Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Transfer Pump Manual

Caricato da

Yhonatan Sosa DiazDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Transfer Pump Manual

Caricato da

Yhonatan Sosa DiazCopyright:

Formati disponibili

Page 1

USERS MANUAL

Issue date : 2/4/2009

INSTRUCTIONS

FOR OPERATION AND MAINTENANCE

OF

CENTRIFUGAL PUMPS FOR LIQUEFIED GASES

Type:

CO120/6.4-C/O

Comm. No.:

ECC39282-01

Customer:

PRAXAIR

Order No.:

186-LFPSG/DM

The purpose of these instructions is to facilitate the operation of your pump and to avoid

errors. Reading these instructions carefully before installation and start-up means safeguarding your interests and will be repaid by satisfactory service and performance of the

machine and low cost of repair.

We recommend you to keep on stock all spare parts mentioned in these instructions and

would be grateful if, when placing orders for spares, you would use our designation and

indicate the number of your pump. You will find the machine number of the name plate of

each pump.

Orders can be placed at :

Sales and service departments

Cryostar-USA

5897 Colony Drive

Bethlehem, PA 18017

Manufacturer

Cryostar-USA

9211 S. Greenleaf Ave.

Santa Fe Springs , CA 90670

Telephone:

fax:

Telephone :

fax :

(484) 281-3401

(484) 281-3402

(562) 903-1290

(562) 903-4511

Page 2

USERS MANUAL

Issue date : 2/4/2009

GLOBAL LOCATIONS

CRYOSTAR FRANCE S.A.

GLOBAL HEADQUARTERS

Zone Industrielle

B.P. 48

Hesingue

F-68221 HEGENHEIM CEDEX

Tel: +33(3) 89 70 27 27

Fax: +33(3) 80 67 59 54

CRYOSTAR SINGAPORE

CRYOSTAR UK

203 Henderson Road

Blk B# 10-09

Henderson Industrial Park

SGP - SINGAPORE 159546

Tel: +65 276 7441

Fax: +65 276 7442

Station Road, Industrial Estate

Unit 4+5

GB - WOMBWELL, Barnsley

S73 OHA, S. Yorkshire

Tel: +44 1226 759 921

Fax: +44 1226 756 729

USER RESPONSABILITY

This equipment will perform in accordance with the instructions and information contained in this manual, and

its referenced documents, when such equipment is installed, operated and maintained in compliance with

such instructions. The equipment must be checked periodically. Defective equipment shall not be used. Parts

that are brocken, missing, plainly worn, distorted or contaminated shall be replaced immediately. Should such

repair or replacement become necessary, CRYOSTAR recommends that a request for service will be made.

We recommend you to keep on stock all spare parts mentioned in these instructions. At the end of the manual

we indicate how to put in an ordre for spares.

The equipment, or any of its parts, shall not be altered without the prior written approval of CRYOSTAR. The

user and /or purchaser of this equipment shall have the sole responsibility for any malfunction which results

from improper use, faulty maintenance, damage, the use of spare parts that are not from CRYOSTAR,

improper repair or alteration by any party other than the manufacturer.

Attention

It is essential to read the directions for use prior to unpacking and installation.

Moreover, the machine must be used and maintained by qualified personnel.

Note

This document is the property of BOC-AG Cryostar. It is not permitted to copy it, or to relate its contents to

other persons, or to misuse it in any other way.

TABLE OF CONTENTS

Page 3

USERS MANUAL

Issue date : 2/4/2009

1. TECHNICAL DATA

1.1. Pump data

1.2. Operating data

1.3. Motor data

1.4. Acoustic pressure

1.5. Test

1.6. Description of the Design

2. SAFETY

2.1. Warning

2.2. Isolation and energy dissipation

2.2.1. Isolation and dissipation of gas process energy

2.2.2. Isolation and dissipation of purging gas energy

2.2.3. Isolation and dissipation of electrical energy

2.3. Safety form for oxygen pump

2.4. Customer safety instructions - Summary

3. STORAGE OF THE EQUIPMENT PRIOR TO INSTALLATION

3.1. BOC AG - Cryostar Delivery Inspection

3.2. Degreasing and Lubricating Grease/Oil for Oxygen Duty

3.3. Inspection by Customers on Arrival

3.4. Storage of the Pump

4. INSTALLATION

4.1. Handling

4.2. Erection

4.3. Installation Scheme

4.4. Storage Tank

4.5. Piping

4.5.1. Suction Line

4.5.2. Discharge Line

4.5.3. Bypass Line

4.5.4. Vent Line

4.6. Valves and Fittings

5. LUBRICANTS

5.1. Characteristics

6. START-UP

6.1. Pre-Start-Up Inspection

6.1.1. Spin Test by Hand

6.1.2. Direction of Rotation

6.1.3. Vent

6.1.4. In labyrinth pump : centering labyrinth rings

6

6

6

6

6

7

8

9

9

10

11

11

11

12

14

16

16

16

16

16

17

17

17

17

17

18

18

19

20

20

20

21

21

22

22

22

22

22

22

Page 4

USERS MANUAL

Issue date : 2/4/2009

6.2. Cool-down and Start-up of the Pump

6.3. Suction Pressure and Mechanical Seal

6.4. Shut-down of the Pump

23

24

25

7. TROUBLE SHOOTING

26

8. MAINTENANCE INSTRUCTIONS

29

8.1. General

8.1.1. Assembly / Disassembly : Table of tightening torques and forces

8.2. Periodical Revisions and Maintenance

8.3. Dismantling of the pump

8.4. Assembly of the Pump

8.5. Adjustment of the Mechanical Seal

9. CRYOSTARS MAINTENANCE AND SPARE PARTS SERVICE

9.1. Order Instructions

10. ANNEX

10.1. NPSH

10.2. Appendix to spare parts lists

10.3. Documentation

29

29

31

32

32

33

34

34

35

35

37

38

Page 5

USERS MANUAL

Issue date : 2/4/2009

LIST OF DRAWINGS AND OTHER ENCLOSURES

DRAWING TITLE

DRAWING

NUMBER

Flow diagram

Handling drawing

Dimensional drawing

Performance curve

Top Assembly

Special tools

Checklist

705070145

708114352

702114258-01

Test curve

763150972-02

763026005

706110196

SPARE PART

LIST NUMBER

E763150972-02

Page 6

USERS MANUAL

Issue date : 2/4/2009

1.

TECHNICAL DATA

1.1.

Pump data

Serial number

Type

Number of stages

Nominal impeller diameter

Speed

Position of suction nozzle

Position of discharge nozzle

Material Execution

Year / Month built

1.2.

Operating data

Medium

Liquid temperature

Max. Suction pressure

Minimum NPSH

Flow rate

Differential head

1.3.

LN2

-196C

5 barg

0.6 m

25 gpm

380 ft

Motor data

Cryostar ref.

Type

Protection

Insulation class

Temperature rise

Frequency

Phase

Voltage

Power

Speed

Forced ventilation

1.4.

ECC39282-01

CO120-6.4 C/O

1

120 mm

6400 rpm

Axial

I

Bronze / Bronze

2007 / 12

792605195-01/004

213T NEMA

IP 55

F

B

104 Hz

3

460 V

10 HP

6400 rpm

3x480V, 60 Hz

Acoustic pressure

Average value

85 dB A

Page 7

USERS MANUAL

Issue date : 2/4/2009

1.5.

Test

Medium

Test speed

Nitrogen

Refer to acceptance report

Note :

Working data have been measured at the test stand.

The test allows pressure to be checked under cryogenic working conditions.

Note : if required, test protocoles, material certificates or pressure test certificates are

included in the quality data book depending on the contract conditions.

Page 8

USERS MANUAL

Issue date : 2/4/2009

1.6.

Description of the Design

The pump is a single stage high speed centrifugal pump driven by an

electromotor.

