Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Plastic em

Caricato da

Ashok PradhanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Plastic em

Caricato da

Ashok PradhanCopyright:

Formati disponibili

Gh.

Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

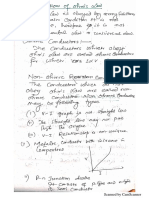

POSTELASTIC STRUCTURAL ANALYSIS

1. Basics of postelastic analysis

In plastic analysis and design of a structure, the ultimate load of the structure as a whole is

regarded as the design criterion. The term plastic has occurred due to the fact that the ultimate load is

found from the strength of steel in the plastic range. This method is rapid and provides a rational

approach for the analysis of the structure. It also provides striking economy as regards the weight of

steel since the sections required by this method are smaller in size than those required by the method

of elastic analysis. Plastic analysis and design has its main application in the analysis and design of

statically indeterminate framed structures.

Fig, 1 Mathematical models for steel

Many mathematical models are considered in nonlinear structural analysis. Choosing the

appropriate mathematical model for the material from which a structure is made is the main key for a

successful structural response evaluation (Fig. 1). The plastic method is applicable to structures

constructed with an ideal elastic-plastic material that exhibits the stress-strain relationship shown in

Figure 2. The moment-curvature relationship for any section of the structure is assumed to have the

ideal form shown in Figure 3. Thus, on applying a uniform sagging moment to a member the momentcurvature relationship is linear until the applied moment reaches the value of Mp the plastic moment

of resistance of the section. At this stage, all material above the zero-strain axis of the section has

yielded in compression and all material below has yielded in tension, and a plastic hinge has formed.

Then the section can offer no additional resistance to deformation, and increase in curvature continues

at a constant applied moment. In addition, in determining the collapse load of a structure, it is

assumed that elastic deformations are negligible and do not affect the geometry of the structure. It

1

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

means that the width-thickness ratio of plate elements is small so that local buckling does not occur

in other words, the sections will classify as plastic. Thus, the structure behaves in a rigid-plastic

manner with zero deformation until the formation of sufficient plastic hinges to produce a mechanism.

With these assumptions, it can be said that the section will reach its plastic moment capacity and then

undergo considerable rotation at this moment. With these assumptions, we will now look at the

behaviour of a beam up to collapse.

Fig. 2

Fig. 3

2. Formation of plastic hinges

Consider a simply supported beam subjected to a uniformly distributed working load of total

magnitude w, as shown in Fig. 4. The elastic bending moment at the ends is wl2/12, and at mid-span is

wl2/24, where l is the span. The stress distribution across any cross section is linear (Fig. 5.a). As w is

increased gradually, the bending moment at every section increases and the stresses also increase. At a

section close to the support where the maximum bending moment is, the stresses in the extreme fibers

reach the yield stress. The moment corresponding to this state is called the first yield moment My, of

the cross section. But this does not imply failure as the beam can continue to take additional load. As

the load continues to increase, more and more fibers reach the yield stress and the stress distribution is

as shown in Fig 5.b. Eventually, the whole of the cross section reaches the yield stress and the

corresponding stress distribution is as shown in Fig. 5.c. The moment corresponding to this state is

known as the plastic moment of the cross section and is denoted by Mp. In order to find out the fully

plastic moment of a yielded section of a beam, we employ the force equilibrium equation, namely the

total force in compression and the total force in tension over that section are equal.

w

wu

plastic hinges

wl 2/12

Mp

wl 2/24

wl 2/12

collapse mechanism

Mp

Mp

Mp /2

Fig. 4 Formation of a collapse mechanism in a fully fixed beam

Mp

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

a) Elastic limit

Hyperstatic structures

Cezar Aanici, Dr. Eng.

b) Elastic-plastic

c) Quasi-fully plasticized

cross-section

Fig. 5

Finally, as the applied load is increased still further, a plastic hinge forms in the center of the

beam, and the distribution of bending moment is as shown. The beam has now been converted to the

unstable collapse mechanism shown above, and collapse is imminent under the ultimate load wu. The

ratio of the collapse load to the working load is:

w

= u

w

where is the collapse the load factor. Since the structure is statically determinate at the point of

collapse, the collapse load is readily determined as:

16 M p

wu =

l

and this value is unaffected by settlement of the supports or elastically restrained end connections.

