAME id] [DATA status(PRESSED/

FREE)]

CompassSTATUS [SENSOR COMPASS] [NAME id] [DATA]

AccelerometerSTATUS [SENSOR ACCELEROMETER] [NAME id] [AXES n]

[Data x,y,z]

ForceSTATUS [SENSOR FORCE]

[NAME id] [DATA value]

TemperatureSTATUS [SENSOR TEMPERATURE] [NAME id] [DATA temp]

CameraSTATUS [SENSOR CAMERA]

[NAME id] [FORMAT type] [RESOLUTION value] [DIMENSION x,y][BYTES n]

[DATA ...]

MicrophoneSTATUS [SENSOR Microphone] [NAME id] [FORMAT type]

[RESOLUTION value][DIMENSION x,y]

[BYTES n] [DATA ...]

5. SETCONF message: this message is sent by

the controller to a sensor or actuator in order

to change its operating mode, return type, etc.

It is followed by a confirmation sent by the

sensor or actuator.

SETCONF [SENSOR name][NAME id]

[PARAMETER x][TYPE value]...[SENSOR namen] [NAME idn] [PARAMETER xn][TYPE valuen] [ACTUATOR

name] [NAME idn] [PARAMETER x]

[TYPE value]...[ACTUATOR namen]

[NAME idn] [PARAMETER xn][TYPE

valuen]

6. CONF message: this message is sent by the

sensor or actuator to the controller in order

to respond to a SETCONF message.

CONF [SENSOR name] [NAME id]

[STATUS OK/ERROR]

7. CHECKOUT message: this message is sent by

the module when it is plugged off.

CHECKOUT [MODULE name]

The process of packing data into the protocol

format and parsing the data received is carried out

both in the main controller and inside the modules

by their processing unit.

4 Examples of TORP Applications

It is important to state that a new TORP family

can be defined for any class of robots. This section

presents a hypothetical TORP family for wheeled

robots and a more detailed case study for a TORP

family of humanoid robots, with the implementation of CP01.

4.1 A TORP Family for Wheeled Robots

For this family, consider that the following modules were defined: body, vision and laser. The

body module could be represented by a commercially available robot like a P2DX [1] that has an

embedded CPU running a unix-based operating

system. In this way, this body model would comprise sonars, IR, bump sensors, odometers and 2

wheels. The vision module could be represented

by a camera mounted in a platform with 2 DOF.

Finally, the laser module could contain a laser

scanner. Mechanically, the base module offers mechanical plugs to other modules connect to. The

vision and laser modules are both terminal modules since they do not provide mechanical connections to other modules. In this configuration

both modules, vision and laser, are external once

they are mounted outside the structure of the base

module. Considering the electrical dimension, the

base module is initial since it contains the system

power source and it is expansible of order 2, once

it provides electrical energy to vision and laser

modules, that are electrically classified as terminal. If this project follows a TORP module-based

approach, all modules should have their processing units, acting according to their needs, communicating through the system network. In this

example, the vision module would be responsible

for having all knowledge regarding how to drive

J Intell Robot Syst

its motors to position the camera according to

the commands sent by the main controller. In the

same way, the body module would be responsible

for acquiring information from all its sensors as

well as for driving the robot.

Consider now that the differential wheels in the

body module will be replaced by omnidirectional

ones. In this case the body module would be the

only one to suffer with these modifications. In

the same way, if an extra DOF is added to the

vision module, this module would be responsible

for controlling this new DOF. The generalization

achieved by the application of the framework over

a traditional robotics model is the major benefit of

TORP. The application of the electrical, mechanical and computational standards proposed allow

this new system to become reconfigurable, modular and interchangeable, at the cost of additional

hardware and software layers.

A TORP specification set for this family is

detailed in Table 2. Additionally, the specification

for the mechanical and electrical plugs would be

required. As for the power limitations, as the

base module was defined electrically as initial, the

voltage/current specifications for the family could

be defined by it: 12V@7.2A. The network protocol

would be Ethernet.

The following subsection presents another application of TORP for a different class of robots.

