Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ferrocement Boat

Caricato da

Nihil In-lineCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ferrocement Boat

Caricato da

Nihil In-lineCopyright:

Formati disponibili

Submitted to Sustainable Economic and Educational Development Society, SEEDS

Ferrocement Boats for Disaster Mitigation In Coastal

Orissa

By Dhanada Mishra, Ph. D. (Michigan)

Department of Civil Engineering, KIIT (Deemed University)

Bhubaneswar, Orissa 751003

dkmishra@kiit.org

Summary

This document presents the basic information on ferro-cement boats and makes an

argument for promotion of this innovative low cost material and appropriate boat

technology for mitigation of recurring disasters in form of floods in coastal Orissa.

Ferro-cement is a composite where chicken wire mesh is used as the reinforcement

in a dense cement mortar matrix. Its properties make for a good timber-substitute

material. It has been used for almost a century in various applications ranging from

boats, building components such as sheets. roof, panels, fence etc. Orissa being a

perennially flood-prone state of India is subject to this disaster on almost a yearly

basis. Due to the slow death of boating in the community because of unavailability

and high cost of good quality boat building timber, the population has to often

depend on external agencies such as the navy for immediate rescue of marooned

people in the aftermath of the floods. This was identified as a critical problem in a

survey conducted by Aagamee Orissa a forum of professionals, activists and

volunteer groups1. While timber boats are expensive to build, ferro-cement boats are

cheaper, relatively uncomplicated technology and versatile with proven track record.

This proposal provides the basics of ferro-cement as a material and the construction

techniques used for ferro-cement. It seeks funding for the construction of several

prototype country style boats of different sizes for trials. It is expected that these

boats would be of use in the upcoming monsoon season.

Peoples Voice on Orissa Floods 2003, A survey by Aagamee Orissa (to be published).

Dhanada Mishra

Page 1

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

Introduction2

The increasing cost and scarcity of durable boat building timbers have affected the

construction of fishing crafts around the world. The developed world has by and large

witnessed the transfer from traditional wooden boat building methods to either less

conventional wood construction techniques (e.g., plywood or wood laminates) or non-wood

materials such as fibre reinforced plastic (FRP), steel, aluminum and ferro cement.

Brief history of Ferro-Cement3

Ferro Cement is the name given by English speaking people to a boat building method

using steel wires covered with a sand cement plaster, patented in 1855 by the French, who

called it Ferciment. Ferciment boats built by the French before 1855 are still in existence

and one at least is still afloat, effectively supplying the answer to "what happens to the steel

and plaster, when the boat is placed in water."

Ferciment boats built by the Italians in the 1940s are still in use and going strong, but they

called the method of construction Ferro-Cemento and the New Zealanders who pioneered

the amateur construction of Ferro-Cemento boats called it Ferro-Cement.

These techniques generally favour less labour intensive methods of construction. In the

developing world where timber is still the predominant boat building material, the scarcity

and high cost of good quality timber have not meant that less wooden boats are being built,

but rather that building quality has deteriorated through the use of poor quality timber. At the

same time, however, attempts have been made to diversify construction methods with

varying degrees of success. The following aspects are critical to the success of any

commercial boat building operation.

1.

2.

3.

4.

5.

Materials

Labour

Site

Design

Cost

Richard O.N. Riley and Jeremy M. M. Turner, Fishing Boat Construction: 3. Building a Ferrocement Fishing

Boat, Fao Fisheries Technical Paper, Rome 1995.

3

From the preface in Hartleys Ferro-Cement Boat building book.

2

Dhanada Mishra

Page 2

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

6. Marketing and Sales

7. After Sales Service

In recent years the destruction of forests has now excluded various species of good quality

boat building timber from general use, reducing availability and spiraling costs upwards.

Plywood offers the chance to achieve strength with lightness and is easily maintained and

repaired. However, its flat sheets impose design limitations in small craft and marine grades

are not widely available.

GRP (glass reinforced plastic) or FRP (fibre reinforced plastic) construction, whilst having a

wide market in developed countries particularly for leisure craft, has been held back in some

underdeveloped countries for various reasons including high setting up costs, requiring

factory air conditioning, dust, humidity, and quality control.

Despite good weight and strength qualities, aluminum alloy requires greater technical

knowledge in its construction to prevent exposure to dissimilar metals and great care whilst

welding or bending, as well as taking account of alloy fatigue so as not to affect the

materials strength.