M

Mp

formation of plastic hinge

Fig. 6 Elastic-plastic response

of beams with different cross-sections

1/R

Fig. 7 Mathematical model

elastic-perfectly plastic

Fig. 8 - Ideal plastic hinge formation - M ip M p + M ip

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

Theoretically, the plastic hinges are assumed to form at points at which plastic rotations occur.

Thus the length of a plastic hinge is considered as zero. However, the values of moment, at the

adjacent section of the yield zone are more than the yield moment up to a certain length L, of the

structural member. This length L, is known as the hinged length. The hinged length depends upon

the type of loading and the geometry of the cross-section of the structural member. The region of

hinged length is known as region of yield or plasticity.

3. Plastic moment of resistance

After the formation of a plastic

hinge in the section shown above, the

rectangular stress distribution shown at is

produced.

Equating

horizontal

compressive and tensile forces:

Pc = Pt

f y' Ac = f y At

where fy and fy are the yield stresses in

tension and compression (which may be

assumed to be equal) and At and Ac are

the cross-sectional areas in tension and

compression. Thus, the plastic moment of

resistance is:

M p = Wp f y

where Mp is the plastic bending moment, Wpl is the plastic section modulus, and fy the yield limit;

For the cross sections subjected to pure axial efforts:

Np = A fy

where Np is the plastic axial force, and A the cross section area.

5. Shape factor

The shape factor is defined by the following relationship:

s =

Wp

Wel

where Wel is the elastic section modulus. The shape factor value strongly depends by the crosssection shape:

- for hot rolled elements:

(y)

(z)

I cross section:

s = 1.85, s = 1.15 1.17;

(z)

(y)

U (or C) cross section:

s = 2.10 , s = 1.20;

- rectangular hollow cross section: s = 1.27 ;

- full rectangular cross section:

s = 1.50 ;

- circular cross section:

s = 1.70 ;

- rhombic cross section:

s = 2.00 ;

- triangular cross section:

s = 2.37.

Thus, for a rectangular section the plastic moment Mp is about 1.5 times greater than the

elastic moment capacity.

4

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

If the section is thin walled, due to local buckling, it may not be able to sustain the moment for

additional rotations and may collapse either before or soon after attaining the plastic moment. It may

be noted that formation of a single plastic hinge gives a collapse mechanism for a simply supported

beam. The ratio of the ultimate rotation to the yield rotation is called the rotation capacity of the

section. The yield and the plastic moments together with the rotation capacity of the cross section are

used to classify the sections.

6. Application

Let find the shape factor of the cross section shown in Figure 9:

8

12

12

zG = 10 .43

AN

[ cm]

G 1+

[ cm]

z1 = 6.02

16

16

AN

z2 = 9.37

zp = 9

11.57

G2

22 - yp = 13

Fully plasticized cross-section

Elastic behaviour

Fig. 9

Solve for the centroid position and for the elastic section modulus:

zG =

18 4 2+16 4 12+24 2 21

= 10.43 cm

18 4+16 4+24 2

18 43

4 163

24 23

+ 18 4 8.432 +

+ 4 16 1.57 2 +

+ 24 2 10.57 2

12

12

12

Wel =

= 1047.07 cm3

11.57

Now, considering that the cross section is fully plasticized, in order to find the plastic

section modulus the new position of the neutral axis must be founded:

A( ) = A( + )

(8+4+12) 2+(22-z p -2) 4=(8+4+6) 4+(z p -4) 4

48+80-4 z p =72+4 z p -16 z p = 9 cm

z :=

1

( 8 + 4 + 6) 4 7 + ( 9 4) 4 2.5

18 4 + 5 4

= 6.02

z :=

2

( 8 + 4 + 12) 2 12 + ( 13 2) 4 6.5

24 2 + 11 4

Wpl := ( 18 4 + 5 4) 6.02 + ( 24 2 + 11 4) 9.37 = 1415.88

cm3

= 9.37

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

The shape factor is:

s =

W pl

Wel

1451.88

= 1.352

1047.07

7. Principles of plastic analysis

Fundamental conditions for plastic analysis

- Mechanism condition: The ultimate or collapse load is reached when a mechanism is

formed. The number of plastic hinges developed should be just sufficient to form a mechanism.

- Equilibrium condition: Fx = 0, Fy = 0, Mxy = 0

- Plastic moment condition: The bending moment at any section of the structure should not

be more than the fully plastic moment of the section.

