Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ThermoKing Transport Frigorifer

Caricato da

ayviwurbayviwurb0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

165 visualizzazioni2 pagineInfrared

cameras reduce maintenance and repair

time at Sweden’s main distributor of

Thermo King transport refrigeration

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoInfrared

cameras reduce maintenance and repair

time at Sweden’s main distributor of

Thermo King transport refrigeration

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

165 visualizzazioni2 pagineThermoKing Transport Frigorifer

Caricato da

ayviwurbayviwurbInfrared

cameras reduce maintenance and repair

time at Sweden’s main distributor of

Thermo King transport refrigeration

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

FLIR

APPLICATION

STORY

Technician Ulf Ohlsson with the ThermaCAM E45

and a huge Thermoking fridge unit

FLIR Systems P and E-series infrared

cameras reduce maintenance and repair

time at Swedens main distributor of

Thermo King transport refrigeration

The transport of perishables such as fresh or frozen food by truck, trailer or train is one of these

industry sectors that directly influence and affect our habits and living standards. These logistic

chains are marked by tight transport schedules and delivery times. A well-functioning cooling

system is a prerequisite to be able to keep them running. Infrared cameras are perfect instruments to maintain the powerful transport refrigerators that keep the goods fresh during their

long way into our home fridges.

H-O NILSSON, located in Gothenburg, Sweden,

is the main distributor of transport refrigeration

giantThermo King in Sweden. Nilssons customers,

served by 25 skilled service technicians, are

predominantly haulage contractors specialized

in temperature-controlled transports. They

mainly work for the local large retail chains

and manufacturers of frozen food products.

Thermo King manufactures refrigeration units

for vehicles and is a market leader in this

sector.

Refrigeration transport units consist of a classic

vapor-compression type of refrigerators.

FLIR

The most powerful systems with heating,

cooling and freezing functions for big trucks

and trailers are self-powered. They need to

be maintained on a regular basis. The better

they are maintained, the better they function

and the less fuel they consume. With their

ability to scan entire surfaces quickly and easily,

infrared cameras significantly contribute to a

fast detection of faults and anomalies.

It doesnt get cold enough in my trailer

A unit might be brand new and working

flawlessly but not doing its main task : cooling

goods as it should be. A careful thermographic

outdoor and indoor inspection of the truck box

Bad cooling in trailer: IR shows that discharge

opening is blocked on the left side

proves whats going wrong: either insulation

problems (moisture intrusion), or thermal

bridges, the intrusion of uncooled air into the

transport box, or other reasons like blocked fans

or condensers inside the box which obstruct

the flowing of cooled air into the box. This

inspection can be done with a low-budget

infrared camera although more pixels helps

to get a clear and convincing view of the

problem.

Saving time: troubleshooting & check-up of

the refrigeration unit

Infrared cameras help to work down an

extensive checklist quickly and easily: hows

the temperature of the vaporizer? Is it equal

on the entire surface? If not, up to 50% cooling

power can be lost. Hows the condition of the

refrigeration circuit compressor and in particular,

the valves in the system? Slow leakages, which

lead to a significant loss of performance are

a frequent problem and they can be traced

quickly.

Hows the electrical control box? Hows the plug

connection outside on the refrigeration unit?

Placed outside of the box its exposed to harsh

conditions and liable to corrosion.

Minimizing troubleshooting time is key for the

efficiency and the profitability of the company.

The number of working hours saved thanks to a

consistent use of thermography at H-O NILSSON

is impressive. A complete conventional

troubleshooting of a refrigeration unit can take

five to six hours. Thanks to an infrared camera,

the job is finished in less than one hour. With

some 8,000 work orders per year and two

FLIR Systems infrared cameras, the return of

investment at HO-NILSSON is huge.

S60 (a predecessor model of the current SC640)

and a 160x120 pixel ThermaCAM E45. We use

both infrared cameras almost every day for all

tasks, he says, although for specific cases where

resolution or burst recording are important, we

only use the S-camera.

