Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Groen SSB-5E/EF Steamer

Caricato da

wsfc-ebayCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Groen SSB-5E/EF Steamer

Caricato da

wsfc-ebayCopyright:

Formati disponibili

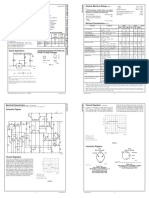

PROJECT NAME:

LOCATION:

SMARTSTEAM100 BOILERLESS STEAMER

ITEM NO:

MODEL SSB-5E/EF

QTY:

Steamer shall be a Groen Model SSB-5E/EF SmartSteam100 stainless steel,

boilerless, convection steamer with a self-contained atmospheric 12 KW electric

steam generating reservoir.

MODEL NO:

AIA NO:

SIS NO:

CONSTRUCTION: Steamer cavity and cabinet

shall be all stainless steel construction, with removable

right and left-side panels, providing access to internal

components. Steamer shall have no side vents for

increased water/spray resistance. Steamer door shall

be all stainless steel with a strong continuous hinge

and field-reversible for left or right swing. Door shall

be insulated and provided with a one-piece, replaceable

seal. Easy-open door handle and latch shall provide

positive lock and seal when door is pushed or slammed

shut. A hidden magnetic door switch shall cut power

to blower fan and shut down power to the steam

generating reservoir when the door is opened. Pan

support racks shall be stainless steel and removable for

easy cleaning. A stainless steel condensate collection

tray shall be positioned under the cavity door.

Finish: Cabinet exterior, including door, shall be a #3

uniform finish. Cavity interior shall be polished stainless

steel. Control panel face plate shall be smudge-resistant

polyester film, ensuring maximum ease in cleaning and

maintenance of an attractive appearance.

UL Listing: Steamer shall be UL and cUL listed.

Sanitation: Steamer shall be designed and

manufactured to meet NSF requirements and all known

health codes. Steamer shall be NSF listed.

Controls: Steamer controls shall include an

on-off rocker switch; electronic timer, with continuous

steam, timed steam and stop buttons; READY light which

indicates when cavity is warm and ready for steaming.

Performance Features: Steamer cavity

that adding/removing food does not lower the cavity

or water temperature. Heat up time to READY shall

typically be 15 minutes or less. Cavity is kept warm

and ready for instant steam between loads. No cavity

warm up required after READY light comes on.

SHORT FORM: 5-Pan Boilerless

Convection Steamer, table top or

stand-mounted, stainless steel, selfcontained, electric heated.

(Model SSB-5EF shown)

Atmospheric Steam Generating

Reservoir: Steamer shall have an electric-

heated steam generating reservoir to provide

atmospheric steam to the cavity at a temperature

of approximately 212 F. The high-efficiency steam

generating reservoir shall have water level sensors.

Electric heating elements shall not be immersed in

water (dry) and replaceable from the rear. Acidic

products and other commercial chemicals shall not

be used to clean the steamer. A daily wipe down of

the steamer cavity, steam lid and floats is sufficient to

maintain optimal operation of the steamer. However,

Groen Descaler or approved equal may be required.

Pan Capacity:

Pan Size/ Type

Total

12 x 20 x 1

10

12 x 20 x2 1/2

12 x 20 x 4

Installation: Steamer shall require 208, 240

or 480 Volt, 3-phase electrical service. Single phase

shall be available for 208 and 240 Volt operation.

Steamer shall be connected to a NH cold water

supply line and a 1-1/2 free venting drain.

OPTIONS/ACCESSORIES:

Factory Stacking Kit

Stainless Steel Support Stand

Pan Rack Kit (for support

stand)

Flanged Foot Kit (for support

stand)

Caster Kit (for support stand)

Heat Shield Kits

4 Adjustable Legs (table top

only)

Water Supply Requirements:

Steamer must be connected to an on-site water

shall have a powerful, side-mounted blower to increase

supply. Water supply at 30 to 60 PSIG with flow at

steam velocity and provide efficient steam distribution

.75 - 1.5 GPM per cavity.

throughout the cavity and between loaded pans. Steam

generator shall deliver 2.4 KW of electric power input per ORIGIN OF MANUFACTURE: Designed and

2-1/2 deep steam pan. Steamer shall have a steam lid manufactured in the United States.

positioned over the steam generating reservoir to ensure

SmartSteam100

144868H Revised 04/12

P/N 146528 REV E

5-Pan Boilerless Convection Steamer, table top or standmounted, stainless steel, self-contained, electric heated.

SSB-5E/EF

P/N 145241 REV H

SERVICE CONNECTIONS & NOTES:

4

1

MINIMUM REAR AND SIDE CLEARANCES:

DRAIN CONNECTION: 1 1/2" [38] HOSE TYPE (DRAIN FREE VENTING).

EACH SIDE = 2" [50.8]

DO NOT CONNECT DIRECTLY TO DRAIN. ALLOW 2" AIR GAP

REAR = 6" [152.4]

WATER SUPPLY: 3/4" MALE HOSE CONNECTION

30 TO 60 PSIG WITH A FLOW RATE OF 0.75-1.50 GPM.

PRESSURE REGULATION IS REQ`D FOR WATER PRESSURE OVER

60 PSI. DO NOT USE TREATED WATER.

DIMENSIONS IN BRACKETS [ ] ARE MM.

