Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pages From API.6d.2008

Caricato da

Donovan BonnerCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pages From API.6d.2008

Caricato da

Donovan BonnerCopyright:

Formati disponibili

API Specification 60/ ISO 14313

10.3.2 Welding inspectors

Personnel performing visual inspection of welding operations and completed welds shall be qualified and

certified to the requirements of AWS QC1, or equivalent, or a manufacturer's documented training

programme.

10.4 NDE of repairs

After defect removal, the excavated area shall be examined by magnetic-particle (MT) or liquid-penetrant (PT)

methods in accordance with Annex A. Repair welds on pressure-containing parts shall be examined using the

same NOE method that was used to detect the defect with a minimum of MT or PT. Acceptance criteria shall

be as specified in Annex A for the appropriate product form. The final NOE activities shall be conducted after

post weld heat treatment unless otherwise agreed.

The NOE requirements specified by the purchaser in 10.1 shall also apply to repair welding.

10.5 Weld end NDE

If the purchaser specifies that weld ends be subjected to volumetric or surface NOE, the examination and

acceptance criteria shall be in accordance with Clause A.22.

10.6 Visual inspection of castings

All castings as a minimum shall be visually inspected in accordance with MSS SP-55.

11 Pressure testing

11.1 General

Each valve shall be tested prior to shipment. The purchaser shall specify which particular supplementary tests

in Annex B shall be performed.

Testing shall be performed in the sequence detailed in 11.2 to 11.5. Pressure testing shall be carried out

before coating of the valves.

If the valve has been previously tested in accordance with this International Standard, subsequent repeat

testing may be performed without removal of the valve external coating.

Test fluid shall be fresh water or, by agreement, light-weight oil having a viscosity not exceeding that of water.

Water shall contain a corrosion inhibitor and, by agreement, antifreeze. The chloride content of test water in

contact with austenitic and duplex stainless steel wetted components of valves shall not exceed

30 IJg/g (30 ppm by mass).

Valves shall be tested with the seating and sealing surfaces free from sealant except where the sealant is the

primary means of sealing. A secondary sealant system, if provided, shall not be used before or during tests.

Tests specified with the valve half-open may also be performed with the valve fully open, provided the body

cavity is simultaneously filled and pressurized through a cavity connection.

If valve-body connections are not available for direct monitoring, methods for monitoring pressures and/or

leakage shall be determined.

Supply pressure shall be stabilized prior to the start of pressure testing and shall be held for the minimum test

durations listed in Tables 9, 10 and 11.

Pressure testing shall be performed in accordance with documented procedures.

52

API Specification 60 II SO 14313

11.2 Stem backseat test

Testing of the backseat shall commence with the packing gland loose. Self-energized packing or seals shall

be removed unless a test port is provided for this test.

The valves shall be filled with the ends closed off and the obturator in the partially open position until leakage

of the test fluid around the stem is observed. The backseat shall then be closed and a minimum pressure of

1,1 times the pressure rating determined in accordance with 7.2 for material at 38C (100 OF) applied for the

duration specified in Table 9.

Monitoring for leakage shall be through a test access port or by monitoring leakage around the loosened

packing.

No visible leakage is permitted at this test pressure.

NOTE

This test is performed prior to hydrostatic shell test.

WARNING - Appropriate safety precautions shall be taken.

Table 9 - Minimum duration of stem backseat tests

Valve size

Test duration

ON

NPS

min

100

~4

150

~6

11.3 Hydrostatic shell test

Valve ends shall be closed off and the obturator placed in the partially open position during the test. If

specified by the purchaser, the method of closing the ends shall permit the transmission of the full-pressure

force acting on the end blanks to the valve body. If present, external relief valves shall be removed and their

connections plugged.

The test pressure shall be 1,5 or more times the pressure rating determined in accordance with 7.2 for

material at 38C (100 OF). The duration shall not be less than that specified in Table 10.

Table 10- Minimum duration of hydrostatic shell tests

Valve size

Test duration

ON

NPS

min

15 to 100

Yz to 4

150 to 250

6 to 10

300 to 450

12 to 18

15

;:?;

500

;:?;

20

30

No visible leakage is permitted during the hydrostatic shell test.