Such a particular case is the detection of very

slow but harmful leaks in heat exchangers or

on solenoid valves, which appear only after

a lengthy temperature and load increase.

The ThermaCAM S60 connected to a laptop

computer allows to spot and trace these leaks

that previously were very difficult to localize

and to explain.

Airleak in insulation curtain separating two temp zones

in refrigeration box

Adding value: IR images before customer

handover

Before handing over a truck or trailer with a new

Thermo King unit to customers, H-O NILSSON

technicians check all functions and take images

of the box. These infrared images in .jpeg format

made by FLIR cameras are then easily stored in

a new customer file and picked up again when

the customer comes in for service or repair.

They also inspect second-hand truck and trailer

bodies for their customers. This way, the infrared

cameras add value to H-O NILSSONs service

and customer care.

As to other adding-value tasks, says Nilsson

tongue-in-cheek, we had a plumber in our

building one day, and we decided to give him

a hand, so we quickly pointed out problem. The

man was quite impressed...

Thanks to Helena Wanerstrand, Market Research Manager

Thermography and Raphael Danjoux ITC Eurasia Program

Development Manager for providing contact and support

12/2006

Starter motor, oil filter of Thermoking fridge unit

All electrical, mechanical parts can be quickly

scanned, says Hans Olof Nilsson.

In addition to our increased ability to detect

faults at an early stage, we are now sure about

changing the right component. Before, we

could only rely on our own experience, now,

thanks to the infrared camera we know for

sure.

Nilsson quickly realized that this certitude could

only be achieved with a good knowledge of

the fundamentals of thermography and the

camera, as well as a correct interpretation of

the imagery. Two members of the team went

to the Infrared Training Center, a renowned

independent training institute offering certified

training courses in many countries, and became

certified thermographers.

Hans Olof Nilsson and his team use a FLIR

Systems 320x240 pixel resolution ThermaCAM

IR image shows thermal bridges and a moisture spot

in the insulation

For further information contact:

FLIR SYSTEMS LTD.

2 Kings Hill Avenue - Kings Hill

West Malling, Kent

ME19 4AQ

United Kingdom

Tel.: +44 (0)1732 221 245

Fax: +44 (0)1732 843 707

e-mail: sales@flir.uk.com

www.infracam.co.uk

Potrebbero piacerti anche

- 2001 Ford F150 ManualDocumento296 pagine2001 Ford F150 Manualerjenkins1100% (2)

- Astm D2000 PDFDocumento38 pagineAstm D2000 PDFMariano Emir Garcia OdriozolaNessuna valutazione finora

- Carrier ListDocumento80 pagineCarrier ListOtman Othman100% (1)

- VC AndrewsDocumento3 pagineVC AndrewsLesa O'Leary100% (1)

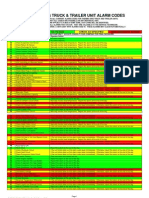

- Alarm Code ChartDocumento2 pagineAlarm Code ChartMatthew Stockford100% (1)

- TK 40933 Thermo King Alarm CodesDocumento4 pagineTK 40933 Thermo King Alarm CodesEko Purwanto100% (1)

- Compressor 05KDocumento29 pagineCompressor 05KgamaggNessuna valutazione finora

- Precedent S-600 Operator's ManualDocumento220 paginePrecedent S-600 Operator's Manualjoel100% (1)

- Truck Edition v-520 RT Series Model 10-20-30 and 50 Single Temperature Systems TruckDocumento68 pagineTruck Edition v-520 RT Series Model 10-20-30 and 50 Single Temperature Systems TruckJorge MartinezNessuna valutazione finora

- Tks 600 PartsDocumento189 pagineTks 600 PartsCarlos Correa100% (1)

- Thermo King Tracking PDFDocumento47 pagineThermo King Tracking PDFOtman OthmanNessuna valutazione finora