4.2 Case Study: CP01 Humanoid Robot

TORP is a generic framework for a large range

of robots. Although it is a feasible framework, its

application is difficult on small-size robots due to

limitations in current technology, like electronic

board sizes, that imply constraints to the selfcontained modules. Its immediate applications to

large robots, like humanoid robots, however, is far

easier.

In order to perform a concept proof of TORP

this section describes the implementation of

a humanoid robot, named CP01. The TORP

family for this robot was idealized as follows:

(i) standard mechanical plug designed to support efforts related to humanoid robot motions

(Table 1); (ii) electrical specification (Table 1),

and (iii) Computational Dimension based on

TCP/IP communication.

Figure 4 presents the CAD design of CP01 robot, first robot implemented based on the TORP

specification set. In its current version, it is a

23 DOF robot with head, two arms and chest,

envisioning future leg expansion, although due

to the use of the TORP framework, a wheeled,

a caterpillar, a n-footed or any other low body

assembly could also be used. CP01 was designed

for human-robot interaction research. Its body

dimensions, particularly its long neck, were purposely designed to permit robots face approximation to human interactor, allowing diverse novel

social behaviors. The full project was designed

according to open-hardware and open-software

concepts, and files are publicly available at [28].

CP01 is composed by eight modules: base,

arms (2), chest, head, image, sound and facial.

Electrical module types and module mechanical

connection classification are shown in Table 3.

Figure 5 presents a connection diagram, in the

electrical and mechanical dimensions, between

modules.

4.2.1 CP01 Electrical Dimension

One of the most important implications of using

TORP protocol lies with respect to power cables

Table 2 TORP specification set for a wheeled robot family

Module

Electrical and mechanical connections

Components

Base

Mechanical: external, expansible of order 2

Electrical: initial, expansible of order 2

Mechanical: external, terminal

Electrical: terminal

Mechanical: external, terminal

Electrical: terminal

DOF: 2

Sensors: sonar, ir, odometer, bumpers

DOF: 2

Sensors: camera

DOF: 0

Sensors: laser

Vision

Laser

J Intell Robot Syst

Fig. 4 CP01 mechanical

CAD drawing.

a Assembly

three-dimensional view;

front-view. b Side-view

(a)

sizing and distribution along the robot. As discussed in Section 2, the average power expected

from a humanoid robot is lower than 3 kW.

In order to attend usual motors and regulators

specifications, a 48 V power source was adopted

for the TORP family of CP01 robot. This voltage

level in mentioned in humanoid robots domain

and expected currents for its usual power would

be about 60 A considering all actuators simul-

(b)

(c)

taneously activated. To fit these requirements, a

8 AWG 3.3 mm diameter cable was used in all

modules and a Molex mini-fit 8 AWG plug family

was adopted as the standard electrical plug for

the whole robot. Once powered, each module was

responsible for regulating voltage for its internal

needs. Regarding electrical specifications, there

are five terminal modules (arms, image, sound,

facial), one expansible of order 1 (base), one

Table 3 CP01 modules

Module

Electrical and mechanical connections

Components

Base

Mechanical: external, expansible of order 1

Electrical: expansible of order 1

Mechanical: external, expansible of order 4

Electrical: initial, expansible or order 4

Mechanical: external, terminal

Electrical: terminal

Mechanical: external, terminal

Electrical: expansible or order 3

Mechanical: internal, terminal

Electrical: terminal

Mechanical: internal, terminal

Electrical: terminal

Mechanical: internal, terminal

Electrical: terminal

DOF: 2

Sensors: none

DOF: 0

Sensors: accelerometer, sonar

DOF: 6

Sensors: accelerometer

DOF: 3

Sensors: accelerometer

DOF: 0

Sensors: camera

DOF: 0

Sensor: none

DOF: 3

None

Chest

Arms

Head

Image

Sound

Facial

J Intell Robot Syst

(a)

(b)

Fig. 5 CP01 modules connection schema. a Electrical schema. b Mechanical schema

expanisble of order 4 (chest) and one expansible of order 3 (head). Gumstixs Verdex PRO

were adopted as embedded devices in all modules

due to their small size (2 cm 8 cm) and high

computational power (Marvell PXA270 400 MHz

XScale processor). There was an exception for

Gumstix RoboAudio, that was adopted in the

sound module. Regulators and sensor/actuator

controllers SMD boards were specially designed

to fit these project requirements.