The pump is mounted with a support to the motor flange.

The pump is directly coupled to the motor shaft. For the support of the

impeller, the motor bearings are of the highest precision and are fully

externally sealed.

The undesirable cold creep from the pump cold end to the bearings is reduced

to a minimum by an insulation ring, small contact surfaces and long support

arms.

The pump seal is a special mechanical seal.

These instructions contain a description of the pump, as well as complete

descriptions of installation, operation and maintenance of the pump.

Options

The rear chamber of the seal can be provided with a connection for N2purging.

A temperature probe can be installed on the motor bearing for maximum and

minimum temperature control. A space heater can be installed on the motor

bearing.

Page 9

USERS MANUAL

Issue date : 2/4/2009

2.

SAFETY

2.1.

Warning

Safety norms applied on site must be scrupulously respected. The

enforcement of a safety area will limit access to authorized personnel

only. Any operation on equipment in use is prohibited

Any operation on equipment in use is prohibited

Any normal operation must be made according to the recommendations

in the instructions

Any repairs must be made according to the recommendations in the

instructions

FATAL OR MOST SERIOUS INJURIES MAY OCCUR IF SERVICE

PERSONNEL DO NOT FOLLOW THE SAFETY REGULATIONS

High voltage is applied in the operation of this equipment.

The use of liquid gases or gases under high pressure has high risk factors

if service personnel do not follow safety regulations.

Fatal or most serious injuries, fire, explosions or suffocation may occur

depending on the liquid gas used in the system. Please, refer to the motor

instructions

Explosion hazard in the presence of oxygen

Cleaning and degreasing for use with oxygen

All components and equipment must be cleaned and degreased and must be

safe for use with oxygen.

Page 10

USERS MANUAL

Issue date : 2/4/2009

After cleaning and degreasing, the components and equipment should be

sealed and protected against contamination. The sealing and protection

should not be removed until immediately before installation. Consult Cryostar.

Explosion hazard in the presence of oxygen !

Carefully remove all degreasing fluid, which may also be extremely

hazardous in the presence of oxygen!

For obvious technical reasons linked to ice formation, it is not possible to

completely isolate all pump components.

Burning hazard !

During cool-down and working periods, it is strictly forbidden to touch

the machine

Our products must be handled with a handling system. Please, refer to

the Installation scheme

2.2.

Isolation and energy dissipation

(Maintenance)

Our products must be installed in a unit which ensures all functions of

cutting, separation, locking, pressure purging and checking

All energy external to our product originating from the customer (electricity,

purging gas, compressed air, N2-purging, etc...) must be isolated and

dissipated by means of isolating switches (hand operated valves with

padlocks, locking electric switches..). Gas line valves must be chosen

Page 11

USERS MANUAL

Issue date : 2/4/2009

carefully so as to permit a VOLUNTARY locking or unlocking of the user with

valve isolation.

2.2.1.

Isolation and dissipation of gas process energy

Components and instruments which permit the isolation and the dissipation of

the gas process energy depend on the users internal procedures of isolation

and energy dissipation and the parameters of their networks. Thus, it is not

possible for CRYOSTAR to plan the installation of this type of equipment on

the supplied machine.

2.2.2.

Isolation and dissipation of purging gas energy

The user must ensure that all purging pipes have been isolated before any

operation on the product.

2.2.3.

Isolation and dissipation of electrical energy

Before each operation on parts or equipment normally under voltage, the

personnel must isolate them when the equipment is at a standstill.

- Cut off and separate the equipment from the supply source by switching off.

- Lock the switch in a separation position with a padlock or any equivalent

locking device. The locking switch must be in an open position.

- Before operation, check that there is no more accumulated residual voltage

(Note : All orange coloured electrical circuit of the electrical equipment

supplied by CRYOSTAR remain permanently under voltage).

All electrical operation should be carried out by trained and authorized

personnel. The electrical connections must be connected by trained and

empowered personnel who must respect the local regulations and

protection rules in force.

Page 12

USERS MANUAL

Issue date : 2/4/2009

2.3.

Safety form for oxygen pump

Physical properties:

. Formula :

. Atomic number

. Molecular weight :

. Molecular dimensions :

. First ionization potential :

. Gas density S.T.P. :

O2

Z=8

31.9988 g.mole-1

4,2-2,8

12.059 eV

1,4289 kg.m-3

Oxygen is a gas colorless, odorless and testeless.

Working recommendations :

. No smoking near the pump.

. Oil and grease stained clothing must not be worn.

. Greasy rags should not be left lying about and the floor must be free of oil stains.

. Work with flame should be avoided in the enclosure of the pump.

Recommendations in case of accident (fires, burnd) :

In case of clothing fires, it is essential to act with maximum speed.

Water is still the best extinguisher in several cases. Hence quick action with a shower, bath or

extinguisher is necessary. It appears that hasty wrapping in a blanket is of doubtful effectiveness.

First aid for burn victims (low temperatures of liquid oxygen) :

Burns of this type are generally local.

Burnt parts of the body should be warmed gradually and then treated as conventional burns.

While awaiting the doctor, carry out the following first aid measures :

. If large blisters have been formed on the skin or if the eyes are suffering from burns, immerse the

burnt area in water or apply cold compresses, and convey the victim to a doctor.

. If the injury is less serious (spattering on the skin, small blisters), immerse the burned area in cold

water until the pain stops, coat the area with vaseline and keep it wet for 24 hours by means of a

cold 30 g/l boric acid solution.

. Do not pierce the blistes.

. Do not touch or undress the victim

. Do not speak to the victim face to face

. If possible, wrap burnt parts of the body in sterilized compresses

. Always summon a doctor immeditately.

Page 13

USERS MANUAL

Issue date : 2/4/2009

. Cover the victim with a sterilized blanket.

Leak detection and analysis :

Before employing a pump intended for use with pressurized oxygen, test the assembly with a leak

detector such as a helium detector.

The atmosphere surrounding an installation containing oxygen must be monitored for oxygen

concentration. Any rise in the latter considerably increase the risk of accident. Portable oxygen

analyzers may be employed.

Page 14

USERS MANUAL

Issue date : 2/4/2009

2.4.

Customer safety instructions - Summary

WARNING

All operations must be carried out by

appropriately trained personnel

AVERTISSEMENT

Toutes les interventions doivent tre

effectues par un personnel habilit

ACHTUNG

Alle Arbeiten mssen von

entsprechend geschultem Personal

ausgefhrt werden

Gases and liquid under high pressure

Gaz et liquides sous haute pression

Flssigkeiten und Gase unter hohem

Druck

LIFTING

Vertical lifting : prevent uncontrolled

rotation

LEVAGE

Levage vertical : Empcher toute

rotation non contrle

HEBEN

Senkrechtes Heben : unkontrolliertes

Drehen vermeiden

PRE-INSTALLATION CHECKS

CONTRLES AVANT

INSTALLATION

Toute pompe doit tre contrle ds

rception

UEBERPRUEFUNGEN VOR DER

INSTALLATION

Jede Pumpe sollte unverzglich nach

Ankunft untersucht werden

Check nameplate details

Vrifier les informations sur la plaque

signaltique

Typenschilddetails prfen

Check stored equipment every 6

months

Vrifier le matriel entrepos tous les

6 mois

Gelagertes Material alle 6 Monate

kontrollieren

No loose fasteners

Pas de fixations desserres

Keine losen Befestigungen

MECHANICAL INSTALLATION

Gaskets and seals correctly mounted

INSTALLATION MECANIQUE

Montage correct des joints et

garnitures

MECHANISCHE INSTALLATION

Korrekte Montage von Dichtungen

und Gleitringdichtungen

Refer to instructions

Se reporter au manuel dinstructions

Siehe Betriebsanleitung

ELECTRICAL INSTALLATION

All operations must be carried out by

appropriately trained personnel

INSTALLATION ELECTRIQUE

Toutes les interventions doivent tre

effectues par un personnel habilit

ELEKTRISCHE INSTALLATION

Alle Arbeiten mssen von

entsprechend geschultem Personal

ausgefhrt werden

Earthed

Mis la terre

geerdet

Check rotation, uncoupled

Vrifier la rotation vide

Maschine in Leerlauf prfen

Connections are tight ?