Collapse mechanisms

When a system of loads is applied to an elastic body, it will deform and will show a resistance

against deformation. Such a body is known as a structure. On the other hand if no resistance is set up

against deformation in the body, then it is known as a mechanism. Various types of independent

mechanisms are identified to enable prediction of possible failure modes of a structure.

a) Beam mechanism

Fig. 4 (right) shows a fully fixed beam and the corresponding mechanism.

b) Panel or Sway mechanism

The Figure 10.a shows a panel or sway mechanism for a portal frame fixed at both ends.

a) Panel (sway) mechanism

b) Gable mechanism

c) Joint mechanism

Fig. 10

c) Gable mechanism

Fig. 10.b shows the gable mechanism for a gable structure fixed at both the supports.

d) Joint mechanism

Fig. 10.c shows a joint mechanism. It occurs at a joint where more than two structural

members meet.

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

Combined mechanism

Various combinations of independent mechanisms can be made depending upon whether the

frame is made of strong beam and weak column combination or strong column and weak beam

combination. The one shown in Fig. 11 is a combination of a beam and sway mechanism. Failure is

triggered by formation of hinges at the bases of the columns and the weak beam developing two

hinges. This is illustrated by the right hinge being shown on the beam, in a position slightly away

from the joint. From the above examples, it is seen that the number of hinges needed to form a

mechanism equals the static redundancy of the structure plus one.

Fig. 11

8. Plastic load factor and theorems of plastic collapse

The plastic load factor at rigid plastic collapse (p) is defined as the lowest multiple of the

design loads which will cause the whole structure, or any part of it to become a mechanism. In a limit

state approach, the designer is seeking to ensure that at the appropriate factored loads the structure

will not fail. Thus the rigid plastic load factor p must not be less than unity. The number of

independent mechanisms (N) is related to the number of possible plastic hinge locations (X) and the

number of degree of redundancy or the static indeterminacy (ns) of the frame by the equation.

N = X - ns

The three theorems of plastic collapse are given below.

(I) Lower bound or Static theorem

A load factor (s) computed on the basis of an arbitrarily assumed bending moment diagram

which is in equilibrium with the applied loads and where the fully plastic moment of resistance is

nowhere exceeded will always be less than or at best equal to the load factor at rigid plastic

collapse, (p). In other words, p is the highest value of s which can be found.

(II) Upper bound or Kinematic theorem

A load factor (k) computed on the basis of an arbitrarily assumed mechanism will always be

greater than, or at best equal to the load factor at rigid plastic collapse (p). In other words, p is the

lowest value of k which can be found.

(III) Uniqueness theorem

If both the above criteria are satisfied, then the resulting load factor corresponds to its

value at rigid plastic collapse (p).

7

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

9. Mechanism method

In the mechanism or kinematics method of plastic analysis, various plastic failure mechanisms

are evaluated. The plastic collapse loads corresponding to various failure mechanisms are obtained by

equating the internal work at the plastic hinges to the external work by loads during the virtual

displacement. This requires evaluation of displacements and plastic hinge rotations. As the plastic

deformations at collapse are considerably larger than elastic ones, it is assumed that the frame remains

rigid between supports and hinge positions i.e. all plastic rotation occurs at the plastic hinges.

Considering a simply supported beam subjected to a point load at midspan or a uniform

distributed working (Fig. 4), the maximum strain will take place at the centre of the span where a

plastic hinge will be formed at yield of full section. The remainder of the beam will remain straight,

thus the entire energy will be absorbed by the rotation of the plastic hinge.

10. Stability

For plastically designed frames three stability criteria have to be considered for ensuring the

safety of the frame. These are:

1. general frame stability,

2. local buckling criterion,

3. restraints.

Effect of axial load and shear

If a member is subjected to the combined action of bending moment and axial force, the plastic

moment capacity will be reduced. The presence of an axial load implies that the sum of the tension

and compression forces in the section is not zero. This means that the neutral axis moves away from

the equal area axis providing an additional area in tension or compression depending on the type of

axial load. The interaction equation is:

Mx

N2

= 1

Mp

Ny

The presence of shear forces will also reduce the moment capacity.

fy

fy

h/2

fy

=

h

z1

fy

fy

Total stresses

Fig. 12

Bending

Axial compression

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

Plastic analysis for more than one condition of loading

When more than one condition of loading can be applied to a beam or structure, it may not

always be obvious which is critical. It is necessary then to perform separate calculations, one for each

loading condition, the section being determined by the solution requiring the largest plastic moment.