4.2.2 CP01 Mechanical Dimension

In order to conduct a proof of concept with respect to the possibility of building a common mechanical plug to a humanoid robot, a very simple

connectorshown in Fig. 6was proposed and

machined for the TORP family of CP01 robot.

This plug is basically composed by two aluminum

tubes with a mechanical interlocking. Aiming a

quick plug, two side buttons were designed in the

J Intell Robot Syst

Fig. 6 Exploded version of CP01 mechanical plug

main tube. When both are pressed, they are compressed into the tube, allowing disengagement.

Once released, both are expelled by the spring to

their original places. Since buttons tend to be the

point of maximum mechanical stress, they were

manufactured in steel instead of aluminum due

to its well known high shear strength. The opposite end of tubes were strongly fixed in modules

chassis. Dynamixel AX-12, RX-64 and EX-106

servomotors and as general purpose micro servomotors were adopted as the motors of CP01.

messages sent/received through the network in

terms of medium level commands. For all levels,

the code was written in C++. The basic class

structure of the system is represented in Fig. 7.

In the following code example, Module is the

class that contains all sensors and actuators implementation. This class is responsible for receiving/sending the information from/to the network

connection, calling the appropriate commands.

Sample code for CP01 software embedded in

modules.

/******* High level function *******/

void Module::checkData() {

string lastDataFromServer;

this->serverSocket

->receive(lastDataFromServer,500);

string str = lastDataFromServer;

// Checks for messages

if (str.find("ACTION",0)

!= string::npos ) {

if (str.find("{MOVE RX64}")

!= string::npos ) {

this->rx64->move(str);

}

if (str.find("{MOVE AX12}")

!= string::npos ) {

this->ax12->move(str);

}

if (str.find("{PLAY SPEAKER}")

!= string::npos ) {

this-speaker->play(str);

}

}

4.2.3 CP01 Communication and Computational

Dimension

CP01 robot modules were modeled as nodes in

a Ethernet-TCP/IP network and a router was inserted in the chest module. CP01 software was

divided into two parts: (i) inside modules and (ii)

controller software. Inside each module, to allow

future changes of hardware without significant

changes, CP01 follows the multilayer software

development. Each module contains a Gumstix

with Linux Open Embedded OS running, and a

Net Pro VX with wi-fi for communication. For

each module, three levels of code were designed:

(i) The low level: refers to direct access to pins,

ports and hardware elements (serial, timer, reset, etc.); (ii) The medium level: refers to macro

commands that can be sent to the peripherals

connected to the control board. For example, the

set of low levels commands that are sent to the

hardware to perform a move in a servo with

specific speed, and (iii) The high level: refers to

the packing/unpacking commands that parser the

Fig. 7 Basic class-diagram for module internal code

J Intell Robot Syst

(a)

(b)

Fig. 8 CP01 Control software. a Interface control with

no module connected. In this representation, the color of

the modules sketch and the absence of visual information

indicate that no module has been plugged in the system.

b As modules are plugged, the color of the sketch changes

and the information received trough the check-in message

regarding the module (number of sensors, sensor data,

position, etc.) are presented in the interface

/*******Medium level function*******/

void MotorRx64::setReturnDelayTime

(char rdt) {

//construct the message to the servo

char *parameter;

parameter = new char[2];

parameter[0] = P_RETURN_DELAY_TIME;

//adress to write

parameter[1] = rdt;

//new adress to be setup

sendGeneralCmd

(INST_WRITE,parameter,2);

//send the command

}

/******* Low level function *******/

int Tserial::getArray

(char *buffer, int len) {

unsigned long read_nbr;

cal interface. The software is responsible for keeping track of each module connected. In Fig. 8a

there is a monitoring window where no module is

connected. As the modules open their connection

with the controller and send a CHECKIN message, the data is interpreted by the control system

and the characteristics of the module (sensors,

read_nbr = 0;

if (serial_handle

!=INVALID_HANDLE_VALUE) {

ReadFile(serial_handle, buffer, len,

&read_nbr, NULL);

}

return((int) read_nbr);