- Operation and Service Manual: Trailer Refrigeration UnitDocumento82 pagineOperation and Service Manual: Trailer Refrigeration Unitsergslip100% (1)

- Process Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesDocumento15 pagineProcess Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesZubair RaoofNessuna valutazione finora

- THERMO KING TK 61377-18-MM TKV500 and TKV600 Maintenance Manual Rev. A 01-19Documento108 pagineTHERMO KING TK 61377-18-MM TKV500 and TKV600 Maintenance Manual Rev. A 01-19Vincent Marmande100% (1)

- Ultima XTC and Ultra XTC Splice Point and Splice Pack LocationsDocumento4 pagineUltima XTC and Ultra XTC Splice Point and Splice Pack LocationsJesusNessuna valutazione finora

- Supra 850Documento84 pagineSupra 850Dajmon DajmonNessuna valutazione finora

- SR-4 Microprocessor Control System For Trailer Multi-Temp Units 55788-2-OD (Rev A, 11-15)Documento428 pagineSR-4 Microprocessor Control System For Trailer Multi-Temp Units 55788-2-OD (Rev A, 11-15)Ian McDaniel (Mc)Nessuna valutazione finora

- 03-F10 Planned Job ObservationDocumento1 pagina03-F10 Planned Job ObservationSn Ahsan100% (1)

- Carrier Transport Air ConditiCarrier Transport AC Op. & Service Manual For Bus Rearmount Models 68RM50-100, 68RM50-101, 68RM50-102Documento36 pagineCarrier Transport Air ConditiCarrier Transport AC Op. & Service Manual For Bus Rearmount Models 68RM50-100, 68RM50-101, 68RM50-102Clifton Jamison50% (2)

- 2013 Vector Unit FTF Handbook PDFDocumento56 pagine2013 Vector Unit FTF Handbook PDFJuan Miguel Marin Quintero100% (1)

- Reefer Operating Instructions - Thermoguard ViDocumento1 paginaReefer Operating Instructions - Thermoguard Viخطاب الشامي0% (1)

- TEC - OPS - VECTOR 1350 - 62-61925-20 - Rev-EDocumento228 pagineTEC - OPS - VECTOR 1350 - 62-61925-20 - Rev-Erivojoh101Nessuna valutazione finora

- 6 Od - LRDocumento32 pagine6 Od - LRمعمر حميد100% (1)

- Using Infrared For Residential Energy SurveysDocumento8 pagineUsing Infrared For Residential Energy SurveysayviwurbayviwurbNessuna valutazione finora

- Operator's Manual: TK-56373-1-OPDocumento83 pagineOperator's Manual: TK-56373-1-OPمعمر حميد100% (1)

- In The Palm of Your Hand: Pocket Wintrac SoftwareDocumento2 pagineIn The Palm of Your Hand: Pocket Wintrac SoftwareOtman Othman100% (2)

- Arion Green Office Building BrochureDocumento8 pagineArion Green Office Building BrochureayviwurbayviwurbNessuna valutazione finora

- SB-210+ SB-210+ Magnum: Maintenance ManualDocumento196 pagineSB-210+ SB-210+ Magnum: Maintenance ManualMd MokbulNessuna valutazione finora

- Nyambe African Adventures An Introduction To African AdventuresDocumento5 pagineNyambe African Adventures An Introduction To African AdventuresKaren LeongNessuna valutazione finora

- Accessories Catalog THERMOKINGDocumento24 pagineAccessories Catalog THERMOKINGCarlos CorreaNessuna valutazione finora

- Manual Datacold 500 RusDocumento26 pagineManual Datacold 500 RusАндрейNessuna valutazione finora

- CRR20 40 - MP D PDFDocumento200 pagineCRR20 40 - MP D PDFMelissa Macias100% (4)