After hydrostatic shell testing, external relief valves shall be fitted to the valve. The connection to the valve

body shall be tested at 95 % of the set pressure of the relief valve for 2 min for valve sizes up to and including

ON 100 (NPS 4), and 5 min for valve sizes ON 150 (NPS 6) and larger. The relief-valve connection shall be

free of visible leakage during this period.

53

API Specification 60/ ISO 14313

The external relief valves shall be set to relieve at the specified pressure and tested in accordance with

11.4.5.

11.4 Hydrostatic seat test

11.4.1 Preparation

Lubricants or sealants shall be removed from seats and obturator sealing surfaces except where the lubricant

or sealant is the primary means of sealing. Assembly lubricants for metal-to-metal contact surfaces may be

used by agreement.

11.4.2 Test pressure and duration

The test pressure for all seat tests shall not be less than 1,1 times the pressure rating determined in

accordance with 7.2 for material at 38C (100 OF). The test duration shall be in accordance with Table 11.

Table 11 -

Minimum duration of seat tests

Valve size

ON

15 to 100

~

150

Test duration

NPS

~

min

to 4

~6

11.4.3 Acceptance criteria

Leakage for soft-seated valves and lubricated plug valves shall not exceed ISO 5208 Rate A (no visible

leakage). For metal-seated valves the leakage rate shall not exceed ISO 5208:1993, Rate D, except that the

leakage rate during the seat test in Clause B.4 shall not be more than two times ISO 5208:1993, Rate D,

unless otherwise specified. The test procedures for various types of block valve are given in 11.4.4.

NOTE

Special application can require that the leakage rate be less than ISO 5208:1993, Rate D.

11.4.4 Seat test procedures for block valves

11.4.4.1

Uni-directional

With the valve half-open, the valve and its cavity shall be completely filled with test fluid. The valve shall then

be closed and the test pressure applied to the appropriate end of the valve.

Leakage from the upstream seat shall be monitored via the valve body cavity vent or drain connection, where

provided. For valves without body cavity or drain connection, or downstream seated valves, seat leakage shall

be monitored at the respective downstream end of the valve (the valve end downstream of the pressurized

test fluid).

11.4.4.2

Bi-directional

With the valve half-open, the valve and its cavity shall be completely filled with test fluid. The valve shall then

be closed and the test pressure applied successively to both ends of the valve.

Seat leakage shall be monitored from each seat via the valve body cavity vent or drain connection, where

provided. For valves without a body-cavity vent or drain connection, seat leakage shall be monitored from the

respective downstream end of the valve.

54

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Technical Writing PDFDocumento129 pagineTechnical Writing PDFKundan Kumar100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Chennai CMDA Master Plan 2026 Volume 3 Sectorial BackgroundDocumento270 pagineChennai CMDA Master Plan 2026 Volume 3 Sectorial BackgroundMalathi Kathirvel100% (1)

- EU MDR FlyerDocumento12 pagineEU MDR FlyermrudhulrajNessuna valutazione finora

- Production of BiodieselDocumento49 pagineProduction of Biodieselteja100% (1)

- MetasploitDocumento9 pagineMetasploitDhamlo KheralaNessuna valutazione finora

- Kgec ProfileDocumento11 pagineKgec ProfileDonovan BonnerNessuna valutazione finora

- IOM-P14-R0 Quarter Turn BVDocumento9 pagineIOM-P14-R0 Quarter Turn BVDonovan BonnerNessuna valutazione finora

- Iso9001 Manual With ProcedureDocumento105 pagineIso9001 Manual With ProcedureAshwin KumarNessuna valutazione finora

- Generon CatalogDocumento11 pagineGeneron CatalogDonovan BonnerNessuna valutazione finora

- 1156 - India - BGAS CSWIP Painting Inspector Grade 2 - High Res - Feb 2012Documento1 pagina1156 - India - BGAS CSWIP Painting Inspector Grade 2 - High Res - Feb 2012Sampath KumarNessuna valutazione finora

- 1165 - India - BGAS CSWIP Painting Inspector Grade 1 - High Res - Feb 2012Documento1 pagina1165 - India - BGAS CSWIP Painting Inspector Grade 1 - High Res - Feb 2012Donovan BonnerNessuna valutazione finora