}

4.2.4 Controller Software

The Controller Software in CP01 runs in a computer external to the robot. The controller was

built in Java with the Java 2D API for the graphi-

Fig. 9 CP01 robot assembled

J Intell Robot Syst

Fig. 10 Sequence of movements of CP01 arm with embedded accelerometer placed next to the shoulder link TMP in order

to evaluate the additional vibration induced in the arm by the addition of the standard plug

actuators, etc.) are presented. Figure 8b shows

modules plugged into the system. Once a module

has checked in into the system, the main controller

is responsible for requesting up to date information of the modules through GETSTATUS

message. The module answers to the controller

with a STATUS message. Then, the information

received is parsed in the controller so that its

graphical interface shows the current status of the

module. In this way, the controller software is able

to visualize and control each module individually

or the whole robot. The TORP architecture is,

therefore, invisible to a human operator.

4.2.5 Final Assembly Evaluation

CP01 robot final assembly is shown in Fig. 9.

In order to evaluate the issues that arise when

establishing a standard mechanical plug instead

(a)

of perfectly clumping parts, an experiment was

conducted. The movement sequence for this experiment can be seen in Fig. 10. In this experiment, a 3-axis accelerometer was inserted in the

shoulder-arm link, just after the TORP Mechanical Plug, in such a way that vibration effects could

be observed. Figure 11 presents the voltage versus

time graphs returned by the accelerometer in its

3-axis. One can verify that spikes in the Z axis

(the plan where there is no ongoing movement)

after movements in the other axis may indicate

that a low vibration was inserted by the plug in the

system. However, its amplitude cannot be understood as significant for robots that do not require

a very precise positioning system, as that required

for industrial or domestic general purpose robots.

Considering the scenario where the robot arm

structure weights approximately 2 kg and measures 0.7 m, moving at low speed with a small

(b)

(c)

Fig. 11 Accelerometer measurements in all three axis for slow (a), medium (b) and high (c) shoulders motors movement

velocities. Axis not rotating in all situations does not present significant vibration

J Intell Robot Syst

Fig. 12 Tensile, compressive and flexion analysis for a 1,000 N load on the aluminum-steel connector. Aluminum and steel

Yield strength are about 97 and 294.8 MPa, respectively

load, it is reasonable to expect that the mechanical

plug will not be subject to a force greater than

1,000 N. Following this assumption, experimental

data obtained with computer simulations for tensile, compressive and flexion analysis for a 1,000 N

load on the aluminum-steel connector shown in

Fig. 12, did not present significant mechanical

deformation, showing that this first version of a

mechanical plug attends the project mechanical

requirements.

5 Results and Discussion

The feasibility of the proposed methodology

for real world robots was demonstrated through

the building of CP01. Experimental results have

demonstrate that robot mechanical abilities are

not significantly affected by the TORP architecture, and that there is at least one set of mechanical plug, electronics and communication apparatus able to satisfy specification requirements.

Besides the functional modification that can be

carried in the TORP robots through the replacement of modules, the aesthetics of the robot can

also be fully modified by the exchange of modules.

For CP01, a new and smaller head will be used

so the robot can have more stability once legs are

added.

Taking into consideration that TORP framework does not limit mechanical nor electrical connectors, as well as network technologies, it is reasonable to expect that new families of robots with

better implementations can arise in the future and

that some of them can become new standards for

certain robot classes.

One of the most serious difficulties faced in the

project was on the design of the power regulation boards, far more complex than usual and in

the limit of the available technologies considering

size/power relation.

Although the work to setup a robot project to

the TORP specification set is hard, the advantages

that overcome this initial trouble are tremendous.

First of all, the re-use of hardware and software

parts in new robots or versions is an easy task

if the robots belong to the same TORP family.

Moreover, the modular architecture provides an

easy way to compare parts of robots. For instance,

distinct models of arms, legs, grippers and others,

can be evaluated regarding their speed, response

time, energy consumption or even control aspects

in the same platform. Yet, groups with different

expertise and using different technologies can apply their developments in the same robot. The

before mentioned advantages of the proposed

framework present possible ways to overcome the

historical drawbacks in robot design and still have

J Intell Robot Syst

full compatibility with previously proposed robotics operating systems and frameworks.