- Ops Manual - Trailer and Rail With Advance MicroDocumento70 pagineOps Manual - Trailer and Rail With Advance MicroRicardo Olvera Quezada100% (1)

- MAXIMA 1000 / 1300 / 1300mt° Spare Parts ManualDocumento98 pagineMAXIMA 1000 / 1300 / 1300mt° Spare Parts ManualОльгаNessuna valutazione finora

- Manual 05k en InglesDocumento22 pagineManual 05k en InglesCocom Ivan100% (2)

- RPM ThermokingDocumento2 pagineRPM ThermokinggeorgebaboNessuna valutazione finora

- Book Speos 2023 R2 Users GuideDocumento843 pagineBook Speos 2023 R2 Users GuideCarlos RodriguesNessuna valutazione finora

- 62-10601 Opera Micro STDDocumento44 pagine62-10601 Opera Micro STDJuan Miguel Marin Quintero100% (1)

- Daikin Inverter ContainerDocumento140 pagineDaikin Inverter ContainerHever Porto RoseroNessuna valutazione finora

- Models 69NT40-489-100 Series 69NT40-511,521& 531Documento40 pagineModels 69NT40-489-100 Series 69NT40-511,521& 531cloviskrelling100% (1)

- List of Modern Equipment and Farm ToolsDocumento15 pagineList of Modern Equipment and Farm ToolsCarl Johnrich Quitain100% (2)

- ManualTK MagnumDocumento173 pagineManualTK Magnumcosminscribd440% (1)

- Thermo King v520 RT Spectrum 50Documento66 pagineThermo King v520 RT Spectrum 50tony100% (1)

- 62-61118-04 Supra - 850 - 850MTDocumento98 pagine62-61118-04 Supra - 850 - 850MTJuan M Marín100% (1)

- TK 61755-2-OD-EN A-Series Control System Single Temperature Units RevE 11-2022 LRDocumento256 pagineTK 61755-2-OD-EN A-Series Control System Single Temperature Units RevE 11-2022 LRTecnico Anzizar100% (1)

- Manual Precedent MultitempDocumento163 pagineManual Precedent MultitempCiwank ToNessuna valutazione finora

- TAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1Documento69 pagineTAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1matheus santosNessuna valutazione finora

- 2013 Softwre and Program BOX LinksDocumento1 pagina2013 Softwre and Program BOX LinksOmar SangronaNessuna valutazione finora

- RefrigerationDocumento6 pagineRefrigerationfufafiNessuna valutazione finora

- 20 Series Catalog v2016Documento68 pagine20 Series Catalog v2016h_878236333Nessuna valutazione finora

- 62 10162Documento70 pagine62 10162Cristobal CamposNessuna valutazione finora

- Hvac Refri - FF REFRIGERANT&OIL CHARGING-PROCEDUREDocumento1 paginaHvac Refri - FF REFRIGERANT&OIL CHARGING-PROCEDUREmanonpomNessuna valutazione finora

- Expertise & Proximity. Welcome To Carrier: Carrier Transicold Service OffersDocumento4 pagineExpertise & Proximity. Welcome To Carrier: Carrier Transicold Service OffersSaMos AdRiian100% (2)

- Thermo King V-Series Cab CommandDocumento2 pagineThermo King V-Series Cab Commandgamagg100% (1)

- 62-02460 - Rev - C - Manual de Peças, Compressor 05KDocumento19 pagine62-02460 - Rev - C - Manual de Peças, Compressor 05KBianca PinudoNessuna valutazione finora

- #0WSMZ120: Workshop ManualDocumento74 pagine#0WSMZ120: Workshop ManualΣτάθης ΣαλNessuna valutazione finora

- Carrier Transicold TECHLINE July2012Documento4 pagineCarrier Transicold TECHLINE July2012Carlitos Enrique Corpus PonceNessuna valutazione finora

- Service Parts List Maxima 2 and Genesis TM 800Documento79 pagineService Parts List Maxima 2 and Genesis TM 800Иван Винокуров100% (1)