- Review of ISO 17021 V2Documento5 pagineReview of ISO 17021 V2Donovan BonnerNessuna valutazione finora

- Autocad2007 Crack NotesDocumento1 paginaAutocad2007 Crack NotesDonovan BonnerNessuna valutazione finora

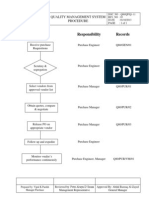

- Process Responsibility Records: Quality Management System ProcedureDocumento1 paginaProcess Responsibility Records: Quality Management System ProcedureDonovan BonnerNessuna valutazione finora

- Training Record (AAR 01)Documento1 paginaTraining Record (AAR 01)Donovan BonnerNessuna valutazione finora

- Honeywell Aquatrol 2000 PDFDocumento60 pagineHoneywell Aquatrol 2000 PDFvsilickasNessuna valutazione finora

- Puch Moped Horn Wiring Diagram (Chrome Oval Switches)Documento1 paginaPuch Moped Horn Wiring Diagram (Chrome Oval Switches)MopedgalNessuna valutazione finora

- 09-03-2023 Ramadhan - Small PDFDocumento13 pagine09-03-2023 Ramadhan - Small PDFAmmarah RamnarainNessuna valutazione finora

- Minimalist CV ResumeDocumento1 paginaMinimalist CV ResumeSijith MathewNessuna valutazione finora

- Santa Letters 2013Documento16 pagineSanta Letters 2013Lebanon_PublishingNessuna valutazione finora

- Fashion Law - Trademark ParodyDocumento12 pagineFashion Law - Trademark ParodyArinta PratiwiNessuna valutazione finora

- FIN323 Project 2021-2022Documento6 pagineFIN323 Project 2021-2022saleem razaNessuna valutazione finora

- Oil and Gas Reloaded: Offshore ArgentinaDocumento9 pagineOil and Gas Reloaded: Offshore ArgentinaMuhammad Fahmi AnbNessuna valutazione finora

- Tween 80 CoADocumento1 paginaTween 80 CoATấn Huy HồNessuna valutazione finora

- User's Guide: Smartpack2 Master ControllerDocumento32 pagineUser's Guide: Smartpack2 Master Controllermelouahhh100% (1)

- A Flight Plan in 10 StepsDocumento4 pagineA Flight Plan in 10 StepsThar LattNessuna valutazione finora

- School MemoDocumento1 paginaSchool MemoBellaNessuna valutazione finora

- Virtual Asset Insurance Risk Analysis - OneDegreeDocumento3 pagineVirtual Asset Insurance Risk Analysis - OneDegreeShaarang BeganiNessuna valutazione finora

- The World Wide WebDocumento22 pagineThe World Wide WebSa JeesNessuna valutazione finora

- Etpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsDocumento3 pagineEtpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsLourdes LimaNessuna valutazione finora

- TQM - Juran ContributionDocumento19 pagineTQM - Juran ContributionDr.K.Baranidharan100% (2)

- CIVPRO - Case Compilation No. 2Documento95 pagineCIVPRO - Case Compilation No. 2Darla GreyNessuna valutazione finora

- Taifun GT User GuideDocumento5 pagineTaifun GT User GuidecarloslarumbeNessuna valutazione finora

- Me Con Compressed Air SystemsDocumento8 pagineMe Con Compressed Air SystemsesvwestNessuna valutazione finora

- Crude Palm OilDocumento4 pagineCrude Palm OilpalmoilanalyticsNessuna valutazione finora

- System Error Codes (0-499)Documento33 pagineSystem Error Codes (0-499)enayuNessuna valutazione finora

- Opposition To Motion For Judgment On PleadingsDocumento31 pagineOpposition To Motion For Judgment On PleadingsMark Jaffe100% (1)

- Allama Iqbal Open University, Islamabad Warning: (Department of Secondary Teacher Education)Documento2 pagineAllama Iqbal Open University, Islamabad Warning: (Department of Secondary Teacher Education)Tehmina HanifNessuna valutazione finora

- Basic CommandsDocumento40 pagineBasic CommandsPrashant RaiNessuna valutazione finora

- SIConitDocumento2 pagineSIConitJosueNessuna valutazione finora