One can argue that the connection of modules

with distinct mechanical properties might be impractical for control purposes of the whole assembly. In fact, this would be a serious constraint if

the information regarding the mechanical aspects

of the module was not informed to the main controller by the module itself. With this information,

special control techniques can be future investigated to assign robustness to the system.

Finally, it is fair to observe that this modulebased framework is better suitable for medium/

high size robots due to constraints regarding current mechanical and electrical technologies.

6 Conclusions and Future Work

This paper summarizes the specification of a new

framework, TORP, proposed for modular collaborative robot projects. The focus in TORP robots

is shifted from components to functional level,

creating an abstraction between high and low level

control, not only in the computational dimension

but also in the mechanical and electrical. It does

not contradict previous standardization, but extends them to new dimensions. At the best of our

knowledge, this work represents the first proposition of standardization at all these dimensions in

robotics.

It is also important to mention that the cost of

the application of this protocol in a robot project

is the insertion of redundancies in all dimensions,

that have impact in robot budget. In fact, one

can argue that it would be cheaper and quicker

to connect sensors and actuators directly to the

controller. In fact, this reasoning was valid also for

PCs in the early 70s. The advantages of such standardization work in long term. It is also important

to keep in mind that TORP direct applications

are for robots build in collaborative situations, i.e.,

where multiple institutions with different interests

and skills want to build a unique robot. However,

any project can adopt this methodology.

In order to upgrade the framework, some improvements are in progress: (i) a new version of

the mechanical plug that incorporates the electrical cables, (ii) simpler self-designed boards for the

modules to reduce the overall project budget, and

(iii) development of control strategies suitable for

application in TORP robots domain.

Finally, we do not claim that TORP is a final

methodology. Although we believe such standardization could have a deep impact on the way we

build robots, we are sure that it represents just

a first step on the direction of the discussion of

necessary standardization in the robotics field.

Acknowledgements Authors gratefully acknowledge

the contribution of Rafael Ribeiro, Victor Nalin, Alan

Morgensztern, Kaue Cruz, Daniel Baggio, Wilson

Canazart, Rafael Chiafarelli and Raphael Bartholo Costa.

Authors would also like to thanks Mauricio Leal, Silveira

Neto and Bruno Souza for developing the remote

interface. CP01 robot was named after Campus Party,

event supported by Futura Networks, that welcomed

the project and made this research possible. CP01 was

sponsored by Micropress.

References

1. Active Media Robotics: P2dx robot. http://www.

mobilerobots.com/ (2010)

2. Aghili, F., Parsa, K.: A reconfigurable robot with

lockable cylindrical joints. IEEE Trans. Robot. 25(4),

785797 (2009)

3. Baillie, J.C.: Urbi: towards a universal robotic lowlevel programming language. In: IEEE/RSJ International Conference on Intelligent Robots and Systems,

pp. 820825 (2005)

4. Baillie, J.C., Demaille, A., Hocquet, Q., Nottale, M.,

Tardieu, S.: The Urbi universal platform for robotics.

In: Intl. Conf. on Simulation, Modeling and Programming for Autonomous Robots, pp. 580591 (2008)

5. Brooks, A., Kaupp, T., Makarenko, A., Williams, S.,

Orebck, A.: Orca: a component model and repository.

In: Brugali, D. (ed.) Software Engineering for Experimental Robotics. Springer Tracts in Advanced Robotics, vol. 30, pp 231251. Springer Berlin, Heidelberg

(2007)

6. Bruyninckx, H., Soetens, P., Koninckx, B.: The realtime motion control core of the Orocos project.

In: IEEE International Conference on Robotics and

Automation, pp. 27662771 (2003)

7. Gerkey, B., Vaughan, R., Howard, A.: The player/stage

project: tools for multi-robot and distributed sensor

systems. In: Proceedings of the 11th International Conference on Advanced Robotics, pp. 317323 (2003)

8. Hu, Y., Wang, L., Zhao, W., Wang, Q., Zhang, L.:

Modular design and motion control of reconfigurable

robotic fish. In: IEEE Conference on Decision and

Control, pp. 51565161 (2007)

9. Jun-Ho, O., David, H., Won-Sup, K., Young, H.,

Jung-Yup, K., Woo, P.: Design of android type

J Intell Robot Syst

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

humanoid robot Albert HUBO. In: International Conference on Intelligent Robots and Systems, pp. 1428