IF THE FLOOR DRAIN ONLY SERVICES

THIS STEAMER, THEN THE DRAIN MAY BE

LOCATED WITHIN THE STEAM FREE ZONE.

STEAM FREE ZONE MUST BE OBSERVED

IF OTHER APPLIANCES CAUSE STEAM AT

THE FLOOR DRAIN.

DO NOT INSTALL STEAMER DIRECTLY

ABOVE STEAM VENTING FLOOR DRAINS

STEAM EXHAUST

ELECTRICAL CONNECTION: SEE CHART

CONDUIT HOLE SIZE: 1-1/4" HOLE

1 1/32

[26]

1 3/8

[35]

1 1/4

1 [25]

1 3/8

[32]

ELECTRICAL REQUIREMENTS

PER COMPARTMENT

[35]

VOLTAGE

PHASE

208

[445]

17 1/2

7 11/16 [195]

240

32 3/4

MOUNTING HOLES IN BASE

USE 3/8"-16 BOLTS WHICH

MUST NOT EXTEND INTO STEAMER

BY MORE THAN 3/8" [10]

480

[832]

17 [432]

58

34

50

29

12

12

12

12

15

12

ALL UNITS 60Hz

REAR OF STEAMER

17 3/8

MAX.

KW

AMPS

1

3

1

3

[441]

STEAM EXHAUST

ELECTRICAL SUPPLY

ELEMENT ACCESS PANEL

WATER SUPPLY

DRAIN

FRONT OF STEAMER

2" [51]

2" [51]

TABLE TOP UNIT WITH

OPTIONAL 4" LEGS OR

COUNTER MOUNTED UNIT

(NOT SHOWN)

4

6

[152]

27 9/16

[700]

1

21 5/8

STEAM FREE ZONE

SEE NOTES

3

13

[330]

2

7 3/4

[197]

13/16 [21]

18

" [4

57

[549]

DRAIN

ALIGN REAR OF UNIT

TO TABLE IF COUNTER

MOUNTED

1 3/4 [44]

7

UNIT

OPTIONAL SUPPORT STAND

21 9/16

[548]

2

1

38 13/16

[986]

31 1/16

[791] MIN

3

44 1/16

[1119]

31 7/8

[810]

FINISHED FLOOR

6 [152]

1 1/2 [38] MIN

2 5/8 [87] MAX

FRONT VIEW

5" [127]

WITH CASTERS

(NOT SHOWN)

OPTIONAL RACKS

SIDE VIEW

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

2013 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

Potrebbero piacerti anche

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Cleveland KDT 12 T and KDT 20 TDocumento2 pagineCleveland KDT 12 T and KDT 20 Twsfc-ebayNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Stero U31 DishwasherDocumento4 pagineStero U31 Dishwasherwsfc-ebayNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- True GDM-19TDocumento2 pagineTrue GDM-19Twsfc-ebayNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Cleveland 1SCEDocumento2 pagineCleveland 1SCEwsfc-ebayNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Cleveland 22cet3.1Documento2 pagineCleveland 22cet3.1wsfc-ebayNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Masterbilt BMOA-GE MerchandisersDocumento2 pagineMasterbilt BMOA-GE Merchandiserswsfc-ebayNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Carter Hoffmann CGM24 Finishing CabinetDocumento2 pagineCarter Hoffmann CGM24 Finishing Cabinetwsfc-ebayNessuna valutazione finora

- Lolo LCF-TPF FryerDocumento2 pagineLolo LCF-TPF Fryerwsfc-ebayNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Carter Hoffmann CW2 Chip WarmerDocumento2 pagineCarter Hoffmann CW2 Chip Warmerwsfc-ebayNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Masterbilt QMVM-L SeriesDocumento2 pagineMasterbilt QMVM-L Serieswsfc-ebayNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Apw FDD & FDDL WarmersDocumento2 pagineApw FDD & FDDL Warmerswsfc-ebayNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Alto Shaam 20-20ESI Combi OvenDocumento4 pagineAlto Shaam 20-20ESI Combi Ovenwsfc-ebayNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Traulsen RRI-ARI LUT-FHSDocumento2 pagineTraulsen RRI-ARI LUT-FHSwsfc-ebayNessuna valutazione finora

- Baker's Pride EP-2828 Deck OvenDocumento2 pagineBaker's Pride EP-2828 Deck Ovenwsfc-ebayNessuna valutazione finora

- Cleveland OGS-6.20 Combi OvenDocumento2 pagineCleveland OGS-6.20 Combi Ovenwsfc-ebayNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Montague 136W36 BroilerDocumento2 pagineMontague 136W36 Broilerwsfc-ebayNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- APW SM-50 Soup WellDocumento2 pagineAPW SM-50 Soup Wellwsfc-ebayNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- APW FD-FDL Heat LampDocumento2 pagineAPW FD-FDL Heat Lampwsfc-ebayNessuna valutazione finora