Unlike the elastic method of design in which moments produced by different loading systems can be

added together, plastic moments obtained by different loading systems cannot be combined, i.e. the

plastic moment calculated for a given set of loads is only valid for that loading condition. This is

because the principle of superposition becomes invalid when parts of the structure have yielded.

11. Application

Let find the collapse mechanism of the following frame system using the combined

mechanism method.

The number of elementary mechanism is:

N= X n = 10 6 = 4

two beam mechanisms (fig. 13.a, b), one sway mechanism (fig. 13.c) and one joint mechanism

(fig. 13.d).

4 5

6

2Mp

Mp

Mp

10

8m

4m

2

4Mp

Mp

4m

Mp

4Mp

2Mp

4Mp

2Mp 2Mp

a)

8m

4Mp

b)

Fig. 13

Mp

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

Mp

Mp

Mp

Mp

Mp

Mp

c)

2Mp

d)

2Mp

Mp

2Mp

Mp

Mp

Mp

Mp

e)

Fig. 13 (cont.)

For the elementary mechanisms the following relationships could be written:

- for the beam mechanism shown in Figure 13.a:

2 4 = M p + 2 M p + 2 M p + 2 M p (a) =

7

M p = 0.875M p

8

- for the beam mechanism shown in Figure 13.b:

13

M p = 0.406M p

32

- for the floor (or displacement) mechanism shown in Figure 13.c:

6

4 = 6 M p (c) = M p = 1.5M p

4

The combined mechanisms are obtained as follows:

- Combining the elementary mechanisms (a) and (b), another possible mechanism results

(Fig. 12.e); the joint mechanism (d) is not useful, because rotating the joint high values for the

internal work are obtained (8Mp - Fig. 12.g clockwise rotation) and, 6Mp, respectively, (Fig.

12.h counterclockwise rotation), higher than the value of the internal work when the joint is

not rotated (Fig. 12.f).

4 8 = 3 4M p + M p (b) =

2Mp

2Mp

Mp

f) La = 3Mp

2Mp

4Mp

4Mp

Mp

Mp

g) La = 8Mp > 3Mp

Fig. 13 (cont.)

10

h) La = 6Mp > 3Mp

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

For the mechanism shown in Fig. 12.e, the equilibrium relationship could be written

in two forms:

inchise

a) L(Fa ) + L(Fc ) = L(aa ) + L(ac ) Larticulatii

a

4 + 2 4 = 7 M p + 6M p 2M p (e) =

11

M p = 0.917 M p

12

b) or directly on the combined mechanism:

4 + 2 4 = 5 M p + 3 2M p (e) =

11

M p = 0.917 M p

12

- Let now combine the mechanisms (12.a), (12.b) (12.i), and (12.d) clockwise joint

rotation (Fig. 12.l, comparing with Fig. 12.k fixed joint, and Fig. 12.m counterclockwise joint

rotation). Thus, on the mechanism shown in Fig. 12.j, the following equilibrium equations could

be written:

4Mp

Mp

Mp

Mp

Mp

4Mp

Mp

4Mp

Mp

Mp

i)

2Mp

Mp

Mp

Mp

4Mp

Mp

4Mp

Mp

Mp

j)

4Mp

2Mp

4Mp 4Mp

4Mp

Mp

k) La = 5Mp

Mp

l) La = 7Mp > 5Mp

Fig. 13 (cont.)

11

2Mp

Mp

Mp

m) La = 12Mp > 5Mp

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

inchise

deschise

a) L(Fb ) + L(Fc ) = L(ab ) + L(ac ) Larticulatii

+ Larticulatii

a

a

4 + 4 8 = 13 M p + 6M p ( M p + 4M p ) + 2M p (j) =

16

M p = 0.444M p

36

b) or directly on the combined mechanism:

4 + 4 8 = 6 M p + 2M p + 2 4M p (j) =

16

M p = 0.444M p

36

Consequently, the collapse load factor is:

u = min im = (b) = 0.406 M p

corresponding to a partial collapse mechanism (beam mechanism) in a second bay of the frame.

12. Biographical method

In what follows, a computer program is presented for evaluating the collapse mechanism of

plane frames applying the biographical method, or, in other words, finding the order of the plastic

hinge formation. The frames must be loaded only with concentrated forces applied strictly in the

joints of the frames, and not on the beams. It means that a beam which is loaded with a concentrated

force somewhere along its span must be divided into separate beams having joint connections where

the forces are located. If a uniform distributed load is applied on to a member, it must be replaced by

its resultant load.