Steel presents the builder with an easier material to work with: there is plenty of information

to consult; the materials are usually readily available worldwide; setting up costs can be

fairly nominal; and good construction provides robust boats. However, in all phases of

construction, steel needs to be nurtured against corrosion attack from initial storage to final

painting stage, particularly in underdeveloped countries where maintenance, if carried out at

all, is very often poorly done, resulting in a reduced life span.

Ferro-cement is a flexible and durable form of construction. It is easy to repair and

possesses many features that help produce a well founded fishing boat. It is particularly

suitable for moderate to heavy displacement designs with well-rounded sections. However,

good supervision in all aspects of construction is desirable, whilst in general the labour can

be semi-skilled. Because ferro-cement materials are analogous to the building construction

industry, material availability worldwide is generally very good and cheap. Despite some

poor construction in various places over the past twenty five years, which has hindered the

Dhanada Mishra

Page 3

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

acceptance of the material somewhat, there are enough fishing boats constructed in ferrocement around the world to give substantial claim for ferro-cement to be positively accepted

in fishing boat building.

What is ferrocement?

Ferrocement is a technical term, not to be confused with ordinary reinforced concrete. It

might be defined as a composite material consisting of a matrix made from hydraulic

cement mortar and a number of layers of continuous steel mesh reinforcement distributed

throughout the matrix. The basic parameters, which characterise ferro-cement are the

specific surface area of reinforcement, the volume fraction of the reinforcement, the surface

cover of the mortar over the reinforcement and the relatively high quality of the mortar.

Figure 1. Schematic diagram of typical ferro-cement sheet.

Ferro-cement behaves like reinforced concrete in its load bearing characteristics, with the

essential difference being that crack development is retarded by the dispersion of the

reinforcement in fine form through the mortar. This makes the material of interest in boat

construction and it has been established that when cracking takes place it results in a wide

distribution of fine cracks, which, in combination with the high alkalinity of the cement rich

mortar, inhibits corrosion in the reinforcing steel.

Dhanada Mishra

Page 4

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

The main advantages of ferro-cement are low cost, the low level of skills required for hull

construction, and reduced maintenance with increased resistance to rot and corrosion when

compared to wood and steel. Claims of low cost can only be substantiated where the

second advantage of low level of skills required can be exploited, for example, in developing

countries with a large unskilled, under-employed and low paid labour force. In industrial

nations, where there is little difference between the cost of skilled and unskilled labour,

these advantages are less apparent or even disappear, explaining the relatively slow growth

in the use of ferro-cement.

The main disadvantages of ferro-cement are its weight and poor impact resistance.

However, these disadvantages only restrict the application, of the material, but need not

detract from its potential. In the case of heavy displacement workboats over 11 m LOA, the

increased weight is of reduced importance; for such craft over 15 ms, the weight will be no

more than that of a similar size steel vessel. Poor impact resistance can be largely

overcome at the design stage by provision of appropriate hull protection members.

It may well therefore be asked why ferro-cement has not been used more widely? This is

due mainly to three factors: bad publicity due to poor amateur and professional

construction; publication in the early years of outlandish claims for strength and low cost of

construction, which in some cases could not be substantiated; the heavy rise in labour costs

in industrialized countries which affected what is generally speaking a labour oriented

material. Although today with the range of building techniques for ferro-cement expanding,

the labour cost factor need not play such an important part.

Technically, ferro-cement has been a well-researched material with American Concrete

Institute having published guidelines and standards on it. There are a number of textbooks

that have been written on it. In spite of that, ferro-cement remains more of an art rather than

a technology.

Orissa Scenario

Orissa is a coastal state of India known for its abundant natural resources but extremely

poor populations. While the numerous waterways of Orissa provide it with a great wealth, it

also causes great hardship to the people because of frequent occurrence of floods. In year

2003, vast areas of the state remained inundated due to flooding of several major rivers,

Dhanada Mishra

Page 5

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

with floodwaters not receding for several weeks together. One of the important learning

from visiting flooded areas and what was subsequently captured in a survey was the fast

disappearing boats from the community. It is well known that ever-increasing price and lack

of availability of good quality timber has affected boat building to a great extent. Traditional

country boats made from timber are not considered to be a viable source of livelihood for a

whole host of reasons. The consequence is that large numbers of people depend on

external intervention for relief and rescue.

Figure 2. J. J. Lambot small reinforced concrete boat (1848).