- Baker's Pride 3836 Pizza OvenDocumento2 pagineBaker's Pride 3836 Pizza Ovenwsfc-ebayNessuna valutazione finora

- Hobart CRS66A DishwasherDocumento12 pagineHobart CRS66A Dishwasherwsfc-ebayNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Solar Powered Water Pumping System PDFDocumento46 pagineSolar Powered Water Pumping System PDFVijay Nishad100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Margarita ForesDocumento20 pagineMargarita ForesKlarisse YoungNessuna valutazione finora

- Meng Mammogram JulDocumento4 pagineMeng Mammogram JulLivia MillNessuna valutazione finora

- HOPE 3-Module 8-Week 5-6Documento9 pagineHOPE 3-Module 8-Week 5-6Freya SalorNessuna valutazione finora

- Vocab PDFDocumento29 pagineVocab PDFShahab SaqibNessuna valutazione finora

- Electronic Price List June 2022Documento55 pagineElectronic Price List June 2022MOGES ABERANessuna valutazione finora

- CLSI Laboratory Documents Development and Control Approved Guideline NAT L COMM CLINICAL LAB STANDARDS 2006 PDFDocumento100 pagineCLSI Laboratory Documents Development and Control Approved Guideline NAT L COMM CLINICAL LAB STANDARDS 2006 PDFErvin RodriguezNessuna valutazione finora

- Hotel Elizabeth in Baguio City: Address: J Felipe Street Cor. Gibraltar Road Mines View Park, Baguio City, PhilippinesDocumento16 pagineHotel Elizabeth in Baguio City: Address: J Felipe Street Cor. Gibraltar Road Mines View Park, Baguio City, PhilippinesI amEllaNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Ce Mark - Application FormDocumento3 pagineCe Mark - Application Formrajivsinghal90Nessuna valutazione finora

- Containers HandbookDocumento26 pagineContainers Handbookrishi vohraNessuna valutazione finora

- Philips Healthcare: Field Change Order ServiceDocumento5 paginePhilips Healthcare: Field Change Order ServiceJimNessuna valutazione finora

- Occlusal Appliance TherapyDocumento14 pagineOcclusal Appliance TherapyNam BuiNessuna valutazione finora

- Iso 15011-2-2009Documento26 pagineIso 15011-2-2009marcosNessuna valutazione finora

- Foundation Engineering. 02 Soil CompressibilityDocumento63 pagineFoundation Engineering. 02 Soil Compressibilitysammy lopezNessuna valutazione finora

- 5070 s14 QP 11Documento16 pagine5070 s14 QP 11OsamaRahimNessuna valutazione finora

- NASA ISS Expedition 2 Press KitDocumento27 pagineNASA ISS Expedition 2 Press KitOrion2015Nessuna valutazione finora

- Internationalresidential Code 2009 Edition Fuel Gas SectionDocumento49 pagineInternationalresidential Code 2009 Edition Fuel Gas SectionZarex BorjaNessuna valutazione finora

- AluminumPresentationIEEE (CompatibilityMode)Documento31 pagineAluminumPresentationIEEE (CompatibilityMode)A. HassanNessuna valutazione finora

- Factors That Contribute To Successful BakingDocumento8 pagineFactors That Contribute To Successful BakingErrol San Juan100% (1)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Implementation of 5G - IoT Communication System 1 - RB - LAB EQUIPMENTDocumento32 pagineImplementation of 5G - IoT Communication System 1 - RB - LAB EQUIPMENTMaitrayee PragyaNessuna valutazione finora

- Ams - 4640-C63000 Aluminium Nickel MNDocumento3 pagineAms - 4640-C63000 Aluminium Nickel MNOrnella MancinelliNessuna valutazione finora

- MGMTDocumento19 pagineMGMTMakrant MohanNessuna valutazione finora

- Supercritical Carbon DioxideDocumento3 pagineSupercritical Carbon DioxideRawda SeragNessuna valutazione finora

- Pearls and Pitfalls in Emergency Radiology Variants and Other Difficult Diagnoses 2013Documento389 paginePearls and Pitfalls in Emergency Radiology Variants and Other Difficult Diagnoses 2013mmbire@gmail.comNessuna valutazione finora

- LM 337Documento4 pagineLM 337matias robertNessuna valutazione finora

- Wire Rope Inspection ProgramDocumento2 pagineWire Rope Inspection Programسيد جابر البعاجNessuna valutazione finora

- CASE 721F TIER 4 WHEEL LOADER Operator's Manual PDFDocumento17 pagineCASE 721F TIER 4 WHEEL LOADER Operator's Manual PDFfjskedmmsme0% (4)

- EBANX Beyond Borders 2020Documento71 pagineEBANX Beyond Borders 2020Fernanda MelloNessuna valutazione finora

- Child Case History FDocumento6 pagineChild Case History FSubhas RoyNessuna valutazione finora

- Cat 880620 R11Documento60 pagineCat 880620 R11pawelprusNessuna valutazione finora