Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Site Book Timber Joist

Caricato da

arkiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Site Book Timber Joist

Caricato da

arkiCopyright:

Formati disponibili

Timber joist

Timber joist

Timber joist ceilings and

separating / compartment

floors

Ceilings to timber joist floors are an

established form of ceiling

construction, widely used in both

new housing and refurbishment.

Separating / compartment floors are

often specified as fire and sound

resisting floors in residential units,

such as flats and apartments, to

meet the requirements of national

Building Regulations.

7

332

www.british-gypsum.com

Key facts

Traditional and established method

Versatile

Use of Gyproc Drywall Timber Screws

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

minimises fixing defects

1

Gypframe RB1 Resilient Bar and Gypframe RB2

SureFix Bar provide enhanced acoustic

performance and eliminate nail-popping

Can achieve high performance levels

Quick and easy to install

1 Gyproc plasterboard - direct fix with Gyproc Drywall

Timber Screw

2 Gypframe RB1 Resilient Bar or Gypframe RB2 SureFix

Bar - indirect fix

7

333

Timber joist

www.british-gypsum.com

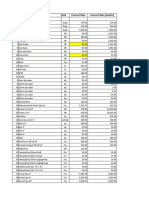

Components

Take-off

quantities1

Gyproc board products

Gyproc WallBoard2 3

Thickness

Width

12.5, 15mm

900, 1200mm

100m2

Gyproc FireLine2 3

Thickness

Width

12.5, 15mm

900, 1200mm

100m2

Gyproc SoundBloc3

Thickness

Width

12.5, 15mm

1200mm

100m2

Gyproc Plank

Thickness

Width

19mm

600mm

100m

Gyproc HandiBoard3

Thickness

9.5, 12.5mm

Width

600, 900mm

7

334

Take-off

quantities1

Glasroc board products

Glasroc MultiBoard

Thickness

Width

6, 10, 12.5mm

1200mm

Glasroc FireCase s

Thickness

Width

15mm

600, 1200mm

100m2

Gypframe metal products

Gypframe RB1 Resilient Bar

Length

3000mm

Gypframe RB2 SureFix Bar

Length

3000mm

100m2

1 Quantities are for 100m2 of regular shaped rectangular ceiling.

Quantities are approximate for a single layer installation with Gypframe

RB1 Resilient Bar or Gypframe RB2 SureFix Bar component at 450mm

centres when specified. Quantities are for guidance only, no allowance

has been made for waste.

100m2

250 m

250 m

2 Moisture resistant boards are specifed in intermittent wet use areas

e.g. shower cubicles.

3

Also available in DUPLEX grades where vapour control is required.

Fixing and finishing products

Gyproc Drywall Timber Screws or

Glasroc FireCase Screws

For a positive direct fix of boards to

timber joists.

Gyproc Drywall Screws

For fixing ceiling lining boards to

Gypframe SureFix Bars or Resilient Bars.

Gyproc Sealant

Sealing air paths for optimum sound

insulation.

Gyproc jointing materials

For seamless jointing.

Thistle Multi-Finish or

Thistle Board Finish

To provide a plaster skim finish.

Take-off

quantities1

1560

1800

1 cartridge per

35m based on

6-10mm bead

Fixing and finishing products

Thistle Spray Finish

Gypsum finish plaster for spray or

hand application.

Take-off

quantities1

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

11m2

per bag

Isover APR 1200

For enhanced acoustic performance.

25mm, 50mm and 100mm.

As required

Isover General Purpose Roll

For providing acoustic / thermal

insulation.

As required

Isover Sound Deadening Floor

As required

10m2

per bag

Slab Rigid Grade

As required

Stone mineral wool

For providing fire performance.