The Proposal

It is proposed that a number of prototype country boats (3-5 model boats about 4 feet long

and 3-4 prototypes about 12 feet) be built in the workshop of Kalinga Institute of Industrial

Technology (KIIT) to demonstrate the ferro-cement technology and ferro-cement boats as

viable replacements of traditional country boats built from timber. Traditionally it is believed

that ferro-cement boats are cost effective only beyond 15 m in length. How ever, it is

expected that with low labour costs in Orissa, ferro-cement boats would be viable even in

smaller sizes.

The program

The following program is proposed:

Build prototype timber country boat (12 feet) using traditional artisans.

Build model ferro-cement boats (4 feet) to test the technique and get a feel for

construction.

Build 12 feet prototype country boat using the timber boat as a model or as a mould.

Dhanada Mishra

Page 6

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

Trial the prototype ferro-cement boat.

Quantify weight, buoyancy, Carrying capacity, speed, ease of handling.

Estimate durability and robustness against impact damage and ease of repair.

Publication of a short how-to guide in Oriya on Ferro-cement boat construction.

At the completion of the above program, a decision can be taken with regard to the technical

and financial viability of setting up a ferro-cement boat manufacturing facility. Further work

can also be done on building of larger fishing boats and recreational boats.

Budget

The following expenditure is envisaged

1. Timber boat (12 feet)

Rs. 5,000/-

2. Ferro-cement model boats (4 feet)

5 x 1000 =

Rs. 5,000/-

3. Ferro-cement prototype boat (12 feet)

4 x 4,000 =

Rs. 16,000/-

4. Testing and field trials

Rs. 10,000/-

5. On-board motor and fittings

Rs. 5,000/-

6. Literature, admin and misc

Rs. 5,000/-

TOTAL PROJECT COST ESTIMATE

Rs. 46,000/-

Progress

The following progress has been made so far

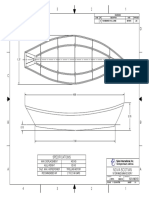

Timber 12 feet country boat prototype complete Dec 2003. See Figure 3 for a

photograph.

Ferro-cement 4 feet model boat (bamboo and chicken wire mesh reinforcement)

complete Jan 2004. See Figure 4 for a photograph.

2nd 4 feet ferro-cement model boat (gunny bag reinforcement complete Mar 2004).

See Figures 5 and 6 for a picture of the clay mold.

Dhanada Mishra

Page 7

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

Skeleton of 12 feet prototype ferro-cement boat with steel rebar and chicken wire

mesh reinforcement is under construction present (see Figure 7).

Concluding Remarks

The ferro-cement boat has an exciting prospect in the context of disaster mitigation in Orissa.

While the small country style boats will be ideal low cost approach to the intermittent needs

of rescue and relief work during floods, larger more sophisticated boats can subsequently

open up commercial opportunities in both boat manufacture as well as potential use in

fishing, transport and recreational use.

Figure 3. County boat built from low cost chakunda timber by traditional village artisan at

KIIT workshop.

Dhanada Mishra

Page 8

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

Figure 4. Model ferro-cement boat being constructed using the direct plaster method.

Figure 5. Clay male mold for casting of ferro-cement boat.

Figure 6. Model ferro-cement boat being finished.

Dhanada Mishra

Page 9

4/22/2004

Submitted to Sustainable Economic and Educational Development Society, SEEDS

Figure 7. Skeleton of the first prototype ferro-cement boat under construction in KIIT

workshop.

Dhanada Mishra

Page 10

4/22/2004

Potrebbero piacerti anche

- Ferro Cement 2Documento22 pagineFerro Cement 2Abhishek DorugadeNessuna valutazione finora

- FerrocementDocumento25 pagineFerrocementNandhini NallasamyNessuna valutazione finora

- Sustainable Boat MakingDocumento13 pagineSustainable Boat MakingNimna ZakariaNessuna valutazione finora

- Fishing Boat ProjectDocumento7 pagineFishing Boat ProjectStephen DuamorNessuna valutazione finora

- Business Plan of HouseboatDocumento5 pagineBusiness Plan of HouseboatMasum BillahNessuna valutazione finora

- How to Make Fiberglass Molds in Simple StepsDocumento7 pagineHow to Make Fiberglass Molds in Simple StepsDanial Iskandar MusliNessuna valutazione finora

- EPS Data SheetDocumento2 pagineEPS Data SheetajoilhamNessuna valutazione finora

- Finish Product Picture: 1 HP Paddle Wheel Aerator - STD - B12 Specification SheetDocumento5 pagineFinish Product Picture: 1 HP Paddle Wheel Aerator - STD - B12 Specification SheetRobert R. TiinNessuna valutazione finora