First, an elastic analysis will be done for

the given external loads Poi. The load factor of a

(1)

(2)

cross section is defined by the ratio between the

2

1

3

plastic moment and the corresponding elastic

one produced by the load combination Poi. This

load factor is calculated for all possible critical

(1)

(2)

cross-sections, thus for all beam ends. (The

NO

bending moment diagrams have linear variations

1

2

3

on all the beams because the frame is loaded

only with concentrated forces applied in the

joints.) The smallest load factor will identify the

(1)

(2)

YES first plastic hinge the first cross-section which

will be fully plasticized.

2

3

1

Then, different parameters will be

computed (displacements, reactive forces etc.) corresponding to this first plastic hinge formation,

multiplying the load factor with all the values already founded from the load combination Poi.

In that cross-section a hinge is now introduced, and the stiffness matrix of the structure is reassembled. This plastic hinge is considered loaded with its corresponding plastic bending moment,

and the modified structure will be used for the next step, to find the second plastic hinge, applying the

same linear structural analysis.

When increasing the magnitudes of the external loads applied on the structure, the variation of

the plastic bending moment is null, but a free cross-section rotation being allowed). All the other

beams of the frame have an elastic structural behaviour.

12

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

INPUT DATA

- joints coordinates

- beam mechanical properties

- boundary conditions

Assembling

the stiffness matrix

LOADS INPUT

HINGE=HINGE + 1

Inverting the N-th stiffness

matrix of the auxiliary

structure

IMPOSSIBLE

POSSIBLE

RESULTS

IN THE N-th AUXILIARY STRUCTURE

- joint displacements

- beam internal efforts

- hinges rotations

THE PLASTIC HINGE IS

CLOSING?

NO

THE NEXT PLASTIC HINGE IS FORMED

- finding the new plastic hinge

- internal efforts in the auxiliary structure

- load factor

- joint displacements

- beam internal efforts

- plastic hinge rotations

Modifying the stiffness matrix of the N-th

auxiliary structure and updating and reassembling

it for the (N+1)-th structure

13

YES

STRUCTURAL

COLLAPSE!

Gh. Asachi Technical University of Iai

Department of Structural Mechanics

Hyperstatic structures

Cezar Aanici, Dr. Eng.

The load factors between the plastic hinges formations are obtained by multiplying the load

factor already founded in the earlier step in the attached (auxiliary) structure, subjected to the load

combination Poi , with the next load factor. This step-by-step technique will continue till the plastic

hinges will form a collapse mechanism, meaning that on the main diagonal of the assembled structural

stiffness matrix a null or negative coefficient will be identified (a singular matrix could not be

inverted).

Closing the plastic hinges

During a proportional load combination, a plastic hinge could be unloaded. The plastic

bending moment of the corresponding cross section could decrease, having a linear elastic behaviour,

but with a remanent (residual) plastic rotation. Such situations are quite frequently possible because

the new plastic hinges developed into the structure modify the internal efforts distribution decreasing

their magnitudes, or having opposite senses

M

in the auxiliary (attached) structure, but only

if the structure has a linear elastic behaviour

between two consecutive steps. When this M

p

case is happening in the auxiliary structure

(the k plastic hinge formation) the hinge

closing

plastic hinge

rotation is in the opposite sense of the (full)

the plastic hinge

formation

hinge rotation. Thus, the auxiliary structure

must be modified (being unacceptable) by

replacing it with another structure with a

removed plastic hinge in the corresponding

cross section, and the stiffness matrix of the

structure will be updated and reassembled.

o

1/R

Fig. 13 Closing the plastic hinge

14

Potrebbero piacerti anche

- 12 Physics Lyp 2016 Central Outside Delhi Set3Documento7 pagine12 Physics Lyp 2016 Central Outside Delhi Set3Ashok PradhanNessuna valutazione finora

- 33 ch6Documento13 pagine33 ch6swccgopalNessuna valutazione finora

- Oscillations PDFDocumento12 pagineOscillations PDFRaviKumarNessuna valutazione finora

- Examples On Mathematical Induction: Trigonometry: Sin Sin 1 SinDocumento11 pagineExamples On Mathematical Induction: Trigonometry: Sin Sin 1 SinAshok PradhanNessuna valutazione finora