As required

7

335

Timber joist

www.british-gypsum.com

Construction tips

Estimated construction time 15 - 20m2 / man hour (single layer ceiling - boarding only) or 8 - 10m2 / man hour (double

layer ceiling - boarding only) ready for finishing

To minimise the risk of cracking at plasterboard joints, use seasoned timber with a moisture content not exceeding that

recommended in BS5268: Part 2. Even timber conforming to the standard will shrink on drying and fixing defects

could occur if plasterboard is fixed directly using nails

To minimise the risk of fixing defects occurring, use Gyproc Drywall Timber Screws for fixing into standard softwood,

super-dried timber (approx. 12% moisture content) and engineered I beams. Fix boards tight to accurately spaced,

aligned and levelled framing. Alternatively, use Gypframe RB2 SureFix Bar which eliminates nail-popping

Select the right length of fixing (nominal entry into timber of 25mm, nominal entry into Gypframe RB1 Resilient Bar and

RB2 SureFix Bar metal of 10mm)

Ensure that the dimensions of timber supports are sufficient to allow positive fixing of plasterboards. Bearing surface of

existing framing can be increased by fixing timber battens

Install cavity barriers where specified

7

336

Airtightness is essential for optimum sound insuation. While most junctions can be sealed with standard jointing

materials, gaps at the perimeter of the ceiling, and other small airpaths, can be sealed using Gyproc Sealant

Construction tips (contd)

Consider fixing DUPLEX grade board as the face layer where a vapour

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

control layer is required

Consider fixing Gypframe RB1 Resilient Bars to partially isolate linings

from the timber framing to provide improved acoustic performance

The designer should ensure that the floor construction is suitable to

support any imposed loads. For construction advice please refer to the

UK Timber Frame Association (UKTFA), website: www.timber-frame.org

Consider the requirements for timber noggings to support board edges

(see Table 1 Requirements for timber noggings)

Electrical and other small service runs can be routed within the floor

cavity

Minimise the number of service penetrations. Where these occur, they

must be adequately fire-stopped by the appropriate contractor

Fixtures should be made into joists, or to supplementary timber

7

337

Timber joist

www.british-gypsum.com

Table 1 - Provision of timber noggings within traditional softwood timber floors

Board

thickness

Maximum joist centres

with noggings

without noggings

mm

mm

6mm Glasroc MultiBoard

450

400

10mm Glasroc MultiBoard

600

450

12.5mm Gyproc plasterboard / Glasroc MultiBoard

600

450

15mm & 19mm Gyproc plasterboard

600

600

Gyproc ThermaLine laminates

600

450

1 To be read in conjuction with Timber noggings within timber floors.

For engineered joists, please consult joist manufacturer / supplier for specific information.

Timber noggings within traditional softwood timber floors (direct fix applications)

7

338

Suitable timber noggings, typically 38mm x 38mm or 50mm x 50mm, may be required between joists and at the ceiling perimeter to

support the edges / ends of the board. The provision of noggings depends on several factors; the thickness of board, spacing of timber

joists and any technical performance requirements, e.g. vapour resistance and fire resistance performance. Table 1 provides information on

the general requirement of noggings. However, reference must also be made to the relevant technical performance tables within the

WHITE BOOK to establish the need for noggings in fire-rated situations. Furthermore, timber noggings should always be incorporated when

fixing boards offering a vapour control layer, irrespective of joist spacing, e.g. DUPLEX grade Gyproc plasterboard and thermal laminates

providing vapour control. Timber noggings are always required around the ceiling perimeter, except when using 15mm Gyproc WallBoard

and 19mm Gyproc Plank in non fire-rated situations. In multi-layer plasterboard ceilings, the provision for noggings relates to the outer layer

board only (unless otherwise stated).

Installation - direct fix plasterboard ceiling

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

1

Direct fix plasterboard ceiling

Install boards to ceilings, prior to lining

walls and partitions, with the long edges

at 90 to the joists. Locate cut ends over a

joist or timber nogging support.

Provide timber noggings (where

required) between joists and at perimeter

to support board edges.

The provision of noggings,

normally 38mm x 38mm, depends on the

thickness of boards used, the spacing of

timber joists and performance criteria

(see Table 1).