- U.S. Navy Ferro - Cement Boat Building Manual Volume 2Documento84 pagineU.S. Navy Ferro - Cement Boat Building Manual Volume 2boomix100% (1)

- 236 Floating StructuresDocumento2 pagine236 Floating StructuresRayodcNessuna valutazione finora

- Section Pb-421 - Plumbing TankDocumento8 pagineSection Pb-421 - Plumbing Tankjames_chan2178Nessuna valutazione finora

- Xo 270 Rs Front CabinDocumento4 pagineXo 270 Rs Front CabinBrian MorganNessuna valutazione finora

- Choosing HullDocumento16 pagineChoosing HullnyaungzinNessuna valutazione finora

- Understanding Boat Design 101 PDFDocumento1 paginaUnderstanding Boat Design 101 PDFŁukasz ZygielNessuna valutazione finora

- Hull Bottom Technology: Step It UpDocumento8 pagineHull Bottom Technology: Step It UpNelson Aguirre BravoNessuna valutazione finora

- ConfuciusDocumento12 pagineConfuciusCarlos Emanuel Gomes Sousa100% (1)

- Boat Building: Boat Building Is The Design and Construction of Boats and TheirDocumento13 pagineBoat Building: Boat Building Is The Design and Construction of Boats and TheirZvonko TNessuna valutazione finora

- NovaScotianMetricStudy PDFDocumento2 pagineNovaScotianMetricStudy PDFtrola666910100% (1)

- Ship and Boat Building and Repair-3Documento5 pagineShip and Boat Building and Repair-3navalmamunNessuna valutazione finora

- Trimaran Hull Design 198Documento10 pagineTrimaran Hull Design 198Elmer VillegasNessuna valutazione finora

- Recycling of FRP BoatsDocumento9 pagineRecycling of FRP Boatsjayaramsomarajan1975Nessuna valutazione finora

- Multipurpose Vessel: Rolldock SUNDocumento40 pagineMultipurpose Vessel: Rolldock SUNChockalingam Ganesh K R0% (1)

- Mason 33 Practical ReviewDocumento5 pagineMason 33 Practical ReviewManuelPérez-Sola100% (1)

- Design of A Channel ReachDocumento27 pagineDesign of A Channel ReachFaris Ahmed Bhatti0% (1)

- An Analysis of Slocum 37 YawlDocumento14 pagineAn Analysis of Slocum 37 YawlMarian IgescuNessuna valutazione finora

- Introduction to Boat Building in CompositesDocumento4 pagineIntroduction to Boat Building in CompositesMax BeeksNessuna valutazione finora

- Bridge DrainDocumento4 pagineBridge DrainAnonymous JDzpaaCNessuna valutazione finora

- 10 Farm Dam ConstructionDocumento3 pagine10 Farm Dam ConstructionOluwaseyi AdegokeNessuna valutazione finora

- Vtt-Finland-Boatbuilding Mtrls PDFDocumento33 pagineVtt-Finland-Boatbuilding Mtrls PDFAnonymous Ik5xaQZNessuna valutazione finora

- Engineered structures for utility and stability: Floating buildings at modern marina sites reflect ongoing advances in engineering skillsDocumento4 pagineEngineered structures for utility and stability: Floating buildings at modern marina sites reflect ongoing advances in engineering skillsRenato Nicoli MendesNessuna valutazione finora

- 4JH3 HteDocumento2 pagine4JH3 HteIvana Muratti JerkovicNessuna valutazione finora

- Roll Motion of Trimaran ShipsDocumento273 pagineRoll Motion of Trimaran ShipsPhilSelborNessuna valutazione finora

- Adrians Turbocraft Article MBO 2015Documento5 pagineAdrians Turbocraft Article MBO 2015Boat YardNessuna valutazione finora

- Watertight Deck 8250 AbDocumento47 pagineWatertight Deck 8250 AbAnonymous pPuhHLKu9yNessuna valutazione finora

- Filtration Improves Rainwater Quality for Rural CommunitiesDocumento8 pagineFiltration Improves Rainwater Quality for Rural CommunitiesGerdy LukmanNessuna valutazione finora

- Understanding Boat Design 103 PDFDocumento1 paginaUnderstanding Boat Design 103 PDFŁukasz ZygielNessuna valutazione finora

- Influence of Vetiver Grass System On Slope Stabilization POWER POINT by AreDocumento13 pagineInfluence of Vetiver Grass System On Slope Stabilization POWER POINT by AreKayode Steven ARENessuna valutazione finora