Les connexions sont-elles serre ?

Sind die Anschlsse fest angezogen ?

Covers must be fitted

Les capots de protection des botes

borne doivent tre en place

Abdeckungen der Klemmenkasten

mssen angebracht sein

Fused and isolated correctly

Protg par coupe circuit et isol

correctement

Korrekt abgesichert und isoliert

Every control box with a heating band

must be on

Toute armoire lectrique quipe

dune rsistance chauffante doit rester

sous tension

Jeder Elektro-Schrank mit Heizband

muss unter Spannung sein

Respect tightness of the control box

while cabling

Respecter ltanchit de larmoire

lectrique lors du cblage

Beim Anschlussen des ElektroSchrank Dichtheit beachten

Shut front protection covers after use

Veiller fermer les capots de

Nach dem Gebrauch vordere

Every pump should be checked

immediately upon delivery

Page 15

USERS MANUAL

Issue date : 2/4/2009

protection en faade aprs utilisation

CONNEXIONS

Vrifier le schma de cblage

Abdeckungen zumachen

ANSCHLUESSE

Anschlsse nach Anschlussplan

berprfen

Check driven equipment is free

Vrifier que la machine entrane soit

libre

Prfen, ob angetriebene Maschine frei

beweglich ist

Correct terminal arrangement

Vrifier le reprage des bornes

PROBLEMS

Pump does not prime

PROBLEMES

La pompe naspire pas

Auf einwandfreien elektrischen

Anschluss achten

PROBLEME

Pumpe saugt nicht

Rated capacity and pressure not

achieved

Dbits et pressions trop faibles

Durchsatz und Frderhhe nicht

erreicht

Mechanical seal leaking

Fuites garniture

Gleitringdichtung undicht

Vibrations

Vibrations

Pumpe vibriert

Pump overloads drive

Moteur surcharg

Pumpe berlastet den Antrieb

Bearings overheated

Roulements schauffent

Lager laufen sich heiss

Refer to supplier

Consulter le fournisseur

Hersteller fragen

MAINTENANCE

Isolate

ENTRETIEN

isoler

WARTUNG

trennen

Refer to supplier for details of

greasing etc...

Pour les dtails de lubrification etc..

consulter le fournisseur

Schmierung usw. siehe

Herstellungsangaben

SPARES

Refer to supplier

PIECES DE RECHANGE

Consulter le fournisseur

ERSATZTEILE

An Hersteller wenden

Quote equipment number, stock

number, designation

Indiquer le numro de la machine, le

numro de plan de la pice, la

dsignation

Maschinennummer,

Zeichnungsnummer, Benennung

angeben

HAZARDOUS AREAS

All operations must be carried out by

appropriately trained personnel

ZONES DANGEREUSES

Toutes les interventions doivent tre

effectues par un personnel habilit

GEFAHRENBEREICHE

Alle Arbeiten mssen von

entsprechend geschultem Personal

ausgefhrt werden

Refer to:

construction standard EN 294

Se reporter :

norme de construction EN 294

Bitte nachschlagen in :

Baunorme EN 294

STORAGE

Storage in a dry environment

the right way round

STOCKAGE

Stockage en lieu sec

lendroit

LAGERUNG

Lagerung in trockenem Raum

Richtig stellen

CONNECTIONS

Check connection diagram

Page 16

USERS MANUAL

Issue date : 2/4/2009

3.

STORAGE OF THE EQUIPMENT PRIOR TO INSTALLATION

3.1.

Cryostar Delivery Inspection

Every pump undergoes a trial operation with liquid nitrogen before leaving our

works, hence only perfectly functioning machines are delivered from our

factory.

3.2.

Degreasing and Lubricating Grease/Oil for Oxygen Duty

Pumps labelled 'degreased for running with oxygen' may be run with

oxygen without further treatment. They are delivered with a grease/oil suitable

for oxygen service. Pumps delivered, by customer request, with mineral

grease, are labelled 'not for oxygen'.

3.3.

Inspection by Customers on Arrival

Every pump should be checked immediately upon delivery, and any damages

incurred during transportation should be reported immediately to the

transporters or to Cryostar. Refer to Sales Conditions, Incoterms, Issue 1990.

3.4.

Storage of the Pump

If the pump is not for immediate use, it must be stored in a dry

environment, protected from oil, dust and water.

Important: The polyethylene wrapping around the pump, and the protective covers on the

pipe connections should only be removed immediately before installation.

CAUTION: Check stored equipment and spare parts at regular intervals e.g. every six

months at minimum. Any moisture, dust, rust etc. must be removed before

use. Note, parts for oxygen service which are stored or installed for more then

six months prior to use must be dismantled and checked carefully prior to

start-up.

The time period given above is our recommendation only and must be

adapted to the users own safety regulations. Fatal or most serious injuries

may occur if service personnel do not follow the safety regulations.

Page 17

USERS MANUAL

Issue date : 2/4/2009

4.

INSTALLATION

4.1.

Handling

Every machine that weights more than 55 kg must only be handled with a

Handling System. Please refer to Handling drawing.

PUMP TYPE

Weight 500 Kg

Pump with gearbox

Weight 500 Kg

Pump without gearbox

VCS

LOX

CBSH

4.2.

HANDLING DRAWING No.

708111520

708114352

705113963

705104881

705111521

Erection

Place skid on a flat surface that has been prepared according to the

dimensional layout drawing and capable of supporting the indicated load.

Secure the skid to the surface with the required amount and size of bolts as

indicated in the foundation drawing. The skid to be preferably grouted to limit

vibration. The stability of the whole installation must be ensured.

4.3.

Installation Scheme

The enclosed installation schematic drawing and operating instructions on the

following pages apply in normal operating circonstances only. Therefore, they

are relatively general and only the most important points for all different

service applications are mentioned. The installation schematic drawing shows

only indispensable equipment and piping for the operation of a pump for

liquefied gases and should be completed accordingly for different applications.

4.4.

Storage Tank

Most suitable is a pressurised storage tank which maintains the required

NPSH of the pump (see par. 10.1). The machine must be installed as close as

possible from the tank.

The tank discharge connection should be in the bottom of the tank and short.

A syphon or plunging pipe are unsuitable as gas which is formed in the line is

collected and cannot leave the pipe.

Page 18

USERS MANUAL

Issue date : 2/4/2009

The diameter of the tank discharge connection should be adjusted to the flow.

It should not be too small (minimum diameter same as the pump suction

connection) to keep the pressure drop small.

4.5.

Piping

Piping must be carefully designed so as not to transmit any stresses or forces

to the pump during operation or during stand still. Temperature contractions

and elongations must also be taken into consideration. For this reason,

flexible pipe parts should be installed.

4.5.1.

Suction Line

The suction line connects the tank discharge and the pump suction connection

and should be as direct and as short as possible.

The pipe must have a constant downwards inclination to the pump to allow

forthcoming gas to return into the tank.

The pipe diameter should be selected and designed for flow with an average

velocity of approx. 1 m/sec. Smaller velocities reduce the friction losses, but

disadvantageously increase the heat inleak accordingly. This reduces the

available NPSH (see

par. 10.1) and increases the gas vaporization loss during the cool down

period.

Good insulation is therefore essential. But it should not hinder the movements

of flexible pipe parts (flexible hose).

In view of gas vaporization losses the shut-off valves and the filter should not

be too large, as larger sizes mean increased heat inleak and longer cool down

time.

Pumps for oxygen service must be protected against foreign particles by a

filter in the suction line. Particles, which enter the pump are a potential fire or

explosion hazard.