- M¡ (VH$ (DKMZ (G¡Õmpývh$) : ZmoqDocumento37 pagineM¡ (VH$ (DKMZ (G¡Õmpývh$) : ZmoqAshok PradhanNessuna valutazione finora

- Form 4 Add Maths Chapter 1Documento25 pagineForm 4 Add Maths Chapter 1Azhar GameMaster100% (1)

- (Zym© (Av G Kêq O A (Yh$V A H$Documento30 pagine(Zym© (Av G Kêq O A (Yh$V A H$Ashok PradhanNessuna valutazione finora

- Cold Working and AnnealingDocumento10 pagineCold Working and AnnealingAshok PradhanNessuna valutazione finora

- Reproduction in OrganismsDocumento10 pagineReproduction in OrganismsAshok PradhanNessuna valutazione finora

- Curret 2Documento2 pagineCurret 2Ashok PradhanNessuna valutazione finora

- Strength of Materials: Er. S K MondalDocumento3 pagineStrength of Materials: Er. S K MondalAshok PradhanNessuna valutazione finora

- Solution, Success Study CircleDocumento4 pagineSolution, Success Study CircleAshok PradhanNessuna valutazione finora

- COLUMMNDocumento2 pagineCOLUMMNAshok PradhanNessuna valutazione finora

- Comparison Between Edge and Screw DislocationDocumento5 pagineComparison Between Edge and Screw DislocationAshok PradhanNessuna valutazione finora

- State Biot Servat Law and Hence Obtain An Expression For The Magnetic Induction Produced by Infinite Long Current Carrying Conductor at Any Point Near ItDocumento5 pagineState Biot Servat Law and Hence Obtain An Expression For The Magnetic Induction Produced by Infinite Long Current Carrying Conductor at Any Point Near ItAshok PradhanNessuna valutazione finora

- Cold Working and AnnealingDocumento10 pagineCold Working and AnnealingAshok PradhanNessuna valutazione finora

- Cold Working and AnnealingDocumento10 pagineCold Working and AnnealingAshok PradhanNessuna valutazione finora

- Manufacturing Process 1 Question BankDocumento6 pagineManufacturing Process 1 Question BankAshok PradhanNessuna valutazione finora

- Cold Working and AnnealingDocumento10 pagineCold Working and AnnealingAshok PradhanNessuna valutazione finora

- Moving Coil GalvanometerDocumento5 pagineMoving Coil GalvanometerAshok PradhanNessuna valutazione finora

- Weekly Test July MMMMMMMMDocumento2 pagineWeekly Test July MMMMMMMMAshok PradhanNessuna valutazione finora

- Comparison Between Edge and Screw DislocationDocumento5 pagineComparison Between Edge and Screw DislocationAshok PradhanNessuna valutazione finora

- Surprize TestDocumento3 pagineSurprize TestAshok PradhanNessuna valutazione finora

- Cold Working and AnnealingDocumento10 pagineCold Working and AnnealingAshok PradhanNessuna valutazione finora

- Current ElectricityDocumento2 pagineCurrent ElectricityAshok PradhanNessuna valutazione finora

- L No 01Documento38 pagineL No 01Annas Equity AnalystNessuna valutazione finora

- Cold Working and AnnealingDocumento10 pagineCold Working and AnnealingAshok PradhanNessuna valutazione finora

- Ess at 12 CN StuDocumento11 pagineEss at 12 CN Stujsmith012xNessuna valutazione finora

- Chapter7cor1 2Documento19 pagineChapter7cor1 2senthilkumar100Nessuna valutazione finora

- OpticsDocumento6 pagineOpticsAshok PradhanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Congratulations! Your Booking Is Now ConfirmedDocumento6 pagineCongratulations! Your Booking Is Now ConfirmedTufail AibaniNessuna valutazione finora

- 2Fw@Iktvo9Ua Xy1I94B: Ruang Final: Tukul3276 Ruang LN: Destroyer174Documento1 pagina2Fw@Iktvo9Ua Xy1I94B: Ruang Final: Tukul3276 Ruang LN: Destroyer174Mackmoer M ZakariaNessuna valutazione finora

- Testing of Transmitter & SwitchesDocumento4 pagineTesting of Transmitter & SwitchesJoost1982Nessuna valutazione finora