- Improved Bailey Batwing Sail GuideDocumento2 pagineImproved Bailey Batwing Sail GuideTom BeeNessuna valutazione finora

- Pod Yak FlatDocumento3 paginePod Yak Flattwinscrewcanoe100% (1)

- Architectural Catalogue RenukootDocumento103 pagineArchitectural Catalogue Renukootprchoudharykp100% (2)

- Dehler 42 Brochure DS 181101Documento35 pagineDehler 42 Brochure DS 181101AlchemistasNessuna valutazione finora

- The Sailing Bible 2009 - The Complete Guide For All Sailors (Adlard Coles Nautical London)Documento96 pagineThe Sailing Bible 2009 - The Complete Guide For All Sailors (Adlard Coles Nautical London)clee9999Nessuna valutazione finora

- Hull With Midplane BoatDocumento4 pagineHull With Midplane BoatVictor Jesus RiosNessuna valutazione finora

- Kitchen Rudders Going Full CircleDocumento24 pagineKitchen Rudders Going Full CircleClyde Steamers100% (1)

- Not A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalDocumento1 paginaNot A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalŁukasz ZygielNessuna valutazione finora

- Fentek CatalogDocumento48 pagineFentek Catalogjoseherreramogollon100% (1)

- Foam Sandwich Construction: How To Build A Foam Sandwich Composite BoatDocumento24 pagineFoam Sandwich Construction: How To Build A Foam Sandwich Composite BoatPhong TuanNessuna valutazione finora

- Spira International 22' Carolina Dory Boat PlansDocumento2 pagineSpira International 22' Carolina Dory Boat PlanslcortezbrNessuna valutazione finora

- Semco Rebate FormDocumento4 pagineSemco Rebate FormDante Pirouz0% (1)

- Types of CementDocumento36 pagineTypes of CementVishvjit RaoNessuna valutazione finora

- Promotion of Bamboo Housing System & Recent Developments: Shri K.Shyamasundar and Jagadish VengalaDocumento12 paginePromotion of Bamboo Housing System & Recent Developments: Shri K.Shyamasundar and Jagadish VengalaPranav DarakhNessuna valutazione finora

- Micro Concrete - ROOFDocumento4 pagineMicro Concrete - ROOFRajesh ChowhanNessuna valutazione finora

- DIY Boat Magazine Index 1995 To 2008Documento7 pagineDIY Boat Magazine Index 1995 To 2008Mickey GabayNessuna valutazione finora

- PolySail InternationalDocumento8 paginePolySail Internationaltwinscrewcanoe100% (1)

- Plywood Hull ConstructionDocumento15 paginePlywood Hull ConstructionlavrikNessuna valutazione finora

- Dreno Tex PDFDocumento10 pagineDreno Tex PDFvranceanu.ovidiu-1Nessuna valutazione finora

- Floating DrydockDocumento1 paginaFloating DrydockAhmed TarekNessuna valutazione finora

- Applications of Composites in Marine Industry: Dr. S. Selvaraju, S.IlaiyavelDocumento3 pagineApplications of Composites in Marine Industry: Dr. S. Selvaraju, S.IlaiyavelabhiNessuna valutazione finora

- Vol. 4 (4) - Dec. 2013: Professor, Department of Civil Engineering, Menoufia University, Shebin El-Kom, EgyptDocumento12 pagineVol. 4 (4) - Dec. 2013: Professor, Department of Civil Engineering, Menoufia University, Shebin El-Kom, EgyptFreddie KooNessuna valutazione finora

- Ferrocement BoatDocumento10 pagineFerrocement BoatNihil In-lineNessuna valutazione finora

- Walter Russell & Lao Russell - (1957) - Atomic Suicide (Abundant Hope Scanned Version)Documento208 pagineWalter Russell & Lao Russell - (1957) - Atomic Suicide (Abundant Hope Scanned Version)Amy Rivers100% (4)

- The Energy Machine of Joseph NewmanDocumento338 pagineThe Energy Machine of Joseph NewmanVladimir Bozic100% (2)

- Tesla Tech Rev18Documento16 pagineTesla Tech Rev18Nihil In-lineNessuna valutazione finora

- Autonomous Region of Bougainville Investment GuidelineDocumento9 pagineAutonomous Region of Bougainville Investment GuidelineNihil In-lineNessuna valutazione finora