1433 (2006)

Kaneko, K., Kanehiro, F., Kajita, S., Hirukawa, H.:

Humanoid robot HRP-2. In: Proceedings of the IEEE

International Conference on Robotics and Automation

(2004)

Kim, J.Y., Park, I.W., Oh, J.H.: Realization of dynamic stair climbing for biped humanoid robot using

force/torque sensors. J. Intell. Robot. Syst. 56(4), 389

423 (2009)

Lund, H., Henningsen, A., Nielsen, R.: Modular robotic system as multisensory room in childrens hospital. In: Proceedings of 14th International Symposium

on Artificial Life and Robotics (ISAROB) (2009)

Madden, J.D.: Mobile robots: motor challenges and

materials solutions. Science 318(5853), 10941097

(2007)

Metta, G., Fitzpatrick, P., Natale, L.: Yarp: yet another

robot platform. Int. J. Adv. Robot. Syst. 3(1), 4348

(2006)

Metta, G., Sandini, G., Vernon, D., Natale, L., Nori,

F.: The iCub humanoid robot: an open platform for

research in embodied cognition. In: PerMIS: Performance Metrics for Intelligent Systems Workshop,

pp. 1921 (2008)

Mondada, F., Bonani, M., Raemy, X., Pugh, J., Cianci,

C., Klaptocz, A., Magnenat, S., Zufferey, J., Floreano,

D., Martinoli, A.: The e-puck, a robot designed for

education in engineering. In: Proc. of the 9th Conf. on

Mobile Robots and Competitions (ROBOTICA 2009),

pp. 5965. IPCB: Instituto Politcnico de Castelo

Branco, Castelo Branco, Portugal (2009)

Montemerlo, M., Roy, N., Thrun, S.: Perspectives

on Standardization in Mobile Robot Programming:

The Carnegie Mellon Navigation (CARMEN) Toolkit,

pp. 24362441 (2004)

Nof, S., Chen, J.: Assembly and disassembly: an

overview and framework for cooperation requirement

planning with conflict resolution. J. Intell. Robot. Syst.

37(3), 307320 (2003)

Park, I.W., Kim, J.Y., Lee, J., Oh, J.H.: Mechanical

design of the humanoid robot platform, HUBO. Adv.

Robot. 21(11), 10351322 (2007)

Pivtoraiko, M., Nesnas, I., Nayar, H.: A reusable software framework for rover motion control. In: International Symposium on Artificial Intelligence, Robotics

and Automation in Space. Los Angeles, CA (2008)

Quigley, M., Gerkey, B., Conley, K., Faust, J., Foote,

T., Leibs, J., Berger, E., Wheeler, R., Ng, A.: Ros: an

open-source robot operating system. In: International

Conference on Robotics and Automation (2009)

22. ROS.org: Ros Software Libraries. http://www.ros.

org/wiki/ (2010)

23. Rusu, R., Maldonado, A., Beetz, M., Gerkey, B.: Extending player/stage/gazebo towards cognitive robots

acting in ubiquitous sensorequipped environments. In:

ICRA Workshop for Networked Robot Systems, 2007.

Rome, Italy (2007)

24. Sakagami, Y., Watanabe, R., Aoyama, C., Matsunaga,

S., Higaki, N., Fujita, M.: The intelligent asimo: system

overview and integration. In: Proceedings of International Conference on Intelligent Robots and Systems,

pp. 24782483 (2002)

25. Seward, D., Bradshaw, A., Margrave, F.: The anatomy

of a humanoid robot. Robotica 14(4), 437443 (2009)

26. Sproewitz, A., Asadpour, M., Billard, A., Dillenbourg,

P., Ijspeert, A.: Roombotsmodular robots for adaptive furniture. In: Proceedings of the IEEE/RAS

International Conference on Intelligent Robots and

Systems (IROS). Workshop on Self-Reconfigurable

Robots, Systems and Applications (2008)

27. Sproewitz, A., Billard, A., Dillenbourg, P., Ijspeert,

A.: Roombots-mechanical design of self-reconfiguring

modular robots for adaptive furniture. In: IEEE International Conference on Robotics and Automation,

pp. 42594264 (2009)

28. TORP: The Open Robot Project Repository. https://

torp.svn.sourceforge.net/svnroot/torp/ (2010)

29. Touretzky, D.S., Tira-Thompson, E.J.: The Tekkotsu

Crew: teaching robot programming at a higher level. In:

Proceedings of the Twenty-Fourth AAAI Conference

on Artificial Intelligence (AAAI-10) (2010)

30. Volpe, R., Nesnas, I., Estlin, T., Mutz, D., Petras, R.,

Das, H.: The claraty architecture for robotic autonomy.