The filter should have approx. 560 micron mesh and the useful surface should

be two times the suction pipe area at minimum.

Manifolds without a constant liquid flow should be shut-off as close as

possible to the branch in order to minimize the liquid gas vaporization.

All piping sections which can be shut-off must be equipped with safety valves

to avoid excessive pressure increase due to the vaporization of liquid gas.

Page 19

USERS MANUAL

Issue date : 2/4/2009

4.5.1.1. Design of the suction line

Installation of the suction line

The pipe must be as short and direct as possible

Well insulated and applying no force to the pump

Same diameter as the pump suction connection (also fittings and valves)

Fitting and valves limited to a minimum

Constant inclination downward to the pump

Required Fittings and Valves

a) Shut-off valve

b) Safety valve

c) Flexible pipe section

d) Filter for oxygen service (only if the pump is used with oxygen)

e) Non-return valve on the pump discharge

Recommendations

e) Shut-off valve in every branch

f) Pressure gauge

g) Gradual pipe diameter changes branch connections

h) Drivaton oblique

Filter even for non oxygen service

k) Insulation

4.5.1.2. Suction line : Installation Errors

Possible Installation Errors

Abrupt pipe or valve diameter

changesPressure drop

Narrow bends, T-branches

Long pipe without insulation

Branch shut-off walve not close enough,

branch pipe not insulated

High point in the line

Flexible elbow

Lack or filter or safety valve

Trouble

Pressure drop

Pressure drop

Pressure drop and heat inleak

Gas formation, the gas will be sucked

into the pump or the suction line will be

clogged

Gas accumulation, gas bubbles will be

sucked into the pump or the suction line

will be clogged

Additional force

Pump or seal failure possible

Note: Pressure drop, heat inleak = lowers the NPSH

4.5.2.

Discharge Line

The discharge pipe should have the same diameter as the discharge

connection of the pump, or somewhat larger for longer piping and when

excessive pressure loss would restrict the flow too much.

Page 20

USERS MANUAL

Issue date : 2/4/2009

The discharge line characteristic must be put into consideration with the pump

characteristic curve!

A shut-off valve, a non-return valve and pressure gauge should be installed in

the discharge line.

4.5.3.

Bypass Line

For faster cool down and for easier start-up a bypass line should be provided.

The bypass pipe should have the same diameter as the pump discharge line

or should be designed for the pump minimum flow.

4.5.4.

Vent Line

A vent pipe with shut-off valve is advantageous for the venting of piping and

pump and for faster cool down.

4.6.

Valves and Fittings

All valves, fittings, filters, manometers, etc.. must be adapted to a companys

own internal safety regulations and must also correspond to health-safety

legislation.

For any damages caused by unsuitable assembly of the piping system,

CRYOSTAR cannot be held responsible.

Page 21

USERS MANUAL

Issue date : 2/4/2009

5.

LUBRICANTS

The following lubricants should be used:

Motor-bearing Grease

ESSO Beacon 325

ESSO Beacon 325

For oxygen service

For service with argon, nitrogen or

hydrocarbon

Caution:

Because of explosion risk, do not use normal, commercially mineraloil-based

lubricants for oxygen service.

5.1.

Characteristics

CHARACTERISTICS

ESSO BEACON 325

UNIT

Appearance

Soap base

Temperature range

Base oil

Kin. viscosity

at 40C

at 100C

Drop point

Penetration-unworked

Penetration-worked x60

Bearing performance against corrosion

Test NF T 60-135

Resistance to water washing out at 40C

Loss

Tests on bearings at high temperature

Test FTMS 791 b-331-2 at 120C

Vaporization losses

Test ASTM D 972 (22 h 121C), loss

AVERAGE VALUE

creamy smooth grease

Lithium

-55 to 120C

synthetic ester

cSt

cSt

C

11.8

3.25

180

260

280

0

% wt

>1000

% wt

0.5

Page 22

USERS MANUAL

Issue date : 2/4/2009

6.

START-UP

6.1.

Pre-Start-Up Inspection

Check whether all pipes, fittings, fixing bolts and electric connections are

ready for start-up.

Prepare the complete system, in which the pump is installed for start-up.

For gearbox driven pumps, check the oil level.

6.1.1.

Spin Test by Hand

Spin the pump by hand using the slinger ring on the pump shaft or an offset

spanner on the motor fan screw to control the rotation.

6.1.2.

Direction of Rotation

Start the motor for a short run (the pump must not be operated without liquid!)

and check whether the pump shaft rotation is the same as the arrow direction

on the pump volute.

6.1.3.

Vent

CAUTION

BEFORE OPERATING THE PUMP, ALL SUCTION LINES, DISCHARGE

LINES AND THE PUMP SHOULD BE VENTED SO AS TO PREVENT

HUMIDITY OR ICE FROM BUILDING-UP IN THE PUMP DURING THE

COOL DOWN PERIOD

THE LENGTH OF TIME FOR THIS WILL VARY DEPENDING UPON LOCAL

CONDITIONS : ONE DAY MINIMUM after a long break

6.1.4.

In labyrinth pump : centering labyrinth rings

Caution : For labyrinth pumps, loosen the labyrinth seal cover screws. Turn

pump on end i.e. rotate the shaft manually to ensure that it rotates

correctly and to ensure the self-centering of the labyrinth rings. Then, the

cover screws of the labyrinth seal may be definitively tightened-up.

Page 23

USERS MANUAL

Issue date : 2/4/2009

6.2.

Cool-down and Start-up of the Pump

(see drawing 'Flow diagram')

WARNING

The pump must not run without liquid!

Safety clothes, gloves, spectacles, etc... according to On-Site regulations

Do not touch the equipment while in use

Warning : Pumps with mechanical seal

Before cooling down, purge the mechanical seal with dry nitrogen for at

least 10 minutes to prevent moisture ingress into mechanical seal area

causing freezing together of seal faces. The mechanical seal purging tubing

must be in stainless steel or in copper. The gas must be clean. Refer to

Suction pressure and mechanical seal.

Warning : For labyrinth pumps, see Starting and pressure regulation of

seal gas

Warning : Pumps with lantern N2-purging

In operation and especially during cooling down period, the warm box must be

purged with gaseous nitrogen to prevent motor bearing and pump end from

freezing.

The nitrogen purging pressure must be 0.15 barg.

It must be started before cooling down the pump.

Nitrogen gas must be dry.

Dew point: -80C

Warning : Pumps with protection chamber N2-purging

The nitrogen purging pressure must be 0.15 barg. Purging in operation and

during cooldown of the pump is necessary. Open seal gas inlet which must be

dry nitrogen.

Warning : Pumps with motor front bearing heater

Heater must be electrically powered.

Open suction valve and bypass valve 6 slowly. Liquid flows from storage tank

into the pump and cools it down. During the cool-down period the pressure

regulating valve 4 is closed and the bypass valve 6 open.

Page 24

USERS MANUAL

Issue date : 2/4/2009

When cooling down, start the pump every 2-3 minutes for a short run of 2 to 3

seconds. This prevents contact freezing of the sealing surfaces.

During cool-down the storage tank pressure rises. This improves the pump

start-up conditions due to improved NPSH - see section NPSH.

When a ventline with block-valve against air inlet is installed in the discharge

or bypass line, cool-down can be accelerated by venting the gas into the

atmosphere. Do not open the shut off valve for too long a period, otherwise

the storage tank pressure will drop too much.

Normally the pump will be cooled down after 10-15 minutes.

The white frost from the pump body then begins to extend to the four support

arms. If the pump is overcooled (support arms completely frosted) it should be

started only after the shaft has been checked for freedom of rotation.

After the pump is well cooled down fully open the suction valve. If one is

installed, close the ventline and block valve and regulate the bypass valve

according to the diameter of the pipe. Start the pump.