Single layer linings

Fix boards to timber supports using

Gyproc Drywall Timber Screws. The

former provide a superior fixing and will

minimise any risk of fixing defects

occurring.

Where screws are used, install at 230mm

centres.

7

339

Timber joist

www.british-gypsum.com

Lightly butt boards (maximum separation

of 3mm), inserting fixings not closer than

10mm from bound edges and 13mm from

cut edges.

Position cut edges to internal angles and

remove the paper burr using fine sand

paper.

Stagger all board end joints.

7

340

Refer to Section 2, General Site

Considerations - Fixing to timber

supports, for recommendations on

fixing tolerances, increasing the bearing

surface of 35mm trussed rafters, and

length of screw-fixings required.

If fixing 15mm Glasroc FireCase S use

60mm Glasroc FireCase Screws and locate

at 150mm centres. In specifications using

Glasroc MultiBoard strips in the cavity, fix to

the side of joists at 300mm centres (top and

bottom).

Double layer linings

Mark the position of joists and

noggings at the perimeter prior to

installing first layer boards. After first layer

boards have been installed, transfer their

dimensions to the lining and mark lines to

indicate the position of timber supports.

Install second layer boards with

edges/ends against the centre line of

supports with all joints staggered in

relation to the first layer.

Installation - indirect fix plasterboard ceiling

1

Indirect fix to Gypframe RB2 SureFix

Bars

Position the bar at maximum 600mm

centres for single layer 15mm thick boards

and at maximum 450mm centres for

single layer 12.5mm.

Fix Gypframe RB2 SureFix Bar through

the single fixing flange to underside of

joists using 36mm Gyproc Drywall Screws.

Run Gypframe RB2 SureFix Bars at 90 to

joists.

Fix the first and last rows of Gypframe

RB2 SureFix Bar as close to the perimeter

wall as possible.

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

Fix noggings of Gypframe RB2 SureFix

Bar to remaining perimeters i.e. those

perimeters parallel to the joists.

7

341

Timber joist

www.british-gypsum.com

If the bars are not long enough to span

the ceiling, join by nesting together under

a joist and a screw through both flanges.

7

342

5

Board fixing

Fix board at 90 to Gypframe RB2

SureFix Bar with end joints staggered.

Locate screws at 230mm centres in the

field of the board and 150mm centres at

board ends. Insert screws no closer than

10mm from bound board edges and

13mm from cut edges.

For a single layer of 12.5mm board

and a single layer of 15mm board use

25mm Gyproc Drywall Screws. Take care

to ensure the screw-fixing through the

plasterboard is not driven into the joist.

If Gyproc Plank is used as an under

layer, insert 32mm Gyproc Drywall Screws

and 42mm when over boarding with

12.5mm board. Lightly butt all board

edges and, in multiple layer applications,

position Gypframe RB2 SureFix Bars at

450mm maximum centres with joints

between layers staggered.

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

6

Partition fixing

If GypWall RAPID or a similar partition

type is to be installed to the underside of

the ceiling, provision should be made to fix

the head channel of the partition. If the

partition is at 90 to the Gypframe RB2

SureFix Bar, connection through to it can

be made using an appropriate length

Gyproc Drywall Screw. If the partition is

parallel to the Gypframe RB2 SureFix Bar,

an extra length of section should be

installed in the line of the partition.

Indirect fix to Gypframe RB1

Resilient Bars

The procedure is similar to that for

Gypframe RB2 SureFix Bars.

