Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ChemEdNZ Aug 2010 Paterson

Caricato da

Shane VerpCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ChemEdNZ Aug 2010 Paterson

Caricato da

Shane VerpCopyright:

Formati disponibili

Chemistry Education in New Zealand August 2010

Coffee chemicals

David Paterson

NZ Science, Technology and Mathematics Teacher Fellow with Syft Technologies Ltd., normally Head of

Science at Cashmere High School (email: pt@cashmere.school.nz)

Everyone loves coffee! And many spend large

amounts of time and money selecting the best coffee

house or lovingly preparing the perfect cup of coffee at home. But how many know exactly what they

are tasting, or realise that the molecules that contribute to the wonderful aroma of roasted coffee can be

highly toxic?

The chemicals that end up floating up from a cup of

coffee are the result of a whole host of reactions that

start with the coffee plant growing peacefully in a

tropical location and end with beans being subjected

to searing heat and scalding hot water. Variations in

any of the steps outlined below will cause changes in

the final flavour of the coffee:

Growing:

Temperature, rainfall, soil quality and the type of

coffee plant used.

Picking:

The timing and method of harvest.

Pulping and fermentation:

Coffee beans are separated from the fruit, or cherry,

by forcing the beans through a wire mesh then fermenting the beans to remove mucilage still attached.

Drying:

Beans are air- or sun-dried for up to four weeks to

reduce water content from 60% to 11%.

tral Nervous System stimulant. It has a very bitter

taste and when added to energy drinks it has to be

masked by flavour compounds to make the drink

palatable.

The flavour of coffee, however, comes from the over

1000 compounds that have been identified in coffee

vapour to date. These develop in the many stages of processing described above and come from a

wide variety of organic families. Some typical coffee compounds are shown in Table 1.

A new way of detecting and identifying volatile organic compounds is to use SIFT-MS (Selected Ion

Flow Tube Mass Spectrometry). This technique

has been recently commercialised by Syft Technologies Ltd. in Christchurch, a spin-off from research

at the University of Canterbury (see Paterson 2009,

2010). This year I have been using the Syft Voice

200 instrument to investigate the aroma compounds in instant and plunger coffees. Samples can

be prepared and measured extremely quickly using

the procedure illustrated in Fig. 1.

Storage:

Green coffee bean flavour peaks within one year.

Burlap bags are best as they allow for air flow around

the beans.

Roasting:

Hundreds of chemicals are produced when amino

acids react with sugars, and oxidations and caramelisation occur.

Push sample

needle into

headspace

Pour some coffee

into sample bottle

Grinding:

The size of particles produced determines which

method of brewing is best.

Brewing:

Using a French Press, drip machine or espresso.

For most people caffeine is the only compound they

consider associated with coffee, a typical cup containing between 65 and 175 mg caffeine. Caffeine

is produced by plants as a pesticide to paralyse and

kill certain insects, but is used by humans as a Cen-

Make a coffee

brew

Draw air from coffee headspace

through the Voice 200 for 1 minute

Fig. 1: Coffee Sampling Technique at Syft Technologies

13

Chemistry Eduction in New Zealand August 2010

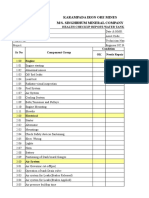

Table 1: A selection of compounds contributing to coffee aroma

Compound

Structure

Individual odour description

3-methylbutanal

Aldehydic, chocolate-like, peach, fatty

2,3-pentanedione

Buttery, caramel-like

Acetic acid

Acidic, sharp, pungent

Ethyl nononoate

Waxy, fruity, rose

Furfural

Nutty, roasted

Furfuryl methylsulfide

Leather-like

2,6-diethylpyrazine

Pyrazine, potato-like

Instant coffee

Naively I assumed that instant coffee contained

actual coffee bean material, but after doing some

simple research was surprised to find this is not the

case. Instant coffee is basically made by brewing up

an industrial sized coffee in a large stainless steel

tank from roasted beans, then separating the water

infused with coffee chemicals and either spray or

freeze drying it.

In order to see if the Syft technique could distinguish between different brands of coffee I analysed

the headspace of four different dry instant coffee

powders (labelled GCD, NG, EFD, CFD) simultaneously scanning for 36 different compounds. The

compound present at the highest levels, by far, was

acetic acid with an average concentration of 3000

ppb. The concentrations of a selection of other coffee volatiles are shown in Fig. 2.