In: Aerospace Conference, 2001, IEEE Proceedings,

vol. 1, p. 1 (2002)

31. Wilkier, D.R.: Muscle. Edward Arnold, London (1976)

32. Willow Garage: PR2 Robot. http://www.willowgarage.

com/ (2010)

33. Yim, M., Shen, W.M., Salemi, B., Rus, D., Moll, M.,

Lipson, H., Klavins, E., Chirikjian, G.S.: Modular selfreconfigurable robot systemschallenges and opportunities for the future. IEEE Robot. Autom. Mag.,

14(1), 4352 (2007)

34. Zykov, V., Chan, A., Lipson, H.: Molecubes: an opensource modular robotics kit. In: Proceedings of the

IEEE International Conference on Intelligent Robots

and Systems (IROS) (2007)

35. Zykov, V., William, P., Lassabe, N., Lipson, H.:

Molecubes extended: diversifying capabilities of opensource modular robotics. In: Proceedings of the

IEEE Intelligent Robots and Systems 2008, SelfReconfigurable Robotics Workshop (2008)

Potrebbero piacerti anche

- Ammended Transitivity Analysis of Nawaz SharifDocumento109 pagineAmmended Transitivity Analysis of Nawaz SharifAamir Riaz Malik100% (1)

- UmtsDocumento1.074 pagineUmtsAamir Riaz MalikNessuna valutazione finora

- LTE ParametersDocumento388 pagineLTE ParametersAamir Riaz MalikNessuna valutazione finora

- UMTS Parameters CMEDocumento49 pagineUMTS Parameters CMEAamir Riaz MalikNessuna valutazione finora

- Mobile Terminated Call SequenceDocumento3 pagineMobile Terminated Call SequenceAamir Riaz MalikNessuna valutazione finora

- Drive Test KPIDocumento5 pagineDrive Test KPIAamir Riaz MalikNessuna valutazione finora

- How To Improve RX QualDocumento2 pagineHow To Improve RX QualAamir Riaz MalikNessuna valutazione finora

- DCR Improvement Steps 2GDocumento1 paginaDCR Improvement Steps 2GAamir Riaz MalikNessuna valutazione finora

- CS Fallback Feature Parameter Description (ERAN2.0 - 01)Documento33 pagineCS Fallback Feature Parameter Description (ERAN2.0 - 01)Aamir Riaz MalikNessuna valutazione finora

- AQM Feature Parameter Description (ERAN2.0 - 01)Documento19 pagineAQM Feature Parameter Description (ERAN2.0 - 01)Aamir Riaz MalikNessuna valutazione finora

- UMTS Admission Control Feature PUC 20090616Documento13 pagineUMTS Admission Control Feature PUC 20090616Aamir Riaz MalikNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Course Title: Computer Network-Lab.: Experiment Name: Star, Bus, Mesh, Hybrid TopologyDocumento9 pagineCourse Title: Computer Network-Lab.: Experiment Name: Star, Bus, Mesh, Hybrid TopologyAlauddinNessuna valutazione finora

- Pulsonix Users GuideDocumento466 paginePulsonix Users GuideRenan CapovillaNessuna valutazione finora

- DLink Product GuideDocumento44 pagineDLink Product GuideSANJEEVNessuna valutazione finora

- Correction Pillar of The Criminal Justice SystemDocumento16 pagineCorrection Pillar of The Criminal Justice SystemKel Evra100% (1)

- Documentum Server 7.1 Administration and Configuration GuideDocumento602 pagineDocumentum Server 7.1 Administration and Configuration Guidefahay90552Nessuna valutazione finora