7

343

Timber joist

www.british-gypsum.com

Ceiling plan direct fix to timber joist

Reflected ceiling plan - single layer. 12.5mm plasterboard with joists at maximum 450mm centres (or 15mm plasterboard

7 with joists at maximum 600mm centres)

7

344

1 Gyproc plasterboard

2 Timber joist

3 Timber noggings to provide support at the perimeter

Ceiling plan direct fix to timber joist

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

8 Reflected ceiling plan - single layer. 12.5mm plasterboard with joists at maximum 600mm centres

1 Gyproc plasterboard

2 Timber joist

3 Timber noggings to provide support at the perimeter

4 Timber noggings to support board edges

7

345

Timber joist

www.british-gypsum.com

Ceiling plan direct fix to timber joist

Reflected ceiling plan - double layer. 12.5mm plasterboard with joists at maximum 450mm centres (noggings may be required to

9 support long edges of board of outer layer if fire-rated)

7

346

1 Gyproc plasterboard

2 Timber joist

3 Noggings to provide support at the perimeter

Ceiling plan direct fix to timber joist

1

Timber joist

Technical support: T 0844 800 1991 F 0844 561 8816 E bgtechnical.enquiries@bpb.com

3

Noggings not required when joists at 406mm centre.

10 Reflected ceiling plan - single layer. 12.5mm Gyproc HandiBoard with joists at maximum 610mm centres

1 Gyproc HandiBoard

2 Timber joist

3 Noggings to provide support at the perimeter

4 Noggings to support board edges

7

347

Potrebbero piacerti anche

- Fireline Ceilings DetailsDocumento14 pagineFireline Ceilings DetailsconorNessuna valutazione finora

- Timber Frame Solutions 03Documento20 pagineTimber Frame Solutions 03sertackcdgNessuna valutazione finora

- GypFloor SILENT sound insulating floorDocumento14 pagineGypFloor SILENT sound insulating floorAnna AldokhinaNessuna valutazione finora

- Montare Pereti Rigips PDFDocumento12 pagineMontare Pereti Rigips PDFAndrei GhebuNessuna valutazione finora

- WB09 Loadbearing Timber Stud 10Documento10 pagineWB09 Loadbearing Timber Stud 10Michael WoodNessuna valutazione finora

- Donn CeilDocumento25 pagineDonn CeilLa RocaNessuna valutazione finora

- WB09 Floor Ceiling and Soffit Systems 10Documento84 pagineWB09 Floor Ceiling and Soffit Systems 10Krish DoodnauthNessuna valutazione finora

- EGGER wood panels for constructionDocumento28 pagineEGGER wood panels for constructionstefan hergheligiuNessuna valutazione finora

- Aircrete Blocks Product GuideDocumento36 pagineAircrete Blocks Product GuideVladoiu Sorin100% (1)

- GYPSUM Separating WallsDocumento28 pagineGYPSUM Separating WallsoinkedNessuna valutazione finora

- PLASTERBOARD PRODUCT GUIDEDocumento32 paginePLASTERBOARD PRODUCT GUIDERUPESHKSNessuna valutazione finora

- Fireclad System BoralDocumento8 pagineFireclad System BoralSuciul E ViuNessuna valutazione finora

- PDS Gyproc WallBoard DUPLEX PDFDocumento3 paginePDS Gyproc WallBoard DUPLEX PDFRATHEESH P.KNessuna valutazione finora

- Placi Osb Catalog General en 49632 PDFDocumento28 paginePlaci Osb Catalog General en 49632 PDFbermisuNessuna valutazione finora

- PDS Gyproc SoundBlocDocumento2 paginePDS Gyproc SoundBlocneeelNessuna valutazione finora

- Site Book ShaftwallDocumento26 pagineSite Book Shaftwalliulian_xroNessuna valutazione finora

- Gyprock 513 Party Wall 201205Documento28 pagineGyprock 513 Party Wall 201205duckeNessuna valutazione finora

- Gyproc HabitoDocumento3 pagineGyproc HabitoumaNessuna valutazione finora

- PDS Gyproc FireLineDocumento2 paginePDS Gyproc FireLineSugumarNessuna valutazione finora

- GPLamDocumento24 pagineGPLammurdicksNessuna valutazione finora

- Gyproc HabitoooDocumento2 pagineGyproc HabitoooumaNessuna valutazione finora

- LYSAGHT Trimdek Optima (Sep 2010)Documento12 pagineLYSAGHT Trimdek Optima (Sep 2010)Budi KuncoroNessuna valutazione finora