Adjust to the required discharge pressure with bypass valve 6. Then

simultaneously open pressure regulating valve 4 and close bypass valve 6.

This starts liquid gas delivery to the consumer.

Do not control the flow with the suction shut off valve! This valve must remain

fully open during operation. Partial closure will decrease the available NPSH

and could disturb the trouble free operation.

6.3.

Suction Pressure and Mechanical Seal

For good priming and trouble-free operation every liquid gas pump needs a

certain net positive suction head (NPSH), i.e. some over pressure above the

liquid gas vapor pressure in the pump suction nozzle (see also section 10.1 NPSH).

Sometimes the geodetical head of the tank (the liquid column above the pump

suction nozzle) is not sufficient to equalize the friction losses and the heat

inleak in the suction line.

In such a case build-up the gas pressure in the storage tank. The necessary

pressure increase in the storage tank is a function of the required pump NPSH

and of the installation, and therefore it can be determined by test only.

Operate the pump with the lowest possible storage tank pressure.

Page 25

USERS MANUAL

Issue date : 2/4/2009

The pump mechanical seal is designed for a suction pressure of 5 bars. Keep

the pump suction pressure as low as possible. This improves the life time of

the mechanical seal.

6.4.

Shut-down of the Pump

(see drawing 'Flow diagram')

For shutdown this sequence should be followed:

1. Shut-off the motor, open the bypass valve 6 and close the pressure

regulating valve 4

2. Close the suction valve

3. After the pump has been defrosted, close bypass valve 6

Page 26

USERS MANUAL

Issue date : 2/4/2009

7.

TROUBLE SHOOTING

Trouble

Probable Cause

Trouble Shooting

Pump does not prime,

Insufficient cool-down

Continue the cooldown

or the priming is

of the pump or insuffi-

or increase suction

lost

cient suction pressure

pressure (NPSH)

(insufficient NPSH)

Vapor pocket in the

Vent the gas from

the

suction line

liquid gas line

Contamination in the

Purge inner parts of

pump

cold end with clean

gas and dry; or dismantle and clean

Worn-out parts

Repair/overhaul cold

end

Wrong direction of

Exchange two phase

rotation

leads on motor

Mechanical seal

Pump suction pressure

Reduce the pump

leaking

too high

suction pressure to

prescribed value

Mechanical seal pre-

Increase the preload

load too low

to prescribed value

Mechanical seal ring

Exchange the seal

worn-out

Page 27

USERS MANUAL

Issue date : 2/4/2009

Trouble

Probable Cause

Trouble Shooting

Rated capacity

Pump does not prime

Improve suction

and/or pressure not

well

conditions, clean the

achieved

suction filter

Vapor in suction line

NPSH not sufficient

Impeller or volute

Clean the clogged

passages clogged

parts

Wear rings worn,

Exchange worn or

impeller damaged

damaged parts

Discharge system back

Check the pump and

pressure higher than

system characteristic

rated

curves and improve

the

system piping

Pump/Motor speed incorrect

Pump overloads drive

Drive rating insuffi-

Exchange the drive

cient

Pump noisy, internal

Repair the pump

rubbing noise

Flow higher than rated

Reduce the flow

Low voltage

Increase voltage to

rated value

Page 28

USERS MANUAL

Issue date : 2/4/2009

Trouble

Probable Cause

Trouble Shooting

Pump vibration

Pump cavitating

Improve suction conditions

Pump operation below

Increase flow to the

minimum recommended

minimum value

flow

Impeller clogged, un-

Clean, balance rota-

balance

ting parts

Pump fixation and/or

Improve fixation

foundation not rigid

enough

and/or foundation

Mechanical parts worn-

Exchange worn-out

out (bearings, impel-

parts

ler, gears etc.)

Bearings over-

Bearings too tight or

Use prescribed

heated or wearing

preload too high

bearings and right

rapidly

preload

Improper lubrication

Improve lubrication,

check lubricant flow

passages

Dirt or water in

Clean or exchange

bearings

bearings

Too high vibration

Reduce vibration as

prescribed above

Page 29

USERS MANUAL

Issue date : 2/4/2009

8.

MAINTENANCE INSTRUCTIONS

8.1.

General

The following maintenance instructions are sufficient in normal use.

Estimates and proposals for spare parts and revisions will be supplied upon

request.

Nevertheless it is not recommended nor practical to attempt to completely

overhaul it due to the close tolerances and precision finishes of the interior

components.

When extensive overhaul works or complete revisions are necessary, we

recommend that the help of our service engineer is requested.

WARNING

Before use, ensure that the pump is not under voltage and that it is not cold. If

necessary, the installation must be isolated and the energy must be dissipated

according to safety procedures.

WARNING

Before use, ensure that no impurity enters into the pump or the pipes.

8.1.1.

Assembly / Disassembly : Table of tightening torques and forces

After manual tightening, the end tightening must be made with a torque

wrench, at 75% of the limit of elasticity or at the drawing value.

Page 30

USERS MANUAL

Issue date : 2/4/2009

Torques and forces for Bolts of type H, in stainless steel, class A1, A2, A4

Bolts class of resistance: 70

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

Torque (Nm)

Max

5.9

14.5

30

50

79

121

174

244

182

234

328

445

Standard

5

12

25

42

66

101

145

203

152

195

273

371

Force (Nm)

Max.

6.85

12.6

20

29.1

40

55

69

88.6

61.5

70.9

90

109.4

Standard

6

11

17

24

33

46

58

74

51

59

75

91

Bolts class of resistance : 80

M6

M8

M10

M12

M14

M16

M18

M20

Torque (Nm)

Max

8

19.3

39.4

67

106

161

232

325

Standard

7

16

33

56

88

134

193

271

Force (Nm)

Max.

9.13

16.7

26.6

38.8

53.3

73.3

92

118.1

Standard

8

14

22

32

44

61

77

98

Torques (Nm) for hexagon socket flat or small head cap screws in stainless

steel, class A2, A4

Screw

type

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

Din 6912

Chc

70

Max

5

12

24

40

66

110

Standard

4

10

20

33

55

92

170

142

Din 7991

Fhc

70

Max.

5

7

21

30

66

Standard

4

6

18

25

0

55

Din 7991

FHc

70

Max

5

8

20

33

50

55

Standard

4

7

17

28

42

46

120

100

75

63

235

196

200

167

Page 31

USERS MANUAL

Issue date : 2/4/2009

8.2.

Periodical Revisions and Maintenance

To ensure trouble free operation over long periods the following maintenance

works must be carried out:

- Every 1000 hours of operation or annually

Dismantle the pump completely, change damaged parts, clean all parts.

- Lubricants

See the section 'Lubrication'.

The time limits given above should be adapted to the type of pump operation,

the atmospheric exposure, the internal operating practice and operating

experience. The given time limits are a recommendation only.

Page 32

USERS MANUAL

Issue date : 2/4/2009

8.3.

Dismantling of the pump

(see drawing 'Cold End')

Dismantle the pump carefully and in the following sequence:

- Disconnect the electrical connections and electrical accessories

- Remove the suction-, by-pass-, discharge-and vent lines, fitting 29, etc.

- For further dismantling , prepare clean work place (cover the work table with

new paper)

- Remove screws 1 with its spring washers 2

- Remove the pump casing 4

- Remove the flexitallic gasket 3

- Remove nuts with its washers (parts 8,9,14)

- Pull-off carefully the inducer 6 of the pump shaft

- Pull-off carefully the impeller 10 of the pump shaft

- Remove keys 7, shim 18, seal ring 11 and shim 13

- Unscrew the mechanical seal clockwise (left thread) from intermediate piece

5

For dismantling or tightening the mechanical seal use only the special tool

drawing no. 768026005.

CAUTION

Using other tools to screw or unscrew the mechanical seal could

damage the seal ring or the whole mechanical seal and must

therefore be avoided.