Fig. 2: Volatiles in four instant coffee powders

14

Clearly there are differences between the coffee

samples, but how significant are they? To answer

this question the data for all 36 compounds from all

four coffees was run through multivariate statistical analysis to look for similarities and differences

between samples. The SIMCA (Soft Independent

Modelling of Class Analogy) method looks for relationships between data sets and creates a visual representation of classes assigned in three dimensions.

The results are shown in Fig. 3 and indicate that

there are significant statistical differences between

the coffee types.

Fig. 3: SIMCA plot for four instant coffees

Chemistry Education in New Zealand August 2010

Plunger ground coffees

Four different commercially roasted and ground coffees were analysed in a similar way to the instant

coffees described above. The most striking difference was the vastly increased concentration of all

volatiles in the plunger coffees, note the scale on the

vertical axis in Fig. 4 compared to that in Fig. 2.

But what exactly is going on chemically? The Syft

technology provides a good way of following such

processes in real time. Some simple experiments

were carried out using the set-up shown in Fig. 5.

Air flows over

the coffee

bean and is

sampled by

the VOICE 200

instrument

Coffee bean in oven

Fig. 5:

Fig. 4: Volatiles in four plunger coffees

Firstly the oven was heated to 200oC, a single green

coffee bean placed in the centre, inside a stainless

steel tube with air being drawn through it. The instrument recorded the concentration of 35 different

volatile compounds for over 15 minutes. The resulting scan is shown in Fig. 6.

Furfural for example is present above the HE coffee sample at a concentration of approximately 4000

ppb or 4 ppm. This is above the Permissible Exposure Limit (PEL) for workers handling furfural as an

industrial solvent, which is 2 ppm for an eight hour

period.

Coffee bean roasting

All coffee aficionados know that coffee beans crack

twice during the roasting process which generally

follows this pattern:

Heating up: The green beans are slowly dried to become yellow and the beans begin to smell like toast

or popcorn.

The first crack occurs at approximately 205C, the

bean doubles in size, becomes a light brown colour,

and experiences a weight loss of approximately 5%.

As the temperature rises from 205C to approximately 220C, the colour changes from light brown

to medium brown and further weight loss occurs.

The second crack occurs between 225-230C, and

the roast colour is defined as medium-dark brown.

The second pop is much quicker sounding and the

beans take on an oily sheen.

Most people recommend stopping the process somewhere between the end of the first crack and midway through the second, depending on the flavour

required.

Fig. 6: SIFT-MS scan of coffee bean at 200oC

The major components of the two peaks are acetic

acid, methanol and propanoic acid. A second experiment was run again using a single coffee bean in the

same apparatus but this time placing the bean in the

oven at 195oC and heating to 250oC over 20 minutes.

The results of this experiment are shown in Fig. 7.

Acetic acid

Hexanoic acid

Methanol

Fig. 7: SIFT-MS scan of coffee bean at 250oC

Two distinct peaks can again be seen but with significantly increased number and concentration of volatiles produced at higher temperatures. The pattern of

compounds seems to match what is expected from

15

Chemistry Eduction in New Zealand August 2010

the various Maillard and oxidation reactions, with

what is left in the beans providing the flavour in the

final cup of coffee.

Future possibilities

With a greater understanding of the chemical changes that occur during coffee processing the ability to

more precisely control the final flavour is possible.

Most coffee products result from combinations

of coffee beans from a variety of sources, blended

to give the desired flavour. By tracking the actual

chemicals released from particular beans more accurate blending should be possible.

A group of researchers at Nestl in Switzerland are

using a similar SIFT machine and a human sensory

panel to predict the final aroma profile of a particular coffee. Using sophisticated statistical analysis

the results from the sensory panel are matched to the

chemical signature from SIFT-MS analysis. Then

the machine is given a new coffee sample and is able

to produce an aroma profile, such as shown in Fig.

8, based on the relative concentrations of chemicals

detected. Thus the flavours of new blends can be

quickly established before the use of expensive panels of expert tasters.

ful coffee flavour. And see what sort of reaction you

get when you comment to your fellow coffee connoisseur that you particularly enjoy a touch of furfural in your brew, or a that a hint of pyrazine really

distinguishes an Ethiopian from a Blue Mountain.

Cheers!

References

1 Lopez-Galilea, I., Andriot, I., De Pena, M., Cid, C., &

Guichard, E. (2008). How does roasting process influence the retention of coffee aroma compounds by

lyophilized coffee extract? Journal of Food Science,

78(3), S165-171.