- Neration of Various SignalsDocumento5 pagineNeration of Various SignalsPREMKUMAR JOHNNessuna valutazione finora

- ANT AMB4520R8v06 3229+datasheetDocumento2 pagineANT AMB4520R8v06 3229+datasheetДобрыня ЭдяNessuna valutazione finora

- Wordpress For Beginners Tutorial EbookDocumento53 pagineWordpress For Beginners Tutorial EbookNicoJulius100% (1)

- Power Budget - Problem Set 2Documento21 paginePower Budget - Problem Set 2Ponmalar SivarajNessuna valutazione finora

- Huawei E3272S-153 Quick Strat Guide (01, En)Documento3 pagineHuawei E3272S-153 Quick Strat Guide (01, En)Nick MullerNessuna valutazione finora

- Programming MCQ: Practice and DiscussionDocumento39 pagineProgramming MCQ: Practice and Discussionshenbagaraman cseNessuna valutazione finora

- Effects of Customer Relationship Management On Market Performance: A Comparative PerspectiveDocumento94 pagineEffects of Customer Relationship Management On Market Performance: A Comparative PerspectiveMelesse MisganawNessuna valutazione finora

- Part 3-FLUENCY FOR IELTS SPEAKINGDocumento14 paginePart 3-FLUENCY FOR IELTS SPEAKINGMỹ Tiên100% (1)

- Tools - For - IMRT - QA-N DoganDocumento86 pagineTools - For - IMRT - QA-N DoganhitsNessuna valutazione finora

- Revised Research ProposalDocumento8 pagineRevised Research ProposaldinehmetkariNessuna valutazione finora

- High Accuracy Forecasting For Configurable Products and Products With VariantsDocumento6 pagineHigh Accuracy Forecasting For Configurable Products and Products With VariantsEmcienNessuna valutazione finora

- Lectra Fashion Brochure - pdf898Documento8 pagineLectra Fashion Brochure - pdf898Kanti ModhwadiaNessuna valutazione finora

- LG LCD CH La73a 47lc7df UbDocumento62 pagineLG LCD CH La73a 47lc7df UbvideosonNessuna valutazione finora

- Guide To Size Hybrid SystemsDocumento7 pagineGuide To Size Hybrid SystemsAmr JmNessuna valutazione finora

- SAP Implementation Project ExampleDocumento2 pagineSAP Implementation Project ExampleChetan BhootraNessuna valutazione finora

- CISA Domain 2 QuestionsDocumento14 pagineCISA Domain 2 QuestionseliNessuna valutazione finora

- GS - No.GBN052E 7: OVAL Coriolis Mass Flowmeter MODEL CN010, CN015 High Pres. TypeDocumento10 pagineGS - No.GBN052E 7: OVAL Coriolis Mass Flowmeter MODEL CN010, CN015 High Pres. TypeTitus Deus PrizfelixNessuna valutazione finora

- National Institute of Technology Rourkela: Answer All Questions. Figures in The Right Hand Margin Indicate MarksDocumento3 pagineNational Institute of Technology Rourkela: Answer All Questions. Figures in The Right Hand Margin Indicate MarksAyusna SubudhiNessuna valutazione finora

- Automated Billing SystemDocumento24 pagineAutomated Billing SystemjamesNessuna valutazione finora

- Syllabus Part Ii - Course Content HINT 730 Information Management in Healthcare Course DescriptionDocumento14 pagineSyllabus Part Ii - Course Content HINT 730 Information Management in Healthcare Course DescriptionSarybell Del ValleNessuna valutazione finora

- Business Growth and Strategy Project FinalDocumento59 pagineBusiness Growth and Strategy Project FinalSonali AgrawalNessuna valutazione finora

- Chris Welman MSCDocumento84 pagineChris Welman MSCPablo Angel ToiaNessuna valutazione finora

- Cr800 ManualDocumento480 pagineCr800 ManualFrancis FordNessuna valutazione finora

- Electrical Part ListDocumento6 pagineElectrical Part ListdachajiNessuna valutazione finora

- Iq Bot v6.0 en PDFDocumento146 pagineIq Bot v6.0 en PDFfjgutierrezpaNessuna valutazione finora

- BigMart Sale Prediction Using Machine LearningDocumento2 pagineBigMart Sale Prediction Using Machine LearningInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Comparison With VirdiDocumento27 pagineComparison With VirdiMinesh SoniNessuna valutazione finora