- I BoxDocumento4 pagineI BoxAndres FelipeNessuna valutazione finora

- EverFresh Controlled Atmosphere Model 69NT40-489-100 SeriesDocumento170 pagineEverFresh Controlled Atmosphere Model 69NT40-489-100 SeriescloviskrellingNessuna valutazione finora

- 30 SDocumento37 pagine30 SAko Bienes Raices100% (1)

- Zanotti DFZDocumento44 pagineZanotti DFZHubert Von Süßer BusartzNessuna valutazione finora

- Installation Manual-A: TK 51286-2-IM (Rev. 3, 02/06)Documento60 pagineInstallation Manual-A: TK 51286-2-IM (Rev. 3, 02/06)GIOVANNENessuna valutazione finora

- Refrigeration Connection: CarrierDocumento4 pagineRefrigeration Connection: CarrierIndustria e mishit CalabriaNessuna valutazione finora

- MicroLink ManualDocumento8 pagineMicroLink ManualAnonymous e97NTlwNessuna valutazione finora

- Maintenance Manual: Thermo King Corp., Minneapolis, MN, U.S.ADocumento52 pagineMaintenance Manual: Thermo King Corp., Minneapolis, MN, U.S.AING. RUBENSNessuna valutazione finora

- Starcool CI5Documento223 pagineStarcool CI5Jonas Matheus Sardena PeresNessuna valutazione finora

- Zephyr 20S Spare Parts ManualDocumento42 pagineZephyr 20S Spare Parts Manualmircomirco100% (1)

- Webasto Air Top HL32 D Workshop ManualDocumento52 pagineWebasto Air Top HL32 D Workshop ManualDavid ButlerNessuna valutazione finora

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Da EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Nessuna valutazione finora

- Application Story: Insulation of Commercial Walk in Freezers Checked With Thermal ImagingDocumento2 pagineApplication Story: Insulation of Commercial Walk in Freezers Checked With Thermal ImagingmariusNessuna valutazione finora

- Applying Infrared Imaging Techniques To Marine Surveying ... ContinuedDocumento8 pagineApplying Infrared Imaging Techniques To Marine Surveying ... ContinuedayviwurbayviwurbNessuna valutazione finora

- Thermography Applications in Technology ResearchDocumento10 pagineThermography Applications in Technology ResearchayviwurbayviwurbNessuna valutazione finora

- Infrared Applications in The Fields of Forensic & Construction Defect EngineeringDocumento8 pagineInfrared Applications in The Fields of Forensic & Construction Defect EngineeringayviwurbayviwurbNessuna valutazione finora

- Hybrid Ventilation ReviewDocumento135 pagineHybrid Ventilation ReviewayviwurbayviwurbNessuna valutazione finora

- AIT RoofMoisture Example ReportDocumento24 pagineAIT RoofMoisture Example ReportayviwurbayviwurbNessuna valutazione finora

- Three Ways The Pest Professional Can Use Infrared ThermographyDocumento12 pagineThree Ways The Pest Professional Can Use Infrared ThermographyayviwurbayviwurbNessuna valutazione finora

- Contents Page: Thermacam Reporter 2000 Professional - Template Building TutorialDocumento10 pagineContents Page: Thermacam Reporter 2000 Professional - Template Building TutorialayviwurbayviwurbNessuna valutazione finora

- Warehouse Asset ProtectionDocumento4 pagineWarehouse Asset ProtectionayviwurbayviwurbNessuna valutazione finora

- Mill Ladle Refractory MonitoringDocumento4 pagineMill Ladle Refractory MonitoringayviwurbayviwurbNessuna valutazione finora

- FLIR B and T Series-EnDocumento296 pagineFLIR B and T Series-EnayviwurbayviwurbNessuna valutazione finora