2 Akiyama, M., et al. (2008). Characterisation of headspace aroma compounds of freshly brewed arabica

coffees and studies on a characteristic aroma compound of Ethiopian coffee. Journal of Food Science,

73(5), C335-C446.

3. Perez-Martinez, M., et al. (2008). Application of multivariate analysis to the effects of additives on chemical and sensory quality of stored coffee brew. Journal

of Agricultural and Food Chemistry, 56, 11845-11853.

4. Rowe, D. (ed). (2005) Chemistry and technology of

flavors and fragrances. UK: Blackwell Publishing

Ltd.

5. Lindinger, C., et al. (2008). When machine tastes

coffee: instrumental approach to predict the sensory

profile of espresso coffee. Analytical Chemistry, 80,

1574-1581.

6. Coffee processing http://www.coffeeresearch.org (retrieved 20 Oct 2009)

7. Roasting profile http://www.ravensbrew.com/NewFiles/roastPage.html (retrieved 20 Oct 2009)

8. Coffee general information http://en.wikipedia.org/

wiki/Coffee (retrieved 20 Oct 2009)

Fig. 8: An aroma profile for a coffee brew

So next time you have a cup of coffee try to visualise

the incredible range of chemicals that are interacting

with your sensory receptors to produce that wonder-

ChemScrapes

9. Syft Technologies Ltd. http://www.syft.com/ (retrieved

20 Oct 2009)

10. Paterson, D. (2009). Furfural fuel and flavour molecule of the future? ChemEd NZ, No. 117, 2-4

11. Paterson, D. (2010). Vanilla: natural or not? ChemEd

NZ, No. 118, 2-6

Brendan Burkett

16

Potrebbero piacerti anche

- Roy BoysDocumento1 paginaRoy BoysShane VerpNessuna valutazione finora

- Fas PDFDocumento1 paginaFas PDFShane VerpNessuna valutazione finora

- ATmega 16 U 2Documento22 pagineATmega 16 U 2luisNessuna valutazione finora

- Pyrex ForDocumento1 paginaPyrex ForShane VerpNessuna valutazione finora

- N1912 90008 PDFDocumento761 pagineN1912 90008 PDFShane VerpNessuna valutazione finora

- FasDocumento2 pagineFasShane VerpNessuna valutazione finora

- Fast Action Axion PDFDocumento1 paginaFast Action Axion PDFShane VerpNessuna valutazione finora

- Fas PDFDocumento6 pagineFas PDFShane VerpNessuna valutazione finora

- FasDocumento2 pagineFasShane VerpNessuna valutazione finora

- SocksDocumento1 paginaSocksShane VerpNessuna valutazione finora

- AsdfDocumento3 pagineAsdfShane VerpNessuna valutazione finora

- Valve Handbook LowRes PDFDocumento37 pagineValve Handbook LowRes PDFMohamad SleimanNessuna valutazione finora

- GingerDocumento3 pagineGingerShane VerpNessuna valutazione finora

- Bland Things Are BlandDocumento12 pagineBland Things Are BlandShane VerpNessuna valutazione finora

- CGH 40006 PDocumento14 pagineCGH 40006 PShane VerpNessuna valutazione finora

- Sam SaidDocumento4 pagineSam SaidShane VerpNessuna valutazione finora

- AsonwDocumento4 pagineAsonwShane VerpNessuna valutazione finora

- A Beam Tracing Method For Interactive Architectural Acoustics - Thomas FunkhouserDocumento69 pagineA Beam Tracing Method For Interactive Architectural Acoustics - Thomas FunkhouserSebastian Peralta RamosNessuna valutazione finora

- Us 7086071Documento9 pagineUs 7086071Shane VerpNessuna valutazione finora

- Understanding The Basis of The Kalman Filter PDFDocumento5 pagineUnderstanding The Basis of The Kalman Filter PDFRenato T. AlmeidaNessuna valutazione finora

- Nasa Software Security ReqsDocumento389 pagineNasa Software Security ReqsShane VerpNessuna valutazione finora

- Parameters Conversion TableDocumento7 pagineParameters Conversion TabledhruvaaaaaNessuna valutazione finora

- Adaptive Weiner FilterDocumento33 pagineAdaptive Weiner FilterShane VerpNessuna valutazione finora

- Parameters Conversion TableDocumento7 pagineParameters Conversion TabledhruvaaaaaNessuna valutazione finora

- Broadband CouplingDocumento81 pagineBroadband CouplingShane VerpNessuna valutazione finora