- Remove screws 15,16

- Remove the intermediate piece 5 with its back-up rings

- Push off the thermal insulation 20 and back-up rings 22

- Dismantle the screws 25,28,17 between the motor flange and the support

and dismantle the support 27

- Dismantle the slinger ring 23 of the shaft

- Remove pin 26 and push off the pump shaft 21

8.4.

Assembly of the Pump

Assemble the pump in the reverse of the stated dismantling sequence. The

following care should be taken:

The mechanical seal ring and the seal ring must be lapped to best surface

quality. Assemble the mechanical seal very carefully, so that its tightness is

guaranteed during stand still as well as in operation. The seal bellow must be

dry.

Page 33

USERS MANUAL

Issue date : 2/4/2009

Do not damage the O-ring.

Before assembling the pump, carefully clean all pump parts and any changed

parts. For a pump in oxygen service, all parts must be degreased.

The flexitallic gasket between pump housing parts must be carefully inserted

and the screws tightened crosswise.

Check the freedom of rotation of the pump shaft.

For special position of the pump discharge nozzle turn the pump housing

against the support.

Never turn the support against the motor flange.

8.5.

Adjustment of the Mechanical Seal

Screw the mechanical seal into the pump casing in an anticlockwise direction

using the special tool.

CAUTION

Left thread. Do not forget the O-ring seal.

Push the mobile ring smoothly on the shaft towards the sealing ring. Measure

with a precision depth gauge the distance between the shaft end and the

mobile ring.

Press the mobile ring up against the mechanical seal up to the shoulder shaft.

Measure the distance between the shaft end and the mobile ring as before.

The difference between both measured distances is the preload of the

mechanical seal.

The correct preload is listed on the checklist. Adjust to the correct preload with

shims between the shaft shoulder and the sealing ring.

Caution:

When the sealing ring is partially worn, adjust the preload so that the sealing

ring is beyond the shoulder of the mechanical seal housing.

Page 34

USERS MANUAL

Issue date : 2/4/2009

9.

CRYOSTARS MAINTENANCE AND SPARE PARTS SERVICE

9.1.

Order Instructions

Lists of spare parts are enclosed with these instructions. On each sectional

drawing, the spare parts are marked with item numbers corresponding with

those on the spare parts list; on the spare parts list, stock part number and

designation are added to each item.

It is advisable to always keep in stock the spare parts recommended in these

lists; you may save unwelcome waiting time.

When ordered the spare parts, please indicate the following:

1.Equipment number

2.Stock number of the required part

3.Designation of the required part

When extensive overhaul works or complete revisions are necessary, we

recommend return of the machine to our works or that the help of our service

engineer is requested.

Page 35

USERS MANUAL

Issue date : 2/4/2009

10.

ANNEX

10.1. NPSH

NPSH = Net positive Suction Head = difference between the static

pressure (Ps) and the actual vapour pressure (Pt) of the vapourfree liquid

in the suction nozzle of the pump.

To allow a cryogenic pump to start and operate correctly, a specific NPSH

must be available.

The NPSH in the suction nozzle of the pump has to prevent local vaporization

of the liquid and can also be described as relative undercooling ( DT). The

actual vapour pressure (Pt) is determined only by the temperature (Ts) in the

suction nozzle of the pump, expressed in meters of liquid head.

The required NPSH (=NPSHr) must be available during starting as well as

during operation of the pump.

The available NPSH (NPSHa) in the suction nozzle of the pump can be

attained or improved by:

- Increasing the static liquid head

- Relative undercooling of the liquid

- Pressure built-up in the tank over the actual vapour pressure

- Better insulation of the piping

- Reduction of pressure loss in the piping

Page 36

USERS MANUAL

Issue date : 2/4/2009

The necessary NPSH must be guaranteed during start-up as well as under

service conditions of the pump.

The necessary NPSH in the suction nozzle may be reached or improved by:

- Increasing the static liquid head (higher position of the tank)

- Undercooling of the liquid

- Pressure increase in the tank

- Better piping insulation in the given installation

- Reduction of piping pressure

Page 37

USERS MANUAL

Issue date : 2/4/2009

10.2. Appendix to spare parts lists

P

Ref. No.

Explanation

Position on drawing

Quantity of parts per unit

Parts subject to normal wear to be kept on stock, to be replaced at each disassembly

Commissioning spares

Recommended spare parts for 2 years operation

XXXXXXXX

IMPORTANT :

Stock number

The prices are subject to change without previous notice. The

prices are net, in French currency, for supply ex works,

including packing, excluding any customs duties or taxes.

The handling charge for orders under Ffr. 250,00 is Ffr.

100,00 per order.

Every part should be replaced by a CRYOSTAR genuine part.

CRYOSTAR accepts no responsability if these rules are not respected.

Page 38

USERS MANUAL

Issue date : 2/4/2009

10.3. Documentation

CRYOSTAR Ref.

DESIGNATION

CRYOSTAR DOC.

Safety valves must be set every year

LEAFLETS

792605195-01/004

Motor

Leroy Sumer

56

1.000

quantity

Unit

Factor

P/N

Description

CO 120-6.4 C/O-FC, PUMP ASSEMBLY

Bill of Material / Nomenclature

Material

Dimentions

Created:14DEC07

Updated:14DEC07

Valid BOM

by:ORTEGAC

Page:

1.000 740150336

PC

Plate Insulating

---------------------------------------------------------------------------------------------------------------------------------------002

1.000

1.000 769111843

PC

Welded support

---------------------------------------------------------------------------------------------------------------------------------------003

1.000

1.000 740081885

C

PC

Pump casing (from casting)

---------------------------------------------------------------------------------------------------------------------------------------004

1.000

1.000 798160823

PC

Spiral wound gasket

---------------------------------------------------------------------------------------------------------------------------------------005

1.000

1.000 740150332

PC

Casing Cover CO120

---------------------------------------------------------------------------------------------------------------------------------------006

1.000

1.000 740108277

PC

Isolating ring

---------------------------------------------------------------------------------------------------------------------------------------007

1.000

1.000 730000169

PC

O-ring

---------------------------------------------------------------------------------------------------------------------------------------008

1.000

1.000 798250060

PC

Mechanical seal

---------------------------------------------------------------------------------------------------------------------------------------009

1.000

1.000 740026827

B

Sealing ring

PC

---------------------------------------------------------------------------------------------------------------------------------------010

1.000

1.000 740104736

PC

Shim

---------------------------------------------------------------------------------------------------------------------------------------011

1.000

1.000 740026828

E

PC

Shim

---------------------------------------------------------------------------------------------------------------------------------------012

2.000

1.000 795080919

PC

KEY

---------------------------------------------------------------------------------------------------------------------------------------013

1.000

1.000 740027146

B

PC

Impeller from casting

---------------------------------------------------------------------------------------------------------------------------------------014

1.000

1.000 740026826

C

PC

Inducer

---------------------------------------------------------------------------------------------------------------------------------------015

1.000

1.000 740150333

PC

Shaft CO120

---------------------------------------------------------------------------------------------------------------------------------------016

1.000

1.000 740111839

PC

Slinger ring shaft

---------------------------------------------------------------------------------------------------------------------------------------017

1.000

1.000 730001637

PC

Hexagon socket set screw cone point

----------------------------------------------------------------------------------------------------------------------------------------

001

Pos

List P/N : 763150972-02

User: ROBLEDS

printed on: 04FEB09 1

1.000

quantity

Unit

Factor

P/N

Description

CO 120-6.4 C/O-FC, PUMP ASSEMBLY

Bill of Material / Nomenclature

Material

Dimentions

Created:14DEC07

Updated:14DEC07

Valid BOM

by:ORTEGAC

Page:

1.000 795080954

PC

Spring type straight pin

---------------------------------------------------------------------------------------------------------------------------------------019