- GYPROCK 547 Residential - Installation - Guide 201111 PDFDocumento56 pagineGYPROCK 547 Residential - Installation - Guide 201111 PDFduckeNessuna valutazione finora

- Gyprock 949 Strata Wall 201202Documento24 pagineGyprock 949 Strata Wall 201202duckeNessuna valutazione finora

- Fire Barrier & Cavity Systems Stop Fires!: KillerDocumento4 pagineFire Barrier & Cavity Systems Stop Fires!: KillerMedhat ElhagrasiNessuna valutazione finora

- 1 Catalogue - Doors Timber 0.5 - 1hrDocumento2 pagine1 Catalogue - Doors Timber 0.5 - 1hrErika BanguilanNessuna valutazione finora

- 09 - PEX20 Screed & Concrete FloorDocumento4 pagine09 - PEX20 Screed & Concrete FloorIbrahim SahinNessuna valutazione finora

- 106000Documento36 pagine106000ThaisailerNessuna valutazione finora

- Plasterboard Installation Manual - Montaj RigipsDocumento52 paginePlasterboard Installation Manual - Montaj Rigipssarmis2Nessuna valutazione finora

- Fire-Resistant Plasterboard: Non-Load Bearing Partition SystemsDocumento16 pagineFire-Resistant Plasterboard: Non-Load Bearing Partition SystemsboyzesNessuna valutazione finora

- 092116Documento7 pagine092116kupaloidNessuna valutazione finora

- Book 6 - Floor & Ceilings Jan 09Documento66 pagineBook 6 - Floor & Ceilings Jan 09Mely PadIlla MaTaNessuna valutazione finora

- PDS Gyproc CoreBoardDocumento2 paginePDS Gyproc CoreBoardShannon HopkinsNessuna valutazione finora

- Tech Bulletin 4 Cladding InstallationDocumento4 pagineTech Bulletin 4 Cladding InstallationAbu NijamNessuna valutazione finora

- NSW Roofing Walling Rainwater and Structural Products BrochureDocumento8 pagineNSW Roofing Walling Rainwater and Structural Products BrochurebarouniamineNessuna valutazione finora

- Foam Fillers Tapes Sealants BrochureDocumento8 pagineFoam Fillers Tapes Sealants BrochureAppavoo DeelenNessuna valutazione finora

- Particleboard-Flooring-BrochureDocumento8 pagineParticleboard-Flooring-Brochurehojese4775Nessuna valutazione finora

- Roof Wall Flashing Architectural Detailing Design GuideDocumento24 pagineRoof Wall Flashing Architectural Detailing Design GuideJapheth AresoNessuna valutazione finora

- Spec TH CH CaoDocumento18 pagineSpec TH CH CaoNguyễn Thúc TiếnNessuna valutazione finora

- Durock Cement Board System Guide en SA932Documento12 pagineDurock Cement Board System Guide en SA932Ko PhyoNessuna valutazione finora

- Ezt-Fc 60-06Documento3 pagineEzt-Fc 60-06ashenafiiNessuna valutazione finora

- PDS Gyproc WallBoardDocumento3 paginePDS Gyproc WallBoardBülent KabadayiNessuna valutazione finora

- C016038Documento2 pagineC016038JNessuna valutazione finora

- PDS Gyproc SoundBloc FDocumento2 paginePDS Gyproc SoundBloc FhartzcarzNessuna valutazione finora

- Product Data Sheet - Gyproc FirelineDocumento3 pagineProduct Data Sheet - Gyproc FirelineSugumarNessuna valutazione finora

- CEMEX ReadyBlock Lightweight File016014Documento8 pagineCEMEX ReadyBlock Lightweight File016014Idrus IsmailNessuna valutazione finora

- GYPROCK 544 Steel Frame Wall Systems 201201Documento48 pagineGYPROCK 544 Steel Frame Wall Systems 201201Karla Anna KovacsNessuna valutazione finora