- R WaveguideDocumento6 pagineR WaveguideShane VerpNessuna valutazione finora

- Flavor ChemDocumento1 paginaFlavor ChemShane VerpNessuna valutazione finora

- RT Duroid 5870 5880 Data SheetDocumento2 pagineRT Duroid 5870 5880 Data SheetNeeresh KumarNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Automated Dish Washer v1.1Documento21 pagineAutomated Dish Washer v1.1Anonymous XXCCYAEY6M67% (3)

- 200150, 200155 & 200157 Accelerometers: DescriptionDocumento16 pagine200150, 200155 & 200157 Accelerometers: DescriptionJOSE MARIA DANIEL CANALESNessuna valutazione finora

- Chapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentDocumento43 pagineChapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentHsieh Yun JuNessuna valutazione finora

- Hetal Patel: Team Leader - SalesDocumento2 pagineHetal Patel: Team Leader - SalesPrashant kumarNessuna valutazione finora

- Water Tanker Check ListDocumento8 pagineWater Tanker Check ListHariyanto oknesNessuna valutazione finora

- Sistine Chapel Ceiling Lesson PlanDocumento28 pagineSistine Chapel Ceiling Lesson PlannivamNessuna valutazione finora

- Personal Finance Kapoor 11th Edition Solutions ManualDocumento26 paginePersonal Finance Kapoor 11th Edition Solutions Manualsiennamurielhlhk100% (28)

- Intervensi Terapi Pada Sepsis PDFDocumento28 pagineIntervensi Terapi Pada Sepsis PDFifan zulfantriNessuna valutazione finora

- Conveyor Control Using Programmable Logic ControllerDocumento7 pagineConveyor Control Using Programmable Logic ControllerWann RexroNessuna valutazione finora

- Ymrtc LogDocumento26 pagineYmrtc LogVinicius Silveira0% (1)

- ICD10WHO2007 TnI4Documento1.656 pagineICD10WHO2007 TnI4Kanok SongprapaiNessuna valutazione finora

- Sample Cross-Complaint For Indemnity For CaliforniaDocumento4 pagineSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- 01 - A Note On Introduction To E-Commerce - 9march2011Documento12 pagine01 - A Note On Introduction To E-Commerce - 9march2011engr_amirNessuna valutazione finora

- FAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureDocumento669 pagineFAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureCIO-CIO100% (2)

- Geometry and IntuitionDocumento9 pagineGeometry and IntuitionHollyNessuna valutazione finora

- Properties of LiquidsDocumento26 pagineProperties of LiquidsRhodora Carias LabaneroNessuna valutazione finora

- Rubric For Aet570 BenchmarkDocumento4 pagineRubric For Aet570 Benchmarkapi-255765082Nessuna valutazione finora

- Internship ReportDocumento36 pagineInternship ReportM.IMRAN0% (1)

- Digital SLR AstrophotographyDocumento366 pagineDigital SLR AstrophotographyPier Paolo GiacomoniNessuna valutazione finora

- Fire Technical Examples DIFT No 30Documento27 pagineFire Technical Examples DIFT No 30Daniela HanekováNessuna valutazione finora

- Jurnal Ekologi TerestrialDocumento6 pagineJurnal Ekologi TerestrialFARIS VERLIANSYAHNessuna valutazione finora

- Tree PruningDocumento15 pagineTree Pruningrita44Nessuna valutazione finora

- IFR CalculationDocumento15 pagineIFR CalculationSachin5586Nessuna valutazione finora

- BECIL Registration Portal: How To ApplyDocumento2 pagineBECIL Registration Portal: How To ApplySoul BeatsNessuna valutazione finora

- 2 AcknowledgementDocumento8 pagine2 AcknowledgementPadil KonamiNessuna valutazione finora

- Frequency Response For Control System Analysis - GATE Study Material in PDFDocumento7 pagineFrequency Response For Control System Analysis - GATE Study Material in PDFNarendra AgrawalNessuna valutazione finora

- Dialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Documento1 paginaDialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Al ImranNessuna valutazione finora

- The Grass Rink Summer Final 2019Documento9 pagineThe Grass Rink Summer Final 2019api-241553699Nessuna valutazione finora

- Docsity Detailed Lesson Plan 5Documento4 pagineDocsity Detailed Lesson Plan 5Sydie MoredoNessuna valutazione finora

- Building For The Environment 1Documento3 pagineBuilding For The Environment 1api-133774200Nessuna valutazione finora