1.000

1.000 709058819

A

PC

Hexagon socket head cap screw

---------------------------------------------------------------------------------------------------------------------------------------020

1.000

1.000 795061119

PC

Conical spring washer

---------------------------------------------------------------------------------------------------------------------------------------021

1.000

1.000 72AP01002

ML

Wire

---------------------------------------------------------------------------------------------------------------------------------------022

8.000

1.000 730150315

PC

SCREW, HEX HEAD, M8 x 30MM SS

---------------------------------------------------------------------------------------------------------------------------------------023

8.000

1.000 730002188

PC

Spring washer

---------------------------------------------------------------------------------------------------------------------------------------028

4.000

1.000 730150314

PC

SCREW, HEX HD, 1/2"-13 x 1.25" SS

---------------------------------------------------------------------------------------------------------------------------------------029

4.000

1.000 730150154

PC

WASHER, LOCK 1/2" , 18-8 SST

---------------------------------------------------------------------------------------------------------------------------------------030

4.000

1.000 769150042

Flex Hose 1/4 ODx10lg

PC

---------------------------------------------------------------------------------------------------------------------------------------031

6.000

1.000 730150309

PC

SCREW, SOCKET HEAD CAP, M10 x 65MM

---------------------------------------------------------------------------------------------------------------------------------------032

6.000

1.000 730000005

PC

Spring washer

---------------------------------------------------------------------------------------------------------------------------------------033

1.000

1.000 792605195-01/004

PC

Asynchron-Motor for variable speed

---------------------------------------------------------------------------------------------------------------------------------------034

1.000

1.000 791564839

PC

Coupling male - BW, conical seal

---------------------------------------------------------------------------------------------------------------------------------------035

1.000

1.000 730150353

PC

NAMEPLATE, CENTRIFUGAL PUMP

---------------------------------------------------------------------------------------------------------------------------------------036

2.000

1.000 740026831

PC

BACK-UP-RING

---------------------------------------------------------------------------------------------------------------------------------------038

2.000

1.000 730150689

PC

PLUG, HEX SOCKET HEAD, 1/8" NPT

========================================================================================================================================

018

Pos

List P/N : 763150972-02

User: ROBLEDS

printed on: 04FEB09 1

Potrebbero piacerti anche

- QCDC - Hydraulic and Manual Quick Connect/Disconnect Couplers For Marine Loading ArmsDocumento2 pagineQCDC - Hydraulic and Manual Quick Connect/Disconnect Couplers For Marine Loading ArmsVasudev ShanmughanNessuna valutazione finora

- Contoh Schedule RepairDocumento17 pagineContoh Schedule RepairUdoy LahNessuna valutazione finora

- JIG (English)Documento22 pagineJIG (English)keenis herreraNessuna valutazione finora

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocumento15 paginePiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNessuna valutazione finora

- OPI600 FE Parts ManualDocumento50 pagineOPI600 FE Parts ManualActivos Fijos0% (1)

- Smo Management Audit Report Q2f19-FoiDocumento12 pagineSmo Management Audit Report Q2f19-FoiBob MackinNessuna valutazione finora

- 10kw Hybrid System 57 6kwhDocumento1 pagina10kw Hybrid System 57 6kwhardeasgrNessuna valutazione finora

- Orbital WeldingDocumento20 pagineOrbital WeldingAshishBohra0% (2)

- Workbook Answers: CCEA GCSE PhysicsDocumento40 pagineWorkbook Answers: CCEA GCSE PhysicsCanioNessuna valutazione finora

- SB Series Sand Pump BrochureDocumento7 pagineSB Series Sand Pump Brochurescribind100% (1)

- N5SC Swivel 1Documento12 pagineN5SC Swivel 1Winda FaleviNessuna valutazione finora

- SEC VIII D1 B PT UF - Part UF Requirements For Pressure Vessels Fabricated by ForgingDocumento6 pagineSEC VIII D1 B PT UF - Part UF Requirements For Pressure Vessels Fabricated by ForgingJoel SantaellaNessuna valutazione finora

- QHP CatalogDocumento7 pagineQHP CatalogsanjeevvangeNessuna valutazione finora

- Instruction Sheet: W-Series Hydraulic Torque WrenchesDocumento40 pagineInstruction Sheet: W-Series Hydraulic Torque WrenchesShag Shaggy100% (1)

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Documento5 pagineSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNessuna valutazione finora

- Cameron t32 IomDocumento20 pagineCameron t32 IomJuan Carlos Sua SuaNessuna valutazione finora

- Vendor: Design Information: Gas BootDocumento2 pagineVendor: Design Information: Gas Boot124swadeshiNessuna valutazione finora

- Ambient Crude Oil StorageDocumento13 pagineAmbient Crude Oil StorageSrihari KodimelaNessuna valutazione finora

- Pa 180010Documento6 paginePa 180010Trịnh Đức HạnhNessuna valutazione finora

- Sonceboz Chart Recorder Motor Spec SheetDocumento2 pagineSonceboz Chart Recorder Motor Spec Sheetjesdcp7Nessuna valutazione finora

- Iso Pro: ISO 5199 Standard Centrifugal PumpsDocumento44 pagineIso Pro: ISO 5199 Standard Centrifugal Pumpsbona INSTtechnicianNessuna valutazione finora

- Sedifilt Oil & Gas Brochure PDFDocumento8 pagineSedifilt Oil & Gas Brochure PDFAalap DerasaryNessuna valutazione finora

- Roof Air Rising of An Ammonia Storage Tank at KPICDocumento12 pagineRoof Air Rising of An Ammonia Storage Tank at KPICHgagselim Selim100% (1)

- Balon Full Valve CatalogDocumento51 pagineBalon Full Valve CatalogVictor Muñoz0% (1)

- Heatless Desiccant Dryers Bochure A4Documento8 pagineHeatless Desiccant Dryers Bochure A4rodonganjaya22Nessuna valutazione finora

- Flowserve ANSI-Pumps PDFDocumento68 pagineFlowserve ANSI-Pumps PDFArup MahantaNessuna valutazione finora

- Elm Pul PR XXX 034 Agc FinalDocumento16 pagineElm Pul PR XXX 034 Agc Finaljagiprem123Nessuna valutazione finora

- Valvulas de SeguridadDocumento4 pagineValvulas de Seguridadleonardo_cortes_90Nessuna valutazione finora

- Is Iso 8573 1 2001Documento8 pagineIs Iso 8573 1 2001herrerafaridNessuna valutazione finora

- Bill of Material: Top ViewDocumento1 paginaBill of Material: Top ViewSudar Wanto100% (1)

- Triplex Pump ManualDocumento11 pagineTriplex Pump ManualDustin WhiteNessuna valutazione finora

- Kamos Gasket RTJDocumento7 pagineKamos Gasket RTJCahya Adi YeftaNessuna valutazione finora

- Hempadur Mastic 45880 & 45881Documento2 pagineHempadur Mastic 45880 & 45881Syarif Irwanto100% (1)

- Vessel DesignDocumento14 pagineVessel DesignElia MekdadNessuna valutazione finora

- Reciprocating Pump Catalog PDFDocumento109 pagineReciprocating Pump Catalog PDFDaniel Erasmo Avellaneda SanchezNessuna valutazione finora

- ANSI/HI 9.6.7: 2015 Edition, 2015Documento4 pagineANSI/HI 9.6.7: 2015 Edition, 2015Agustindao93Nessuna valutazione finora

- Dragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198Documento16 pagineDragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198jesus alfonso fragozo calderonNessuna valutazione finora

- LPG Pump IOM LGL2 LGL3 PDFDocumento12 pagineLPG Pump IOM LGL2 LGL3 PDFAfani Roma A100% (1)

- Pipeline and Piping RepairDocumento18 paginePipeline and Piping RepairkhoerulNessuna valutazione finora