- USGBoral Installation Manual Oct14Documento68 pagineUSGBoral Installation Manual Oct14Eric Vergel de DiosNessuna valutazione finora

- CFS GRP Fibreglass RoofingDocumento26 pagineCFS GRP Fibreglass RoofingJonNessuna valutazione finora

- SarfDocumento51 pagineSarfSantosh ThakurNessuna valutazione finora

- Building Works Specification: Two Storey HouseDocumento12 pagineBuilding Works Specification: Two Storey HouseKhalid AwanNessuna valutazione finora

- Rockwool Fire Barrier SystemsDocumento8 pagineRockwool Fire Barrier Systemsaag0475Nessuna valutazione finora

- Polymax Accoustic Design GuideDocumento11 paginePolymax Accoustic Design GuidempwasaNessuna valutazione finora

- Promat TD BoardDocumento6 paginePromat TD BoardAlex BrustanNessuna valutazione finora

- Panelex DataDocumento1 paginaPanelex DataTimothy GordonNessuna valutazione finora

- Gypsum PlasterboardDocumento7 pagineGypsum PlasterboardJerusalemsNessuna valutazione finora

- Family Handyman Big Book of ProjectsDa EverandFamily Handyman Big Book of ProjectsFamily HandymanNessuna valutazione finora

- Tropical Architecture 2Documento78 pagineTropical Architecture 2Zianne CalubNessuna valutazione finora

- SciFi Science Fictionpmi Ethical Decision Making FrameworkDocumento2 pagineSciFi Science Fictionpmi Ethical Decision Making FrameworkBrandon García AlonsoNessuna valutazione finora

- How To Incorporate Lighting Efficiency Into Tenant Fit Outs - F02Documento61 pagineHow To Incorporate Lighting Efficiency Into Tenant Fit Outs - F02arkiNessuna valutazione finora

- Session 5 - Tareq ShaheenDocumento30 pagineSession 5 - Tareq ShaheenarkiNessuna valutazione finora

- After 2017Documento2 pagineAfter 2017NonoyTaclino100% (1)

- Manual PrimaveraDocumento700 pagineManual PrimaverajessicaNessuna valutazione finora

- Project Management Professional HandbookDocumento41 pagineProject Management Professional HandbookSara Lopez100% (1)

- Team Leadership Style PDFDocumento38 pagineTeam Leadership Style PDFDavid Sulca CoronadoNessuna valutazione finora

- After 2017Documento2 pagineAfter 2017NonoyTaclino100% (1)

- Iso 45001 RevealedDocumento34 pagineIso 45001 Revealedarki100% (9)

- Ricardo Vargas Simplified Pmbok Flow 6ed Color En-A3Documento1 paginaRicardo Vargas Simplified Pmbok Flow 6ed Color En-A3Hero Sa Mac100% (1)

- 3672324a - Pleasance-Lutron Product Bro FINAL - SGDocumento17 pagine3672324a - Pleasance-Lutron Product Bro FINAL - SGarkiNessuna valutazione finora

- Floor Catalogue Low ResDocumento36 pagineFloor Catalogue Low ResChristina MooreNessuna valutazione finora

- Islamic ArchitectureDocumento11 pagineIslamic Architecturearki100% (1)

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Documento14 pagineDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoNessuna valutazione finora

- Annexure - IDocumento348 pagineAnnexure - IShankar BiradarNessuna valutazione finora

- 시멘트와 콘크리트 관련 ISO 표준Documento5 pagine시멘트와 콘크리트 관련 ISO 표준Jhonernest Berrios GallegoNessuna valutazione finora

- Dead Load Calculation for Mezzanine Floor SlabDocumento2 pagineDead Load Calculation for Mezzanine Floor SlabJenna Mortel-DoligolNessuna valutazione finora

- 631A Tampines FinalizeDocumento4 pagine631A Tampines FinalizeShah ZaliNessuna valutazione finora