- Jacksons Tesla Wireless Coil Instructions Apr 21 2011Documento50 pagineJacksons Tesla Wireless Coil Instructions Apr 21 2011zunder12100% (1)

- Jacksons Tesla Wireless Coil Instructions Apr 21 2011Documento50 pagineJacksons Tesla Wireless Coil Instructions Apr 21 2011zunder12100% (1)

- Materialqualitaeten EDocumento2 pagineMaterialqualitaeten EjvilamaiorNessuna valutazione finora

- Differientiation Through The Weave PU Hoses From 3 Ply PU HosesDocumento9 pagineDifferientiation Through The Weave PU Hoses From 3 Ply PU HosesAaron Homing NiNessuna valutazione finora

- Bus Duct-SPBDDocumento5 pagineBus Duct-SPBDSimbu ArasanNessuna valutazione finora

- Surface Preparation & Painting Procedure SampleDocumento29 pagineSurface Preparation & Painting Procedure SampleSyaiful Rasyidi TamsirNessuna valutazione finora

- Stone Masonry and Brick Stone MasonryDocumento3 pagineStone Masonry and Brick Stone MasonryMuhafeez GoolabNessuna valutazione finora

- Catalog of Seamless Steel Line Pipe of NSSMCDocumento8 pagineCatalog of Seamless Steel Line Pipe of NSSMCRoshan ShanmughanNessuna valutazione finora

- Cemfil 60 WW 12 2010 Rev6 ENDocumento2 pagineCemfil 60 WW 12 2010 Rev6 ENsilviaNessuna valutazione finora

- Lipaton SB 5813Documento2 pagineLipaton SB 5813yasafyNessuna valutazione finora

- Cast IronsDocumento4 pagineCast IronsMohamad FaizulNessuna valutazione finora

- PRIMO Chemicals CatalogDocumento29 paginePRIMO Chemicals CatalogPrimo Talk100% (1)

- Rochor Station Pile Design CalculationsDocumento15 pagineRochor Station Pile Design CalculationsDifa LiuNessuna valutazione finora

- Flat RoofDocumento2 pagineFlat RoofHarry ThienNessuna valutazione finora

- Sprayed Concrete TechnologyDocumento318 pagineSprayed Concrete TechnologyoltaiyrxNessuna valutazione finora

- Paint As A Building MaterialDocumento32 paginePaint As A Building MaterialJohn MorganNessuna valutazione finora

- Genova PlumbingDocumento127 pagineGenova PlumbingCatur PamungkasNessuna valutazione finora

- Technical Guide - Typical Pavement ProfilesDocumento10 pagineTechnical Guide - Typical Pavement Profilesmodest_dhuNessuna valutazione finora

- KD Waterbay Book Floorplan 1b-2b 1Documento12 pagineKD Waterbay Book Floorplan 1b-2b 1api-277642280Nessuna valutazione finora

- Clase N 5Documento4 pagineClase N 5Xthian Vidal CortezNessuna valutazione finora

- Grip Systems Catalog Inch 2012Documento389 pagineGrip Systems Catalog Inch 2012Casey100% (1)

- Module 1Documento50 pagineModule 1chris_m_germain100% (1)

- Metal Alloys Guide: Properties and Applications of Aluminum, Copper, Nickel, Titanium and Their AlloysDocumento31 pagineMetal Alloys Guide: Properties and Applications of Aluminum, Copper, Nickel, Titanium and Their AlloysAsyiqotul UlyaNessuna valutazione finora

- Piping Systems Solutions Brochure PDFDocumento13 paginePiping Systems Solutions Brochure PDFjensdcv100% (1)

- Jan 2010 Oxylink Updated Sales Presentation PDFDocumento44 pagineJan 2010 Oxylink Updated Sales Presentation PDFdainguyenlamNessuna valutazione finora

- 31003Documento4 pagine31003Elliott RussellNessuna valutazione finora

- Ficha Tecnica - Edgetherm - THM - 3000Documento2 pagineFicha Tecnica - Edgetherm - THM - 3000edocducNessuna valutazione finora

- Building A Cedar Strip CanoeDocumento8 pagineBuilding A Cedar Strip CanoecagedraptorNessuna valutazione finora

- Technical Report Writting Curing of Concrete PDFDocumento9 pagineTechnical Report Writting Curing of Concrete PDFBia MughalNessuna valutazione finora

- KBIIDocumento13 pagineKBIInetozx100% (1)

- Swedish FirDocumento4 pagineSwedish FirLagman T. CelestinoNessuna valutazione finora