- Pressure VesselDocumento85 paginePressure VesselAsad Abbas100% (1)

- Low Torc ValveDocumento4 pagineLow Torc Valvejinyuan74100% (2)

- Operation & Maintenance Manual Model Aph Hydraulic ActuatorDocumento69 pagineOperation & Maintenance Manual Model Aph Hydraulic ActuatorSasan AbbasiNessuna valutazione finora

- Hlep / Vsax: High Performance Cryogenic Reciprocating PumpsDocumento4 pagineHlep / Vsax: High Performance Cryogenic Reciprocating Pumpsbarun1977Nessuna valutazione finora

- Model 70 Dry Gas FilterDocumento4 pagineModel 70 Dry Gas FiltercartarNessuna valutazione finora

- Uztel OrizontalDocumento5 pagineUztel OrizontalDorin RaduNessuna valutazione finora

- The Best Information in Your Pocket About Bottom Hole Assembly BHADocumento8 pagineThe Best Information in Your Pocket About Bottom Hole Assembly BHAHezron Bryian ManurungNessuna valutazione finora

- Cameron 4 Way Valve (Prover Unit)Documento3 pagineCameron 4 Way Valve (Prover Unit)Yasser MahmoudNessuna valutazione finora

- JWS 400Documento2 pagineJWS 400николайNessuna valutazione finora

- Manual Champion Pl70Documento32 pagineManual Champion Pl70De Luna BraulioNessuna valutazione finora

- Metering Pumps SpecDocumento2 pagineMetering Pumps Spececsuperal100% (1)

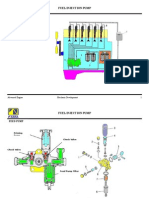

- SA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02Documento5 pagineSA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02altipatlarNessuna valutazione finora

- Ficha Técnica TANQUE BESTANKDocumento6 pagineFicha Técnica TANQUE BESTANKGhislaine SousaNessuna valutazione finora

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Documento3 pagineDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyaleNessuna valutazione finora

- C-051-VP-070-BDGS-PRO-0013 Rev. A Acceptance Test Procedure FAT - SAT - Start-Up - Insp Ection CommentsDocumento7 pagineC-051-VP-070-BDGS-PRO-0013 Rev. A Acceptance Test Procedure FAT - SAT - Start-Up - Insp Ection CommentsAH WINKELNessuna valutazione finora

- 9504A-9504B Pump Skid As Build Drawing PDFDocumento2 pagine9504A-9504B Pump Skid As Build Drawing PDFnull nullNessuna valutazione finora

- Emsco F 350 Pump PartsDocumento2 pagineEmsco F 350 Pump Partschymax3mNessuna valutazione finora

- Data Sheet AgitatorDocumento10 pagineData Sheet AgitatorEdi KurniawanNessuna valutazione finora

- Reciprocating Pumps - NDPDDocumento2 pagineReciprocating Pumps - NDPDDhanny MiharjaNessuna valutazione finora

- ITP For Reciprocating PumpDocumento2 pagineITP For Reciprocating PumpShahShNessuna valutazione finora

- 20 RR NOV 300Q-5 Technical Data SheetsDocumento2 pagine20 RR NOV 300Q-5 Technical Data SheetsJorge SoriaNessuna valutazione finora

- Hydrostatic Test ProcedureDocumento11 pagineHydrostatic Test Procedurevena rizkyNessuna valutazione finora

- Installation Manual SKC Series Pump-1Documento26 pagineInstallation Manual SKC Series Pump-1Huraira AliNessuna valutazione finora

- Instruction Manual - Ultra Pompe V16.1Documento31 pagineInstruction Manual - Ultra Pompe V16.1AdvanDooremaalNessuna valutazione finora

- Axial Split Volute Case PumpsDocumento21 pagineAxial Split Volute Case Pumpshardik sakariya100% (1)

- 009 - Teresa Electric v. PSCDocumento2 pagine009 - Teresa Electric v. PSCNikki Emm0% (1)

- Control Sheet RwadDocumento9 pagineControl Sheet RwadrawadNessuna valutazione finora

- PC200-8 KomatsuDocumento636 paginePC200-8 Komatsujoao maria100% (1)

- Aerial Propeller - Aerial Navigation (Unedited Bloomfield-Moore On John Keely)Documento27 pagineAerial Propeller - Aerial Navigation (Unedited Bloomfield-Moore On John Keely)Gregg Martin100% (1)

- Characterization of Surface Deposits On Human HairDocumento12 pagineCharacterization of Surface Deposits On Human HairpigcognitoNessuna valutazione finora

- Husky Hypet 400Documento148 pagineHusky Hypet 400Bir Kamaldeep Singh100% (7)

- LKP CatalogDocumento3 pagineLKP Catalogvikas_ojha54706Nessuna valutazione finora

- Victron Pylontech Up2500 Us2000 Us3000 Us2000c Us3000c Us5000 Us5000b Us5000c Pelio-L Up5000 Phantom-S Force-L1 l2Documento15 pagineVictron Pylontech Up2500 Us2000 Us3000 Us2000c Us3000c Us5000 Us5000b Us5000c Pelio-L Up5000 Phantom-S Force-L1 l2Warren MorseNessuna valutazione finora

- 3 CombustionDocumento30 pagine3 CombustionCllyan ReyesNessuna valutazione finora

- Earthing 1Documento9 pagineEarthing 1renjithas2005Nessuna valutazione finora

- Chemistry Project: Saturated Solutions: Measuring SolubilityDocumento8 pagineChemistry Project: Saturated Solutions: Measuring SolubilityAbhay Kumar NayakNessuna valutazione finora

- Deputy Engineer ElectricalDocumento3 pagineDeputy Engineer ElectricalSargi BeepumohanNessuna valutazione finora

- Easygen 1000 SeriesDocumento4 pagineEasygen 1000 SeriesLahir Untuk MenangNessuna valutazione finora

- Accenture 5G Municipalities Become Smart CitiesDocumento20 pagineAccenture 5G Municipalities Become Smart CitiesEkastrielNessuna valutazione finora

- Divyanshu Singh - 94 - Tyco - Edp - Exp 5Documento3 pagineDivyanshu Singh - 94 - Tyco - Edp - Exp 5tanmay ghoraiNessuna valutazione finora

- Wave GuidesDocumento141 pagineWave GuidesVamshi Krishna100% (1)

- Inorganic Chemistry SummaryDocumento8 pagineInorganic Chemistry SummaryClara1212Nessuna valutazione finora

- CM 01 PacemakerDocumento3 pagineCM 01 PacemakerJhonatan RodriguesNessuna valutazione finora

- Electrical Characteristics (KA7812A) : Parameter Symbol Conditions Min. Typ. Max. UnitDocumento3 pagineElectrical Characteristics (KA7812A) : Parameter Symbol Conditions Min. Typ. Max. UnitSec!Nessuna valutazione finora

- Temperature Control in The Neonate: Dr. Johanus Edwin, SpaDocumento20 pagineTemperature Control in The Neonate: Dr. Johanus Edwin, SpaHeskianoGoeltomNessuna valutazione finora

- Gravitation Power Generation Grom GravityDocumento30 pagineGravitation Power Generation Grom GravityAlmubeen0% (1)

- Low Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDocumento8 pagineLow Carbon Lining For Tunnelling Precast Segment - How Dramix® Fibre Reinforced Concrete Could Facilitate This AchievementDeyuan GuoNessuna valutazione finora

- Photoelectron SpectrosDocumento16 paginePhotoelectron SpectrosAditiNessuna valutazione finora

- AH-RESI DatasheetDocumento2 pagineAH-RESI DatasheetRahul ShelkeNessuna valutazione finora

- 4fuel Injection PumpDocumento9 pagine4fuel Injection PumpJoko Sukariono100% (2)

- 1025936797Documento184 pagine1025936797Wilson AgudeloNessuna valutazione finora