- Checklist FormworkDocumento2 pagineChecklist FormworkSreyleap Nhet100% (2)

- CIVIL MATERIAL RATESDocumento25 pagineCIVIL MATERIAL RATESNishan GajurelNessuna valutazione finora

- What Is Lintel BeamDocumento18 pagineWhat Is Lintel BeamMuhammadYounosMianNessuna valutazione finora

- LG Spareparts: Parts Forhome A Pplia N CesDocumento14 pagineLG Spareparts: Parts Forhome A Pplia N CeschuminhNessuna valutazione finora

- Shree Chintamani Developers, Kadakpada (R4)Documento4 pagineShree Chintamani Developers, Kadakpada (R4)Jai GaneshNessuna valutazione finora

- Post Tension Ing DesignDocumento59 paginePost Tension Ing DesignFrank StephensNessuna valutazione finora

- MS ISO Standards for Water SupplyDocumento3 pagineMS ISO Standards for Water SupplyPipi KNessuna valutazione finora

- FANGER 197O PMV Model PDFDocumento8 pagineFANGER 197O PMV Model PDFDesiree ClarkNessuna valutazione finora

- Design of reinforced concrete corbels for shear and moment resistanceDocumento2 pagineDesign of reinforced concrete corbels for shear and moment resistancemoseslugtu632475% (4)

- Structure Design Calculation For General Cargo Warehouse & CFSDocumento170 pagineStructure Design Calculation For General Cargo Warehouse & CFSAugusto Rafael PereiraNessuna valutazione finora

- Module 2 Septic Tank and Rectangular Manhole ProblemsDocumento9 pagineModule 2 Septic Tank and Rectangular Manhole ProblemsSyedNessuna valutazione finora

- MICROPILE HISTORY AND DESIGNDocumento28 pagineMICROPILE HISTORY AND DESIGNMelissa SammyNessuna valutazione finora

- Vamsiram Builders - IT Park BrochureDocumento8 pagineVamsiram Builders - IT Park BrochureJeelani BashaNessuna valutazione finora

- 3600-2009 (A1)Documento11 pagine3600-2009 (A1)RekhaRaju0% (1)

- Hap Ehelp 009 1Documento3 pagineHap Ehelp 009 1maheshNessuna valutazione finora

- ASHRAE 90.1 Large Office Building Modeling SpecificationsDocumento22 pagineASHRAE 90.1 Large Office Building Modeling SpecificationsMohamad AsrulNessuna valutazione finora

- 4STY 20CL PozorrubioCS On Micropile FoundationDocumento65 pagine4STY 20CL PozorrubioCS On Micropile FoundationKaren Balisacan Segundo RuizNessuna valutazione finora

- Introduction to Prestressed Concrete BasicsDocumento84 pagineIntroduction to Prestressed Concrete BasicsArhamNessuna valutazione finora

- Cassette FCU (One Way) PDFDocumento16 pagineCassette FCU (One Way) PDFHadi Khajouee NejadNessuna valutazione finora

- Tle 8Documento9 pagineTle 8Edralyn LuadNessuna valutazione finora

- Vernacular Term Quiz 1Documento85 pagineVernacular Term Quiz 1Zane BevsNessuna valutazione finora

- Construction Method for State Islamic University of Malang ProjectDocumento9 pagineConstruction Method for State Islamic University of Malang ProjectBudi SetiadiNessuna valutazione finora

- Glass Unloading Tools Supply-Forklift SkewerDocumento2 pagineGlass Unloading Tools Supply-Forklift SkewerHan JoeNessuna valutazione finora

- U.S. Shotcrete Standards Update: by Charles HanskatDocumento3 pagineU.S. Shotcrete Standards Update: by Charles HanskatmalikNessuna valutazione finora

- Construction Techniques in A High Rise BuildingDocumento32 pagineConstruction Techniques in A High Rise Buildingtaruntaru15379% (19)