- Night Sky Radiant Cooling - Influence On Outdoor Thermal Imaging AnalysisDocumento18 pagineNight Sky Radiant Cooling - Influence On Outdoor Thermal Imaging AnalysisayviwurbayviwurbNessuna valutazione finora

- Flare Gas Monitoring SystemsDocumento4 pagineFlare Gas Monitoring SystemsayviwurbayviwurbNessuna valutazione finora

- How Do Be Successful in Building Thermography ITC Whitepaper PDFDocumento10 pagineHow Do Be Successful in Building Thermography ITC Whitepaper PDFayviwurbayviwurbNessuna valutazione finora

- Electric Substation MonitoringDocumento4 pagineElectric Substation MonitoringayviwurbayviwurbNessuna valutazione finora

- TNote Fog PDFDocumento4 pagineTNote Fog PDFayviwurbayviwurbNessuna valutazione finora

- Tutorialtruss PDFDocumento17 pagineTutorialtruss PDFayviwurbayviwurbNessuna valutazione finora

- Learning TheoryDocumento7 pagineLearning Theoryapi-568999633Nessuna valutazione finora

- PronounsDocumento6 paginePronounsHải Dương LêNessuna valutazione finora

- Bathinda - Wikipedia, The Free EncyclopediaDocumento4 pagineBathinda - Wikipedia, The Free EncyclopediaBhuwan GargNessuna valutazione finora

- UBMM1011 Unit Plan 201501Documento12 pagineUBMM1011 Unit Plan 201501摩羯座Nessuna valutazione finora

- CUET 2022 General Test 6th October Shift 1Documento23 pagineCUET 2022 General Test 6th October Shift 1Dhruv BhardwajNessuna valutazione finora

- Instruction Manual 115cx ENGLISHDocumento72 pagineInstruction Manual 115cx ENGLISHRomanPiscraftMosqueteerNessuna valutazione finora

- Asu 2019-12Documento49 pagineAsu 2019-12janineNessuna valutazione finora

- PNGRB - Electrical Safety Audit ChecklistDocumento4 paginePNGRB - Electrical Safety Audit ChecklistKritarth SrivastavNessuna valutazione finora

- Four Hour Body Experiment Tracker TemplateDocumento4 pagineFour Hour Body Experiment Tracker Templatechanellekristyweaver100% (1)

- Yarn HairinessDocumento9 pagineYarn HairinessGhandi AhmadNessuna valutazione finora

- STARCHETYPE REPORT ReLOADED AUGURDocumento5 pagineSTARCHETYPE REPORT ReLOADED AUGURBrittany-faye OyewumiNessuna valutazione finora

- Risha Hannah I. NazarethDocumento4 pagineRisha Hannah I. NazarethAlpaccino IslesNessuna valutazione finora

- Nature of Science-Worksheet - The Amoeba Sisters HWDocumento2 pagineNature of Science-Worksheet - The Amoeba Sisters HWTiara Daniel25% (4)

- Islamiyat ProjectDocumento21 pagineIslamiyat ProjectSubhan Khan NiaziNessuna valutazione finora

- Physico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegDocumento9 paginePhysico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegZyuha AiniiNessuna valutazione finora

- Electromagnetism WorksheetDocumento3 pagineElectromagnetism WorksheetGuan Jie KhooNessuna valutazione finora

- Heirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseDocumento2 pagineHeirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseAlvin Dela CruzNessuna valutazione finora

- Medabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink ForumsDocumento5 pagineMedabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink Forumsdegraded 4resterNessuna valutazione finora

- Marieb ch3dDocumento20 pagineMarieb ch3dapi-229554503Nessuna valutazione finora

- Jurnal Vol. IV No.1 JANUARI 2013 - SupanjiDocumento11 pagineJurnal Vol. IV No.1 JANUARI 2013 - SupanjiIchsan SetiadiNessuna valutazione finora

- ATAL Selected FDPs AY 2023 24Documento15 pagineATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)