- Republic Act No. 8792 Electronic Commerce Act OF 2000Documento17 pagineRepublic Act No. 8792 Electronic Commerce Act OF 2000John Paul SorianoNessuna valutazione finora

- 1830 PSS-14 R3.6 Photonic Service Switch DS 20120330Documento7 pagine1830 PSS-14 R3.6 Photonic Service Switch DS 20120330CROIX ROUGENessuna valutazione finora

- Data Communication & NetworksDocumento8 pagineData Communication & Networksrukhsar siddiqueNessuna valutazione finora

- PacketWave 600 Series Quick Start GuideDocumento6 paginePacketWave 600 Series Quick Start GuideAnees SiddiquiNessuna valutazione finora

- VPC SI System ArchitectureDocumento12 pagineVPC SI System ArchitectureK OuertaniNessuna valutazione finora

- Airborne Internet: Sree Narayana Gurukulam College of EngineeringDocumento21 pagineAirborne Internet: Sree Narayana Gurukulam College of EngineeringkevinNessuna valutazione finora

- Setting Mikrotik Smk-1Documento3 pagineSetting Mikrotik Smk-1Anang Ma'rufNessuna valutazione finora

- Technical Paper Presentation TOPICSDocumento1 paginaTechnical Paper Presentation TOPICSMITHUN K50% (2)

- v5.1.0.ERN - External v0.5Documento44 paginev5.1.0.ERN - External v0.5Ashraf SaeedNessuna valutazione finora

- 91 Computer ScienceDocumento28 pagine91 Computer ScienceAravind Shankar0% (1)

- HACKING - THE NO-NONSENSE GUIDE - Learn Ethical Hacking Within 12 Hours! PDFDocumento107 pagineHACKING - THE NO-NONSENSE GUIDE - Learn Ethical Hacking Within 12 Hours! PDFCyril Jean-BaptisteNessuna valutazione finora

- Powerflex 750-Series Ac Drives: Programming ManualDocumento548 paginePowerflex 750-Series Ac Drives: Programming ManualJose GimenezNessuna valutazione finora

- Basics of Information TechnologyDocumento4 pagineBasics of Information TechnologyYou TubeNessuna valutazione finora

- Applied Sciences: Photonic Integrated Circuits For NGPON2 ONU Transceivers (Invited)Documento19 pagineApplied Sciences: Photonic Integrated Circuits For NGPON2 ONU Transceivers (Invited)RomanNessuna valutazione finora

- IPv6@ESTG-Leiria IPv6Wireless Relatorio FinalDocumento94 pagineIPv6@ESTG-Leiria IPv6Wireless Relatorio FinalAndré MadeiraNessuna valutazione finora

- Manual Camaras Hik-Vision DS-2CD21XX-I PDFDocumento75 pagineManual Camaras Hik-Vision DS-2CD21XX-I PDFIngenieria5 OficanonNessuna valutazione finora

- Voice-Over Internet Protocol (Voip) Audit/Assurance ProgramDocumento45 pagineVoice-Over Internet Protocol (Voip) Audit/Assurance ProgramElisha MushaijaNessuna valutazione finora

- 406 A BluetoothDocumento9 pagine406 A BluetoothAlexander KlassenNessuna valutazione finora

- CN LAB Viva QuestionsDocumento4 pagineCN LAB Viva QuestionsJeremiah ENessuna valutazione finora

- ISeries System Operator ReferenceDocumento130 pagineISeries System Operator ReferencePanzo Vézua GarciaNessuna valutazione finora

- Part#10 Tristation SOEDocumento21 paginePart#10 Tristation SOEsheikhusama91100% (1)

- GFA-226B VersaMax SEDocumento2 pagineGFA-226B VersaMax SEerik masongNessuna valutazione finora

- Application Layer: CS CSDocumento14 pagineApplication Layer: CS CSShailaja UdtewarNessuna valutazione finora

- Building An Inexpensive Oracle RAC 11g R2 On LinuxDocumento84 pagineBuilding An Inexpensive Oracle RAC 11g R2 On Linux유중선Nessuna valutazione finora

- eCPRI V 1 1 2018 01 10Documento62 pagineeCPRI V 1 1 2018 01 10sabareNessuna valutazione finora